Title Page

-

Site conducted

-

Each time you enter an area make sure that the operator present is told that you are here conducting a safety audit and who is with you.

-

Conducted on

-

Audit Team is?

-

Crew

Reception

-

Please ask these questions to the operator responsible for that area during the audit. Remember that each time you talk to an operator let them know "you are auditing Andola's Safety policy's and any answer they give is correct and they can not be penalized for any answer"

-

No operator in this area

-

Who is answering questions today? (first name & last initial)

-

is the operator wearing/have available all appropriate PPE

-

What do you do if you encounter a problem or a procedure you are not familiar with?

-

Do you know where to meet for a fire evacuation

-

Do you know where the Emergency Evacuation Alarm button is?

-

Does operator know where SDS sheets are kept

-

Does operator know what "Operator Right to refuse" means?

-

What does SOP stand for and where is it

-

Do workers know the symptoms of heat cramps/heatstroke, or frost bite/hypothermia?

-

Does operator know how to get first aid assistance when needed? ( where office is and who is certified first aid)

-

What does operator do if he finds equipment/tools that are unsafe (A: report immediately )

-

Are there any safety problems you would like to point out

-

Please have operator sign ( type first name last initial)

-

Are SDS sheet binder present?

-

Are the SOP's binder present?

Lab (Operator)

-

Please ask these questions to the operator responsible for that area during the audit. Remember that each time you talk to an operator let them know "you are auditing Andola's Safety policy's and any answer they give is correct and they can not be penalized for any answer"

-

No operator in this area

-

Who is answering questions today? (first name & last initial)

-

Any lose clothing or jewelry

-

is the operator wearing/have available all appropriate PPE

-

What do you do if you encounter a problem or a procedure you are not familiar with?

-

Do you know where to meet for a fire evacuation

-

Do you know where the Emergency Evacuation Alarm button is?

-

Does operator know where SDS sheets are kept

-

Does operator know what "Operator Right to refuse" means?

-

What does SOP stand for and where is it

-

Do workers know the symptoms of heat cramps/heatstroke, or frost bite/hypothermia?

-

Does operator know how to get first aid assistance when needed? ( where office is and who is certified first aid)

-

What does operator do if he finds equipment/tools that are unsafe (A: report immediately )

-

Are any items in the area that shouldn’t be

-

Are there any safety problems you would like to point out

-

please describe and take picture if possible

-

Please have operator sign ( type first name last initial)

Lab Arrival / Equipment

-

Currently not operating

First Aid Station/ Harness

-

Is the First Aid inspection box tag filled out? are supplies needed?

-

Are all the First Aid/CPR certificates valid? (flag if within 3 months of expire)

-

Are all the Working at heights certificates valid? (good for 3 years) (flag if within 3 months of expire)

-

Are all the Articulating Boom certificates valid? (good for 3 years) (flag if within 3 months of expire)

-

Is the defibrillator charged and operational? (through the clear window there should be a green flashing light)

-

Are all harnesses stored properly?

-

Safety poster present

Facilities

-

This includes : Lunchroom, outdoor Area(smoking), lockers, Women's washroom, Men's washroom

-

Is housekeeping needed

-

Outdoor Area

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

Lunchroom tables

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

Locker Area

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

Washrooms

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

Front Entrance

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

Are any items in the area that are unsafe?

-

Is the SDS binder present

-

Check that all items needed on board are present.

