Title Page

-

Workplace

-

SWMS No

-

Conducted on

-

Prepared by

-

Location / address

COMPANY DETAILS

-

Amalgamated Property Maintenance (Brisbane) Pty Ltd

-

Unit 6, 17-19 University Drive Meadowbrook, Qld 4131

-

ABN: 75 611 172 626

-

Business Contact: 07 3732 6515

-

Email Address: info@amalgamatedgroup.com.au

-

SWMS Activity/Task Description:

-

Site Contact:

PRINCIPAL CONTRACTOR DETAILS

Principal Contractor details

-

The builder or the organisation you are working for.

-

Principal Contractor Company Name:

-

Project Name:

-

Job Address:

-

Date SWMS provided to Principal Contractor:

SWMS APPROVAL

-

SWMS APPROVED BY: (Employer/PCBU/Director/Owner

-

SWMS APPROVED BY: (Principal Contractor)

-

Date:

-

Name and Signature of person responsible for reviewing and ensuring compliance with SWMS:

-

ALL PERSONS INVOLVED IN TASK MUST HAVE THIS SWMS COMMUNICATED TO THEM PRIOR TO WORK COMMENCING:

- Daily Tool Box/Pre Start Talks will be undertaken to identify, control and communicate additional site hazards.

- Work must cease immediately if incident or near miss occurs. SWMS must be amended in consultation with relevant persons.

- Amendments must be approved by nominated persons and communicated to all affected workers before work resumes.

- SWMS must be made available for inspection or review as required by WHS legislation.

- Record of SWMS must be kept as required by WHS legislation (until job is complete or for 2 years if involved in a notifiable incident). -

Select to acknowledge the above has been read and understood

RELEVANT WORKERS

- Relevant workers. Workers must be consulted in the development, approval and communication of this SWMS.

-

Name:

HIGH RISK CONSTRUCTION WORK & PPE

SWMS Scope

-

SWMS SCOPE: This SWMS covers general painting procedures using platform ladders, work platforms, hop-ups, hand tools, power tools, spray guns.

This work activity involves the following High Risk Construction Work activity

-

Confined Spaces

-

Asbestos

-

Structures or buildings involving alterations or repairs that require temporary support to prevent collapse

-

A risk of persons falling more than 2 metres including work on telecommunication towers

-

Work in an area that may have a contaminated or flammable atmosphere

-

Work carried out adjacent to a road, railway or shipping lane, traffic corridor

-

Work near water or other liquid that involves risk of drowning

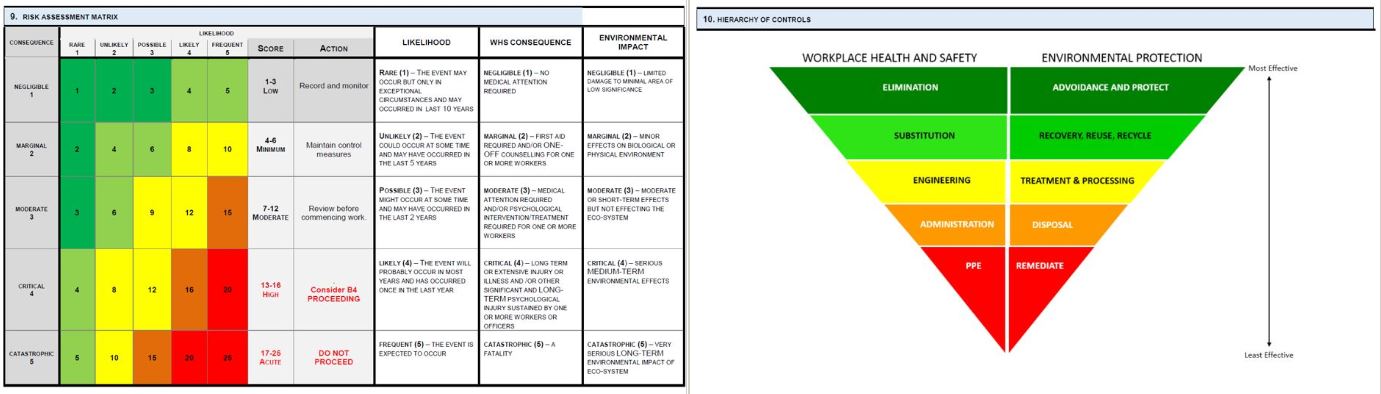

Risk Assessment Matrix & Controls

-

-

Confirmation Risk Assessment Matrix read and understood

Personal Protective Equipment (PPE)

-

Ensure all PPE meets relevant Australian Standards. Inspect and replace PPE as needed.

