Title Page

-

Engineer Name

-

Date of this Assessment

-

Date of next Assessment

-

Site Name

-

Site Location

-

Creators; P Whitehouse, R Bowen, S Jennings

Approved By; Owen Needles -

Thorlux Lighting, Merse Road, North Moons Moat. Redditch. B98 9HH. Tel. 01527583200

-

Version 1.0

Risk Assement

-

Instructions for Use

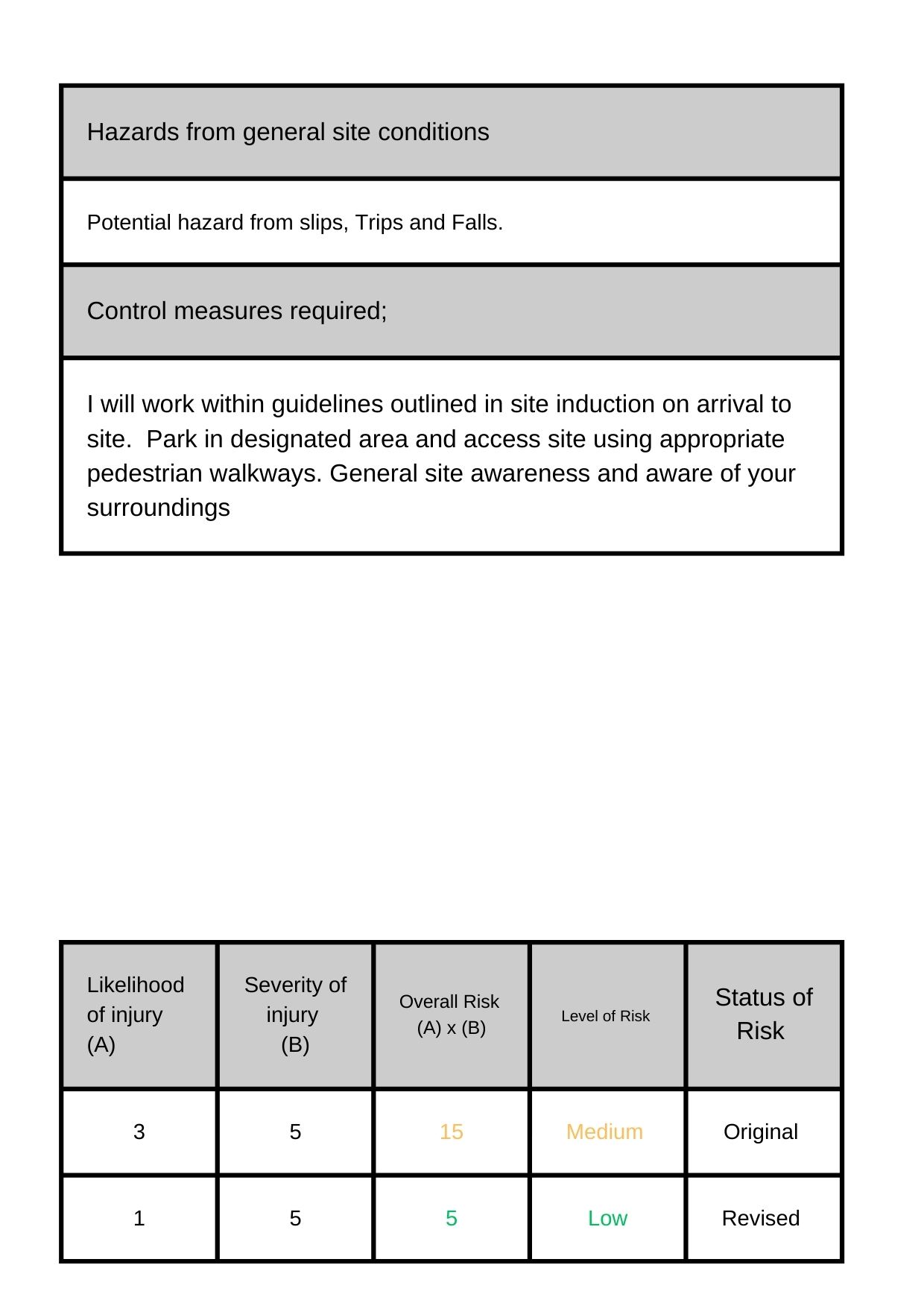

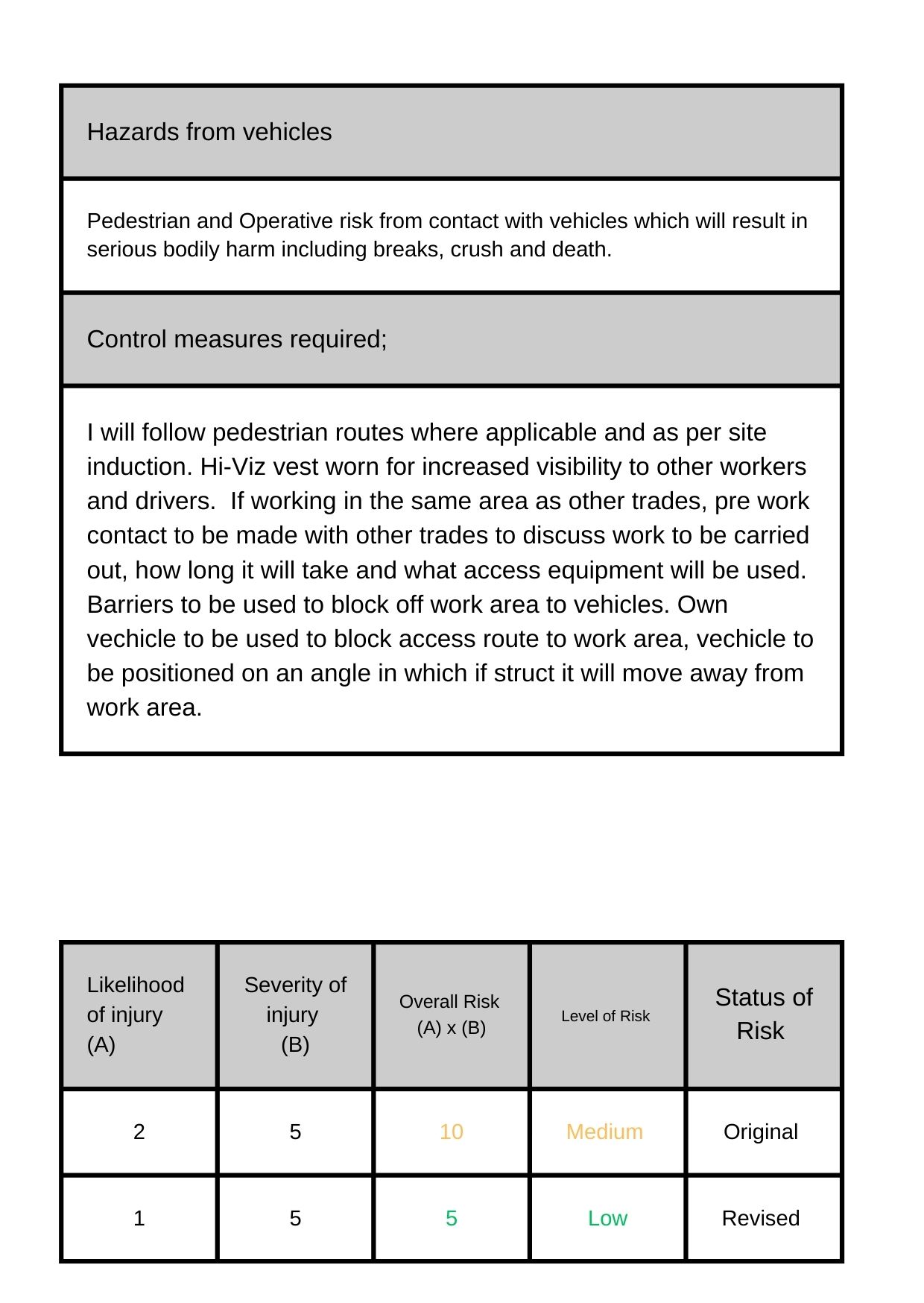

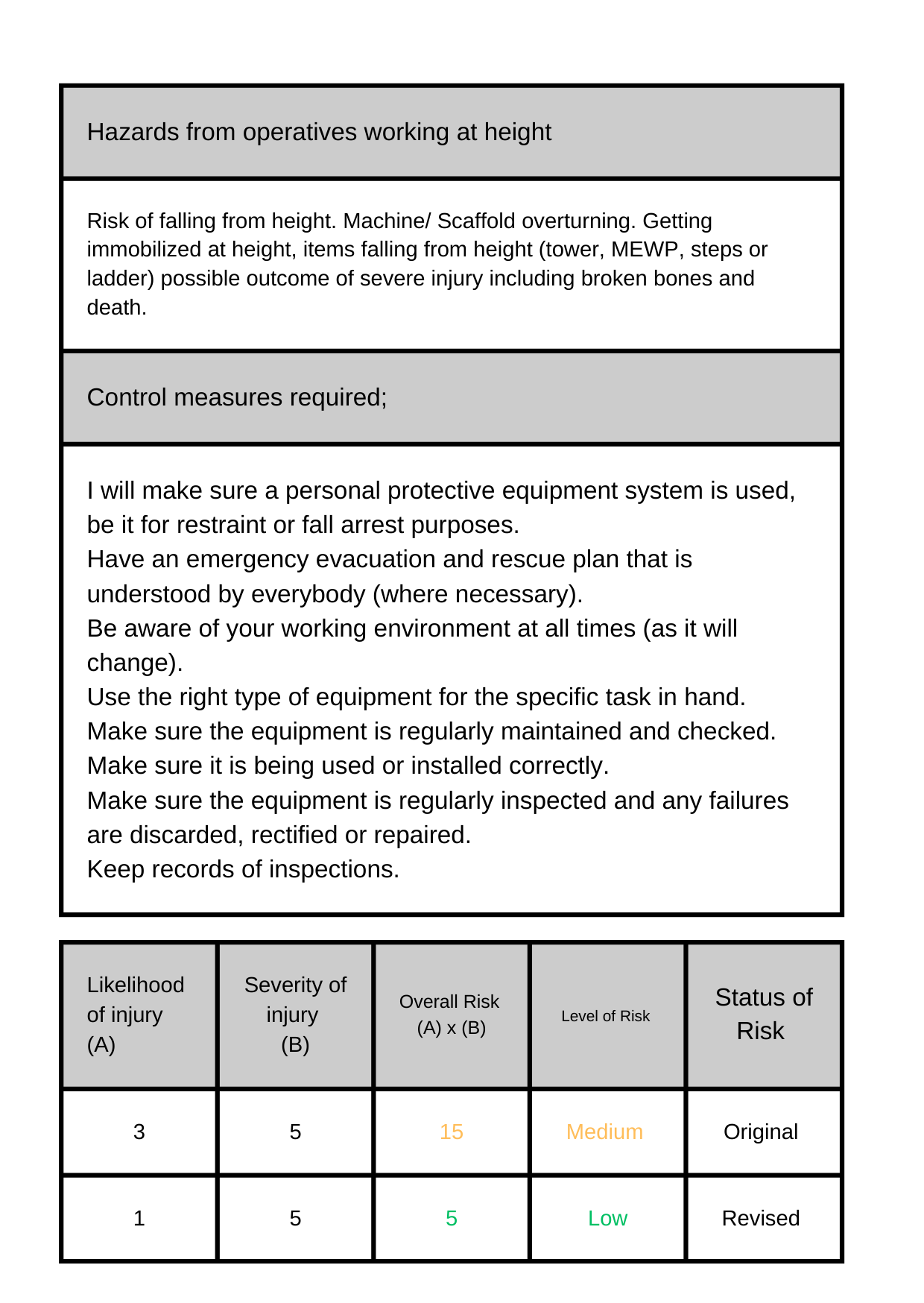

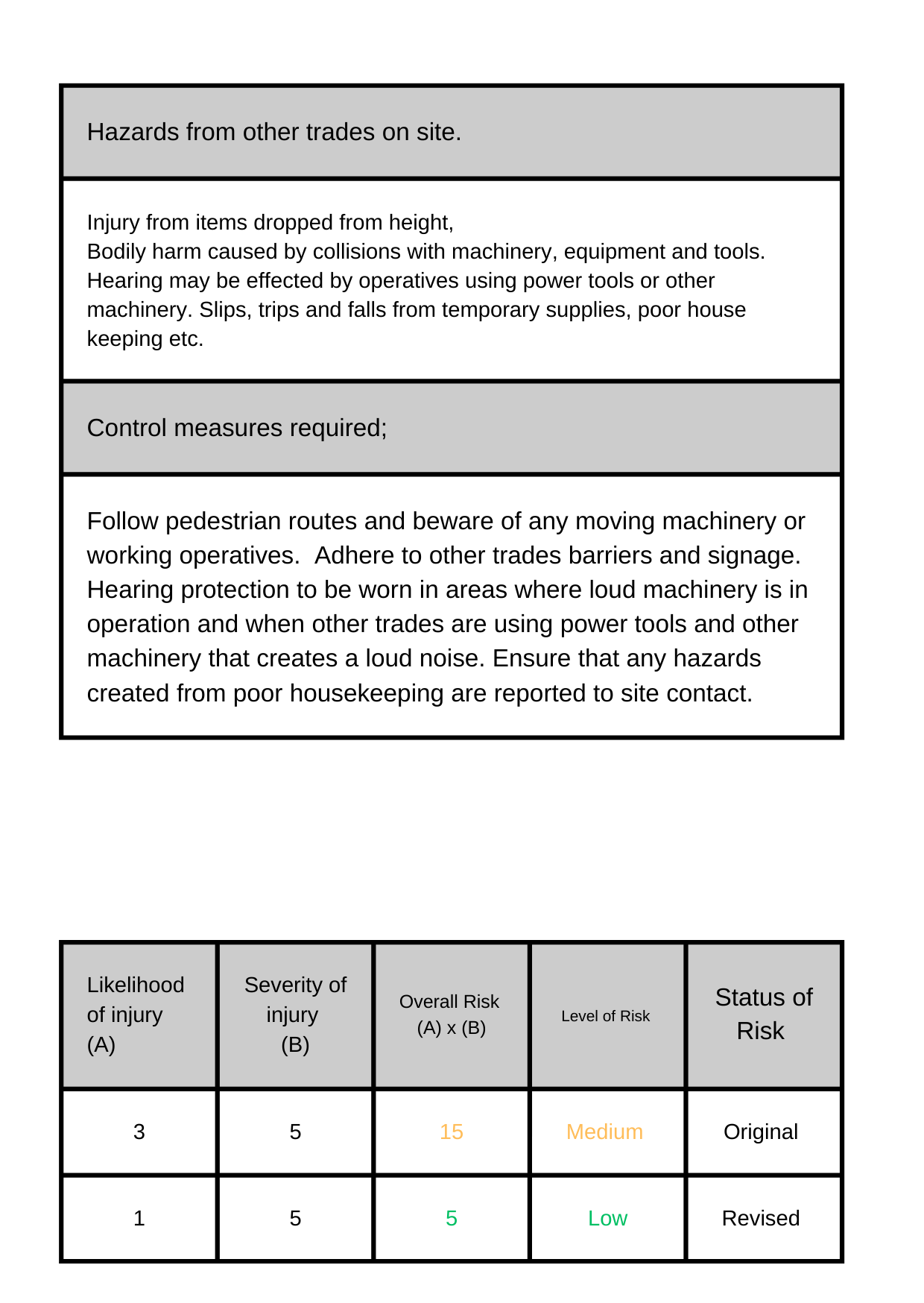

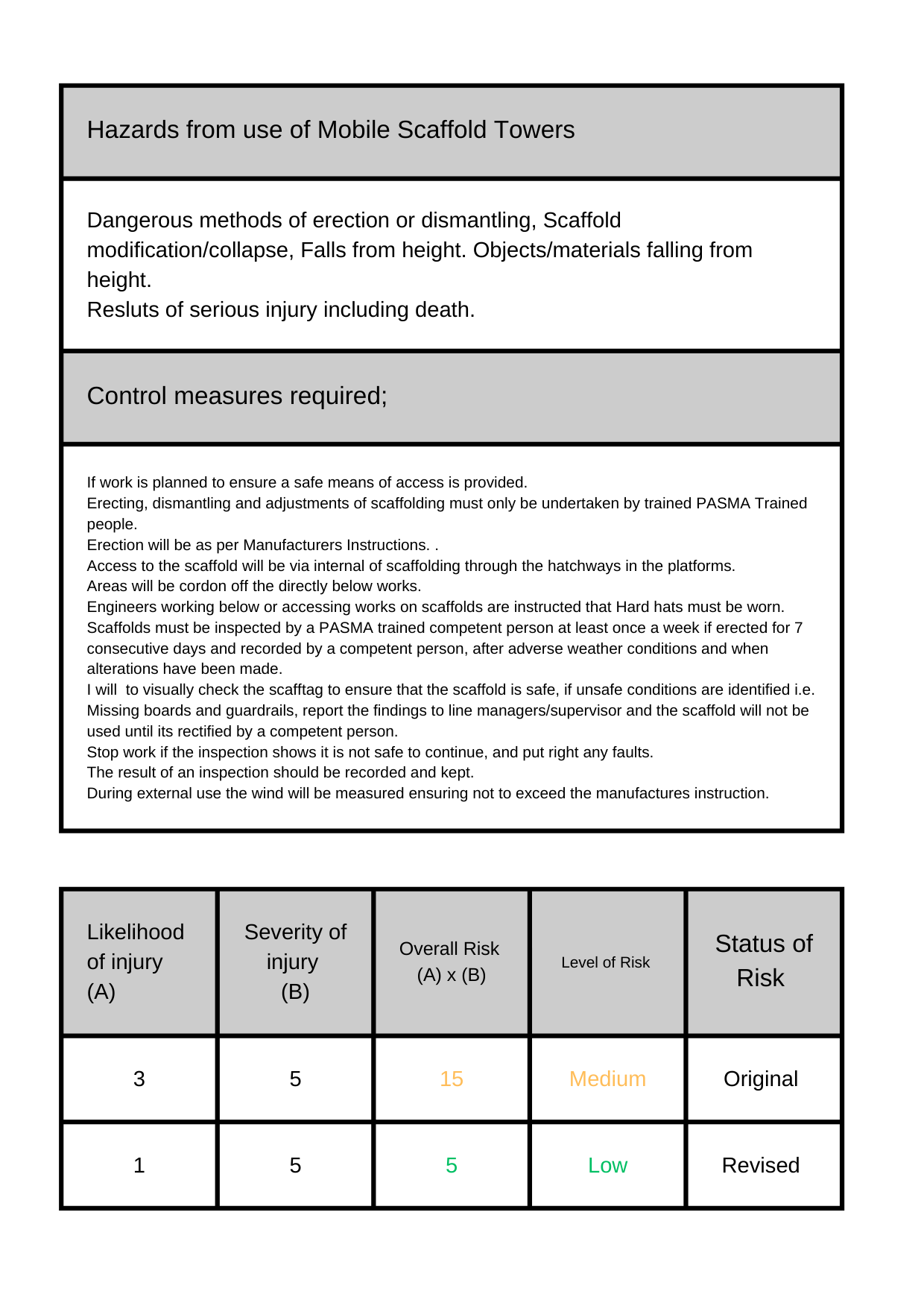