-

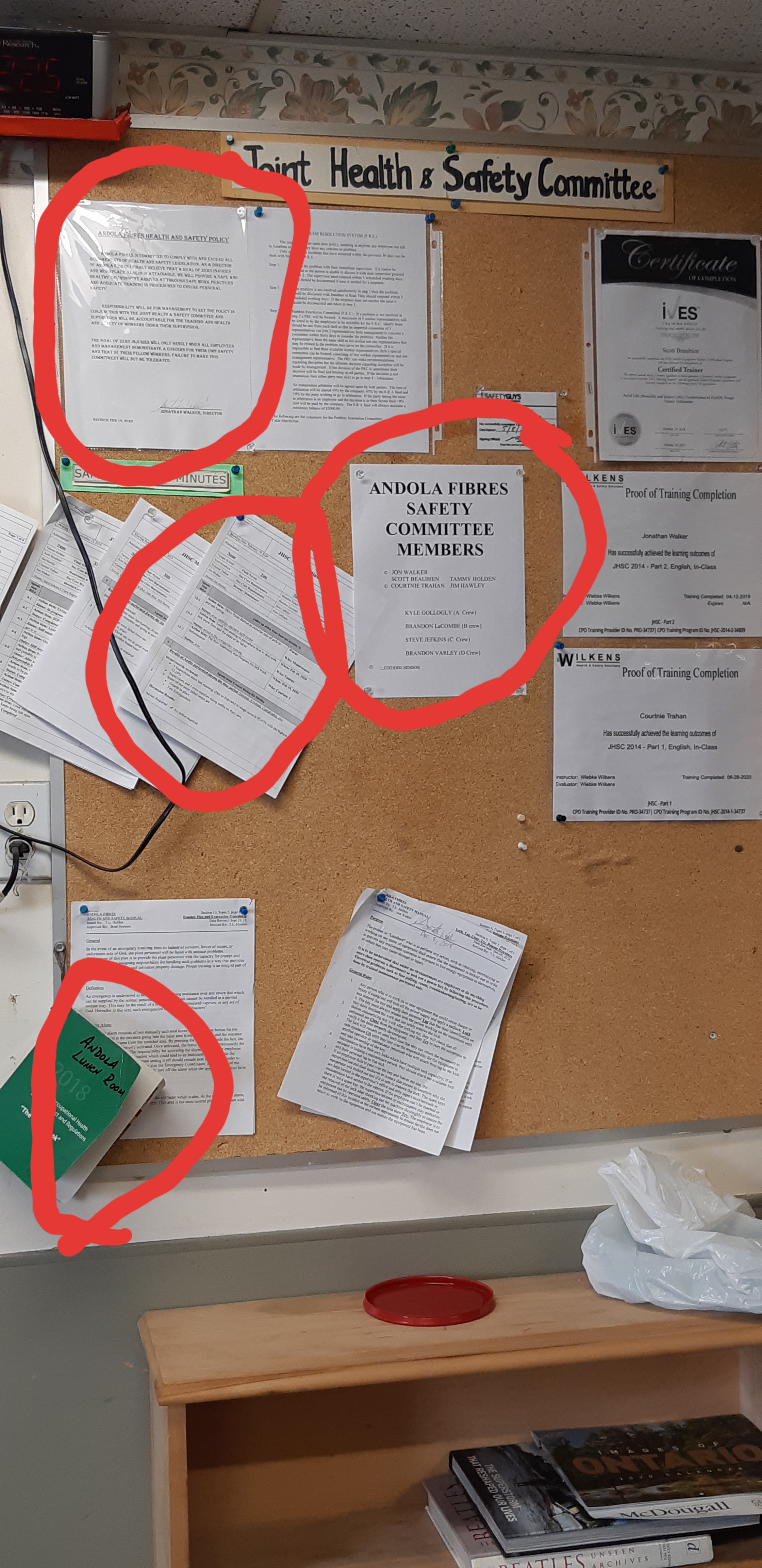

The Health and Safety Policy

-

The Last meeting minutes

-

The list of committee members

-

The green book pocket version

-

The Harassment Policy (on coke fridge)

-

ONLY women should enter the women's washroom, if NO ONE IS AVAILABLE please check this box

-

ONLY Men should enter the men's washroom, if NO ONE IS AVAILABLE please check this box

-

is absorbal readily available?

