Information

-

Customer

-

Site Address

-

Post code

-

Site Number

-

Date of Inspection

-

Inspected by

-

Site reference (if applicable)

System Description and Operation

Preventative Maintenance and Safety Check

-

Type of System

-

Control Panel Make/Model

-

Operator Make/Model

-

Loop Fitted

-

Loop Type

- Entry

- Exit

- Safety

-

Safety Beams

-

Make and Model

-

Warning lights fitted

-

Warning lights

-

Safety Edges fitted

-

Safety edge Locations

- Vertical (second to close)

- Vertical (First to close)

- Horizontal Front (second to close)

- Horizontal (first to close)

- Other

-

Signs fitted

-

Length of opening (mm)

-

Fire Drop Unit

-

Provide details

-

Radio transmitter

-

Provide details

-

Digital Keypad?

-

Provide details and codes

-

Touch/card/fob

-

Details

General Check list

General Maintenance Checklist

-

Any physical defects or problems?

-

Lube or grease all moving parts

-

Clean and inspect safety beams for any cracks or damage

-

Check safety edges for wear and stretching

-

Check signage

-

Check mechanical clearances and running tolerances including ground and chassis clearance

-

Check physical stops at each end of travel of gates/barrier arms. Are there any signs of damage or over-run to report?

-

Carry out visual checks of underground loop chases for erosion of sealer. Is seal damaged?

-

Check supporting structures, hinges, bearings etc.

-

Check electric cables and conduit.

-

Check Manual release

-

Test safety edges by depressing each. Ensure the equipment immediately stops or stops and return to the open position

-

Operation of fire switch OK?

-

Why?

-

Photo

-

Is the condition of the gate controller housing ok?

-

Provide details

-

Gate/Barrier/Shutter Runners and Rollers ok and free from grinding or binding?

-

Provide details

-

Defects/Issues

Manual release electrical isolation details

Key Type

-

Is there a means to isolate any magnetic locks?

-

Suggestion to add a Keyswitch for emergency manual release operation, Type and location

-

Photo

-

Key Type

-

Key Number

-

Key box available

-

Manual Key in box

-

Manual instructions in box

-

System complies with current Machinery Regulations, HSE notifications and DHF Codes of Practice

-

Supply details

Electrical Check

-

Does electrical installation appear sound, safe and in reasonable condition

- Yes

- No

-

Supply details

-

Photo

-

Correct containment used

-

Details

-

Means of isolation safe and accessible?

-

Details

-

All wiring at barrier / gate checked for loose or badly made connections

-

Details

-

Additional Information

Asset List and risk assessment

-

Risk assessments and method statements must be carried on all sites to ensure that the risk of injury or fatality is eliminated to users or members of the general public as a result of system design

The Provisions and Use of Work Equipment Regulation (PUWER) requires that Powered machinery is regularly maintained every six months.

MAINTENANCE PROCEDURES - POWERED/AUTOMATIC GATES

Regular preventative maintenance helps to prolong the system and will conserve reliability.

During each Planned Preventative Maintenance service WE shall perform the following work:

· Check and record the equipment, its condition and oil levels

· Take photographs of the equipment to highlight problems and to aid reporting of defects

· Compliance assessment - Carry out a survey to highlight any areas of concern and offer appropriate recommendations for improvement

Note: If the gate system is deemed to be unsafe, then We shall switch off power and issue a Condemned letter as per Health and Safety Executive, GATESAFE and Door and Hardware Federation advice and guidance as the liability of a unsafe gate rests with the last person to service the system