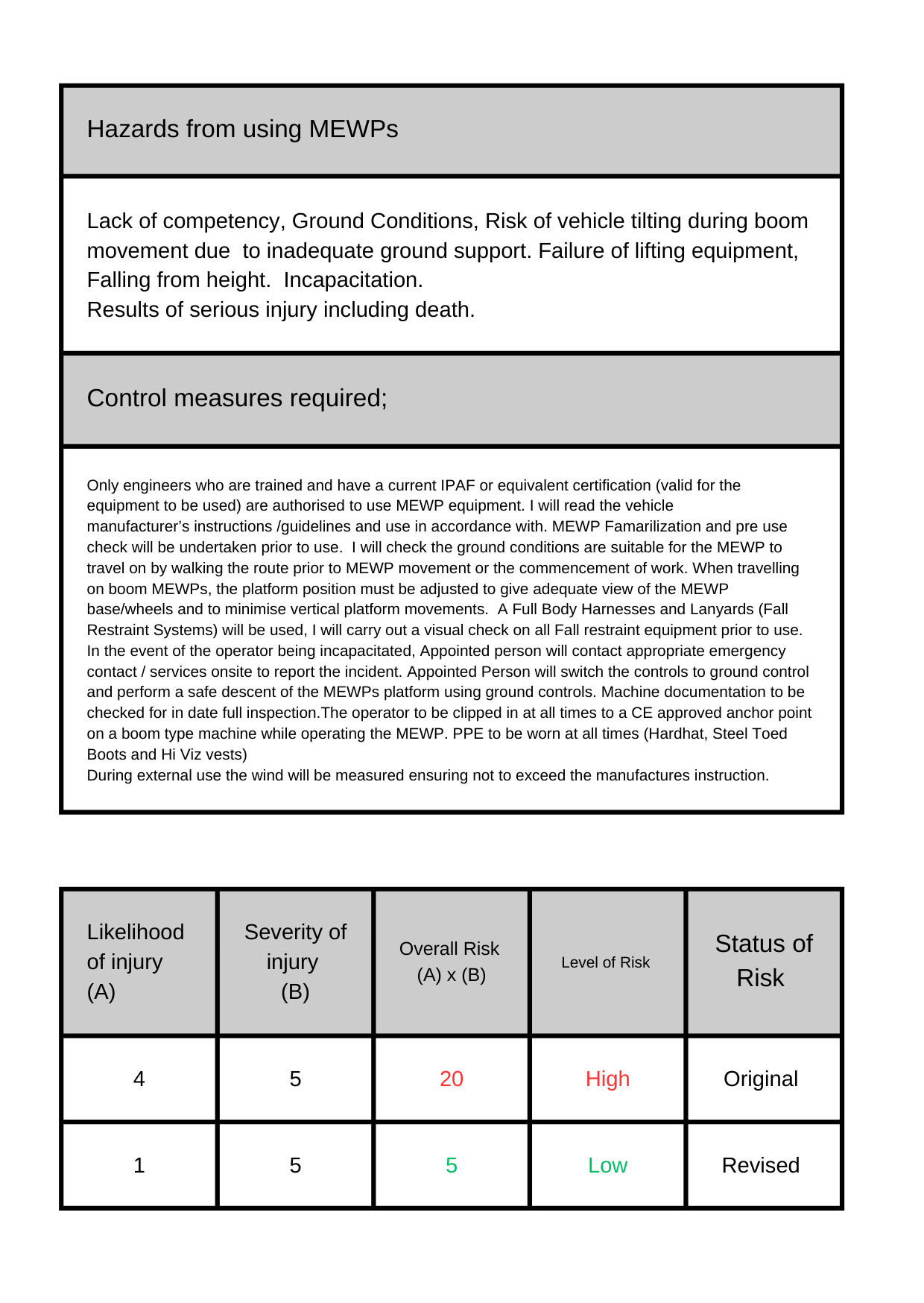

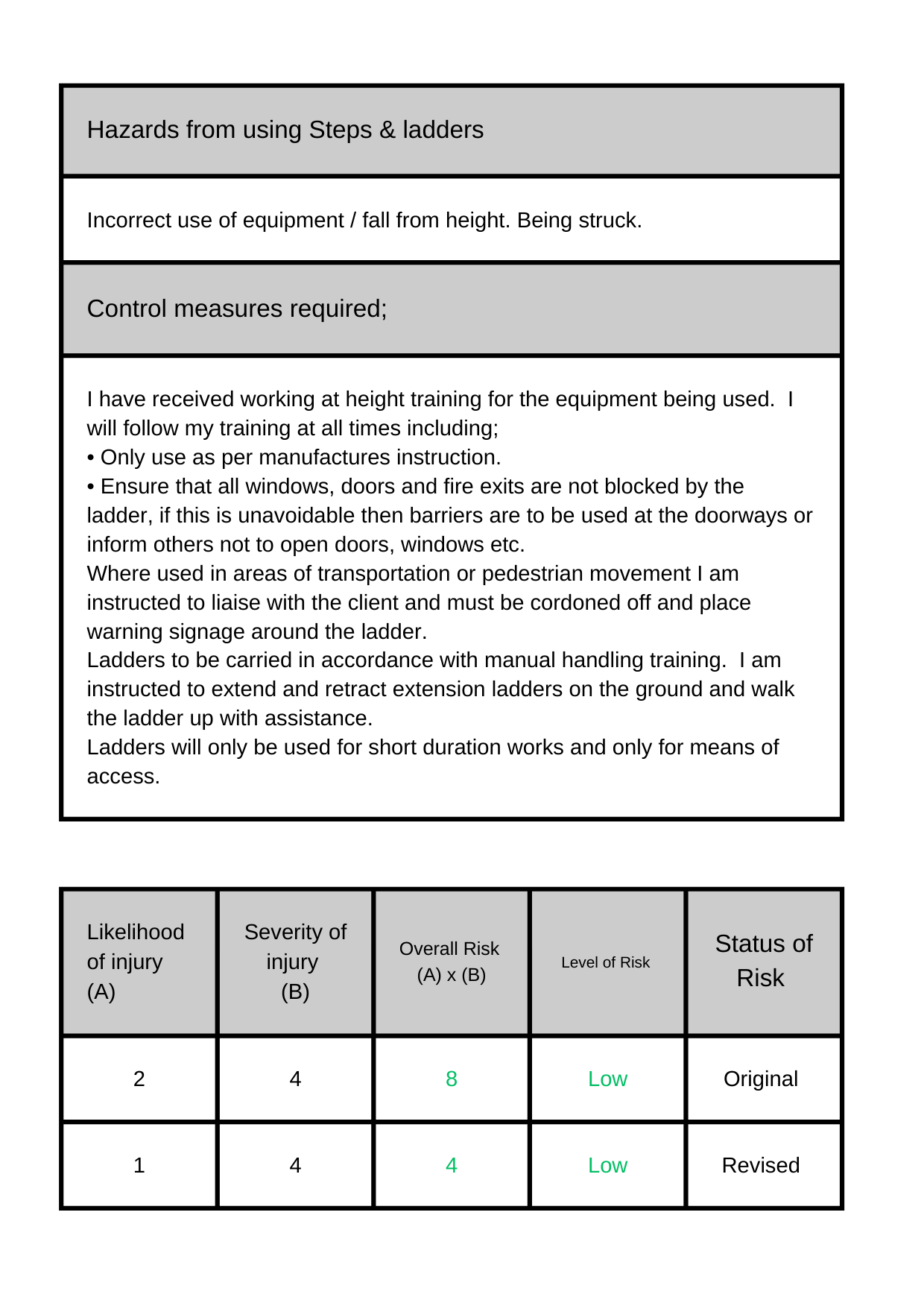

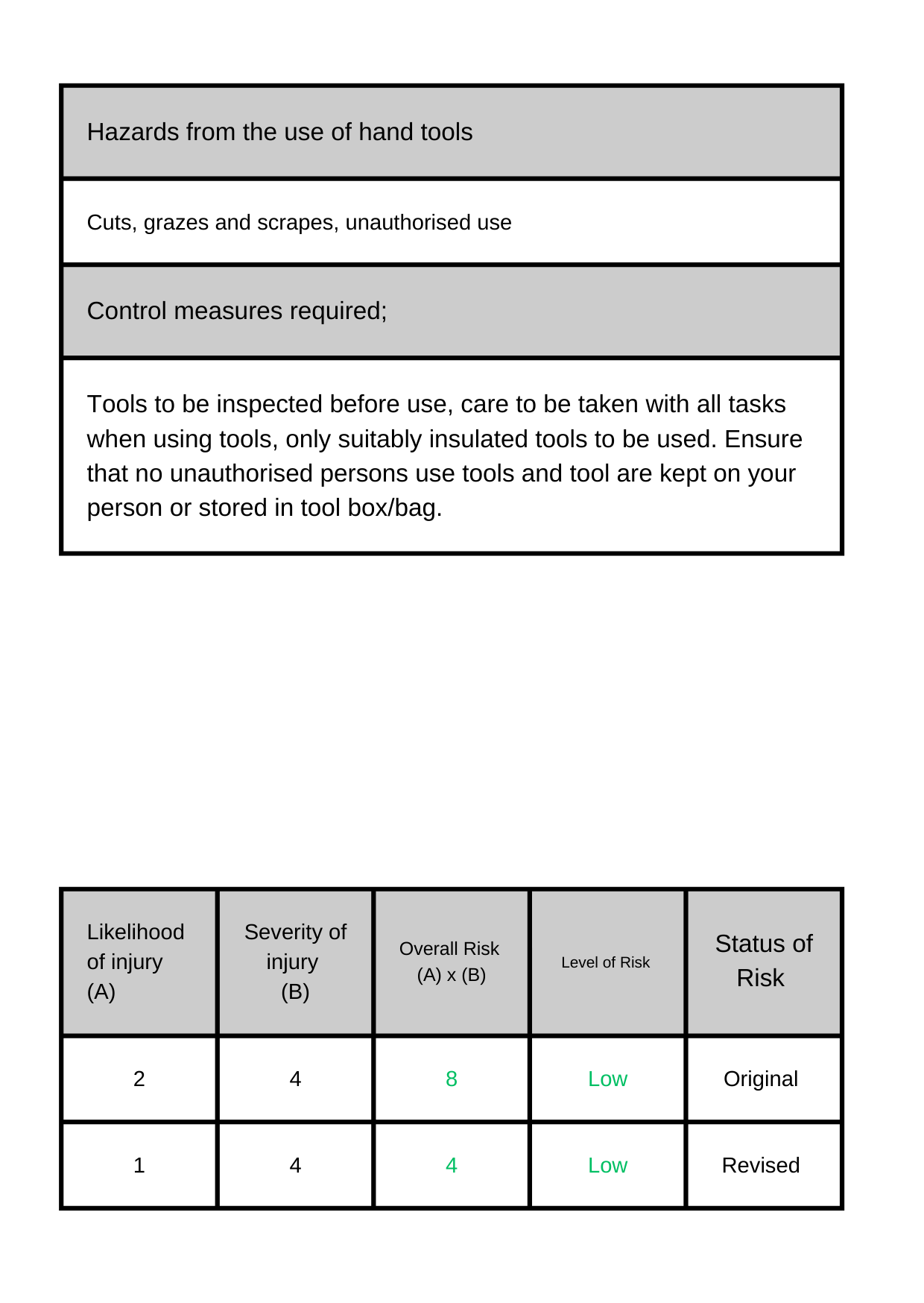

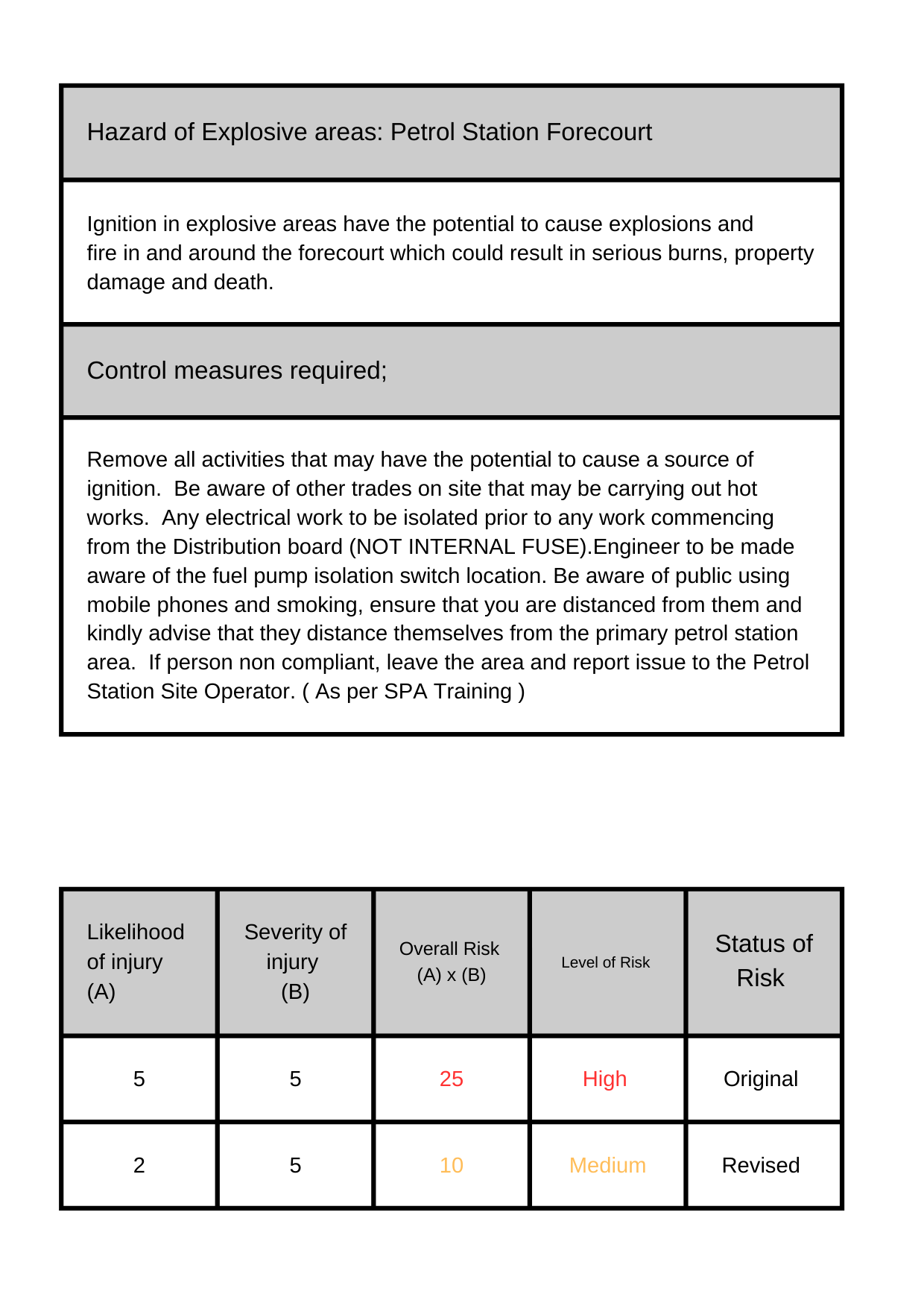

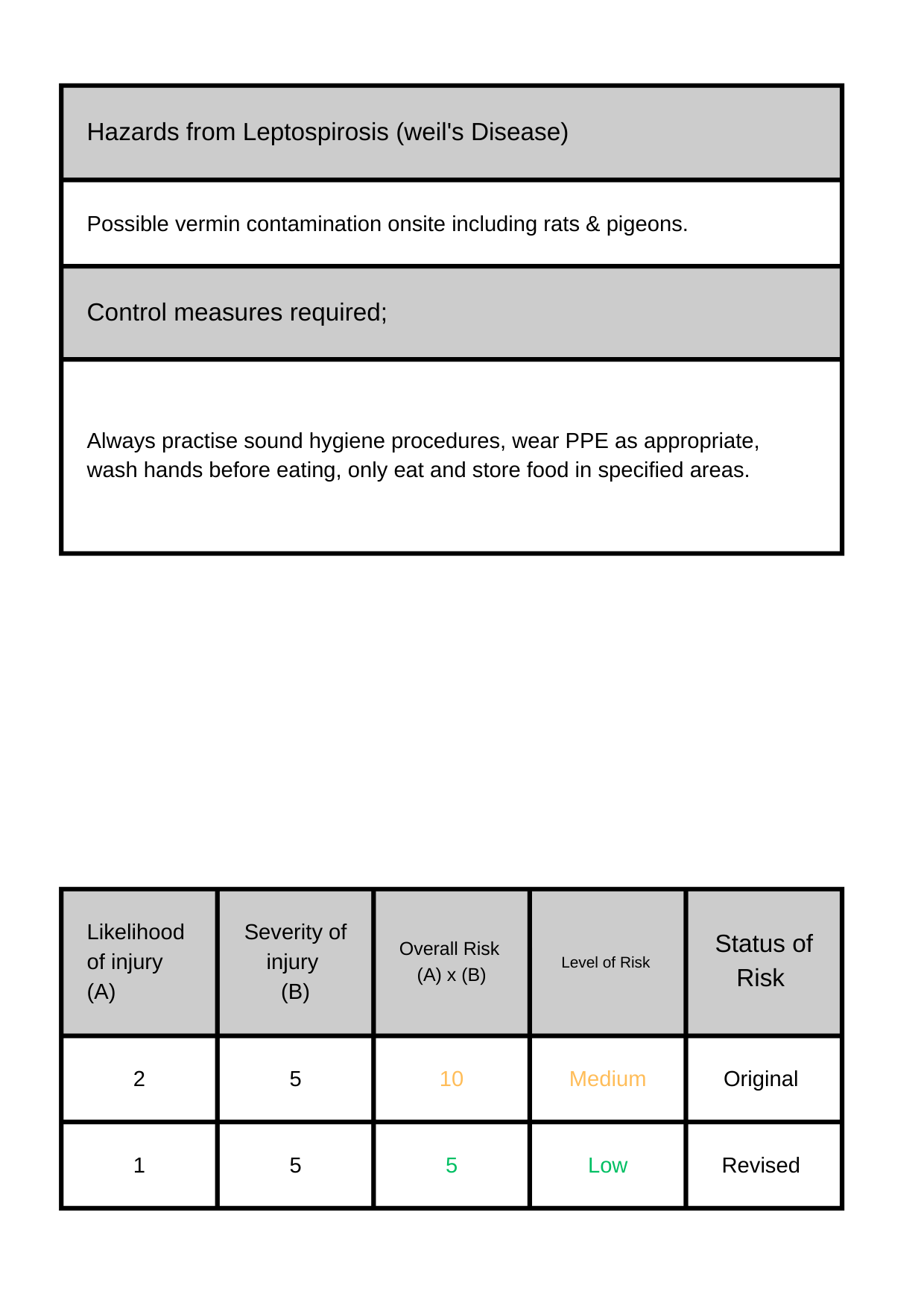

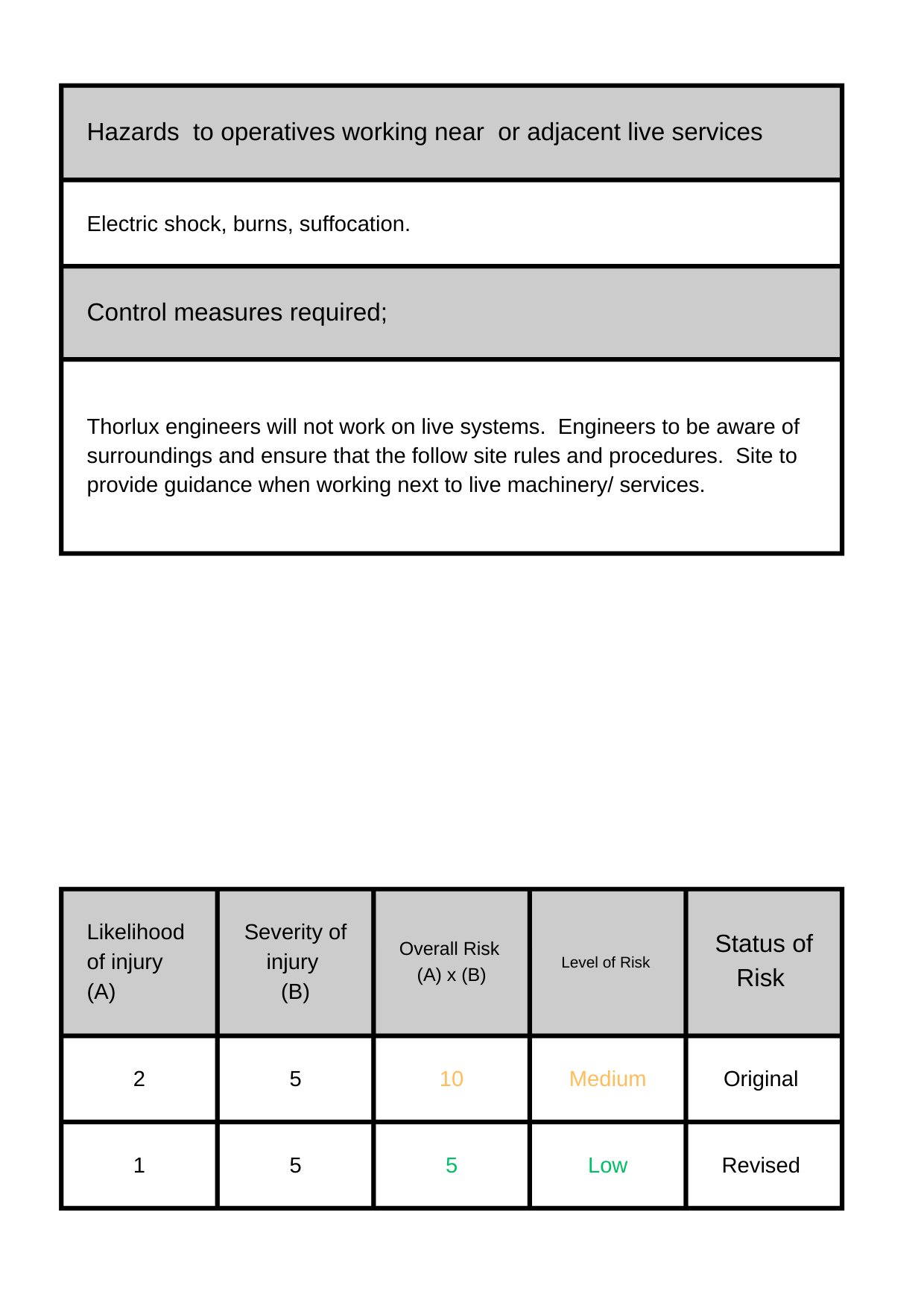

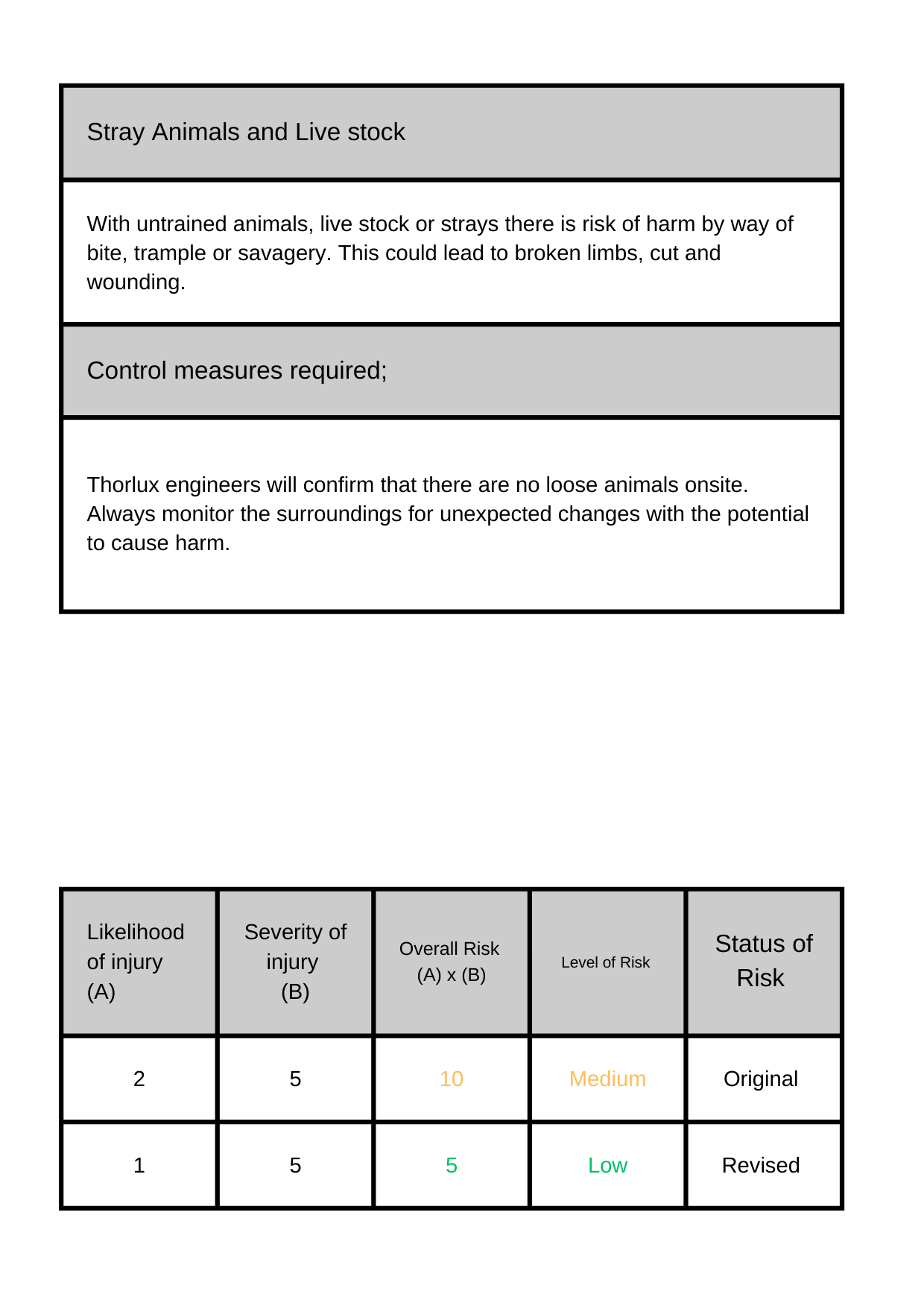

Each hazard must be assessed for the Likelihood of possible Injury (A) and the potential Severity of any resulting Injury (B).

The numeric assessments are then multiplied to achieve an overall risk rating (AxB) for each of the hazards.

LOW RISK = An Overall Risk of 6 or Less (Carry out work activity - implement control measures to further reduce risk if possible).

MEDIUM RISK = An Overall Risk of between 7 - 9 (Implement additional control measures and conduct further specific assessment to reduce the risk further).

HIGH RISK = An Overall of 10 or More (Work is not to commence until the risk has been reduced or removed). -

Likelihood of Injury (A)

1 = Zero to Extremely Low

2 = Low

3 = Likely

4 = Very Likely

5 = Almost Certain -

Severity of Injury (B)