-

Emergency Exit Location: in the locker area above the main entrance door (blue door). TO TEST: Switch the black switch on the left side of the Exit sign to ensure both lights work. Open door to make sure there is nothing blocking the exit (this includes ice)

-

Emergency exit not blocked

-

Is emergency lighting adequate and tested

Line 1 Operator

-

Please ask these questions to the operator responsible for that area during the audit. Remember that each time you talk to an operator let them know "you are auditing Andola's Safety policy's and any answer they give is correct and they will not be penalized for any answer"

-

No operator in this area

-

Who is answering questions today? (first name & last initial)

-

Any lose clothing or jewelry

-

is the operator wearing/have available all appropriate PPE

-

What do you do if you encounter a problem or a procedure you are not familiar with?

-

Do you know where to meet for a fire evacuation

-

Do you know where the Emergency Evacuation Alarm button is?

-

Do you know where the panic button is located?

-

Does operator know where SDS sheets are kept

-

Does operator know "Operator Right to refuse" mean?

-

What does SOP stand for and where is it

-

Do workers know the symptoms of heat cramps/heatstroke, or frost bite/hypothermia?

-

Does operator know how to get first aid assistance when needed? ( where office is and who is certified first aid)

-

What does operator do if he finds equipment/tools that are unsafe (A: report immediately )

-

Are any items in the area that shouldn’t be

-

Are there any safety problems you would like to point out

-

please describe and take picture if possible

-

Please have operator sign ( type first name last initial)

-

Are all safety boxes checked off and good on operator sheet (fire extinguisher, oil bin, guards and locks)

-

please take picture

Line 1 Arrival

-

In every Area if there is a fork truck please complete this inspection

Truck Audit

-

Which Truck is being Audited

- Truck 1

- Truck 2

- Truck 3

- Truck 4

- Truck 5

- Truck 6

- Truck 7

- Truck 8

- Truck 9

-

The pad is signed off

-

fire extinguisher present and inspections up to date

-

Is the operator using the equipment properly and safely during the audit?

-

You should be able to stand in the area of the operator desk to answer these. If not please attach a note.

-

Is housekeeping needed

-

What type of housekeeping is needed

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

air hose has correct end and no holes.

-

face shield for vent is there.

-

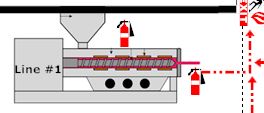

Is there a clear fire response plan posted for each work area?

-

Slip tape on stairs/ladders

-

All handling units stored properly? Boxes, Bales, Bins, Barrels, Containers

-

-

fire extinguishers (2) present and inspections up to date

-

Are extinguisher locations conspicuously marked?

-

Are extinguishers easily accessible?

-

Is the Eye Wash bottle present and easily accessible?

-

Are tools kept in their proper place?

-

Oil bucket being emptied

-

Ladders in good condition and stored properly

Line 1 Equipment

-

Please have a quick look over of equipment and answer the following questions.

-

Line is not running

Feed System

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

-

Emergency Exit Location: is on the wall by the feed system. TO TEST: Flip black switch on left side of exit sign and ensure both lights work. open door and check for obstructions.

-

Emergency exit not blocked

-

Is emergency lighting adequate and tested

Hopper and Fans

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Extruder

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Water Bath

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Pelletizer

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Shaker Tray

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Line 3 Operator

-

Please ask these questions to the operator responsible for that area during the audit. Remember that each time you talk to an operator let them know "you are auditing Andola's Safety policy's and any answer they give is correct and they will not be penalized for any answer"

-

No operator in this area

-

Who is answering questions today? (first name & last initial)

-

Any lose clothing or jewelry

-

is the operator wearing/have available all appropriate PPE

-

What do you do if you encounter a problem or a procedure you are not familiar with?

-

Do you know where to meet for a fire evacuation

-

Do you know where the Emergency Evacuation Alarm button is?

-

Do you know where the panic button is located?

