Title Page

-

Site conducted

-

Date

-

Location

-

Technician

-

Work Order Number

-

Notification Number

-

Machine Model

-

Machine Serial Number

-

Machine Serial Number

-

Company

-

Customer Number

-

Contact Name

-

Contact Phone

-

Hour Meter - Engine

-

Hour Meter - Separator

-

Combine Software Version

-

Weight System Software

Before running

-

Check for blanking plates in cylinder drum

-

Does the customer need them in?

-

Check Torque Of Bolts 81Ft/Lbs

-

Remove Blanking Plates

Running Check

-

Engine RPM Toggle Switch

-

Road/Harvest Mode Toggle Switch

-

Threshing Engagement Toggle Switch

-

Header Engagement Switch

-

Road Test Harvest Mode (1st Gear 0-8 km/h )

-

Road Test Harvest Mode (2nd Gear 0 - 12 km/h)

-

Road Test Driving Mode (1st Gear 0 - 12 km/h)

-

Road Test Driving Mode (2nd Gear 0 - 25 km/h)

-

Engine RPM Range

-

Cylinder Speed Range (240-1680)

-

Concave Travel

-

Cleaning Fan Speed Range

-

Unload Auger Swing

-

Unload Auger Engage

-

Knife Speed Adjustment

-

Header Canvas Speed Adjustment

-

Header Drum Speed Adjustment

-

Header Reel Functions (in/out) (up/down)

-

Combine Clean Out Feature Operation

-

Confirm Automation Settings

-

Neutral Creep

-

Park Brake Operation

-

Horn

-

Wipers

-

Cab Fan Operation

-

Temperature Control

-

Shields and Guards

-

Tire/Rim Damage

-

Wheel Bolt Torque

-

Tire Pressure

-

Back Up Alarm

-

Cylinder Vibration

-

Oil Leaks

-

Frame Damage

-

Notes

Cab

-

Check for DTC's

-

Step Operation

-

Hand Rail

-

Door latch And Seal

-

Rubber mounts on door glass (bolts are tight)

-

Cab Glass

-

Tilt Wheel

-

Mirrors Condition

-

Mirror Operation

-

Seat Adjustment

-

Seat Switch Operation

-

Park Break Alarm

-

Neutral Start Operation

-

Interior lights

-

Aux Switches

-

Turn Signals And Marker Lights

-

Field And Road Lights

-

Grain Tank Light

-

Grain Tank Full Switch

-

Notes

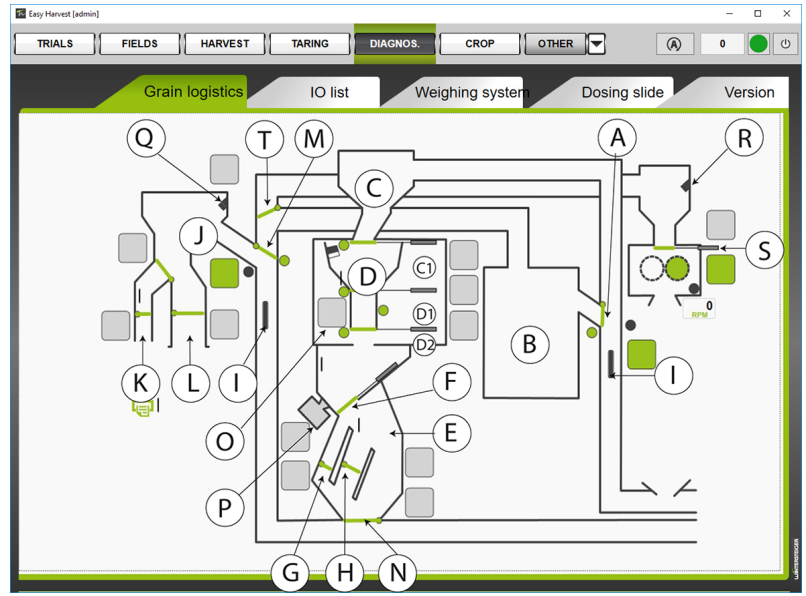

Grain logistic operation

-

-

-

-

Grain Tank/Weighing System Gate Movement (A)

-

Cyclone Gate Movement (C1)

