Title Page

-

Division

-

Date of inspection

-

Prepared by

-

Note: Operators are responsible to inspect rigging prior to each use.

General

-

Verify no slings are shortened with knots, bolts or other makeshift devices.

-

Verify hooks are not cracked, opened more than 15% from normal throat opening, or twisted more than 10 degrees.

Wire Rope Slings

-

Remove from service any sling that has:

-

Does it have less than 10 randomly distributed broken wires in any one rope lay?

-

Does it have less than 5 broken wires in any one strand in one rope lay?

-

Example of Broken Wire

-

Free of any broken core strands?

-

Example of Wear

-

Are they free of wear or scraping of 1/3 the original diameter of outside individual wire?

-

Example of Excessive Kinking

-

Free of excessive kinking?

-

Example of Distortion

-

Free of any other damage resulting in distortion of the wire rope structure?

-

Example of Heat Damage

-

Free of heat damage or welding arc strikes?

-

End attachments are not cracked, deformed or worn?

-

Free of corrosion of the rope or end attachments?

-

Are the sling capacity charts are readily available?

Chain Slings

-

Are the capacity tags are in place, securely attached and legible?

-

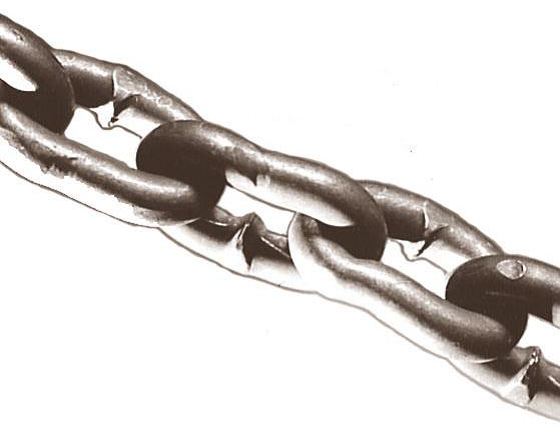

Example of Bent and Stretched chain

-

Free of deformation or elongation of any chain links?

-

Example of Welding Arcs

-

Free of any welding arc strikes to any links?

-

Example of Heat Damage

-

Free of any signs of heat damage?

-

Are all labels in place and clearly legible?

Synthetic Web Slings

-

Remove from service any sling that has the following.

-

Example of Chemical Damage

-

Is the webbing free of chemical damage?

-

Free of any signs of burning, charring or melting?

-

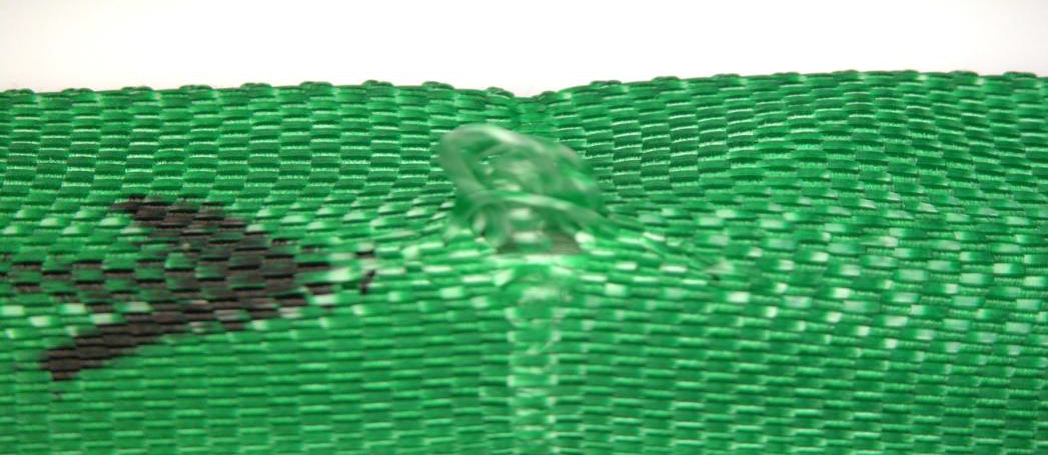

Example of a snag.

-

Example of acceptable cut.

-

Free of snags, tears, punctures or cuts?

-

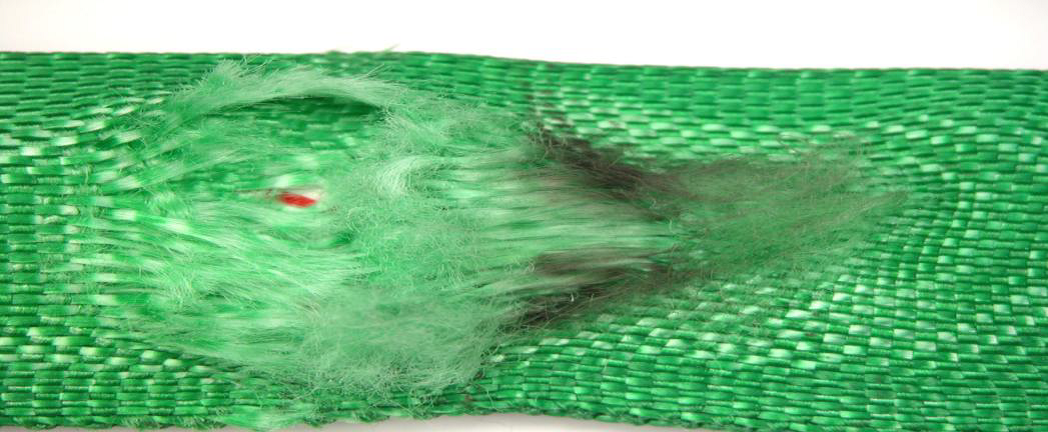

Example of Broken or worn stitches

-

Free of broken or worn stitches?

-

Example of not readable tag.

-

Is the capacity tag readable?

Operational Inspection

-

Are the load weights are known by operator.?

-

Are the slings not loaded in excess of rated capacity?

-

Are the slings padded at sharp edges.?

-

Are the employees clear of suspended loads?

-

Will any shock loading occur?

-

Are the Alloy Chain slings not exposed to temperatures above 1,000 deg. F?

-

Are the polyester or nylon synthetic web slings not exposed temperature greater than 180 deg. F?

-

Are the polypropylene synthetic web slings not exposed temperature greater than 200 deg. F?

-

Are the eye-bolts shouldered with the load (washers or nuts may be used)?

-

Are the Nylon synthetic web slings not exposed to acids or phenolics?

-

Are the Polyester and Polypropylene synthetic web slings not exposed to caustics?

-

Are the slings with aluminum fittings not exposed to caustics?

Lifting Hardware

-

Are the shackle diameters are not worn more than 10% of there nominal diameter?

-

Are the eye-bolts not bent?

-

Are the rated capacity and torquing specifications legible on swivel hoist rings?

-

Are the below-the-hook lifting devices rated for capacity?

-

Are all hardware free from structural deformation, cracking or heat damage?

-

Are all below-the-hook lifting devices that significantly add to the load weight labeled for weight?

-

Are all shackles and eye-bolts made of alloy steel?

-

Are all shackles and eye-bolts labeled with Safe Working Load (SWL) or Working Load Limit (WLL) or industry standard capacity charts are conspicuously posted?

-

Has there been no hardware/parts substitution?

-

Inspector Name and Signature