-

Does operator know where SDS sheets are kept

-

Does operator know "Operator Right to refuse" mean?

-

What does SOP stand for and where is it

-

Do workers know the symptoms of heat cramps/heatstroke, or frost bite/hypothermia?

-

Does operator know how to get first aid assistance when needed? ( where office is and who is certified first aid)

-

What does operator do if he finds equipment/tools that are unsafe (A: report immediately )

-

Are any items in the area that shouldn’t be

-

Are there any safety problems you would like to point out

-

please describe and take picture if possible

-

Please have operator sign ( type first name last initial)

-

Are all safety boxes checked off and good on operator sheet (fire extinguisher, oil bin, guards and locks)

-

please take picture

Line 3 Arrival

-

In every Area if there is a fork truck please complete this inspection

Truck Audit

-

Which Truck is being Audited

- Truck 1

- Truck 2

- Truck 3

- Truck 4

- Truck 5

- Truck 6

- Truck 7

- Truck 8

- Truck 9

-

The pad is signed off

-

fire extinguisher present and inspections up to date

-

Is the operator using the equipment properly and safely during the audit?

-

You should be able to stand in the area of the operator desk to answer these. If not please attach a note.

-

Any and all signage in place (elevator)

-

Is housekeeping needed

-

What type of housekeeping is needed

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

air hose has correct end and no holes.

-

face shield for vent is there.

-

Is there a clear fire response plan posted for each work area?

-

Slip tape on stairs/ladders

-

All handling units stored properly? Boxes, Bales, Bins, Barrels, Containers

-

-

fire extinguishers (2) present and inspections up to date

-

Are extinguisher locations conspicuously marked?

-

Are extinguishers easily accessible?

-

Is the Eye Wash bottle present and easily accessible?

-

Are tools kept in their proper place?

-

Oil bucket being emptied

-

Ladders in good condition and stored properly

Line 3/ Blender Room Equipment

-

Line is not running

Feed System

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Hopper and Fans

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

-

Emergency Exit Location: is on the back wall by the blender room. TO TEST: Flip black switch on left side of exit sign and ensure both lights work. open door and check for obstructions.

-

Emergency exit not blocked

-

Is emergency lighting adequate and tested

Blender Room #3

-

All guards in place and secured

-

Blender Pit covered?

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

Blender Pit cleaned out (looking if its over half or full)?

-

All tools stored properly

Extruder

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Water Bath

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Pelletizer

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Shaker Tray

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Tube Stripper Operator

-

Please ask these questions to the operator responsible for that area during the audit. Remember that each time you talk to an operator let them know "you are auditing Andola's Safety policy's and any answer they give is correct and they will not be penalized for any answer"

-

No operator in this area

-

Who is answering questions today? (first name & last initial)

-

Any lose clothing or jewelry

-

is the operator wearing/have available all appropriate PPE

-

What do you do if you encounter a problem or a procedure you are not familiar with?

-

Do you know where to meet for a fire evacuation

-

Do you know where the Emergency Evacuation Alarm button is?

-

Does operator know where SDS sheets are kept

-

Does operator know "Operator Right to refuse" mean?

-

What does SOP stand for and where is it

-

Do workers know the symptoms of heat cramps/heatstroke, or frost bite/hypothermia?

-

Does operator know how to get first aid assistance when needed? ( where office is and who is certified first aid)

-

What does operator do if he finds equipment/tools that are unsafe (A: report immediately )

-

Are any items in the area that shouldn’t be

-

Are there any safety problems you would like to point out

-

please describe and take picture if possible

-

Please have operator sign ( type first name last initial)

-

Are all safety boxes checked off and good on operator sheet (fire extinguisher, oil bin, guards and locks)

-

Please take photo

Tube Stripper Arrival/ Equipment

-

In every Area if there is a fork truck please complete this inspection

Truck Audit

-

Which Truck is being Audited

- Truck 1

- Truck 2

- Truck 3

- Truck 4

- Truck 5

- Truck 6

- Truck 7

- Truck 8

- Truck 9

-

The pad is signed off

-

fire extinguisher present and inspections up to date

-

Is the operator using the equipment properly and safely during the audit?