1 = Slight or No Injury

2 = First Aid or Minor Injury

3 = Minor Injury or Illness

4 = Major Injury

5 = Major Injury or Fatality

Hazard

-

Type of Hazard

- Site Conditions

- Vehicles

- Working at Height

- Other Trades

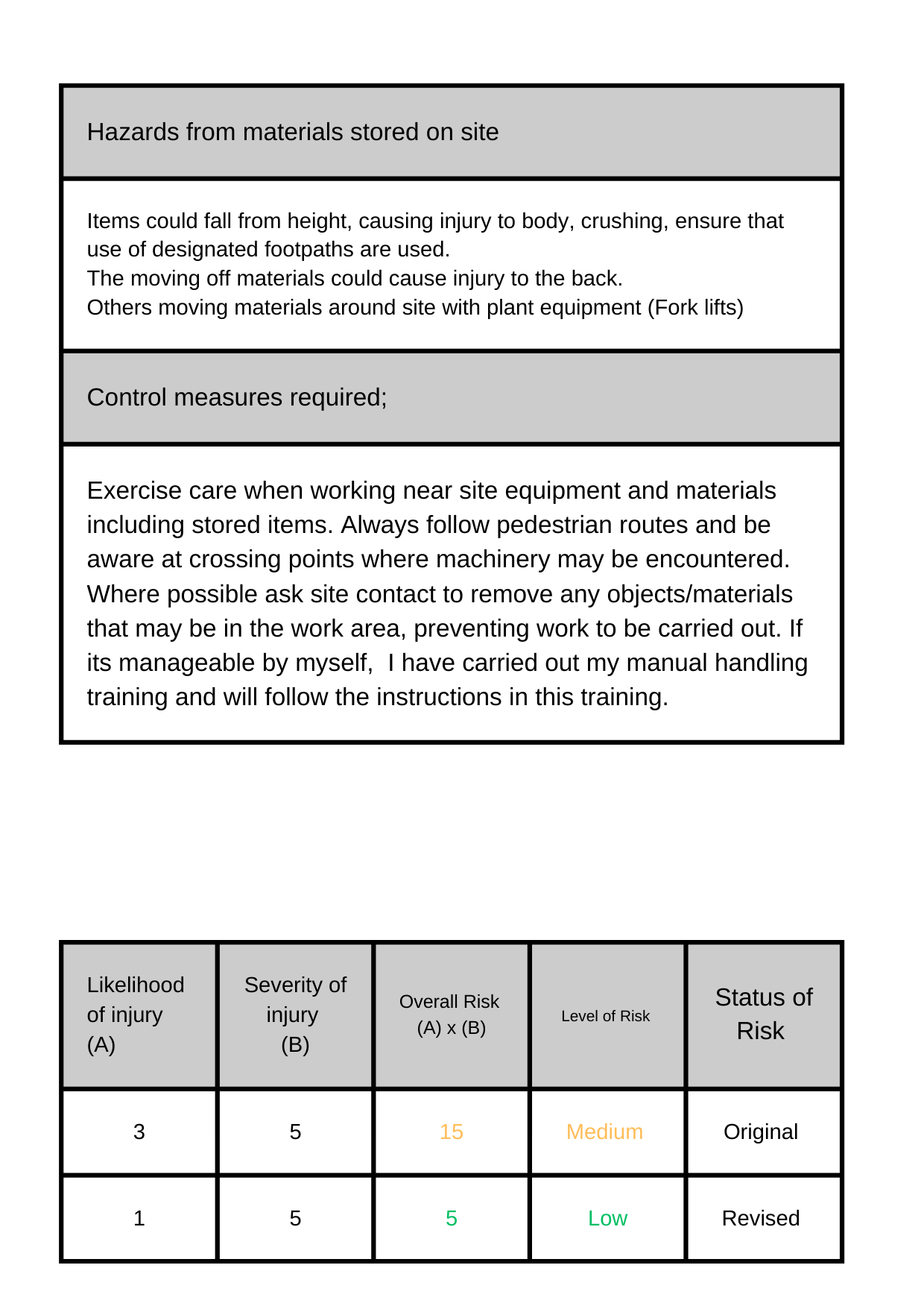

- Materials Stored on Site

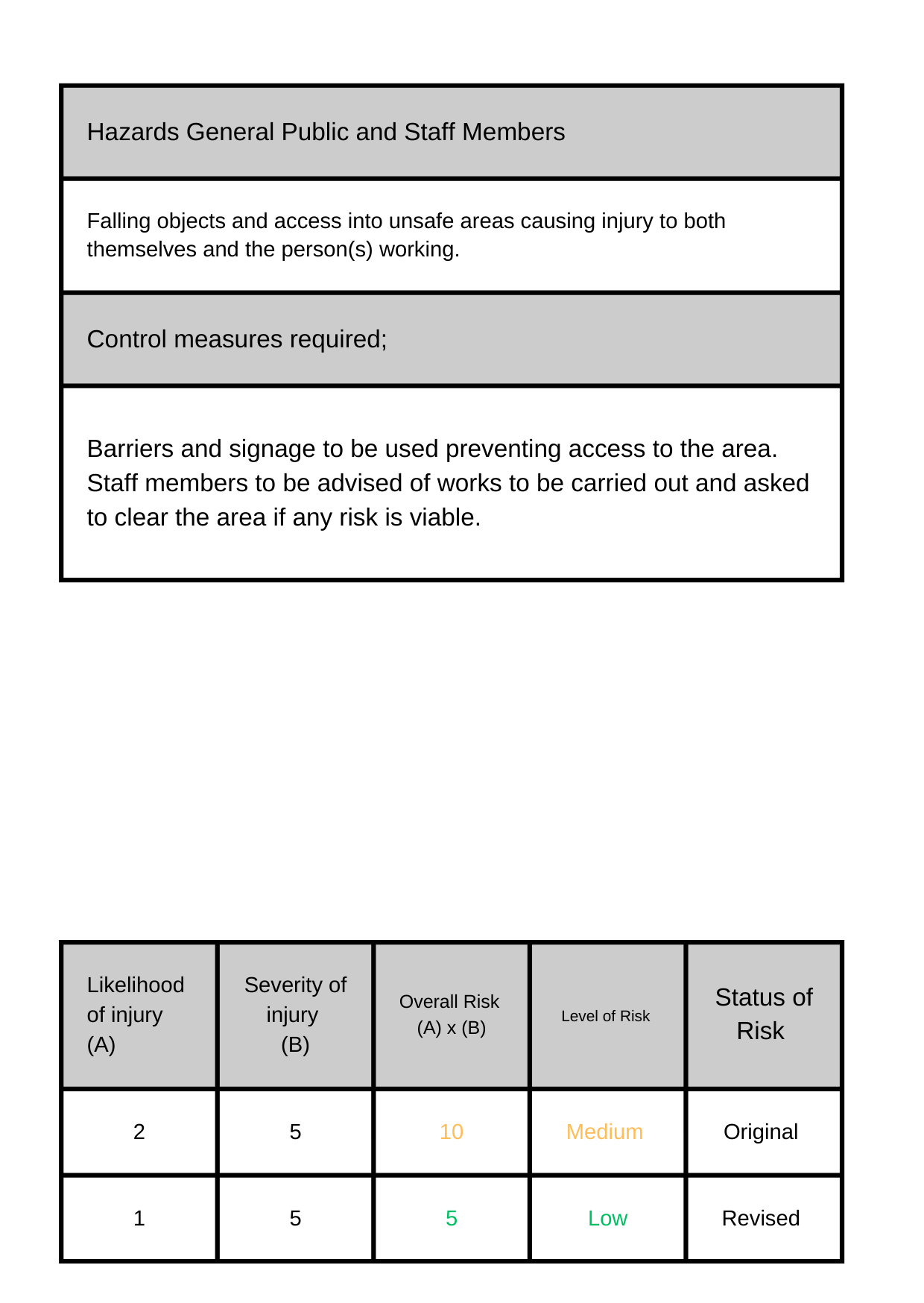

- Public and Staff Members

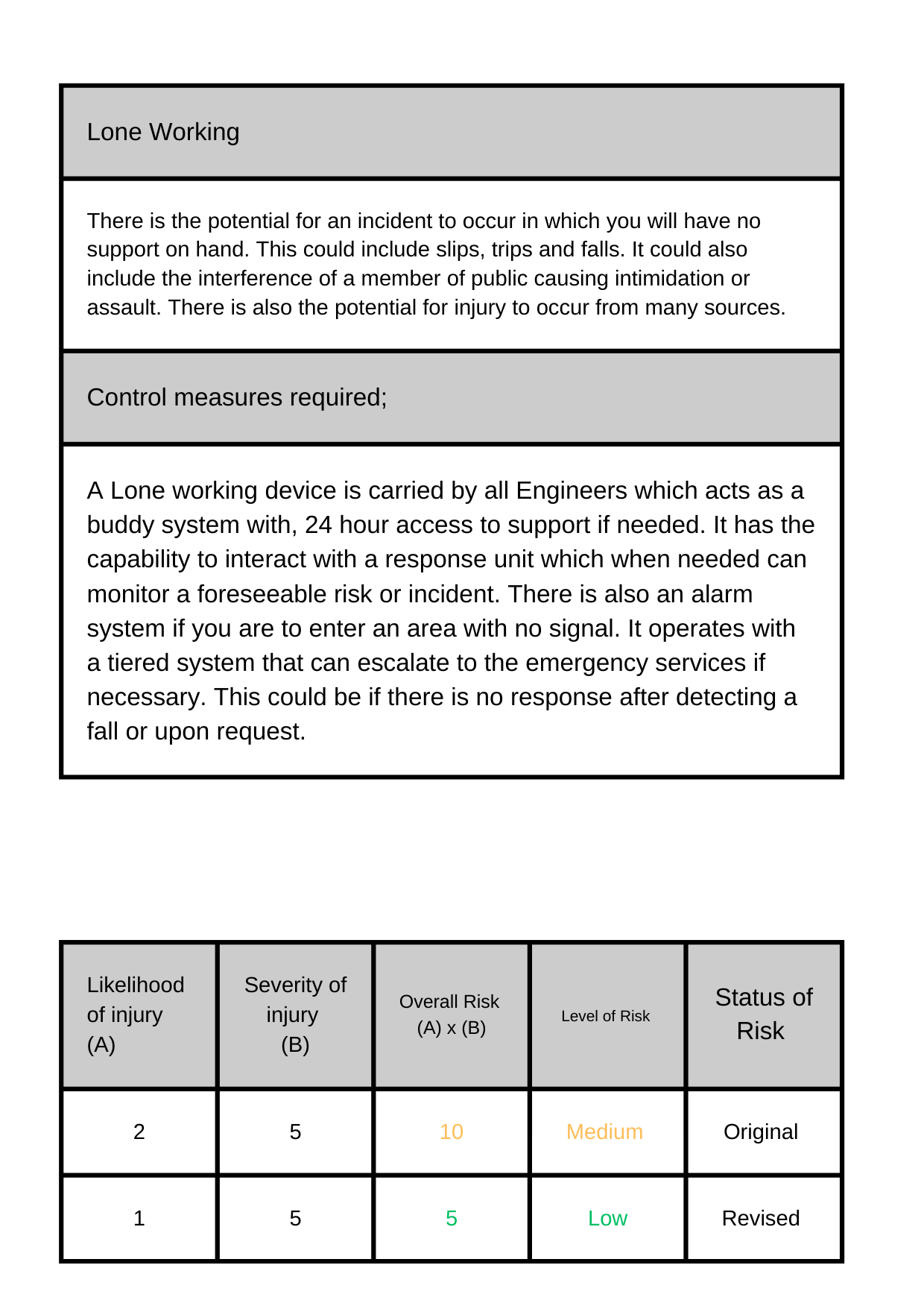

- Lone Working

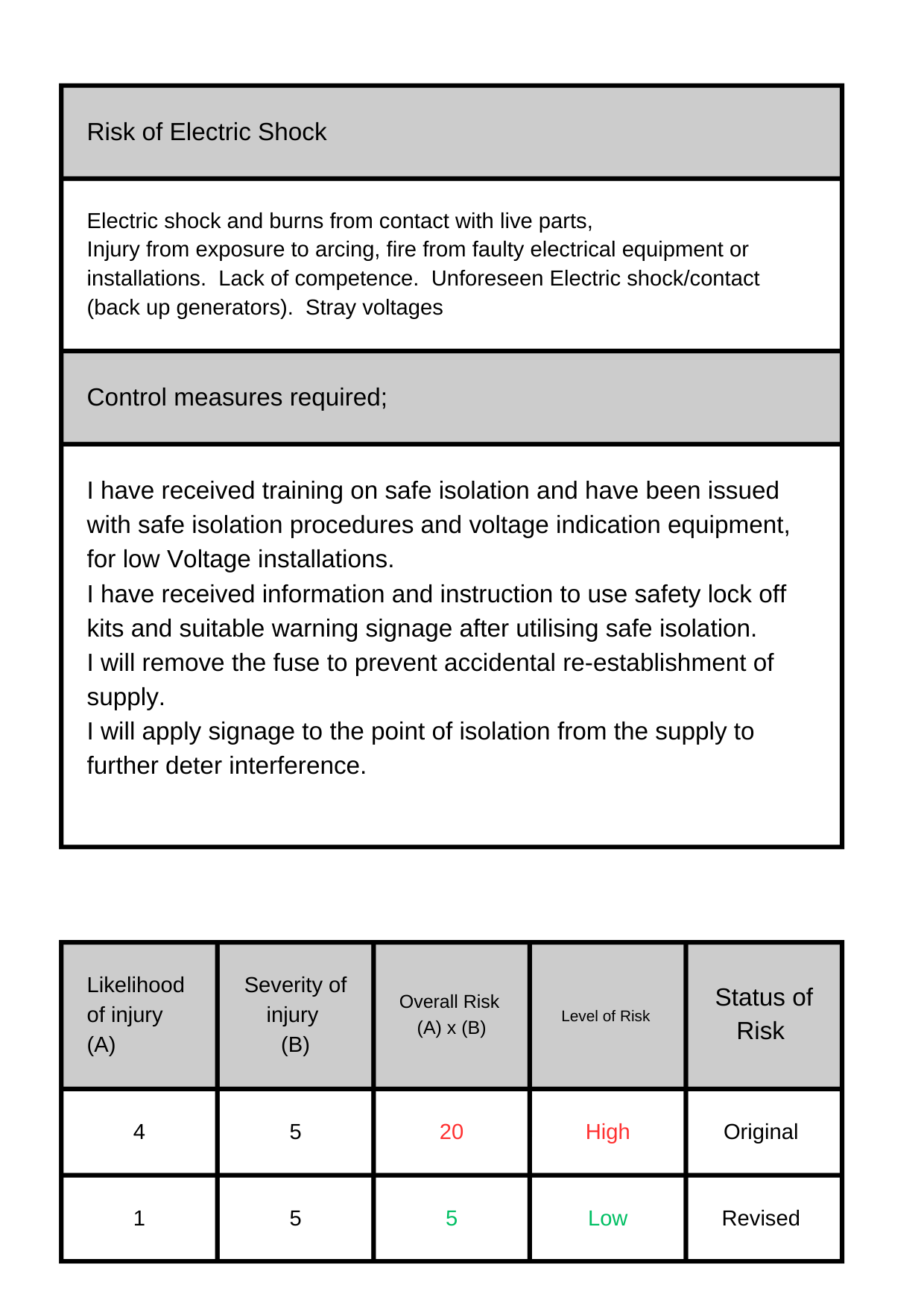

- Electrocution

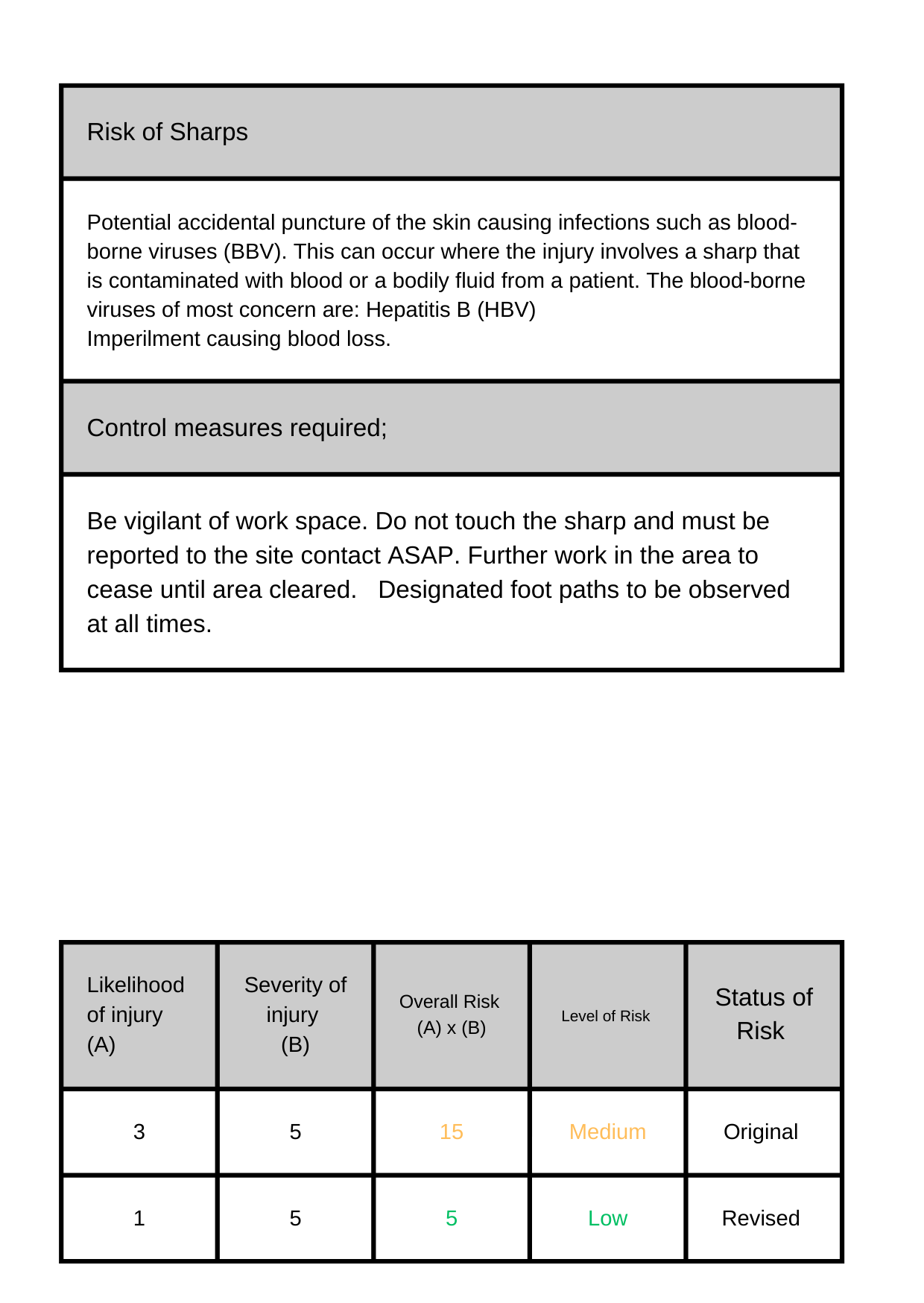

- Risk of Sharps

- Use of Mobile Scaffold Tower

- Use of MEWPs

- Use of Step Ladders

- Use of Hand Tools

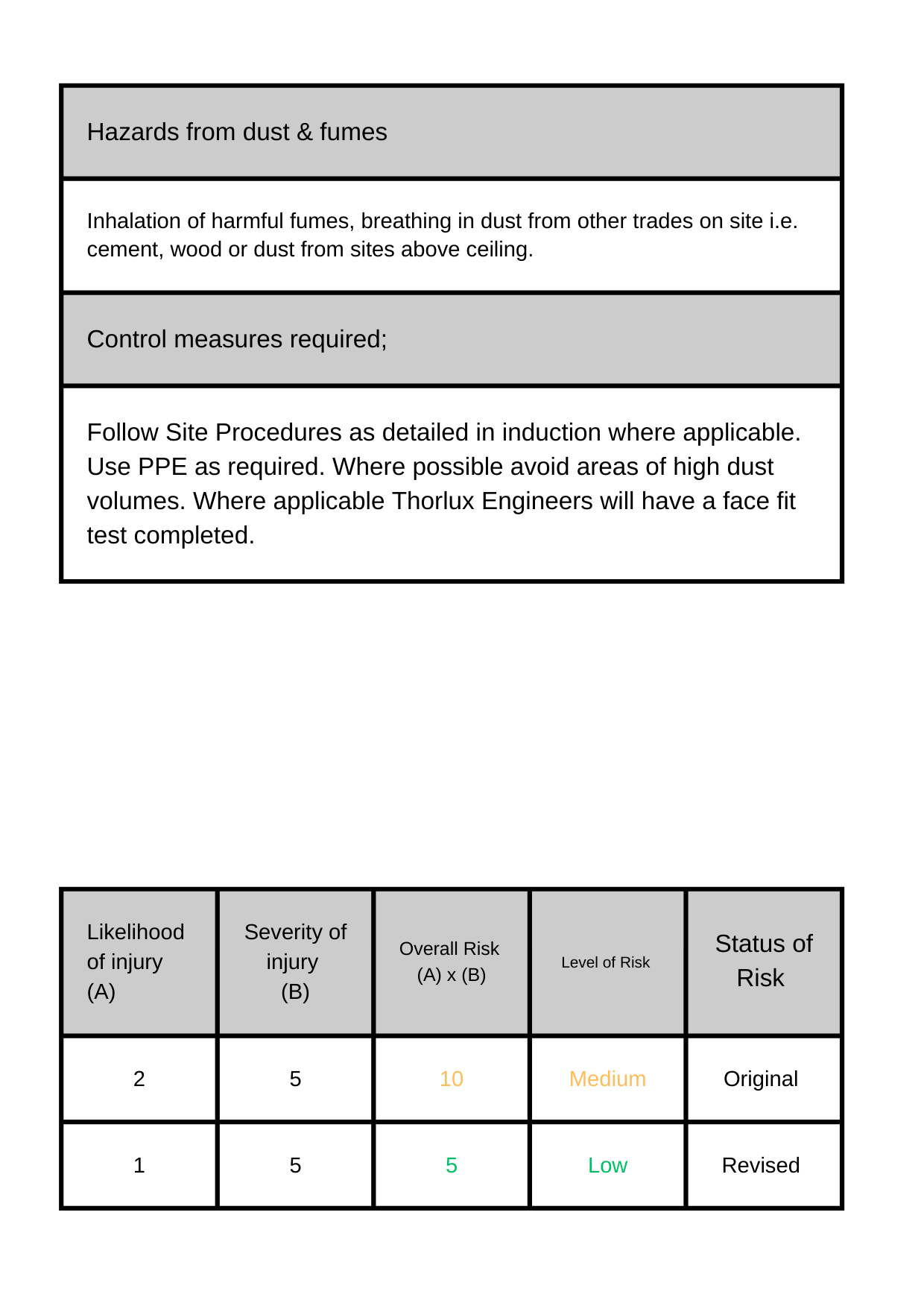

- Dust & Fumes

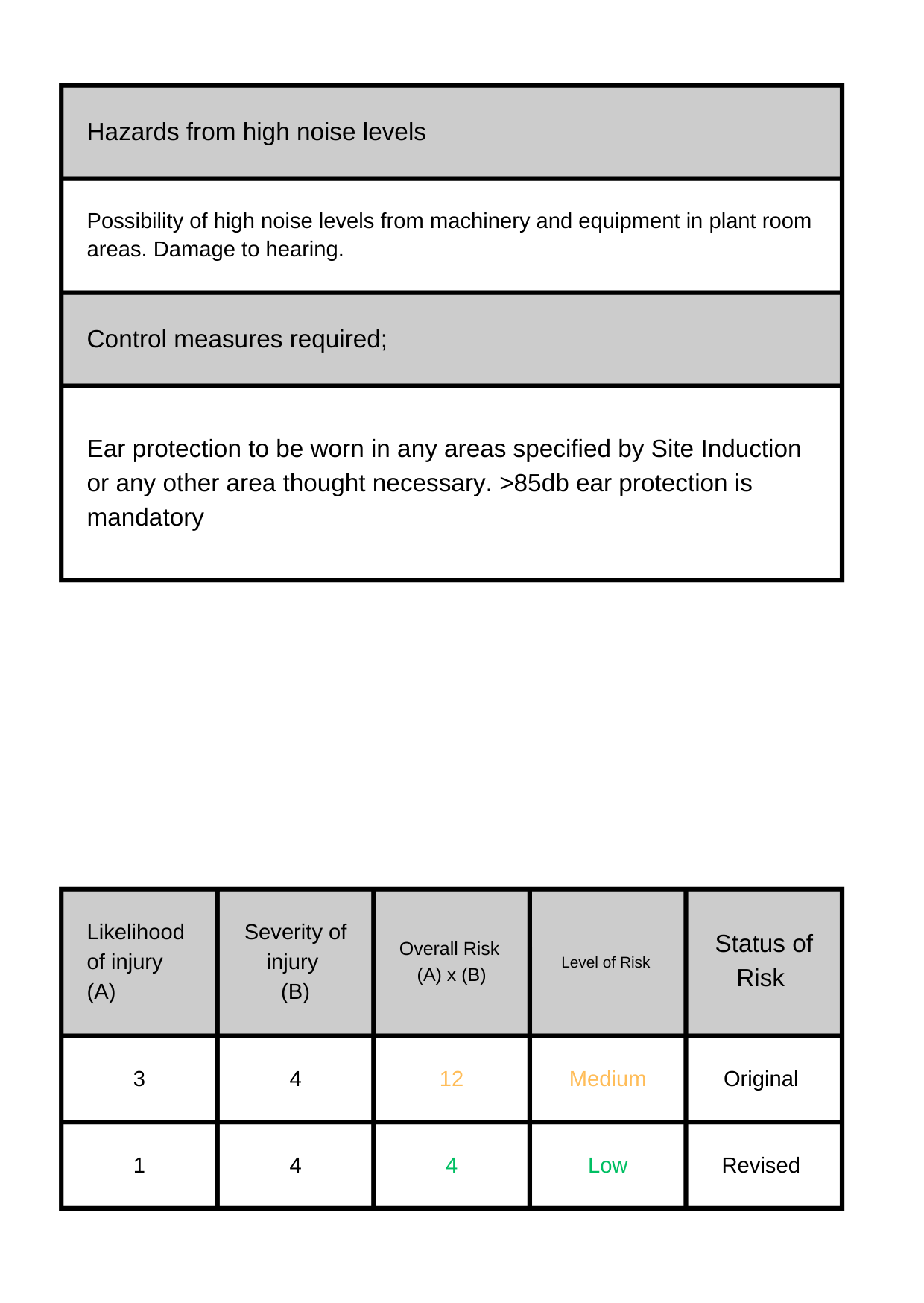

- High Noise Levels

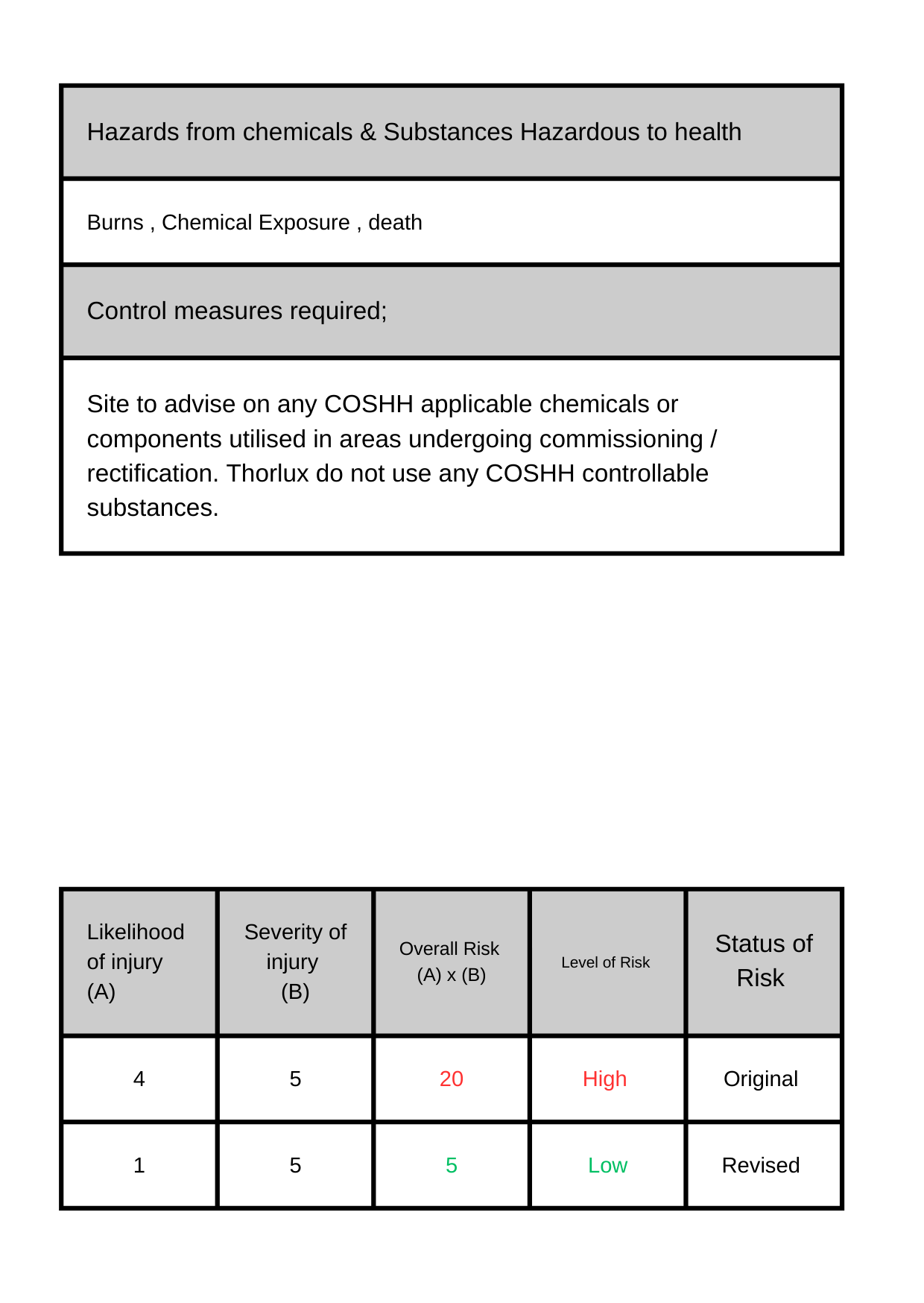

- COSH

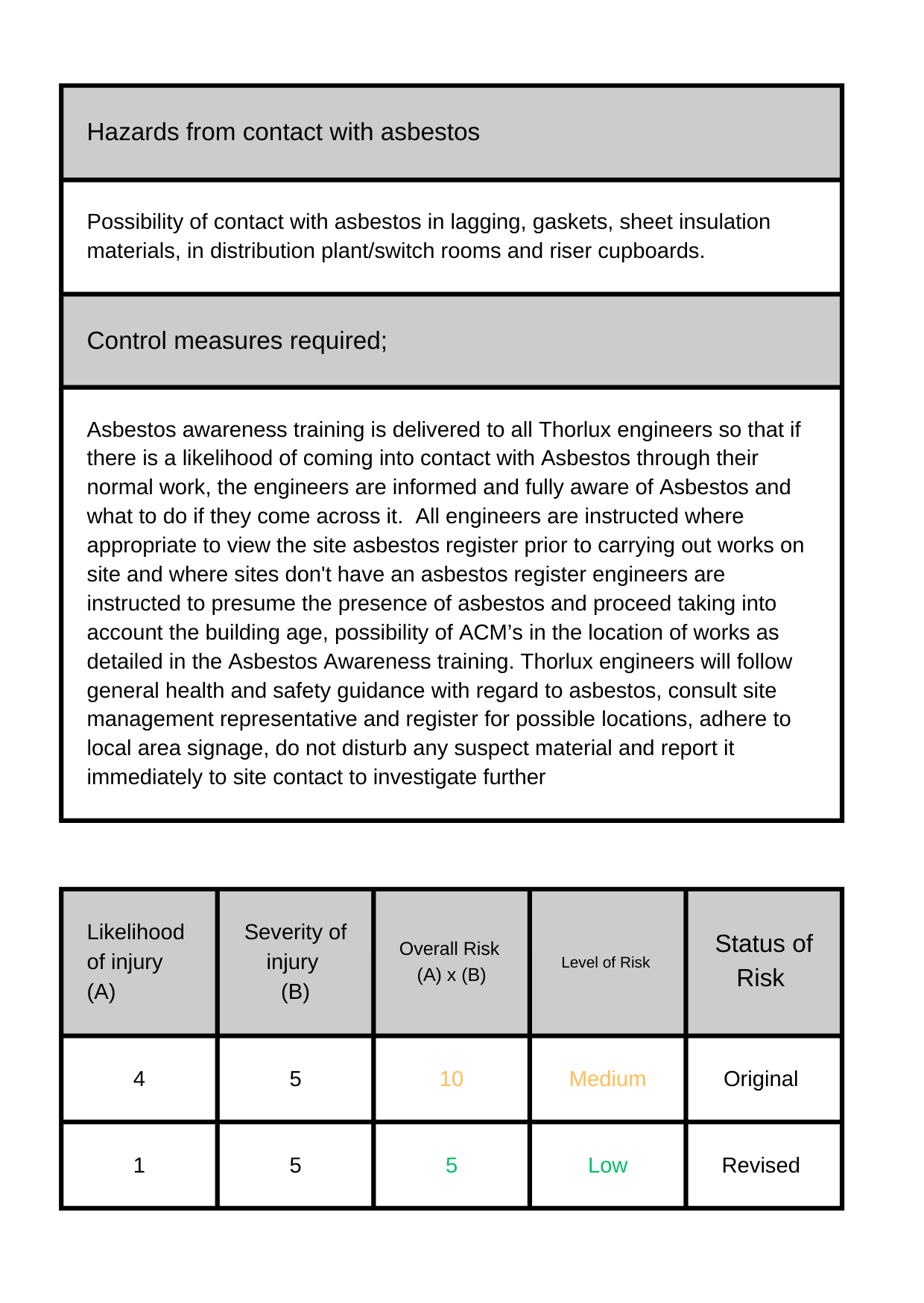

- Contact with Asbestos

- Petrol Station Forecourt

- Weil's Disease

- Working Near or Adjacent live services

- Stray Animals

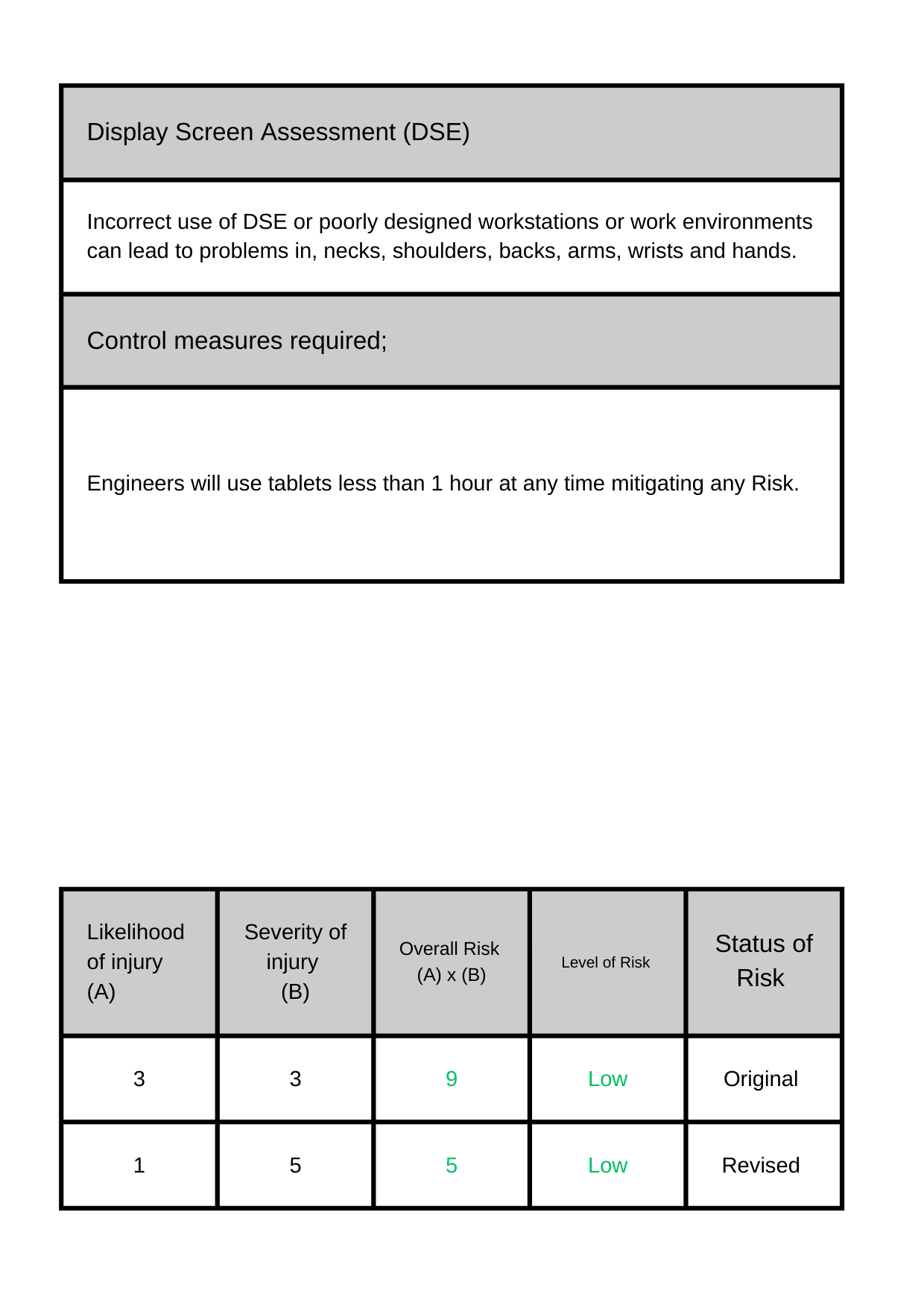

- DSE

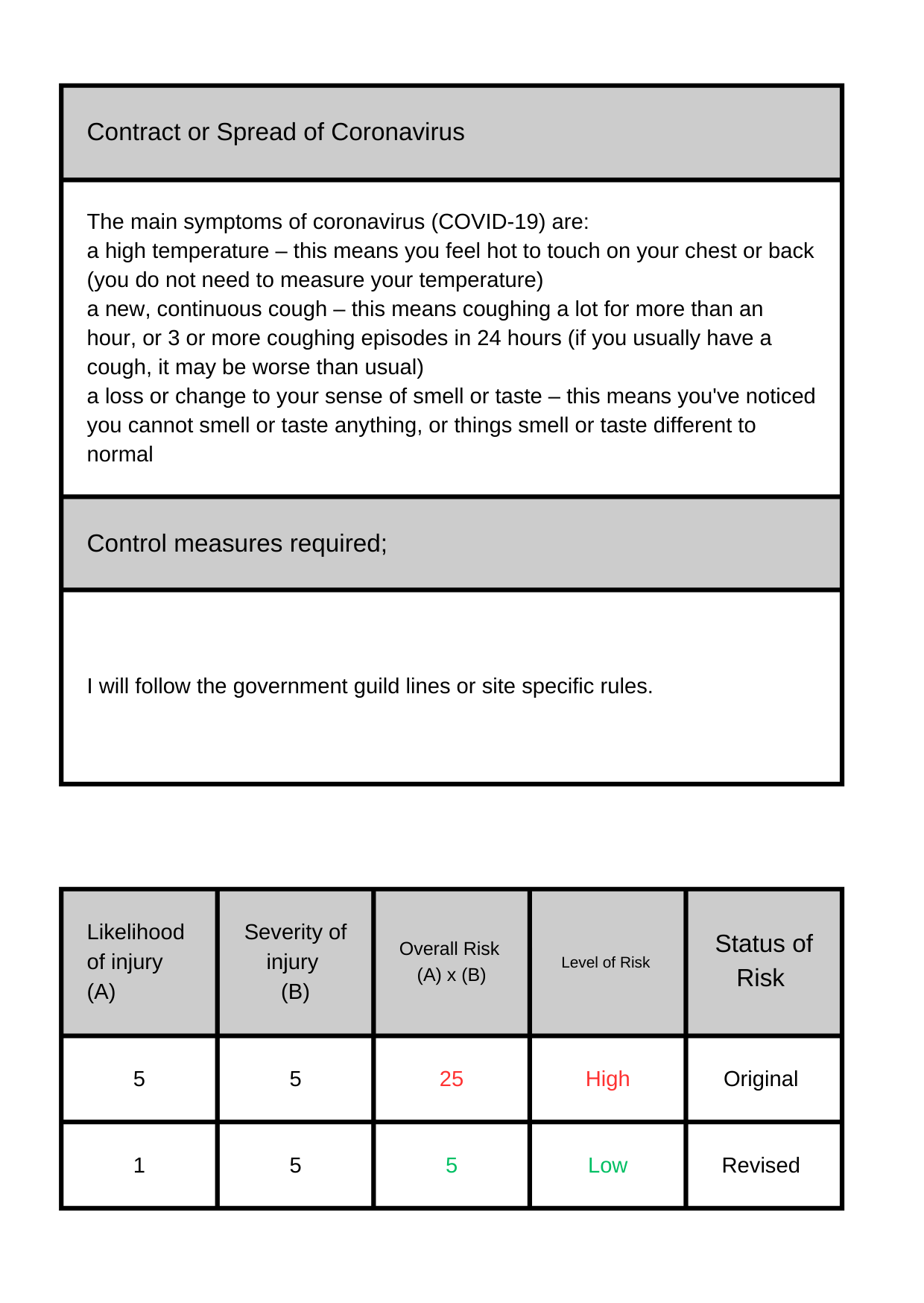

- Covid

-

Hazards from general site conditions

-

Hazards from vehicles

-

Hazards from operatives working at height

-

Hazards from other trades on site.

-

Hazards General Public and Staff Members

-

Lone Working

-

Risk of Electric Shock

-

Risk of Sharps

-

Hazards from use of Mobile Scaffold Towers

-

Hazards from using MEWPs

-

Hazards from using Steps & ladders

-

Hazards from the use of hand tools

-

Hazards from dust & fumes

-

Hazards from high noise levels

-

Hazards from chemicals & Substances Hazardous to health

-

Hazards from contact with asbestos

-

Hazard of Explosive areas: Petrol Station Forecourt

-

Hazards from Leptospirosis (weil's Disease)

-

Hazards to operatives working near or adjacent live services

-

Stray Animals and Live stock

-

Display Screen Assessment (DSE)

-