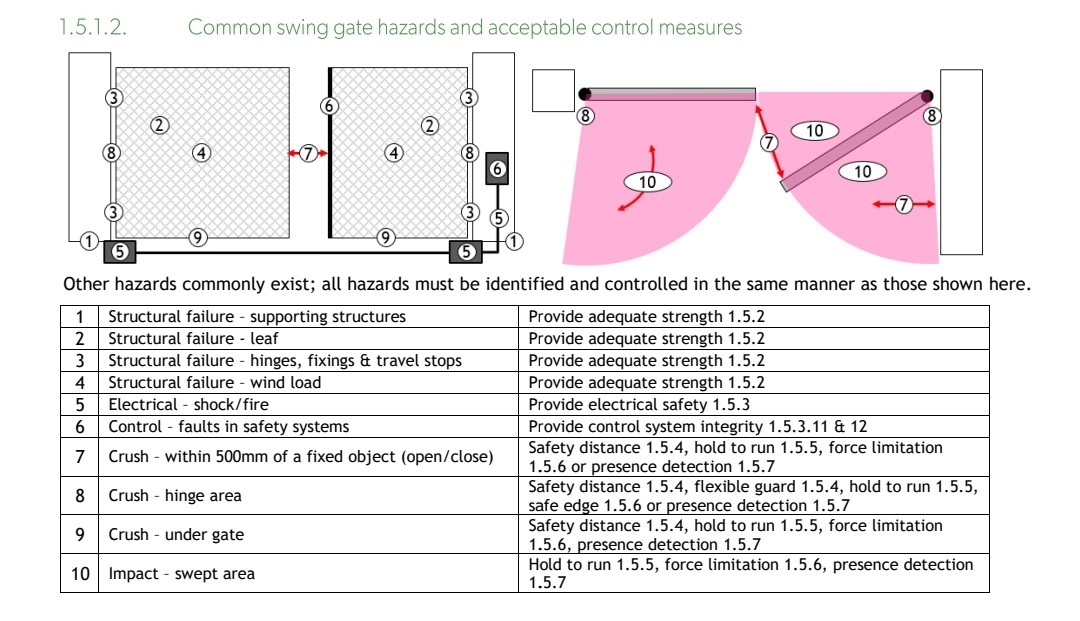

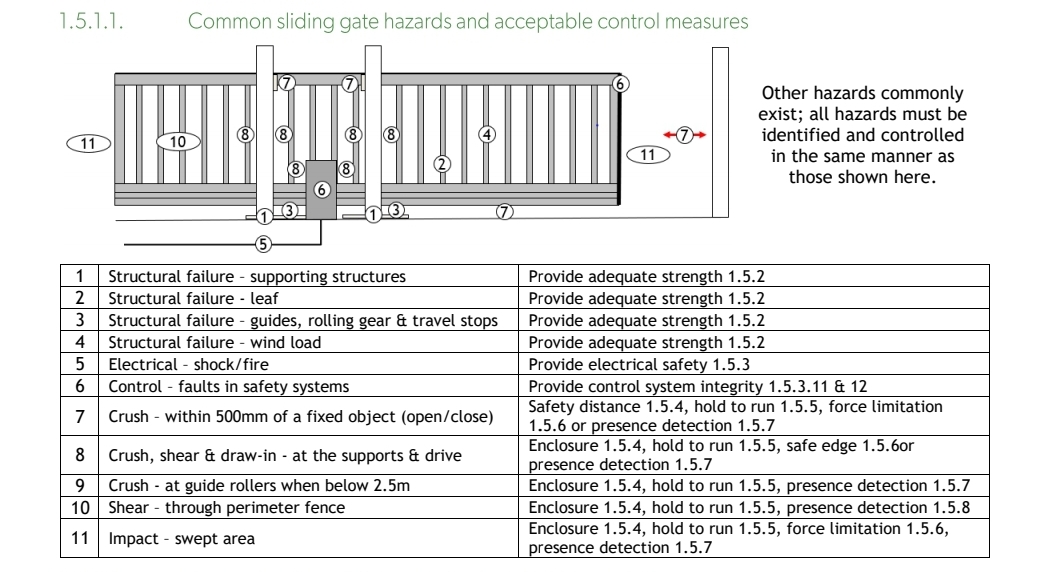

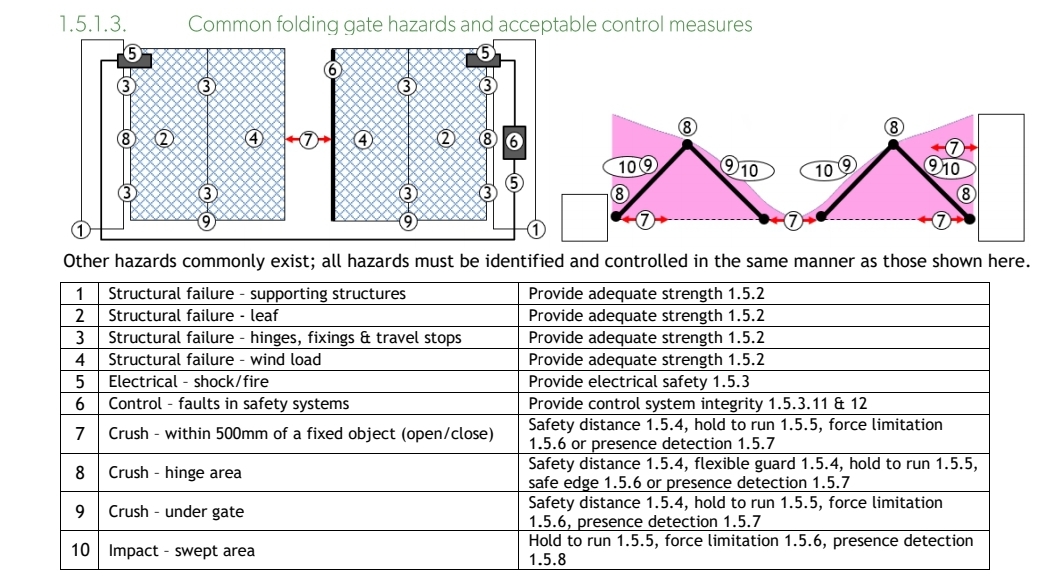

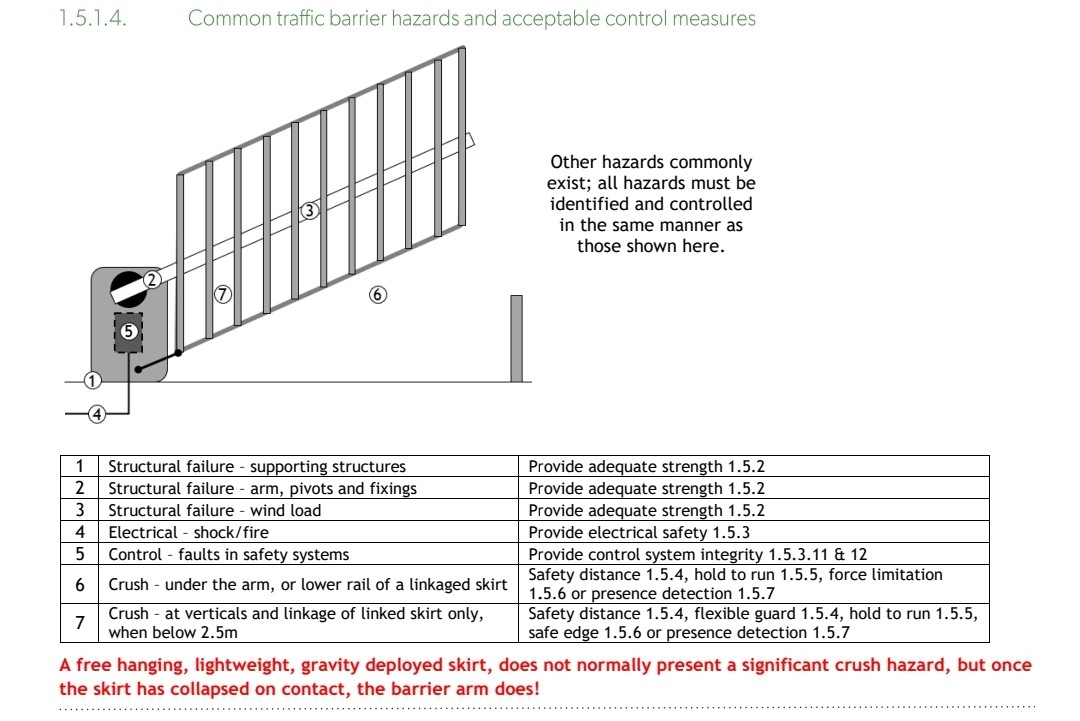

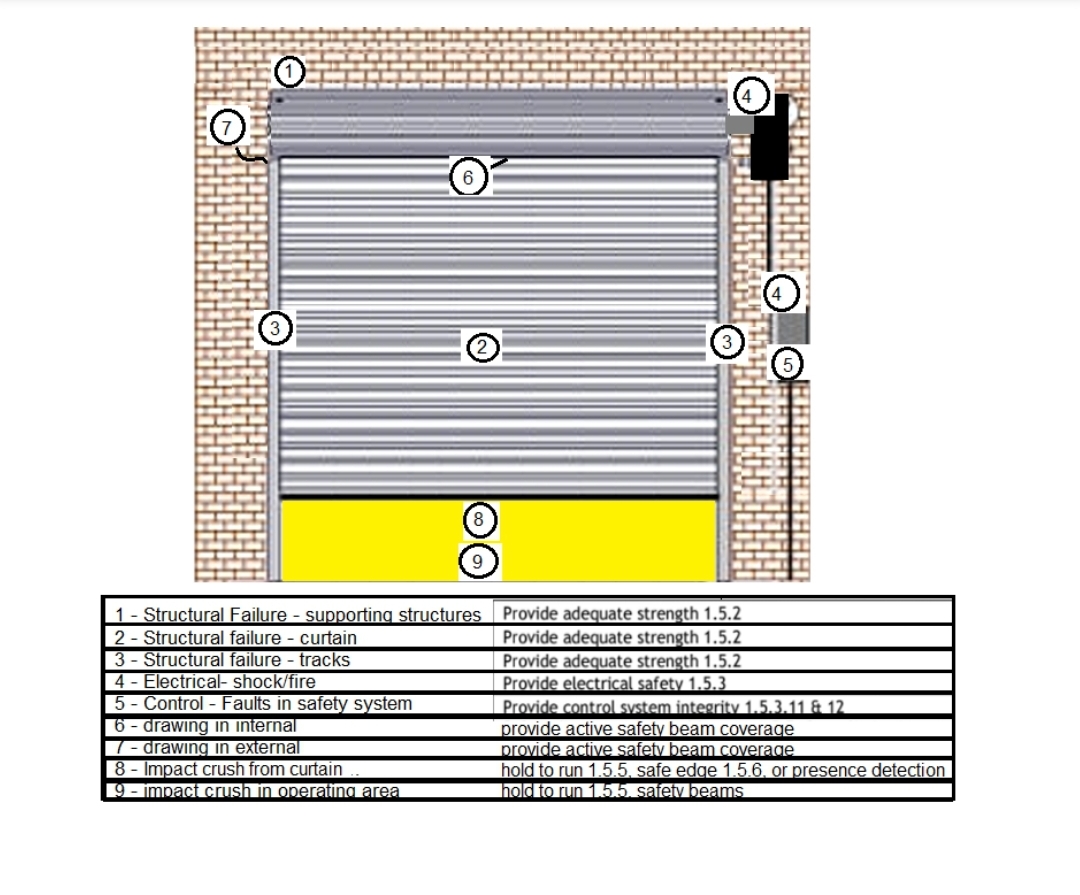

Risk Diagram identifying numbers and assessment

-

Type of System

-

-

All risks currently accounted for?

-

Engineer name and signature

-

Risk identifying numbers and proposed means of control

-

Enginneer Name and Signature

-

-

All risks currently accounted for?

-

Engineer Name and Signature

-

Risk identifying numbers and proposed means of control

-

Engineer Name and Signature

-

-

Are all risks currently accounted for?

-

Engineer Name and Signature

-

Risk identifying numbers and proposed means of control

-

Engineer Name and Signature

-

-

All risks currently accounted for?

-

Engineer Name and Signature

-

Risk identifying numbers and proposed means of control

-

Engineer Name and Signature

-

-

All risks currently accounted for?

-

Engineer Name and Siganture

-