-

Top Weighing Bucket Gate Movement (D1)

-

Bottom Weighing Bucket Gate Movement (D2)

-

Dosing Slide (optional) Movement (F)

-

Dosing Small Sample (optional) Movement (G)

-

Dosing Large Sample (optional) Movement (H)

-

Seed Detectors Operation (I) Test By opening and closing (M) and (A)

-

Small Discharge Chute (optional) Movement (K)

-

Large Discharge Chute (optional) Movement (L)

-

Grain tank/Sampler Gate Movement (M)

-

Injector Flap movement (N)

-

Separator (O)

-

NIRS Optics (optional)

-

Cracker Level Sensor (optional) (R)

-

Open Cracker shut-off Valve (optional) (S)

-

Cracker Direction Switch (optional) (T)

Remove Header

-

Remove Header

Header

-

L/H Hyd. Connections

-

Air Tank Condition

-

Drain Water From Air Tank

-

Auger Drive Hyd. Motor Condition

-

Auger Drum Condition

-

Auger Finger Condition

-

Auger Finger Timing

-

Reel Level

-

Reel bat condition

-

Poly finger condition

-

Does the reel Creep down

-

L/H Reel Lift Cylinder Condition

-

L/H Reel Lift Cylinder Safety Stop

-

Reel Drive Motor Condition

-

Reel Lift Arm Condition (inspect for cracks at hinge point)

-

L/H Short Auger Condition

-

L/H Short Auger Condition

-

Blow Out Solenoid Condition

-

Air Line Condition

-

Knife Drive Motor Condition

-

Knife Drive Speed Sensor Condition

-

Knife Drive Rear Arm/Bushing Condition

-

Knife Drive Guide Arm/Bearing/ Pivot Bolt Condition

-

Remove and Check Pivot Bolt for wear

-

Guide Arm Carrier/Bushing Block

-

Remove Belly Pan And Clean Out

-

Knife Sections Condition

-

Knife Guard Condition

-

Crop Divider Conditon

-

Rock Dam Condition

-

Conveyor Belt Condition

-

Conveyor Belt Tension

-

R/H Blow Out Solenoid Condition

-

R/H Air Line Condition

-

R/H Reel Lift Cylinder Condition

-

R/H Short Auger Drive Motor

-

R/H Short Auger Condition

-

Reel Position Sensor Condition

-

R/H Hyd. Connectors

-

R/H Electrical Connector

-

Frame Damage

-

Oil Leaks

-

Notes

Front

-

Lift Cylinder Condition

-

Short Conveyor Condition

-

Remove Cover to Check Hyd Hoses

-

L/H Hyd Connectors

-

R/H Hyd and Electrical Connectors

-

Steering Motor Condition

-

Beater Drum Condition

-

Oil Leaks

-

Frame Damage

-

Notes

Left Side

-

Short Conveyor Hyd Motor Condition

-

Beater Drum Belt

-

Beater Drum Drive Pulley

-

Beater Drum Driven Pulley

-

Remove and Inspect Concave

-

Upper Hyd Block Condition (leaks and Valve Condition)

-

Lower Hyd Block Condition

-

Storage Conveyor Condition

-

Eccentric Bearing Condition

-

Eccentric Drive Bearing

-

Cross Auger Hyd Motor Condition

-

Fuel Tank Condition

-

Frame Damage

-

Oil Leaks

-

Notes

Harvest Master & Cyclone

-

System air set to 100PSI

-

Air leaks

-

Air Cylinder Condition

-

Air Lines

-

Gate Operation

-

Sensors

-

Screens on top of cyclone

-

Wiring

-

Notes

Rear

-

Remove Sieves

-

Conveyor Belt Condition

-

Conveyor Belt Straightness And Tension

-

Chopper Rotary Knives

-

Chopper Stationary Knives

-

Chopper Bearings

-

King Pin Bolts Check That They Are Tight X16

-

Wheel Bearings

-

Steering Cylinder

-

Hold Downs

-

Chopper Pulley

-

Gas Shocks

-

Oil Leaks

-

Frame Damage

-

Notes

Seed Destruction Cracker

-

Is There A Cracker

-

Do the grinder rollers move freely by hand

-

Drive Belt Condition

-

Air Leaks

-

Grinding roller Distance sensor

-

Grinding roller gap (0.2mm)