-

High Visibility

-

Foot Protection

-

Hearing Protection

-

Head Protection

-

Eye Protection

-

Face Protection

-

Hand Protection

-

Breathing Protection

-

Protective Clothing

-

Fall Arrest

-

Sun Protection: Broad brimmed hat, UV rated clothing, SPF 30+ sunscreen, tinted safety glasses with adequate UV protection

-

Rings, watches, jewellery that may become entangled in machines must not be worn. Long and loose hair must be tied back.

JOB STEP 1. PLANNING AND PREPARATION

Potential Hazard: Lack of consultation may lead to potential outcomes for personal injury, property damage &/or environmental incident.

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Liaise with Principal Contractor to establish the following on-site systems and procedures are in place and take note of:

Health and Safety rules

- Induction for all workers - site specific and toolbox meetings

- Supervisory arrangements

- Communication arrangements

- All relevant workers are appraised for required competencies & for any pre-existing medical conditions if working in remote or isolated locations

- PPE required

- Site plans - showing no go zones

- Traffic Management Plan

- Exclusion Zones

- Risk Assessments

- SWMS and JSA's

- Injury reporting procedures

- Hazard reporting procedures.

Existing premises (commercial or private residence).

* Liaise with client to determine whether:

- Electrical devices, power points, switchboards etc. are in a safe condition and RCD protected

- Commercial premises - establish that the following on-site systems and procedures are in place:

- Site-specific induction including emergency procedures

* Consultation in relation to hazards and risks. Ensure:

- Consult with the person you are carrying out the work for on the potential hazards and risks associated with the task

- If represented by an elected Health and Safety Representative (HSR), they must be included in any consultation

- Any other persons on site who are affected by the same matter are consulted and co-operative arrangements are made

- Document consultation and action items

* It is advised that information be provided to client to advise them of the following:

- Excess clutter to be removed (if applicable)

- Sharps will not be collected and work will not proceed if sharps are observed (include other prohibited items as necessary)

- If safety shoes/boots are required for work they may need to be worn inside. Ensure work shoes are clean and acceptable to wear inside if needed

- Cash and any valuables must be removed from easily visible/accessible areas

* Animals must be secured / removed. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contamination/Contact with Hazardous Materials

-

Are you working with hazardous substances?

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Storage area provided for hazardous substances used on site, away from public access

* SDS sheets to be provided for all hazardous substances

* All unidentified hazardous materials to be removed from the work site prior to commencement or SDS sheet provided where agreed. * Waste material to be removed daily from work area and placed in bins provided or disposed appropriately * Adequate task specific PPE to be worn when handling hazardous substances -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 2. TRAINING AND CAPABILITIES

Potential Hazard: Lack of training or the assessment of capability may lead to personal injury, property damage &/or environmental incident.

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* All workers and contractors to complete an ASG Induction and a Site Induction prior to commencement on site

* Ensure all persons entering site have a General Construction Induction Card (white card)

* Ensure all relevant workers have undertaken training and/or received instruction in the use of control measures. Including:

- All workers are trained in this SWMS and relevant Safe Operating Procedures and SDS documentation and signed off prior to commencement on site

- Correct use of equipment including selecting, fitting, use, care of and maintenance

- Use of supervision where required (e.g. new starters or new equipment)

- Using hazardous chemicals/atmospheres

- Safety Data Sheets (SDS)

- Ensure supervisors, foremen etc. are suitably experienced in the type work to be conducted.

