Title Page

-

Site Location

- Belfast

- Birmingham

- Brighton

- Bristol

- Carlisle

- Chester

- Colchester

- Dubai

- Dublin

- Edinburgh

- Exeter

- Glasgow

- Hong Kong

- Jersey

- Leeds

- Leicester

- Liverpool

- London, Senator House

- Manchester Pinnicle

- Manchester Trident

- Newcastle

- Isle of Man, Onchan

- Preston

- Salisbury

- Shipley

- Singapore

- Stockport

- Southampton OMH

- Swindon

- Southampton OMP

- York

-

Assessment Date

-

Assessor

-

Description of Premises

-

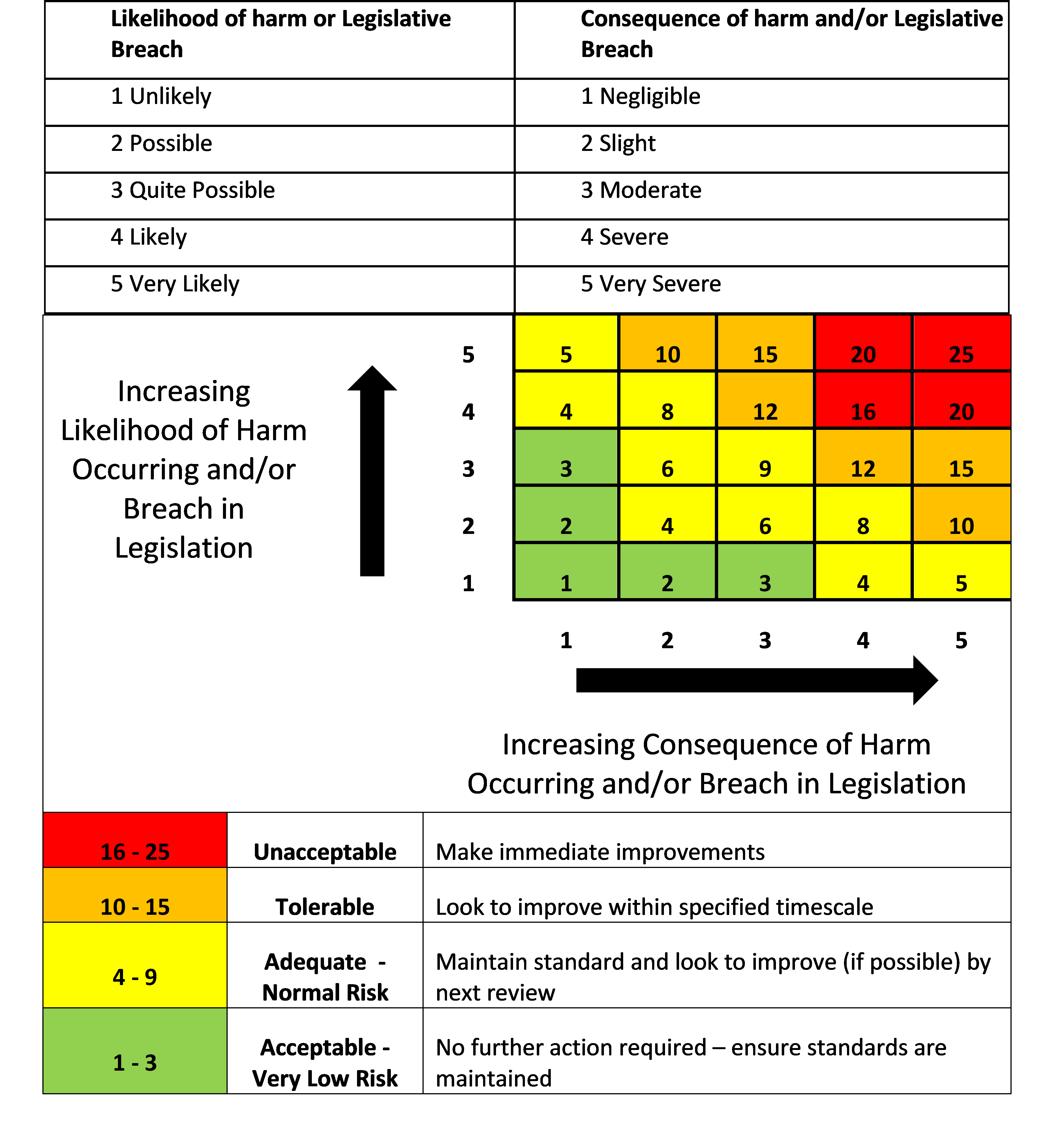

The SHE Risk Assessment is a comprehensive review of both quality of delivery and compliance to recognised industry practice for all in scope services. The Assessment has been designed to measure performance against a consistent standard in operation across the Quilter PLC portfolio. The attached matrix is utilised to establish the level of risk and thus any further controls that may be required.

Areas of Inspection

Documentation

-

HSE policies displayed

-

HSE Law Poster

-

Insurance documents

-

Are suitable risk assessments in place covering the range of activities undertaken on site and have these been subject to review within the last 12 months?

