Information

-

Customer

-

Site Address

-

Post code

-

Site Number

-

Date of Inspection

-

Inspected by

-

Site reference (if applicable)

Preventative Maintenance and Safety Check

-

Risk assessments and method statements must be carried on all sites to ensure that the risk of injury or fatality is eliminated to users or members of the general public as a result of system design

The Provisions and Use of Work Equipment Regulation (PUWER) requires that Powered machinery is regularly maintained every six months.

MAINTENANCE PROCEDURES - POWERED/AUTOMATIC GATES

Regular preventative maintenance helps to prolong the system and will conserve reliability.

During each Planned Preventative Maintenance service SCCIA shall perform the following work:

· Check and record the equipment, its condition and oil levels

· Take photographs of the equipment to highlight problems and to aid reporting of defects

· Compliance assessment - Carry out a survey to highlight any areas of concern and offer appropriate recommendations for improvement

Note: If the gate system is deemed to be unsafe, then SCCIA shall switch off power and issue a Condemned letter as per Health and Safety Executive, GATESAFE and Door and Hardware Federation advice and guidance as the liability of a unsafe gate rests with the last person to service the system

Gates

-

Control type

-

Provide details

Standard Preventative Maintenance

-

Gate location (1)

-

Gate direction

- entry

- exit

-

Take a photo of gate from entrance side of gate

-

Manufacturer

-

Model

-

Loops fitted

-

Loops fitted

-

IR beams fitted

-

IR Beams

-

Warning lights fitted

-

Warning lights

-

Safety Edges fitted

-

Safety edges

-

Signs fitted

-

Length of Gate (mm)

-

Operating Equipment

-

Battery back up?

-

Provide details

-

Fire Drop Unit

-

Provide details

-

Radio controlled?

-

Provide details

-

Digital Keypad?

-

Provide details

-

Token

-

Provide details

-

Touch/card/fob

-

Provide details

-

Gate location (2)

-

Gate direction

- entry

- exit

-

Take a photo of gate from entrance side of gate

-

Manufacturer

-

Model

-

Loops fitted

-

Loops fitted

-

IR beams fitted

-

IR Beams

-

Warning lights fitted

-

Warning lights

-

Safety Edges fitted

-

Safety edges

-

Signs fitted

-

Length of gate (mm)

-

Operating Equipment

-

Battery back up?

-

Provide details

-

Fire Drop Unit

-

Provide details

-

Radio controlled?

-

Provide details

-

Digital Keypad?

-

Provide details

-

Token

-

Provide details

-

Touch/card/fob

-

Provide details

Additional Gates

-

Additional gates

-

Gate location (3)

-

Gate direction

- entry

- exit

-

Take a photo of gate from entrance side of gate

-

Manufacturer

-

Model

-

Loops fitted

- Yes

- No

-

IR beams fitted

- Yes

- No

-

Warning lights fitted

- Yes

- No

-

Correct and adequate signage

- Yes

- No

-

Length of gate (mm)

-

Operating Equipment

-

Battery back up?

-

Provide details

-

Fire Drop Unit

-

Provide details

-

Radio controlled?

-

Provide details

-

Digital Keypad?

-

Provide details

-

Token

-

Provide details

-

Touch/card/fob

-

Provide details

-

Additional gates

-

Gate location (4)

-

Gate direction

- entry

- exit

-

Take a photo of gate from entrance side of gate

-

Manufacturer

-

Model

-

Loops fitted

- Yes

- No

-

IR beams fitted

- Yes

- No

-

Warning lights fitted

- Yes

- No

-

Correct and adequate signage

- Yes

- No

-

Length of barrier (mm)

-

Operating Equipment

-

Battery back up?

-

Provide details

-

Fire Drop Unit

-

Provide details

-

Radio controlled?

-

Provide details

-

Digital Keypad?

-

Provide details

-

Token

-

Provide details

-

Touch/card/fob

-

Provide details

General

General

-

Installation checked for squareness and levels ok?

-

Provide details

-

Motors and operation of each item of installed equipment tested. Any evident visible or audible contra-indications?

-

Provide details

-

Inspect and sweep out any debris from motor pits and rail gullies. Is there flooding or excessive build up of debris?

-

Provide details

-

Clean and lubricate hinge bearings, locks, drive systems and control gear (Tick to confirm)

-

Check mechanical clearances and running tolerances. Are there any excessive or unusual wear patterns?

-

Provide details

-

Check physical stops at each end of travel of gates/barrier arms. Are there any signs of damage or over-run to report?

-

Provide details

-

Carry out visual checks of underground loop chases for erosion of sealer. Is seal damaged?

-

Advise client

-

Upgrade processor firmware to approved version of safety software to meet current safety standards, if applicable?

-

Inspect and test fixtures and fittings and electrical equipment. Any visible deterioration?

-

Provide details

-

Are supporting structures, hinges, bearings etc. sound and secure?

-

Provide details

-

Are electric cables in conduit, properly routed and undamaged?

-

Provide details

-

User manuals/instructions available and up to date?

-

Provide details

-

Check that infra-red photocell protection beams are clear and unobstructed and wipe lenses with a soft dry cloth

-

Whilst gate(s) are closing, cover each photocell lens in turn (eg. Hold a post card over one lens). Ensure gate(s) immediately stop or stop and return to open.

-

Location of the mains isolator

-

Is UKCA conformity plate attached to the system?

-

Does emergency manual release provide free running option?

-

Provide details

-

Are start up, stop and emergency stop devices functional?

-

Provide details

-

Check all connections, remake any loose or defective cable terminations - OK?

-

Provide details

-

Any loose bolts, nuts or screws have been tightened and all ok?

-

Provide details

-

Check the security of motor fixing bolts and base plate. Any signs of deterioration to concrete base?