- All workers and contractors to carry licences where appropriate

- Pre-start Meeting to be held daily to refresh and update issues and keep lines of communication open. Periodic Toolbox meetings to be held and minuted -

Risk-Rating after control measures have been implemented

-

Person responsible to implement control measures:

JOB STEP 3. TRANSPORTING PLANT & EQUIPMENT

Potential Hazard: Environmental incident/spills

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Ensure all chemicals container lids are securely fitted

* Secure so paints cannot move / become damaged / spill during transit.

* Remove structures that may be contaminated by hazardous residues

* Disposal of all contaminated materials in sealed bags or containers that are labelled * Vacuum and clean up area after surface preparation and job completion * Waste material to be removed from work area and disposed of as dried waste in approved landfill

* Brushes and rollers to be washed in wash bins where provided or to be disposed of via waste bins unless contaminated with hazardous substances and in that case must be disposed of as hazardous waste

* Dried empty paint tins can be recycled and should be disposed of via council metal recycling facilities

* DO NOT pour any leftover product down the drain. Retain in a marked sealed container for future use or dispose via special chemical waste collection programs such as those run by 'Paint Back’ scheme -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Struck by moving objects

-

-

Risk-Rating before control measures have been implemented

-

- Secure so paints / equipment cannot move during transit. - Isolate vehicles when loading and unloading - Wear hi vis clothing so you are easily identified

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Injury to public / property damage

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Ensure ladders and components are well secured to the transport vehicle:

- The overhang of horizontally stored equipment beyond the support points of the rack should be minimised

- The support points should be constructed of material such as wood or rubber-covered pipe to minimise the effects of vibration, chafing and road shock

- Securing the equipment to each support point will greatly reduce the damaging effects of road shock

- Ensure the vehicle is suitable for the type and size of the equipment

- The equipment must be restrained to prevent unacceptable movement during all expected conditions while in transit:

* The load restraint system must meet the Regulation Performance Standards (see relevant authority)

- Tie a red flag (identifying marker) on the end of any ladder/plank that extends beyond the rear of the vehicle

- Ensure straps are placed over the sides of the ladders / planks and in between the rungs of the ladders to keep extension ladders from moving forward or backward. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 4. ARRIVAL AT SITE - LOADING / UNLOADING

Potential Hazard: Adjacent to road/powered mobile plant movement

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Park working vehicle in driveway or allocated parking to avoid travelling across roads when delivery working equipment

* Segregation of mobile plant and workers by the use of hard barricades and signage

* Check constantly for changing hazards while working and monitor work position at all times. Ensure:

- High visibility clothing worn at all times

- Do not stand behind reversing vehicles

- Allow sufficient distance from plant during operation (allow sufficient room for equipment failure - such as arm/boom failure or plant rollover)

- No work is conducted in established "no go zones" for pedestrians

* Alertness at all times. Listen for:

- Reversing alarms/beepers - Calls from Plant Operators or spotters

* Safety/warning signs, Spotters, traffic barriers etc. must be obeyed as required

* Work positions should be in clear sight of plant operators

* Follow traffic management plan requirements * All operators of mobile equipment must have current licence and have had adequate training -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Personal injury, property damage &/or environmental incident.

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Assess conditions at site on arrival. Ensure:

- Ensure site-specific induction is undertaken (include location of amenities, first aid facilities, emergency plans & evacuation points, communication, contact persons etc.)

- Assess mobile phone reception

- Work site is exactly as detailed in Terms of Agreement or contract

- Suitable access for all equipment required

- Suitable space for operation of equipment

- Suitable lighting, including night-works

* Conduct risk assessment to identify potential hazards such as:

- Work at heights (above 2m)

- Lighting

- Ventilation

- Presence of hazardous materials such as asbestos, lead, silica etc.

- Location of existing services (heating, water, pipes, electrical leads)

- Dust

- Temperature etc.

- Exposed electrical switchboards/power points

- Duration of manual handling tasks (such as working with arms above shoulder height). -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 5. WORK AREA SET UP

Potential Hazard: Fire

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* DO NOT smoke during re-fuelling

* Ensure re-fueling is undertaken in well-ventilated area, clear of ignition sources

* Ensure fire extinguisher available and in date.

- Unleaded petrol: Fire extinguisher - Dry chemical powder, foam, CO2. Never use water to extinguish an Unleaded Petrol fire.