-

Equipment is not running

-

Is housekeeping needed

-

What type of housekeeping is needed

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

Is there a clear fire response plan posted for each work area?

-

All handling units stored properly? Boxes, Bales, Bins, Barrels, Containers

-

fire extinguisher present and inspections up to date

-

Are extinguisher locations conspicuously marked?

-

Are extinguishers easily accessible?

-

Are tools kept in their proper place?

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

Blender Station Operator

-

Please ask these questions to the operator responsible for that area during the audit. Remember that each time you talk to an operator let them know "you are auditing Andola's Safety policy's and any answer they give is correct and they will not be penalized for any answer"

-

No operator in this area

-

Who is answering questions today? (first name & last initial)

-

Any lose clothing or jewelry

-

is the operator wearing/have available all appropriate PPE

-

What do you do if you encounter a problem or a procedure you are not familiar with?

-

Do you know where to meet for a fire evacuation

-

Do you know where the Emergency Evacuation Alarm button is?

-

Do you know where the panic button is located?

-

Does operator know where SDS sheets are kept

-

Does operator know "Operator Right to refuse" mean?

-

What does SOP stand for and where is it

-

Do workers know the symptoms of heat cramps/heatstroke, or frost bite/hypothermia?

-

Does operator know how to get first aid assistance when needed? ( where office is and who is certified first aid)

-

What does operator do if he finds equipment/tools that are unsafe (A: report immediately )

-

Are any items in the area that shouldn’t be

-

Are there any safety problems you would like to point out

-

please describe and take picture if possible

-

Please have operator sign ( type first name last initial)

Blender Station Arrival

-

In every Area if there is a fork truck please complete this inspection

Truck Audit

-

Which Truck is being Audited

- Truck 1

- Truck 2

- Truck 3

- Truck 4

- Truck 5

- Truck 6

- Truck 7

- Truck 8

- Truck 9

-

The pad is signed off

-

fire extinguisher present and inspections up to date

-

Is the operator using the equipment properly and safely during the audit?

Blender Room #2

-

All guards in place and secured

-

Blender Pit covered?

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

Blender Pit cleaned out (looking if its over half or full)?

Blender Station Area

-

Is housekeeping needed

-

What type of housekeeping is needed

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

All handling units stored properly? Boxes, Bales, Bins, Barrels, Containers

-

Are tools kept in their proper place?

Blender Room #1

-

All guards in place and secured

-

Blender Pit covered?

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

Blender Pit cleaned out (looking if its over half or full)?

Loading Dock 1-4

-

In every Area if there is a fork truck please complete this inspection

Truck Audit

-

Which Truck is being Audited

- Truck 1

- Truck 2

- Truck 3

- Truck 4

- Truck 5

- Truck 6

- Truck 7

- Truck 8

- Truck 9

-

The pad is signed off

-

fire extinguisher present and inspections up to date

-

Is the operator using the equipment properly and safely during the audit?

-

Emergency Exit Location: between the old warehouse and loading doors 1-4. TO TEST Black button on the bottom of exit sign ensure both lights work. Open door and check for obstructions and stairs are clear (ice and snow in winter)

-

Emergency exit/stairs not blocked

-

Is emergency lighting adequate and tested

-

-

fire extinguisher present and inspections up to date

-

Are extinguisher locations conspicuously marked?

-

Are extinguishers easily accessible?

-

The glad hand locks are in place when truck is being loaded

-

The wheel chocks are in place when truck is being loaded

-

all door lights are operational (test each one black switch on back)

-

check pins, tracks and track guards for each door.