Hazards from materials stored on site

-

Contract or Spread of Coronavirus

Method Statement

-

Type of work being carried out.

-

Persons Affected by the Works

- Clients Staff

- Sub-Contractors

- Visitors

-

Proposed days of work

-

Number of Thorlux Employees who will be involved in the works

-

Lead Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Lead Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Lead Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Lead Engineer Name and Signature

-

Method Statement;

>Attend site and meet site contact, before commencing any work Thorlux Engineer will to report to client and inform them of area and nature of works to be carried out.

>Attend any site induction and sign into site. Obtain a permit to work if required, permit will require cancelling on completion of day or if Engineer leaves site, and sign out at site/Estates Office

>Area/location of works to be checked against issued Asbestos Register to identify areas where ACM's may be present, if ACM's are discovered or believed to present then all works are to stop

and engineer report to client contact.

>All work areas to be controlled access, to prevent the General public if appropriate.

>Selection of access equipment to be assessed as fit for purpose, appropriate for task, and duration.

>Before you start ensure that you are happy with the task that you are undertaking, IF IN DOUBT STOP AND SPEAK TO YOUR MANAGER.

Smartscan GEN 1 Commissioning:

>confirm any alterations to drawings / Smartscan groups and update drawing.

>Create Company and Site on website.

>Set up Smartscan Gateway.

>Programme each fitting with Building Address / Group Address / Device Address.

>Enable RF and Join Network.

>Update drawing of UDID.

>Back up and upload Gateway.

>Set Gateway Polling.

>Commission smart parameters.

>Confirm Motion line Group using Smart Remote or Scene Panel.

