Supplier Information

Supplier Information

-

Supplier ID

-

Conducted on

-

Prepared by

-

Region

-

Please Specify.

-

Service Line

- CNC 3 Axis Milling (Standard)

- CNC 3 Axis Milling (Precision)

- Sheet Metal

- 3D Printing

- CNC Turning (Precision)

- CNC Turning (Standard)

-

What Technology has been used?

-

Is Dim 3.60mm within +/-0.1mm?

-

Is Ø10.08 within +/-0.1mm?

-

M4x0.7 Thread in Spec?

-

Please specify the issue

-

Is Dim 25.00mm within +/-0.1mm?

-

Is Dim 19.00mm within +/-0.1mm?

-

Is Dim 43.00mm within +/-0.1mm?

-

Is Dim 54.00mm within +/-0.1mm?

-

Is Dim 30.00mm within +/-0.1mm?

-

Is Dim 50.00mm within +/-0.1mm?

-

Is Dim 3.60mm within +/-0.05mm?

-

What tolerance did they achieve?

-

Is Ø10.08 H7 within (+0.018mm/-0)?

-

What tolerance did they achieve?

-

M4x0.7 Thread in Spec?

-

Please specify the issue

-

Is Dim 25.00mm within +/-0.05mm?

-

What tolerance did they achieve?

-

Is Dim 19.00mm within +/-0.05mm?

-

What tolerance did they achieve?

-

Is Dim 43.00mm within +/-0.05mm?

-

What tolerance did they achieve?

-

Is Dim 54.00mm within +/-0.05mm?

-

What tolerance did they achieve?

-

Is Dim 30.00mm within +/-0.05mm?

-

What tolerance did they achieve?

-

Is Dim 50.00mm within +/-0.05mm?

-

What tolerance did they achieve?

-

Is Dim 50.00mm within +/-0.20mm?

-

What tolerance did they achieve?

-

Is Dim 25.00mm within +/-0.20mm?

-

What tolerance did they achieve?

-

Is Ø6mm within +/-0.20mm?

-

What tolerance did they achieve?

-

Is 40.00mm within +/-0.20mm?

-

What tolerance did they achieve?

-

Is Dim 15.93mm within +/-0.05mm?

-

Is Dim 3.23mm within +/-0.05mm?

-

Has Ø6 achieved the H7 tolerance? (+0.012/-0)

-

M4x0.7 Thread in Spec?

-

Please specify the issue

-

Is Dim 48.33mm within +/-0.05mm?

-

Is Dim Ø33.35mm within +/-0.05mm?

-

Is Dim 73.48mm within +/-0.05mm?

-

Is Dim 15.93mm within +/-0.1mm?

-

Is Dim 3.23mm within +/-0.1mm?

-

Is Dim Ø6 within +/-0.1mm?

-

M4x0.7 Thread in Spec?

-

Please specify the issue

-

Is Dim 48.33mm within +/-0.1mm?

-

Is Dim Ø33.35mm within +/-0.1mm?

-

Is Dim 73.48mm within +/-0.1mm?

Feature Analysis & Aesthetic Quality

Feature Analysis

-

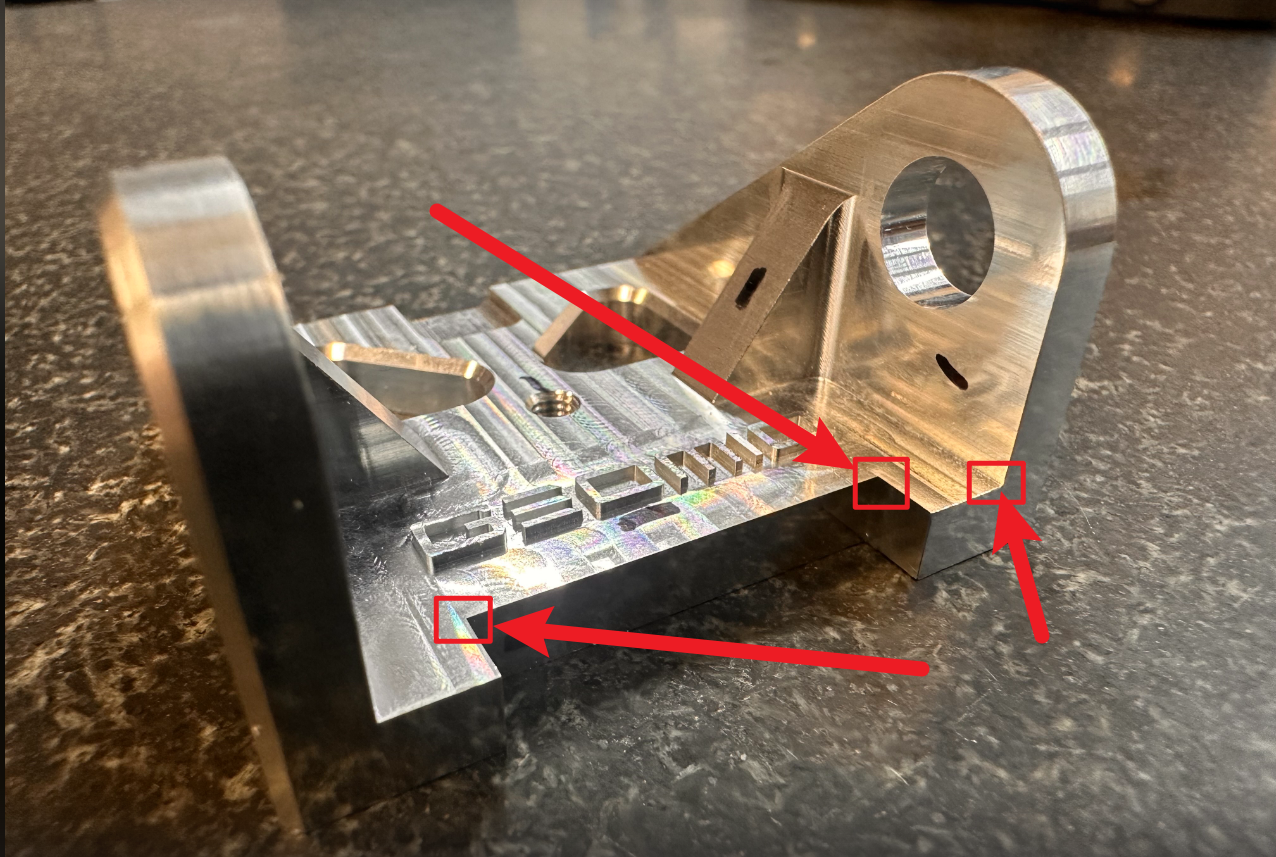

Example of a good Edges and Corners Sharp, please use this as an example.

-

Are the Edges and Corners Sharp?

-

Has the parts went to deburring process?

-

Acceptable criteria for Deburring process.

Aesthetic Quality

-

Instruction: Surface Roughness Chart.

-

Required Surface Roughness achieved?

-

What is the value Achieved?

-

Is the Surface roughness on the internal face consistent?

-

Instruction: Pass/Fail Criteria for the internal face.