Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

-

Auditor

-

Add signature

Equipment and Materials

-

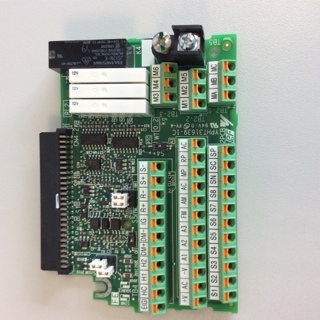

Review the operators knowledge of the solder equipment.<br><br>Record photographic evidence of solder equipment being used by operator.<br><br><br>

-

Ask the operator to explain and demonstrate the process of solder iron tip maintenance, and 5s standard for solder work station.<br><br>Was the operator able to explain and demonstrate solder tip maintenance process to IPC-A-610 standard?<br><br>Was the operators cleaning sponge clean and clear of debris?<br><br>Was the solder operators work area clean and clear of solder debris?<br><br>Record photographic evidence.

-

Ask the operator to explain how they verify correct solder is being used?<br><br>Operator should be able to explain that solder type is stated on the TKN files.<br><br>Record photographic evidence of TKN File that references solder type and photograph of solder type being used by operator.

-

How does the operator verify correct type of Flux is being used?<br><br>Record photographic evidence of flux container with type of flux identified on the container.

Documentation and Records

-

Detail Yaskawa solder training completed by the operator.<br><br>Review training records with HR.<br><br>Record photographic evidence.<br><br><br><br>

-

Has the operator completed Yaskawa multimeter training PTB019?<br><br>Review operator training records in HR.<br><br>Record photographic evidence.

-

Has the operator completed record sheets QA1322 Multimeter check sheet and QA1328 Solder Iron check on a daily basis.<br><br>Record photographic evidence.

-

Ask the operator to show document QA1202 Yaskawa Soldering Standard Reference Booklet that shows and describes common types of solder defects?<br><br>Was the operator able to provide a copy of QA1202?<br><br>Did the operator understand the purpose of the document?<br><br>Record photographic evidence.

-

Ask the operator to show the documentation that explains the IGBT pin layout that has to be checked by the multimeter?<br><br>Was the operator able to produce a copy of the Cosmos PCB Continuity Guide EWI01195?<br><br>Did the operator understand the the purpose of the document.<br><br>Record photographic evidence.

-

Verify the operator understands cosmos line QC plan?

Product

-

Ask the operator to explain and demonstrate the process of solder iron verification checks and where these checks are recorded?<br><br>What is the process if the solder iron fails verification checks?<br><br>Record photographic evidence.

-

Ask the operator to explain and demonstrate the process for multimeter verification checks and where these checks are recorded?<br><br>What is the process if the multimeter fails verification checks?<br><br>Record photographic evidence.

-

Review the operators solder process technique and output?<br><br>Record photographic evidence.

-

Verify operator is using correct solder mask during solder process.<br><br>Record photographic evidence.<br><br>

-

Review operators solder inspection techniques?<br><br>Verify against solder defect booklet QA1202.<br><br>

-

Review the operators multimeter process technique?<br><br>Verify this against Technical specification EWI01195.<br><br>Ask the operator explain Technical specification EWI01195.

Risks

-

Verify that the operator understands the risks associated with the solder process.<br><br>Record solder defect types described by the operator.<br><br>Record other defects to PCB described by the operator which could occur.<br><br>

Health and Safety

-

Verify that the operator understands the health and safety aspects of the solder process.<br><br>1. Use of LEV<br>2. Wear safety glasses<br>3. Understand safety associated with materials from safety data sheets.<br>4. Solder iron located in holder when not used.<br>5. Solder iron turned off when not used at dinner break or end of shift.

Summary of Competence

-

Make a statement about the final competence achieved.