Title Page

-

Document No.

-

Audit Title

-

NCI facility location

-

Conducted on

-

Prepared by

-

Location

-

Key Plant Management team members

Machine Guarding Program

-

Is a Guarding process in place for all department?

-

Are regular Guarding audits conducted?

-

Has a Guarding emphasis committee been established for the facility?

-

Does the audit process include a method for prioritizing Guarding hazards?

-

Are maintenance work orders utilized to correct Guarding deficiencies in a timely manner?

Material Storage

-

Are standardized coil storage procedures established and utilized in the facility?

-

Are there no discrepancies in coil storage application?

-

Warehouse materials are stored in an orderly manner?

-

Rack systems are in good condition, secured to the floor, and have posted weight capacity ratings.

-

Finished materials are stored in an organized and safe manner.

-

Material handling systems, being utilized to transfer or move material, have established procedures and employees are trained on these procedures?

Cranes and lifting devices

-

Daily pre-shift inspections are completed by plant personnel?

-

Comprehensive monthly inspections are completed and documented?

-

Lifting device (lifting belts, coil hooks, coil caddies, spreader bars, and chains) monthly inspections are documented in detail and filed for reference as needed.

-

Bi-annual die penetrant or magna flux inspections of critical welds are completed, documented, and filed for reference.

Electrical Safety

-

The facility has competent, qualified electricians on staff.

-

Electrical Arc Flash PPE, rated voltage tools, and rescue equipment is available and in good condition.

-

Electrical panels are labeled with current Program Arc Flash labels.

-

Electrical panel has identification labels for panel or breaker function and voltage rating.

-

There is adequate clearance in front of electrical panel or breaker disconnects.

Confined Space

-

Facility confined space areas are identified and have specific identification labeling.

-

A confined space listing has been completed and documented on the NCI confined space register.

-

All confined space areas identified on the register have an individual documented hazard analysis completed and on file.

-

Confined space training is current?

-

Confined space entry, rescue, and monitoring equipment is available and utilized a required by the hazard assessment?

-

Management oversight is provided for the confined space program.

Hand and finger safety

-

The correct PPE is being utilized to help prevent hand and finger injuries?

-

Employees are aware of the "Line of Fire" safety concept to prevent injuries?

-

Production processes are designed in a manner where there are no exposure to employees from Line of Fire. (If no, please list in notes)

Reporting of incidents and injuries

-

Employees understand their responsibility of reporting all near hits, injuries, and property damage events?

-

Reported incidents are investigated timely and completed within 5 working days of the event occurrence?

-

The are no open incident reports for the facility as of this date?

-

The first aid area has a log for employees to input data entries on any first aid supplies which are use?

-

First responders are in place and training is current?

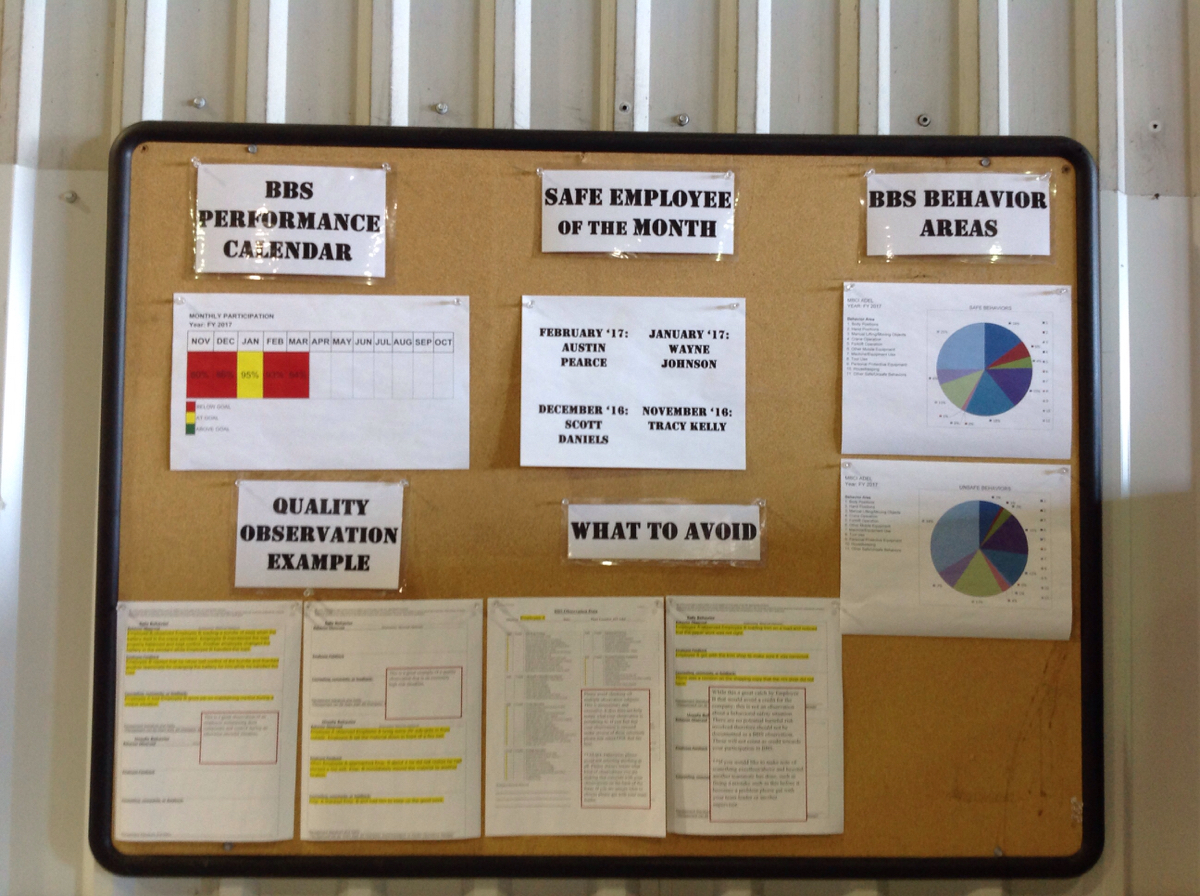

BBS/Safety Conversation Program

-

The facility has an active BBS program?

-

Employees conduct and document Safety Conversations?

-

A BBS coordinator has been established at the facility?

-

Training on BBS has been conducted for team leaders?

-

Training on BBS has been conducted for departmental employees?

NCI Fleet Safety Program

-

NCI Fleet drivers are home based and utilized from the facility?

-

The NCI Fleet safety program is utilized for the Fleet drivers?

-

Monthly safety topics are provided for the Fleet drivers and signed acknowledgment forms are turned in as proof of review?

-

Quarterly Fleet driver meetings are held at the plant?

Trailer fall prevention

-

Fall prevention methods are provided to team members who work on trailer elevated surfaces?

-

Has a Hazard analysis been completed on trailer fall procedures to determine risk?

-

Methods to prevent falls from trailers are in process.