Information

-

Job

-

Prepared by

-

Date

-

JSA__of__

-

Location

-

Description of Work

-

Risk Score

1. Sequence Hazard Control

-

Sequence of Job Steps

-

Sequence of Job Steps:

Examining a specific job by breaking it down into a series of steps or tasks will expose potential hazards that may be encountered.

To determine where a step begins and ends, look for an activity, or a change in direction or movement.

Be sure to list all the steps needed to perform the job. -

Hazards

-

Potential Hazards:

A hazard is a potential danger. The purpose of the JSA is to identify ALL hazards, both those produced by the environment and conditions and those connected with the job procedure.

To identify hazards, answer these questions about each step:

1. Is there danger of the employee striking against, being struck by, or otherwise making injurious contact with an object?

2. Can the employee be caught in, by, or between objects?

3. Is there potential for a slip, trip, or fall?

4. Could the employee suffer strains from pushing, pulling, lifting,bending, or twisting?

Close observation and knowledge of the job is important. Examine each step carefully to find and identify hazards and the actions, conditions and possibilities that could lead to an accident. -

Risk Control Measures

-

Risk Control Measures:

Using the first two columns as a guide, what actions an procedures are necessary to eliminate or minimize the hazard that could lead to an accident, injury or illness.

Begin trying to: (1) Engineer the hazard out; (2) Provide guards, safety devices, etc.; (3) Provide PPE; (4) Provide job instruction training; (5) Maintain good housekeeping; (6) Insure good ergonomics(position person in relation to the machine or other elements in such a way to improve safety)

List the recommended safety operating procedures. Say exactly what needs to be done to correct the hazard, i.e. "Lift with leg muscles". Avoid general statements, i.e. "Be careful".

Give recommended action or procedure for each hazard.

Serious hazards should be corrected immediately.

Quantitative Risk Assessment(QRA)

1. Hazard Identification

Work Location

-

Along Roadway(urban)

-

Along Roadway(rural)

-

Along Railroad

-

Difficult Entry/Exit

-

Temperature Extreme

-

Engulfment

-

Confined Space

Hazardous Area

-

Working Height

-

Remote Area

-

No Line of Sight

-

Low-laying Area

-

Wet/Ice Conditions

-

Unstable Soil

-

Open Trench

-

Wind

High Risk

-

Traffic Movement

-

Falling Objects

-

Trip/Fall Hazards

-

Electrical Shock(HV)

-

Pinch Points

-

Manuel Handling

-

Moving Machinery

-

Rotating Machinery

-

Ladders

-

Rail Movement

-

Poor Visability

-

Noise Levels

-

Haz Materials

-

Haz Chemicals

-

Elevated Work

-

Sharp Objects

-

Heat/Sunlight

-

Pneumatics

-

Pressurized Fluids

-

Flamm. Materials

2. Precautions

Required PPE

-

Leather Safety-Toe Boots

-

Safety Glasses

-

Hardhat

-

Class II Hi-Viz Vest

-

Chaps

-

Harness

-

Gloves

-

Type

-

Goggles

-

Full Face Shield

Required MOT

-

Cones

-

Barrels/Drums

-

Adv. Warning Signs

-

Arrow Board

-

Blue Lights(Police)

-

Lighted Devices

-

Flagman x1

-

Flagman x2

3. Environmental Hazards

-

Air Pollution(Dust/Fumes)

-

Noise(Traffic/Equipment)

-

Spills

-

Soil Erosion

4. Equipment Required

-

Static Equipment

-

Mobile Equipment

-

Hand Tools

-

Electrical Tools

-

Hydraulic Equipment

-

Pneumatic Tool/Equipment

-

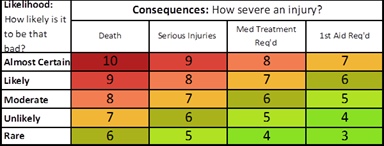

Risk Rating Table:

Extreme: 9-10

High: 7-8

Medium: 5-6

Low: 3-4 -

-

Signature