Information

-

Audit Title

-

Client

-

Contractor Name

-

Conducted on

-

Prepared by

-

Location

-

Audit Team

-

Document No.

1.0 - Previous Audit/Inspection

-

1.1 - Has the previous audit or site inspection been reviewed?

-

1.2 - Have all previous corrective action items been signed off?

2.0 - WHS Administration & Records

-

2.1 - Is the WHS Management Plan available to all workers and contractors?

-

2.3 - Are Incident report forms and insurance forms available?

-

2.4 - Are Toolbox talks and hazard identification processes completed regularly?

-

2.5 - Are SWMS available on site and have been reviewed and signed off by relevant workers prior to a specific task being carried out?

-

2.6 - Has a site specific induction been complete for all workers and visitors on site?

3.0 - Emergency Management & Signage

-

3.1 - Is an emergency management plan available on site and are details of what to do in an emergency situation communicated to all personnel on site?

-

3.2 - Is the evacuation plan displayed in prominent areas around the site?

-

3.3 - Is signage available showing the principal contractor’s name, contact details and location of any site office

-

3.4 - Are all applicable safety hazard and warnings signs available (eg asbestos work in progress, restricted area, plant in use)

-

3.5 - Are extinguishers available with adequate signage?

-

3.6 - Do extinguishers have current service tags?

4.0 - Amenities

-

4.1 - Are amenities adequate for the number of personnel on site?

-

4.2 - Are the site amenities clean and tidy with rubbish regularly removed?

5.0 - First Aid

-

5.1 - Are First aid kits and facilities available, clearly labelled, accessible and fully stocked?

-

5.2 - Are trained First Aid Officers available on site?

-

5.3 - Are First aid procedures, first aider names and emergency contact numbers displayed/available?

6.0 - Electrical Safety

-

6.1 - Does all electrical equipment have current test/tag date?

-

6.2 - Are records of electrical and RCD testing available on site?

7.0 - Work at Heights

-

7.1 - Work at height is performed IAW the hierarchy of controls? (On ground or solid construction; fall prevention devices; work positioning systems; fall arrest; ladders)

-

7.2 - Workers are adequately trained to work at heights?

-

7.3 - Are Emergency and rescue procedures available for activities involving working at heights?

-

7.4 - Has the construction of fall prevention devices been signed off by a competent person?

-

7.5 - Are ladders Industrial Rated and in good condition?

8.0 - Personal Protective Equipment

-

8.1 - Is adequate PPE available - Respirators; Hearing; Eye; Footwear; Clothing; Skin/UV; Gloves; Sharps?

9.0 - Plant, Machinery and Hand Tools

-

9.1 - Is all plant/machinery secured appropriate to prevent unauthorised use?

-

9.2 - Are daily plant inspection checklists completed for each item of plant?

-

9.3 - Do all operators hold relevant certification, including drivers license, white card and are adequately trained and competent to operate plant/machinery?

-

9.4 - Are flashing lights visible and reverse sounders operational on all plant and machinery on site?

-

9.5 - Does plant and machinery have ROPS/FOPS and seat belts that are operational and in good working order?

-

9.6 - Does all plant and machinery have adequate guarding available and in use during operation?

-

9.7 - Do all excavator attachments have safety devices/pins activated during use?

-

9.8 Are safe working loads displayed and any load measurement devices operating correctly?

10.0 - Hazardous Substances

-

10.1 - Is a Hazardous Substance Register available and does it contain the details of substances used or stored on site?

-

10.2 - Are Safety Data Sheets are available for all hazardous substances used or stored on site?

-

10.3 - Are all containers appropriately labelled?

-

10.4 - Are all hazardous substances stored appropriately and in accordance with SDS?

-

10.5 - Are workers trained in the use of hazardous substances?

-

10.6 - Is appropriate PPE available when using hazardous substances?

-

10.7 - Is an eye wash station and shower easily accessible when using chemicals?

-

10.8 - Is a spill kit accessible and fully stocked?

11.0 - Asbestos and Demolition Work

-

11.1 - Does the Asbestos Removal and Demolition contractor/s hold appropriate licences to carry out the work?

-

11.2 - Has the regulator been notified 5 days before any demolition (if applicable work is being carried out) or asbestos removal work is carried out?

-

11.3 - Is a relevant (demolition or asbestos) Supervisor/s available or present on site when work activities are being carried out?

-

11.4 - Are workers and supervisors adequately trained and competent to conduct relevant activities and are records of training readily available on site?

-

11.5 - Have exclusion zones been set up to prevent unauthorised access to demolition/asbestos removal areas?

