Title Page

-

Site conducted

-

Conducted on

-

undefined

-

Prepared by

-

Location

-

Machine make & model

-

Machine serial

-

Customers reference for machine (if applicable)

PUWER ASSESSMENT

Regulation 4 - Suitability of the Work Equipment

-

Is the equipment being used for its designed, adapted and intended purpose?

-

Is the equipment suitable for use in its enviroment, e.g. in a flammable atmosphere?

-

Is the installation standard important to achieve essential health and safety measures?

Regulation 5 - Maintenance

-

Are the Health and Safety features maintained in an efficient condition?

-

Is the work equipment in good working order?

-

Is the work equipment subject to regular maintenance, eg. In accordance with manufacturers instructions?

-

Is the equipment or its safety devices subject to planned preventive maintenance?

-

Is the work equipment subject to statutory inspection/examination?

-

Is the equipment being used for its designed, adapted and intended purpose?

-

Is the equipment suitable for use in its enviroment, e.g. in a flammable atmosphere?

-

Is the installation standard important to achieve essential health and safety measures? Yes No N/A

-

What control method is used to log the above maintenance?

Regulation 6 - Inspection

-

Have competent personel been identified to carry out inspections?

-

Has the installation been inspected and results been recorded?

-

Are the installation conditions inspected at regular intervals as instructed by the OEM of the equipment?

Regulation 7 - Specific Risks

-

Are risk assessment required under any other regulations. Eg. noise, COSHH, DSE, manual handling Management regulations?

-

Are current records for these assessments available?

Regulation 8 - information andInstructions

-

Have operators and supervision adequate health and safety information for the equipment available to them eg manufacturers operating instructions?

-

Is the information readily accessible and available to the user/operator?

-

Are written procedures required for the safe operation and maintenance of the work equipment?

-

If procedures are required are they available?

Regulation 9 - Training (Operation-Maintenance)

-

Are those who operate, inspect and maintain the work equipment competent?

-

Have all personel who operate, inspect and maintain the work equipment received appropriate training?

-

Have all personel who supervise the operation, inspection or maintenance of work equipment received appropriate training?

Regulation 10 - Conformity with EC/UKCA requirements

-

Does the work equipment comply with the relevent EC/UKCA product directive or harmonised standards eg.is it CE Marked

-

Do you have a copy of the relevent declaration of conformity?

Regulation 11 - Dangerous parts of Machinery

-

Is access to dangerous parts of the equipment prevented?

-

Is the danger eliminated prior to access under normal operating conditions?

-

Are the guards, safety devices or systems of work suitable and not easily by passed or disabled?

-

Are the guards, safety devices or systems of work adequately maintained and inspected?

-

Is there an 'override' facility which suspends normal safeguards?

-

Are the permissable uses of the override facility understood and documented in a safe system?

-

Is the override facility under strict supervisory control?

Regulation 12 - Protection against Specified Hazards Have any of the specified hazards been identified and risk assessed?

-

Ejection of materials from the equipment including swarf, tool tips, components, high pressure fluids or anything that could cause injury

-

Rupture or disintegration of parts including components, hoses, pipework or anyrtghing else which could cause injury

-

Fire or overheating of equipment

-

unintended discharge of particles, gas etc

-

unintended explosion etc.

Regulation 13 - High and Low Temperatures

-

Are areas of forseeable access at the temperatures likely to cause burns or similar injury?

-

Are contact surfaces suitably instulated or provided with hazard warning?

Regulation 14 - Start controls

-

Are there sufficient easily identified and maintained controls for starting or restarting?

-

Are the controls readily accessible and protected against inadvertent operation?

-

Do all manual controls require a deliberate action to operate?

-

Are the controls provided for changing operating conditions, eg. Speed, pressure, direction etc?

-

Does start up or restart require deliberate operation of the start control, eg. After resetting a safety device?

Regulation 15 - Stop Controls

-

Is the equipment provided with a readily accessible stop control?

-

Does the stop control mechanism bring the work equipment safely to a safe condition?

-

Are braking systems required for the work equipment?

-

Does the stop control mechanism operate in priority to controls which start or change operating conditions?

-

Is it necessary for all sources of energy to be switched off after stopping the equipment?

-

Is it necessary for stored energy to be isolated or dissipated?

