Information

-

Prepared by

-

Conducted on

-

Site

Please assess the points below based on your observation (Rate/comment /provide photos).

-

1. Safety is recognized as top priority:<br>- Information SIM board is compliant and updated<br>- NM File updated

-

-

2. People wear PPE:<br>- Check safety shoes.<br>- Check other PPE if requested (gloves, goggles ...)

-

-

3. Storages are safe:<br>- No rack foot without protector. No part able to fall.<br>- No pallet location without pallet stoppers.<br>- Rack feet, protectors and pallet stoppers are in good status (no shock, no bent or twisted part).

-

-

4. 5S is in place, Gangways and pedestrian aisles are clear:<br>- No things out of place, 5S respected. <br>- No pallet or parcel in the gangways.<br>- All gangways are clean and free for forklifts and small train (if any).<br>

-

-

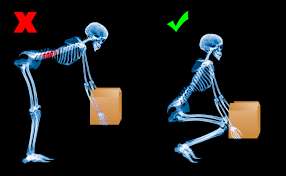

5. Ergonomic<br>-Is ergonomic lifting rules applied and use. <br>-Are there any tasks at risk for MSD. <br>-Is all heavy lift identified (max 10 kg.) <br>-Is there any knowledge of Ergonomics in the department.

-

-

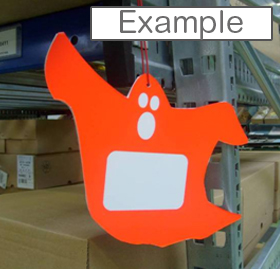

6. Bubak is implemented and operated:<br>- Bubak available on SIM boards or posted to spot a risky situation. If you recognize some risk during factory tour, post the Bubak there.<br>- If all Bubak on SIM boards, ask for some recent example and go and see the solution at the workplace.<br>- Bubak is posted in SIM 3 board

-

-

7. People are working safely:<br>- All machines covers are in place when in operation, no over-bridging device (shunt) is used, hands or parts of the body cannot be squeezed by machines in operation.<br>- No standing part able to hurt somebody if falling (pallet, sheet metal part ...)<br>- Workplaces and tools are in good status (no apparent damage, no risk of injury ...)

-

-

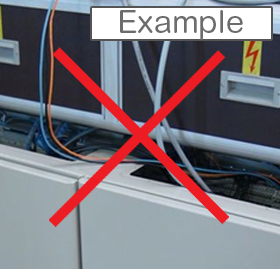

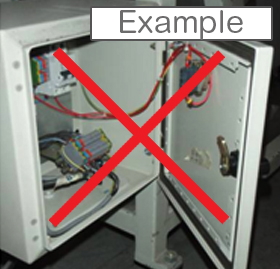

8. Electrical installation:<br>- No obvious electrical risk (no bare wire or plug, no broken electrical socket, no "hand-made" device ...).<br>- The test areas are segregated by physical fences and access is restricted. Appropriate warning signs are used (lights, display ...).<br>- Authorized people are identified (cap, shirt ...) or an updated list is posted on the fences of the areas.<br>

-

-

9. Zoning is respected, floor and workplaces are clean.<br>Waste is properly sorted:<br>- Floor zoning is respected (check WIP ...), floor and workplaces are clean (no paper, no sticker, no wooden piece ...).<br>- Visual check of bins

-

-

10. Accesses to emergency exits and fire fighting devices are clear .<br>- Nothing obstructs the way to fire-extinguisher, water pipes (if any), smoke-extractor, emergency exits.

-

-

11. Forklifts and waterspider are operated safely:<br>- Adapted speed<br>- No fork raised when forklift in motion<br>- Minimum distance between forklifts and pedestrians (1m in motion, 3m when forks raised)<br>- Daily check (according regulation for forklifts, according to Department recommandations for waterspider)

-