-

11.6 - Have all essential services been identified and, where applicable, decommissioned?

-

11.7 - Is the asbestos register available on site and kept up to date?

-

11.8 - Has/will all asbestos material be removed prior to demolition activities commencing?

-

11.9 - Is a Demolition Plan and/or Asbestos Removal Control Plan available on site?

-

11.10 - Are workers carrying out licensed asbestos removal work provided with regular health monitoring? (Note; before commencing work and at least every 2 years)

-

11.11 - Are appropriate decontamination facilities available for the asbestos removal work area?

-

11.12 - Has all asbestos waste been contained and labelled IAW the GHS before the waste is removed from the asbestos removal area?

-

11.13 - Has all asbestos waste been disposed of at an authorised disposal location, and are records available?

-

11.14 - If asbestos removal work is completed, has a clearance inspection certificate been issued by an independent licensed asbestos assessor (Class A)/independent competent person (Class B)?

-

11.15 - Are the results/reports of air monitoring available at the workplace and been adequately communicated to workers and other relevant persons?

12.0 Chain of Responsibility

-

Are all contractors NVHAS accredited?

-

Are procedures in place to ensure compliance with mass or dimension requirements under the National Heavy Vehicle Law? (e.g. weighbridge dockets; on-board scales; loading documentation; know how much is permitted on the vehicle when fully loaded and know the allowable dimensions).

-

Are procedures in place to ensure compliance with load restraint and driver fatigue requirements under the National Heavy Vehicle Law? (Speed limiters are compliant and in use; appropriate restraint equipment is provided; records kept of drivers' activities including work/rest times; rosters and schedules do not require drivers to exceed work/rest times or speed limits).

-

Are procedures in place to ensure heavy vehicles are roadworthy and appropriately maintained? (e.g. system to raise a defect or concern; regular vehicle maintenance/pre-start checks)

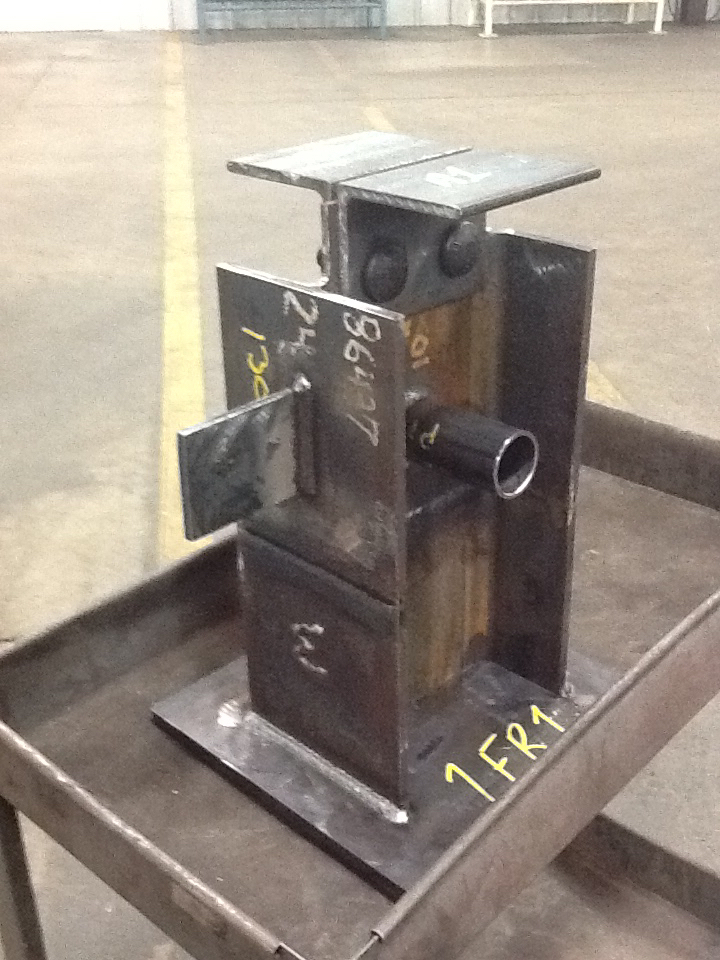

13.0 - Site Inspection & Activity Review

-

13.1 - Are activities on site being conducted IAW relevant safe work method statements? (Note: Review activities against documented SWMS).

-

13.2 - A site inspection has been completed and there are no areas of concern?

Sign Off

-

On site representative's signature

-

Auditor's signature

-

Enter any additional information here, including email addresses for relevant stakeholders.