Regulation 16 - Emergency Stop

-

Are sufficient readily accessible emergency stops provided in circumstances where existing or conventional safe guards do not prevent risk of injury?

-

Does the emergency stop operate in priority to all other controls, eg.start or stop controls?

-

Does the emergency stop bring the equipment safely to a safe condition?

Regulation 17 - Controls

-

Are all controls clearly visible, identifiable and appropriately marked?

-

Are the controls readily accessible, in a safe position and operators free from danger when using them?

-

"So far as reasonably practicable can the operator of any control ensure that from the position of the control, no person is in a place where there is risk to there health & safety? "

-

If no, are there systems in place to ensure their health and safety?

-

If no, are there suitable audible or visible warning devices which are activated before the equipment starts?

Regulation 18 - Control Systems

-

Does the control system as configured create any increased risk to health and safety?

-

Does a failure of any part of the control system or its power supply lead to a 'Fail-Safe' condition which will not impede the 'Stop' or 'Emergency Stop' controls'?

Regulation 19 - Isolation from sources of Energy

-

Are there means to physically isolate equipment from all sources of energy?

-

Are the means of isolation clearly identifiable and accessible?

-

Is a safe method of reconnection provided which does not expose any person to a risk of injury?

-

Is a safe system of work in place?

Regulation 20 - Stability

-

Has the work equipment been fixed and/or stabilised to prevent the risk of injury?

Regulation 21 - Lighting

-

Is the area encompassing the work equipment suitably and sufficiently lit for all funtions?

Regulation 22 - Maintenance Operations

-

Has the equipment been designed or modified to enable maintenance to be carried out safely?

-

Are safe systems of work in place to allow the maintenance to be undertaken safely?

-

Have risk assessments been completed for maintenance operations?

Regulation 23 - Markings

-

Are all necessary health and safety markings to current standards and clearly visible?(start,stop,E-Stop controls etc?

Regulation 24 - Warnings

-

Are any warnings or warning devices required eg. Visual, audible etc?

-

Are the warnings or warning devices provided both suitable,(eg. audible, clearly visible, unambiguous, easily understood and maintained?

RISK ASSESSMENT & RISK REDUCTION STRATEGY

-

Assessed by

-

Date

Hazard

-

Description of hazard

-

Risk related to hazard

-

Who might be harmed?

-

Regualtion failed

-

Risk likelihood

-

Risk consequences

-

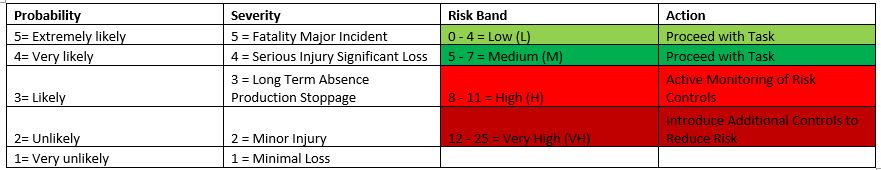

Use this risk matrix to identify the risk level:

-

Probability and severity

-

Risk level

-

Hazard causing risk can be eliminated?

-

Can something be implemented to control this risk (risk control measure)?

-

Describe the proposed control measure:

-

Briefly describe the existing control measure:

-

Further action needed to control the risk?

-

Select the "Action" icon to create an action, assign it to someone, and set a due date.

-

Eliminate the hazard causing the risk.

-

Can something be implemented to control this risk (risk control measure)?

-

Describe the proposed control measure:

-

Further action needed to control the risk?

-

Select the "Action" icon to create an action, assign it to someone, and set a due date.

-

Monitor this risk.

-

Can something be implemented to control this risk (risk control measure)?

-

Eliminate the hazard causing the risk.

-

Describe the proposed control measure:

-

Can something be implemented to control this risk (risk control measure)?

-

Describe the proposed control measure:

-

Eliminate the hazard causing the risk.

-

Can something be implemented to control this risk (risk control measure)?

-

Describe the proposed control measure:

-

Eliminate the hazard causing the risk.

-

Resulting probabilty and severity

-

Resulting risk level

-

To ADD another hazard to the risk assessment/ reduction strategy, select the "+" icon next to Hazard.

To END the assessment, select the "Next Page >" button at the bottom right.