Risk Identifying numbers and suggested means of control

-

Engineer Name and Signature

-

Additional comments

-

Asset Condition

-

Switch System Off!

-

Engineer Name

-

Does system require switch off?

-

Switch System Off!

-

Engineer Name and Signature

-

Estimated life expectancy years?

-

Estimated life expectancy years?

-

Asset Motor(s)

-

Asset Age

-

Asset Condition

-

Switch System Off!

-

Engineer Name

-

Does system require switch off?

-

Switch System Off!

-

Engineer name

-

Estimated life expectancy years?

-

Estimated life expectancy years?

-

-

Asset Control Equipment

-

Asset Age

-

Asset Condition

-

Switch System Off!

-

Engineer Name

-

Does system require switch off?

-

Switch System Off!

-

Engineer name

-

Estimated life expectancy years?

-

Estimated life expectancy years?

-

Additional recommendations, photos and sign off

Overall condition / Performance of system / additional information

-

Any additional photos

-

Recommendations (list items you would recommend)

-

Engineer

-

Client representative (if available)

-

As the person in control of the gate, you have a legal duty of care to users and visitors to the premises (including trespassers).

If the gate is not safe, any party injured by the gate is likely to be able to sue for damages.

If you have insurance covering such risks, your insurance contract is likely to oblige you to disclose any material facts to your insurer including, in such case that the gate is not considered safe.

If the gate is part of an undertaking, the person in control of it will have additional duties under Section 3 of the Health and Safety at Work Act 1974.

If the premises are also a workplace, there are specific duties under the Regulation 18 of the Workplace (Health, Safety and Welfare) Regulations 1992, as well the general duty imposed by Section 2 of the 1974 Act.

Failure to meet the duties imposed by health and safety legislation can result in criminal proceedings in line with the possibility of unlimited fine at Crown Court.