Baler Operator

-

Please ask these questions to the operator responsible for that area during the audit. Remember that each time you talk to an operator let them know "you are auditing Andola's Safety policy's and any answer they give is correct and they will not be penalized for any answer"

-

No operator in this area

-

Who is answering questions today? (first name & last initial)

-

Any lose clothing or jewelry

-

is the operator wearing/have available all appropriate PPE

-

What do you do if you encounter a problem or a procedure you are not familiar with?

-

Do you know where to meet for a fire evacuation

-

Do you know where the Emergency Evacuation Alarm button is?

-

Do you know where the panic button is located?

-

Does operator know where SDS sheets are kept

-

Does operator know "Operator Right to refuse" mean?

-

What does SOP stand for and where is it

-

Do workers know the symptoms of heat cramps/heatstroke, or frost bite/hypothermia?

-

Does operator know how to get first aid assistance when needed? ( where office is and who is certified first aid)

-

What does operator do if he finds equipment/tools that are unsafe (A: report immediately )

-

Are any items in the area that shouldn’t be

-

Are there any safety problems you would like to point out

-

please describe and take picture if possible

-

Please have operator sign ( type first name last initial)

-

Are all safety boxes checked off and good on operator sheet (fire extinguisher, oil bin, guards and locks)

-

Please take a photo

Baler Arrival / Equipment

-

In every Area if there is a fork truck please complete this inspection

Truck Audit

-

Which Truck is being Audited

- Truck 1

- Truck 2

- Truck 3

- Truck 4

- Truck 5

- Truck 6

- Truck 7

- Truck 8

- Truck 9

-

The pad is signed off

-

fire extinguisher present and inspections up to date

-

Is the operator using the equipment properly and safely during the audit?

-

Equipment is not running

Arrival

-

DO NOT GO UP STAIRS You should be able to stand in the area of the operator desk to answer these. If not please attach a note.

-

Is housekeeping needed

-

What type of housekeeping is needed

- Excessive Fibre

- Excessive Water

- Excessive Oil

- Excessive Pellet

- Needs Organization

- Pump-out

- Hydraulic Fluid

-

air hose has correct end and no holes.

-

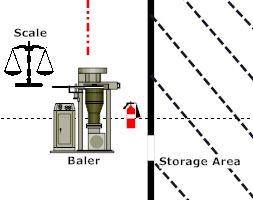

Is there a clear fire response plan posted for each work area?

-

All handling units stored properly? Boxes, Bales, Bins, Barrels, Containers

-

-

fire extinguisher present and inspections up to date

-

Are extinguisher locations conspicuously marked?

-

Are extinguishers easily accessible?

-

Are tools kept in their proper place?

-

Ladders in good condition and stored properly

Equipment

-

All guards in place and secured

-

All electric cords in good working condition

-

Power boxes are locked out if equipment is down and all locks present with tags

-

All tools stored properly

Fork Trucks

- Truck Audit

-

Which Truck is being Audited

- Truck 1

- Truck 2

- Truck 3

- Truck 4

- Truck 5

- Truck 6

- Truck 7

- Truck 8

- Truck 9

-

The pad is signed off

-

fire extinguisher present and inspections up to date

-

Is the operator using the equipment properly and safely during the audit?

Genie Lift

-

Is the genie lift being used

-

If genie lift is in use, has an inspection been completed

-

Has the harness inspection and documentation been completed

-

Is the operator using the equipment properly and safely during the audit?

-

is it stored in a safe manner

Emergency Lighting / Panic Buttons

-

How to test Panic Button System: Go inside and let office know of testing( check if they are on conference call as no testing should be done during call), then one person needs to stand at warehouse and one needs to stand at scale. When the panic button is pushed the corresponding lights should flash in both areas.

-

Does line 1 panic button work

-

Does line 1 light system work

-

Does line 3 panic button work

-

Does line 3 light system work

End of Audit

End of Inspection

-

Who completed this inspection

-

Who completed this inspection

-

Who completed this inspection