-

Provide details

-

Check operation of limit switches are ok? Adjust as required.

-

Provide details

Safety Edges

-

Visually inspect each component for splitting or puncturing of the rubber or degeneration of the supply tubing, welding joints or other defect that could compromise safety by affecting the efficiency of the system?

-

Provide details

-

Test safety edges by depressing each. Ensure the equipment immediately stops or stops and return to the open position

-

Check for change in conditions or use patterns and assess impact, noting any deficit in advisable safety systems relevant to current norms. All ok?

-

Provide details

-

Check batteries on photocells are ok? Change if required

-

Provide details

-

Operation of fire switch OK?

-

Provide details

-

Operation lights are in good working order?

-

Provide details

-

Adequate clear signage in place?

-

Provide details

Slide Gate

-

Is the condition of the gate controller housing ok?

-

Provide details

-

Inspect general condition of hinges, gate stops, safety edges, photocells, reflectors and enclosure and clean if required - OK?

-

Provide details

-

Check condition of gate runners - OK?

-

Provide details

-

Check condition of wheels and apply lubricant - all OK?

-

Provide details

-

Check condition of toothed track - OK?

-

Provide details

-

Check security of motor fixing bolts and base plate. Report any deterioration of concrete base(s) - OK?

-

Provide details

-

Check condition of guides and lubricate - OK?

-

Provide details

-

Scan running rail by taking line of sight. Report any damage or variation - OK?

-

Provide details

-

Check / adjust guide rollers and ensure tightness of fixing nuts - OK?

-

Provide details

-

Check upper edge of guide rollers for flat spots indicating slippage. Report if worn - OK?

-

Provide details

-

Check free movement of limit switch actuator arm(s) and roller(s) - OK?

-

Provide details

-

Check slow down efficiency at each end of travel - check gates does not slam - OK?

-

Provide details

Addition

Key Type

-

Key Type

-

Key Number

-

Key box available

-

Manual Key in box

-

Manual instructions in box

Report on any required works

-

Check safety systems are compliant, shared pedestrian use, internal key pad, Push to exit bars, Break glass, Gaps and External Beams.

-

System complies with current Machinery Regulations, HSE notifications and DHF Codes of Practice

-

Supply details

Electrical Check

-

Electrical certificate available for barrier and in date

- Yes

- No

-

Does electrical installation appear sound, safe and in reasonable condition

- Yes

- No

-

Supply details

-

Source off power

-

Breaker size

-

Cable type

-

Cable size

-

Correct containment used

-

Details

-

Spur for barrier / gate in waterproof containment

-

Details

-

All wiring at barrier / gate checked for loose or badly made connections

-

Details

-

Additional Information

Installation diagram and assessment

-

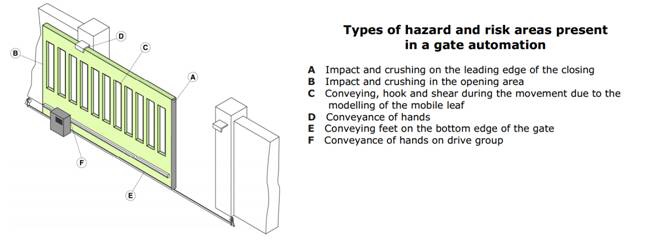

Identify (if relevant) potential hazards at points labelled on diagram, and comment below

-

Include Diagram from library

-

A - impact / crushing on the leading edge of the closing

-

B - impact / crushing in the opening area

-

C - conveying, hook and shear during the movement due to the modelling of the mobile leaf

-

D - conveyance of the hands

-

E - conveying feet on the bottom edge of the gate

-

F - conveyance of hands on drive group

-

Comments

Force Dynamics Testing BS EN 12445

-

Force Testing - at time of installation or refurbishment / safety upgrade undertake full Force Testing.

Partial Force Testing will be undertaken annually thereafter

Testing the force dynamics are horizontally 500mm, 300mm and 50mm test method.

Results stipulate a maximum of 400N of crushing force allowed before the gate should start to reverse under control by a safety edge or amperometric control:

- Swing gate between hanging style and post and gate closing leaves

· Sliding or cantilever gate closing leaf and run-back leaf (500mm test if within distance of an obstruction)

· Each test point is measured 3 times top middle and bottom

· The average value is then calculated from these results and submitted as a PASS or FAIL

· A compliant force testing device must be used. -

Is force testing required on this visit?

-

Undertake partial force test to ensure compliance (Best Practice - is one bad reading then the whole system will be tested)

-

Provide details

-

Review photograph plans etc for alteration since previous visits - have conditions changed since last service visit?

-

Undertake and complete new "Safety Compliance Survey"

-

Is client advice notice required?

Overall condition and Sign Off

Overall condition / Performance of system / additional information

-

Any additional comments

-

Any additional photos

-

Defects (list defects that need attention)

-

Recommendations (list items you would recommend)

-

Engineer

-

Client representative (if available)

-

As the person in control of the gate, you have a legal duty of care to users and visitors to the premises (including trespassers).

If the gate is not safe, any party injured by the gate is likely to be able to sue for damages.

If you have insurance covering such risks, your insurance contract is likely to oblige you to disclose any material facts to your insurer including, in such case that the gate is not considered safe.

If the gate is part of an undertaking, the person in control of it will have additional duties under Section 3 of the Health and Safety at Work Act 1974.

If the premises are also a workplace, there are specific duties under the Regulation 18 of the Workplace (Health, Safety and Welfare) Regulations 1992, as well the general duty imposed by Section 2 of the 1974 Act.

Failure to meet the duties imposed by health and safety legislation can result in criminal proceedings in line with the possibility of unlimited fine at Crown Court.