Information

Assessment Details

-

Document No.

-

Audit Title

-

Add the scope of the Assessment.

-

Department

-

Date of Assessment

-

Assessor

-

Signature of Assessor

-

Trainee Name & Employee No

-

Trainee Signature

-

Add photograph of the employee.

Future Training Requirements

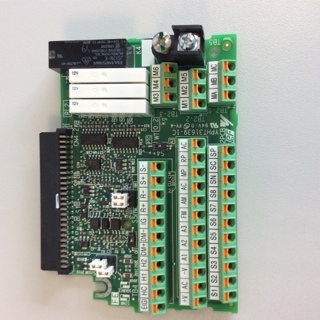

Equipment

-

Review operator knowledge about equipment.<br><br>Does the operator know how the equipment is fit for use?<br><br>Does the operator know how to recognise faults?<br><br>What does the operator do if the equipment appears to be faulty?<br><br>Can the operator change silicone tubes / nozzles without help?<br><br>Can the operator make minor adjustments within the set up parameters without help?

Documentation & Records

-

Does the operator understand and use the technical?<br><br>Verify that the operator can access the technical specification in the system.<br>Verify that they know how to confirm that the specification selected is correct.<br>Ask the operator to explain some key steps of the specification to ensure that they can understand the details and requirements.<br><br>Record competence level.<br>Record details of the sample reviewed.<br><br>Record details of the sample checked and comments from the operator.

-

Does the operator understand the work instructions?<br><br>Verify that the operator can access the work instructions in the system.<br>Verify that they know how to confirm that the instruction selected is correct.<br>Ask the operator to explain some key steps of the instruction to ensure that they can understand the details and requirements.<br><br>Record competence level.<br>Record details of the sample reviewed.

-

Does the operator understand the records which are required?<br><br>Verify that the operator understands the records to be updated in the system.<br><br>Verify that they know the reason for the records.<br><br>Verify that they know where records are stored.<br><br>Record competence level.<br>Record details of the sample reviewed.

-

Does the operator understand the Quality Control Plan?<br><br>Verify that the operator can access a copy of the QC Plan.<br><br>Verify that the operator understands the structure of the QC Plan and can explain how some of the controls in the plan are implemented.<br>

Product

-

Review the operator I process technique and output.<br><br>Does the operator use the equipment correctly and safely?<br><br>Verify 3 different samples of various types of PCB to ensure the operator can follow different instructions and specifications.<br><br>Record details of each sample and any defects in the product.

-

Verify that the final product condition is checked correctly.<br><br>Did the operator verify the product condition using correct equipment and with reference to the specification?<br><br>Ask the operator to talk through the inspection process, explaining what is being checked and why.<br><br>Verify that the PCB is marked withe the correct inspection mark at the correct place.<br><br>Record details of this feedback.

Risk

-

Verify that the operator understands the risks to the product at each key stage of the process.<br>The operator should know the risks and controls for product quality.<br><br>Cross refer to the QC Plan.<br><br>Record feedback from the operator.

-

Verify that the operator understands the process risks at each key stage.<br>The operator should know the risks and controls for the process.<br><br>Cross refer to the work instructions.<br><br>Record feedback from the operator.

Health and Safety

-

Verify that the operator can use the equipment safely.<br><br>Refer to work instructions and equipment guidelines.<br><br>Record any instances where poor safety is witnessed.

Summary of competence

-

Make a statement about the final competence achieved.<br>