Title Page

-

Ladder ID

-

Material of Ladder

-

Size (ft.)

-

Department

-

Department name?

-

Location of Ladder

-

Date of Inspection

-

Prepared by

-

All ladders will have either a brass or colored tag with an identification number or a clearly visible equipment number for accountability and inspection purposes.

-

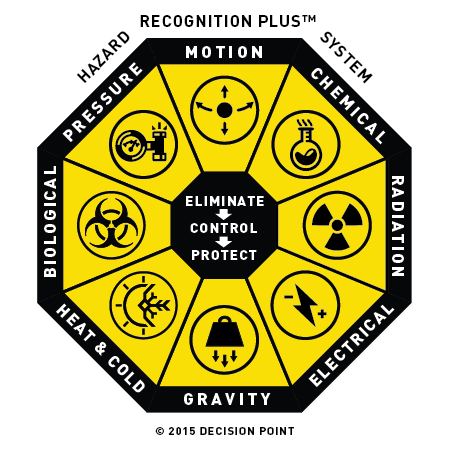

When inspecting a ladder consider the following points:

-

Steps: Loose, Cracked, Bent, or Missing

-

Why is this not applicable?

-

Rails: Cracked, Bent, Split, or Frayed Rail Shields

-

Why is this not applicable?

-

Labels: Missing or Not Readable

-

Why is this not applicable?

-

Pail Shelf: Loose, Bent, Missing, or Broken

-

Why is this not applicable?

-

Top: Cracked, Loose, or Missing

-

Why is this not applicable?

-

Spreader: Loose, Bent, or Broken

-

Why is this not applicable?

-

General: Rust, Corrosion, or Loose

-

Why is this not applicable?

-

Other: Damage to Bracing, Shoes, or Rivets

-

Why is this not applicable?

Post Audit

-

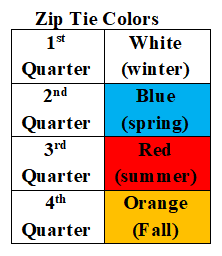

If there are no deficiencies found and the equipment is deemed safe and operational, attached the appropriate color zip tie and return the equipment to its regular storage location.

-

Any equipment that does not have the appropriate color zip tie will be considered unsafe and/or inoperable until an inspection and functions check is completed and the appropriate zip tie is attached

-

If there is a deficiency or malfunction found that renders the equipment unsafe or inoperable tag it with a red “Do Not Operate” tag and completely remove it from service.

-

Defective equipment should be held in a central location where it cannot be confused as a serviceable piece of equipment, it will remain in this location until it can be properly disposed of.

-

Ladder Inspection Results

- Damaged - tagged as damaged and removed from use

- Good condition - tagged and returned to use

-

Other Comments or Corrective Actions not otherwise mentioned

-

Signature of Person Inspecting