-

Equipment service records

-

Facility service records

-

Staff inductions

-

Have all accidents/incidents/near misses been recorded and reported using the online form?

-

Asbestos report

-

Confined spaces

-

CDM

-

Contractor control

-

COSHH assessments

-

DSEAR

-

Have DSE assessments been completed for all relevant staff and any actions completed or closed?

-

Driving at work

-

EICR / PAT

-

Events

-

Health surveillance

-

Home working

-

Legionella

-

Lone working

-

New and expectant mothers

-

Violence and aggression

-

Young persons

-

Others identified

Facility Safety

-

Safe access and egress

-

Free from trip hazards

-

Adequate lighting

-

Safety signage and communication

-

Vehicles and pedestrian segregation

-

Housekeeping

-

Are there effective access control arrangements to site, including visitor book and restricted areas (plant rooms/roofs/etc)?

-

Others identified

COVID

-

Is a suitable and sufficient COVID Risk Assessment displayed?

-

Is home working evident?

-

One way systems

-

Social distancing

-

COVID signage and communication

-

Cleaning, hygiene and wash stations

-

PPE

-

Others identified

First Aid

-

Has an assessment of first aid needs been completed?

-

Is there an up to date schedule of first aiders displayed on site?

-

Do you have access to a first aid box that is correctly stocked and readily available?

-

Are first aid boxes checked regularly and documented records available to reflect this?

Fire

-

Does the site have a valid Fire Risk Assessment (FRA) and have any significant findings been addressed?

-

Fire Drills

-

Fire Detection

-

Emergency Lighting

-

Fire fighting equipment, dry risers and suppression systems

-

Fire signage

-

Escape and exit routes

-

Incident Marshals and Fire Safety Training

-

Gas safe

-

Housekeeping / Waste Management / Cable Management

-

Compartmentation

-

Others identified

Welfare

-

Eating and rest facilities

-

Sanitary Conveniences

-

Changing Area

-

Dust / Noise

-

Others identified

Working Practices

-

Manual handling

-

Use of ladders

-

Safety observations

-

Emergency preparedness awareness

-

Others identified

Personal Protective Equipment

-

If required, is PPE acceptable

-

Other

Equipment

-

Cleanliness

-

Equipment suitability

-

Lifting equipment / Manual Handling Aids

-

Other identified

COSHH/Storage

-

Racking / Shelving

-

Materials storage

-

Have all hazardous substances been identified and recorded on a COSHH register?

-

Are SDS available for all hazardous substances used on site?

-

Are all chemicals used stored in appropriate facilities to prevent misuse/environmental harm?

Waste Management

-

Waste streams clearly signed and communicated

-

Waste segregated & controlled

Access Equipment

-

Lifts - are maintenance and statutory inspection records valid and available?

-

Window Cleaning Cradles - are maintenance and statutory inspection records valid and available?

-

Window Cleaning Cradles - are training/competence records valid and available?

-

Safety Harnesses and Anchor Points - are maintenance and statutory inspection records valid and available?

Back of House

-

Are traffic/pedestrian routes clearly segregated?

-

Are external/circulation areas well-lit and free from clutter?

-

Are levels of housekeeping adequate to all back of house areas/plant rooms?

-

Are items of plant/equipment adequately guarded (waste compactors/lift motor rooms)?

-

Have noise assessments conducted for applicable plant rooms?

Catering

-

Is there a documented food safety system (based on HACCP principles) in place and has the system been reviewed within the last 12 months?

-

Have all food handlers received training appropriate to their work? (Eg. CIEH Level 2 Certificate in Food Hygiene)

-

Are all personnel wearing appropriate clean over clothing and maintaining an acceptable standard of personal cleanliness and hygiene?

-

Are all stored products (dry, chilled and frozen) properly stored, adequately labelled and within date codes?

-

Are all freezers and refrigerators operating at or below their specified operating temperature?

-

Are the operating temperatures checked at least twice daily and recorded?

-

Are temperatures of hot and cold service equipment checked regularly and recorded?

-

Is an effective cleaning schedule in place (with records available to reflect this) and cleaning standards monitored by a senior member of staff?

-

Has kitchen ductwork been inspected for cleanliness within the last 2 years and based on usage, is there a regular cleaning regime in place for kitchen extract ducts?

-

Is all catering equipment subject to suitable servicing/ maintenance, in line with manufacturers recommendations?

Assessment Outcome

-

The following gives an overall assessment based upon the findings within the risk assessment in line with the above risk matrix

-

What is the overall site risk likelihood? 1 - Unlikely / 2 - Possible / 3 - Quite Possible / 4 - Likely / 5 - Very Likely

-

What is the overall site risk severity? 1 - Negligible / 2 - Slight / 3 - Moderate / 4 - Severe / 5 - Very Severe

-

What is the overall site risk? (Likelihood x Severity)

Inspection Sign Off

-

Assessment Carried Out By:

-

Signature

-

Report Issued To:

-

Signature