>Carry out systems test on fittings with in the motion line group.

>Confirm group times out and re-triggers as a group.

>Programme time sequences as per pre-commissioning form / instruction.

>Set light levels as per pre-commissioning form / instruction.

>Record light levels onto drawings.

>Set scene parameters as requested on pre-commissioning form or via onsite contact.

>Test to confirm correct operation once setting programmed.

>confirm additional light levels (Sec.)

>Record any access issues, height of fittings onto drawings.

>Detailed report of any issues found during commissioning, parts used, areas not commissioned and signature obtained.

>Make relevant people aware of any outstanding issues / re-visits required.

>Should anything change significantly, a dynamic risk assessment (attached to this RAMS Document) will be completed to further identify and mitigate any risk that may be present.

CONDUCT ON SITE:

>Engineer to follow all H&S, PPE requirements set out in the site induction.

>Work environment to be kept Clean and tidy, all hand tools to be stored securely in tool bag/box when not being used.

>Thorlux engineer to carry out a general clean of area if required on completion of rectification or commissioning works or at the end of his shift if multiple days in same area.

>If a Thorlux Engineer discovers Sharps or bodily fluids, they are to inform client or staff site contact and ensure area is made safe until sharps are safely removed and clean area. If Engineer

suffers puncture from Sharps, his priority into attend A&E for treatment prior to reporting incident. After treatment report to Thorlux Manager. Engineer MUST NOT touch or try to dispose

Sharps or clean any bodily fluids.

>Engineer to be aware of any area will be affected by external weather conditions such as Heatwaves or sudden downpours which may effect the areas normal ambient conditions.