-

Foreign Objects Magnets ( are they clean)

-

Cracker bearing Condition

-

Accelerator bearing Condition

Right

-

Rotary Screen Gap

-

Rotary Screen Belt

-

Rotary Screen Jackshaft Bearings

-

Rad Condition

-

Battery Condition

-

Chopper Belt Condition

-

Blower Fan Bearings

-

Blower Fan Driven Belts

-

Air Tube Condition

-

Hyd Drive Belt

-

Hydraulic Motor Spline Adapter

-

Chopper/Fan Drive Belt

-

Threshing Engagement Belt

-

Shaker Drive Belt

-

Shaker Driven Belt

-

Eccentric Driven Belt

-

Main Conveyor Driven Belt

-

Cylinder Belt

-

Cylinder Drive Pully

-

Cylinder Driven Pully

-

Cleaning Fan Drive Belt

-

Cleaning Fan Tension pully

-

Cleaning Fan Bearings

-

Eccentric Bearings

-

Inspect All Tensioner

-

Washer Fluid

-

Inspect Fuse Panel

-

Is there Mouse Damage

-

Oil Leaks

-

Frame Damage

-

Notes

Engine

-

Ladder

-

Engine Side access Door

-

Compressor Belt

-

Air Compressor Condition

-

Compressor Mount

-

Main Drive Belts

-

Drive Belt Pulley Condition ( Remove Belt tension)

-

Coolant Level

-

Sight Glass

-

Rad Hoses

-

Cooling Fan Fins

-

Water Pump

-

Air Intake Hoses

-

Exhaust Mount

-

Muffler Conidtion

-

Pan Gasket

-

Head Gasket

-

Air Filter Mount

-

Air Filter Housing

-

Fan/Alt Belt Condition

-

Coolant Leaks

-

Exhaust Leaks

-

Oil Leaks

-

Frame Damage

-

Notes

Grain Tank

-

Auger Bearings

-

Bubble up Auger Condition

-

Vertical unloading auger condition

-

Vertical Unloading Auger upper bearing

-

Vertical unloading auger lower bearing

-

Horizontal unloading Auger condition

-

Unloading Auger Tube Condition

-

Unloading Auger Down Spout Condition

-

Is the Unloading Auger Cap Bent Out

-

Unload Auger Mounting Pin

-

Cross Auger Condition

-

Cross Auger Bearings

-

Grain Tank Sensor Condition

-

Down Spout Condition

-

Frame Damage

-

Notes

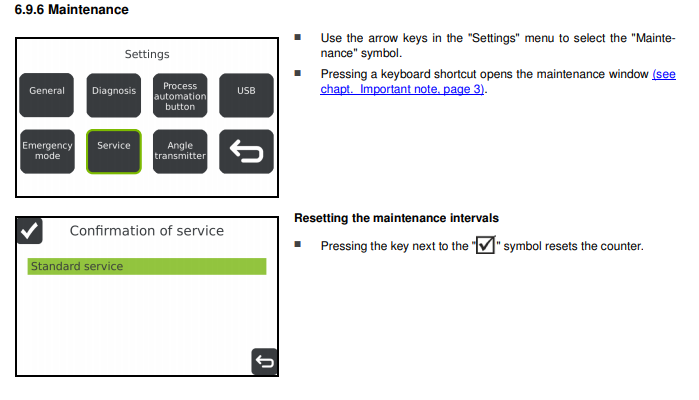

Service

-

Engine Oil And Filter

-

Hyd Oil And Filter

-

Compressor Oil 10W40

-

Fuel Filter

-

In-Line Fuel Filter

-

Engine Air Filters

-

Cab Filter

-

D.E.F filter

-

Reset Service Hours

-

-

Clean Cab glass/sweep cab floor

-

Notes

Final Run

-

Complete Run Check For 15 Min @ Full Throttle While Monitoring

-

Sweep Out Cab/Clean Cab Glass

Parts

-

Where there parts ordered for this machine

-

Ordered From SLC

-

Ordered From AT

-

Ordered From Other

-

Freight Cost