>If Thorlux Engineer should be exposed to physical/verbal abuse, inappropriate comments or lewd behaviour they are to withdraw immediately in a calm controlled manner and report the

incident to site contact. -

Access Equipment (If needed)

-

WHERE LADDERS ARE USED:

>Select the Right Ladder

>Inspect the Ladder

>Check Weather Conditions

>Set Up on a Stable Surface

>Lock the Spreaders

>Position the Ladder Correctly

>Climb and Descend Carefully

>Do Not Overload

>Secure Tools and Equipment -

WHERE MOBILE TOWERS ARE USED:

>If a Podium Tower is selected then Engineer must hold PASMA licence.

>Ensure that the scaffold is dropped by the Hire company in a safe/suitable place agreed with site contact. This should be a place where it can be also stored for collection once works complete.

>Barrier off the work area to prevent access by others. -

WHERE MEWPS ARE USED:

If MEWPS to be used, Engineer must hold IPAF for appropriate equipment.

>Locate MEWPS, check documentation to confirm in date full inspection of the machine.

>Perform operational checks on machine to confirm all controls and equipment functioning.

>Locate work area and safely move the MEWPS to the work area with an operator wearing an inspected harness and clipped on fixed lanyard.

>Barrier off the work area to prevent access by others

>Inspect work area to ensure safe access and egress for mewps i.e.: no overhead power lines. Barrier off work area.

>Return the MEWP to the collection point once work on MEWPS is complete. -

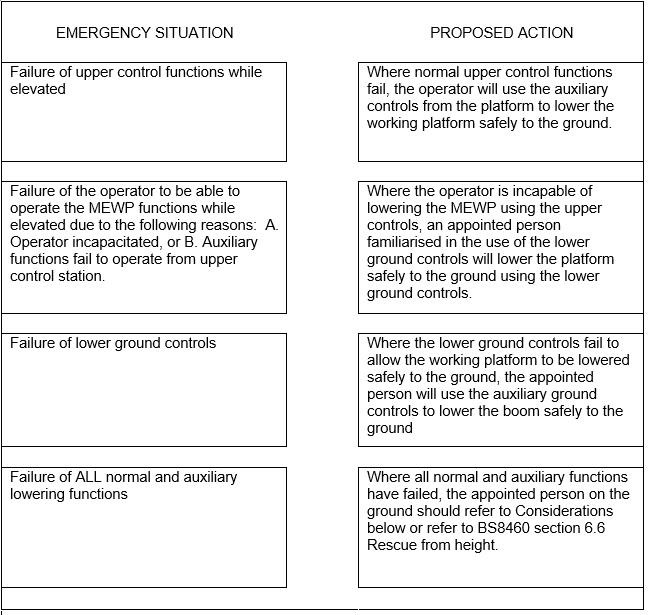

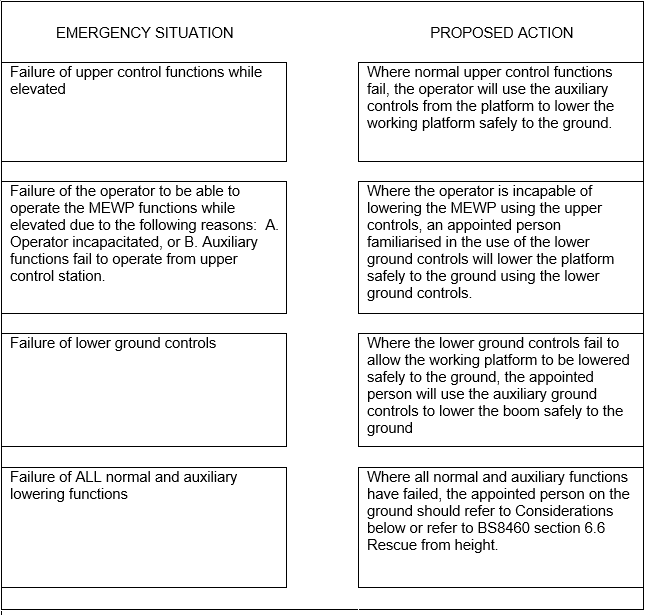

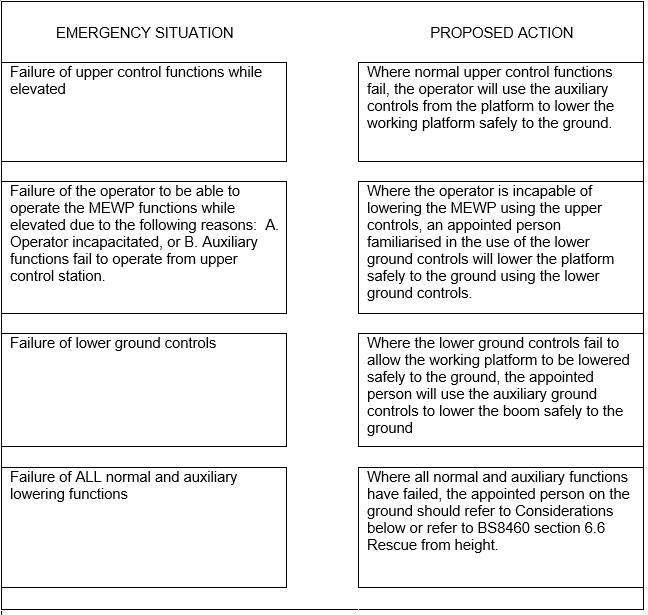

MEWP Rescue Plan;

Consideration for mid-air rescue;

A mid-air, platform to platform rescue should only be considered in exceptional

circumstances and only after:

• All normal and auxiliary lowering procedures have been attempted and these

are unable to lower the platform.

• Site management have contacted the competent and authorised service

engineer listed in the rescue plan, to report failure of normal and auxiliary

lowering systems and request engineering assistance.

If after inspection by the competent engineering assistance, it is not possible to affect

a timely repair to allow the machine to be brought to the ground safely, senior site

management should be contacted for permission to carry out mid-air rescue.

Or

Where the competent engineering assistance is not readily available and an

immediate risk exists to the health and safety of any of the occupants from remaining

in the elevated basket until an engineer can attend, then senior site management

should be contacted for permission to carry out mid-air rescue.

Code of practice for mid-air rescue;

A. Rescue using another MEWP should only be performed once a site-specific risk

assessment has been carried out and a specific plan has been documented and

approved by senior management.

B. The rescue machine must be positioned so as to enable the rescue procedure to

be carried out without compromising the safety of any personnel involved in the

rescue procedure.

C. The platforms of both machines must be adjacent to each other with a minimal

gap between them, unless exceptional circumstances mean this is not possible.

(Where this is not possible, the circumstances shall be recorded onto the risk

assessment form.)

D. Where reasonably practicable, precautions should be taken to prevent inadvertent

movement of both platforms during the transfer.

E. The person being rescued (transferred from basket to basket) should wear a full

body harness with an adjustable lanyard – the lanyard should be attached to the

anchor point on the rescue machine before transfer takes place.

F. Care must be taken not to overload the rescue machine during transfer. This may

mean making more than one journey to complete the rescue.

Further guidance on mid-air rescue can be found in ISO 18893:2014 - 6.1.2.8 -

Persons Affected by the Works

- Clients Staff

- Sub-Contractors

- Visitors

-

Proposed days work Work

-

Number of Thorlux Employees who will be involved in the works

-

Lead Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Lead Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Lead Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Lead Engineer Name and Signature

-

Method Statement;

>Attend site and meet site contact, before commencing any work Thorlux Engineer will to report to client and inform them of area and nature of works to be carried out.

>Attend any site induction and sign into site. Obtain a permit to work if required, permit will require cancelling on completion of day or if Engineer leaves site, and sign out at site/Estates Office

>Area/location of works to be checked against issued Asbestos Register to identify areas where ACM's may be present, if ACM's are discovered or believed to present then all works are to stop

and engineer report to client contact.

>All work areas to be controlled access, to prevent the General public if appropriate.

>Selection of access equipment to be assessed as fit for purpose, appropriate for task, and duration.

>Before you start ensure that you are happy with the task that you are undertaking, IF IN DOUBT STOP AND SPEAK TO YOUR MANAGER.

Smartscan GEN 2 Commissioning:

>confirm any alterations to drawings / Smartscan groups and update drawing.

>Create Company and Site on website.

>Set up Smartscan Gateway via Smartscan website.

> Rf enable and programme each fitting with with Pre authorised Building Channel number and UDID.

>Update drawing of UDID.

> Working from Smartscan website join all fittings and syncronize settings.

>Set all groups and basics parameters from Smartscan website.

>Confirm group times out and re-triggers as a group.

>Programme time sequences as per pre-commissioning form / instruction.

>Set light levels as per pre-commissioning form / instruction.

>Record light levels onto drawings.

>Set scene parameters as requested on pre-commissioning form or via onsite contact.

>Test to confirm correct operation once setting programmed.

>confirm additional light levels (Sec.)

>Record any access issues, height of fittings onto drawings.

>Detailed report of any issues found during commissioning, parts used, areas not commissioned and signature obtained.

>Make relevant people aware of any outstanding issues / re-visits required.

>Should anything change significantly, a dynamic risk assessment (attached to this RAMS Document) will be completed to further identify and mitigate any risk that may be present.

CONDUCT ON SITE:

>Engineer to follow all H&S, PPE requirements set out in the site induction.

>Work environment to be kept Clean and tidy, all hand tools to be stored securely in tool bag/box when not being used.

>Thorlux engineer to carry out a general clean of area if required on completion of rectification or commissioning works or at the end of his shift if multiple days in same area.

>If a Thorlux Engineer discovers Sharps or bodily fluids, they are to inform client or staff site contact and ensure area is made safe until sharps are safely removed and clean area. If Engineer

suffers puncture from Sharps, his priority into attend A&E for treatment prior to reporting incident. After treatment report to Thorlux Manager. Engineer MUST NOT touch or try to dispose

Sharps or clean any bodily fluids.

>Engineer to be aware of any area will be affected by external weather conditions such as Heatwaves or sudden downpours which may effect the areas normal ambient conditions.

>If Thorlux Engineer should be exposed to physical/verbal abuse, inappropriate comments or lewd behaviour they are to withdraw immediately in a calm controlled manner and report the

incident to site contact. -

Access Equipment (If needed)

- Swing Back Ladder

- Mobile Scaffold

- MEWP

-

WHERE LADDERS ARE USED:

>Select the Right Ladder

>Inspect the Ladder

>Check Weather Conditions

>Set Up on a Stable Surface

>Lock the Spreaders

>Position the Ladder Correctly

>Climb and Descend Carefully

>Do Not Overload

>Secure Tools and Equipment -

WHERE MOBILE TOWERS ARE USED:

>If a Podium Tower is selected then Engineer must hold PASMA licence.

>Ensure that the scaffold is dropped by the Hire company in a safe/suitable place agreed with site contact. This should be a place where it can be also stored for collection once works complete.

>Barrier off the work area to prevent access by others. -

WHERE MEWPS ARE USED:

If MEWPS to be used, Engineer must hold IPAF for appropriate equipment.

>Locate MEWPS, check documentation to confirm in date full inspection of the machine.

>Perform operational checks on machine to confirm all controls and equipment functioning.

>Locate work area and safely move the MEWPS to the work area with an operator wearing an inspected harness and clipped on fixed lanyard.

>Barrier off the work area to prevent access by others

>Inspect work area to ensure safe access and egress for mewps i.e.: no overhead power lines. Barrier off work area.

>Return the MEWP to the collection point once work on MEWPS is complete. -

MEWP Rescue Plan;

Consideration for mid-air rescue;

A mid-air, platform to platform rescue should only be considered in exceptional

circumstances and only after:

• All normal and auxiliary lowering procedures have been attempted and these

are unable to lower the platform.

• Site management have contacted the competent and authorised service

engineer listed in the rescue plan, to report failure of normal and auxiliary

lowering systems and request engineering assistance.

If after inspection by the competent engineering assistance, it is not possible to affect

a timely repair to allow the machine to be brought to the ground safely, senior site

management should be contacted for permission to carry out mid-air rescue.

Or

Where the competent engineering assistance is not readily available and an

immediate risk exists to the health and safety of any of the occupants from remaining

in the elevated basket until an engineer can attend, then senior site management

should be contacted for permission to carry out mid-air rescue.

Code of practice for mid-air rescue;

A. Rescue using another MEWP should only be performed once a site-specific risk

assessment has been carried out and a specific plan has been documented and

approved by senior management.

B. The rescue machine must be positioned so as to enable the rescue procedure to

be carried out without compromising the safety of any personnel involved in the

rescue procedure.

C. The platforms of both machines must be adjacent to each other with a minimal

gap between them, unless exceptional circumstances mean this is not possible.

(Where this is not possible, the circumstances shall be recorded onto the risk

assessment form.)

D. Where reasonably practicable, precautions should be taken to prevent inadvertent

movement of both platforms during the transfer.

E. The person being rescued (transferred from basket to basket) should wear a full

body harness with an adjustable lanyard – the lanyard should be attached to the

anchor point on the rescue machine before transfer takes place.

F. Care must be taken not to overload the rescue machine during transfer. This may

mean making more than one journey to complete the rescue.

Further guidance on mid-air rescue can be found in ISO 18893:2014 - 6.1.2.8 -

Persons Affected by the Works

- Clients Staff

- Sub-Contractors

- Visitors

-

Proposed days work Work

-

Number of Thorlux Employees who will be involved in the works

-

Lead Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Lead Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Lead Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Additional Engineer Name and Signature

-

Lead Engineer Name and Signature

-

Method Statement;

>Attend site and meet site contact, before commencing any work Thorlux Engineer will to report to client and inform them of area and nature of works to be carried out.

>Attend any site induction and sign into site. Obtain a permit to work if required, permit will require cancelling on completion of day or if Engineer leaves site, and sign out at site/Estates Office

>Area/location of works to be checked against issued Asbestos Register to identify areas where ACM's may be present, if ACM's are discovered or believed to present then all works are to stop

and engineer report to client contact.

>All work areas to be controlled access, to prevent the General public if appropriate.

>Selection of access equipment to be assessed as fit for purpose, appropriate for task, and duration.

>Before you start ensure that you are happy with the task that you are undertaking, IF IN DOUBT STOP AND SPEAK TO YOUR MANAGER.

RECTIFICATION:

>Locate faulty luminaires/Thorlux Product

>Engineer to check above ceiling grid for excessive dust or waste materials prior to commencing works.

>Safely access luminaires within barriered off area.

>Isolate the fittings by local isolation or if required, have entire circuit isolated and locked off, signage to be displayed with engineers contact details.

(Isolation of Lighting circuits to be carried out by client or customer if appropriate, and permit to be issued to Thorlux Engineer.)

>If local point of Isolation is available such klik rose, this can be used as form of safe Isolation, however, this can only be used if Thorlux Engineer can maintain sole control of point.

All extraneous metalwork and containment to be wanded using Voltage Indication stick, however all circuits are to be tested dead with Voltage testers and Proving Units prior to commencing

works on luminaires on that circuit.

>Repair fittings as required

>record Parts used.

>Power up fittings and check for correct operation. Reprogram if necessary.

>Remove barriers from work area

>Should anything change significantly, a dynamic risk assessment (attached to this RAMS Document) will be completed to further identify and mitigate any risk that may be present.

CONDUCT ON SITE:

>Engineer to follow all H&S, PPE requirements set out in the site induction

>Work environment to be kept Clean and tidy, all hand tools to be stored securely in tool bag/box when not being used.

>Replacement parts i.e. batteries, to be stored in a suitable area, old batteries to be taped up before being boxed up.

>Thorlux engineer to carry out a general clean of area if required on completion of rectification or commissioning works or at the end of his shift if multiple days in same area.

>If a Thorlux Engineer discovers Sharps or bodily fluids, they are to inform client or staff site contact and ensure area is made safe until sharps are safely removed and clean area. If Engineer

suffers puncture from Sharps, his priority into attend A&E for treatment prior to reporting incident. After treatment report to Thorlux Manager. Engineer MUST NOT touch or try to dispose

Sharps or clean any bodily fluids.

>Engineer to be aware of any area will be affected by external weather conditions such as Heatwaves or sudden downpours which may effect the areas normal ambient conditions.

>If Thorlux Engineer should be exposed to physical/verbal abuse, inappropriate comments or lewd behaviour they are to withdraw immediately in a calm controlled manner and report the

incident to site contact. -

Access Equipment (If needed)

- Swing Back Ladder

- Mobile Scaffold

- MEWP

-

WHERE LADDERS ARE USED:

>Select the Right Ladder

>Inspect the Ladder

>Check Weather Conditions

>Set Up on a Stable Surface

>Lock the Spreaders

>Position the Ladder Correctly

>Climb and Descend Carefully

>Do Not Overload

>Secure Tools and Equipment -

WHERE MOBILE TOWERS ARE USED:

>If a Podium Tower is selected then Engineer must hold PASMA licence.

>Ensure that the scaffold is dropped by the Hire company in a safe/suitable place agreed with site contact. This should be a place where it can be also stored for collection once works complete.

>Barrier off the work area to prevent access by others. -

WHERE MEWPS ARE USED:

If MEWPS to be used, Engineer must hold IPAF for appropriate equipment.

>Locate MEWPS, check documentation to confirm in date full inspection of the machine.

>Perform operational checks on machine to confirm all controls and equipment functioning.

>Locate work area and safely move the MEWPS to the work area with an operator wearing an inspected harness and clipped on fixed lanyard.

>Barrier off the work area to prevent access by others

>Inspect work area to ensure safe access and egress for mewps i.e.: no overhead power lines. Barrier off work area.

>Return the MEWP to the collection point once work on MEWPS is complete. -

MEWP Rescue Plan;

Consideration for mid-air rescue;

A mid-air, platform to platform rescue should only be considered in exceptional

circumstances and only after:

• All normal and auxiliary lowering procedures have been attempted and these

are unable to lower the platform.

• Site management have contacted the competent and authorised service

engineer listed in the rescue plan, to report failure of normal and auxiliary

lowering systems and request engineering assistance.

If after inspection by the competent engineering assistance, it is not possible to affect

a timely repair to allow the machine to be brought to the ground safely, senior site

management should be contacted for permission to carry out mid-air rescue.

Or

Where the competent engineering assistance is not readily available and an

immediate risk exists to the health and safety of any of the occupants from remaining

in the elevated basket until an engineer can attend, then senior site management

should be contacted for permission to carry out mid-air rescue.

Code of practice for mid-air rescue;

A. Rescue using another MEWP should only be performed once a site-specific risk

assessment has been carried out and a specific plan has been documented and

approved by senior management.

B. The rescue machine must be positioned so as to enable the rescue procedure to

be carried out without compromising the safety of any personnel involved in the

rescue procedure.

C. The platforms of both machines must be adjacent to each other with a minimal

gap between them, unless exceptional circumstances mean this is not possible.

(Where this is not possible, the circumstances shall be recorded onto the risk

assessment form.)

D. Where reasonably practicable, precautions should be taken to prevent inadvertent

movement of both platforms during the transfer.

E. The person being rescued (transferred from basket to basket) should wear a full

body harness with an adjustable lanyard – the lanyard should be attached to the

anchor point on the rescue machine before transfer takes place.

F. Care must be taken not to overload the rescue machine during transfer. This may

mean making more than one journey to complete the rescue.

Further guidance on mid-air rescue can be found in ISO 18893:2014 - 6.1.2.8