* Avoid breathing vapours or contact with fuel

* If clothing is splashed with fuel, change immediately

* Do not siphon or swallow fuel as this can be fatal

* Do not eat, drink or smoke during/after-handling fuel until hands are carefully washed

* Shower and wash immediately after work. Wash clothes in separate wash from other clothes. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contact with electricity

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Instruct and train staff in appropriate and correct use of all electrical devices and electrical safety

* All electrical tools are to be tested and tagged according to legislative requirements * Only trained workers are permitted to use powered tools on site

* Ensure all circuits have safety switches

* Inspect all equipment prior to use

* Regularly maintian all equipment as per the manufacturers' recommendations -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Property damage / injury to other worker/public

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Check all plant and equipment using a pre-check list prior to operation

* Use plant and equipment in accordance with training and manufacturers' recommendation

* Only use plant and equipment that is appropriately tagged and within certification periods e.g. calibration

* Only use plant and equipment for its intended purpose

* Only use plant and equiment that you are trained to use -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Falls from height

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* All scaffolding over 4m high must be erected by a ticketed scaffolder

* Use of platform ladders must be in accordance with the Standard Operating Procedure

* DO NOT access roof area

* Prevent access to unsafe areas using physical barriers and warning signs

* Use perimeter guards

* Use aerial access equipment - cherry picker

* When using elevated platforms, check and use secure fall arrest harness and lanyard prior to elevating work platform OPERATING ELEVATED WORK PLATFORMS * When using elevated work platform, check and use secure fall arrest harness and lanyard prior to elevating work platform.

* Harness to be tagged and Harness Register provided * Safety harness to be worn and connected to designated anchorage point at all times whilst in the EWP basket

* Pre-starts to be completed prior to use of equipment * If outriggers are fitted ensure they are fully extended and on a solid bearing * Ensure tyres are inflated to correct pressure (where necessary) * Keep materials within the confines of the basket of the scissor lift * Set up exclusion zone around the base of the machine and appropriate signage to be put in place where deemed necessary

* In the event of an operator being unable to operate the basket controls on the scissor lift, a person at ground level should walk

to the ground controls and operate these to lower the scissor lift * NEVER operate EWP when wind speeds exceed 12.5m/sec operating outdoors * DO NOT stand on hand rails or mid rails of the scissor lift basket * DO NOT place body parts in a position where they could be crushed between machine and other structures

* DO NOT use as a crane or hoist or to push or pull other objects * DO NOT move the machine whilst the basket is elevated * DO NOT overload the basket and observe and do not exceed SWL and permitted number of occupants

* NEVER use ladders or other items to gain additional height * Always lower the Elevated Work Platform at the end of the shift, position in a safe location, remove keys and secure SCAFFOLDING * All scaffolding must be erected by a ticketed scaffolder * Only approved platform ladders, trestles and scaffolding are to be used * All plant to be inducted to site prior to use -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Falling objects

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

Ensure training in emergency response for chemical spill. Emergency response -fuel spill:

1. Stop the source of the spill or leak or release

- If that is not possible & it is safe to do so - stop the spill or release from spreading

2. Turn off any ignition sources if safe to do so

3. Use gravel or other material to stop fuel entering drains/water courses

4. Clean up spill as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Slips, trips & falls on the same level

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Undertake a work area inspectionprior to commencement and remove and impediments that may casue slips, trips or falls

* Ensure all plant and equipment is stored correctly and in a safe manner

* Where possible set up a 'Paintshop' area that is isolated from public access

* Good housekeeping to keep all excess materials stored in designated areas -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Noise

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Always maintain a safe working distance from plant and equipment and maintain eye contact with the plant operator when approaching the machine

* ALWAYS wear hearing protection where noise levels exceed 85dB -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Lifting/carrying & setting down - Muscular stress/musculoskeletal disorder (MSD)

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Where possible reduce the size/weight of items prior to handling

* Where any one item exceeds 20kgs then a lift aid or double lift assistance is required

* Use additional workers where repetitive handling of small items is required

* If hand unloading is required ensure that the correct handling techniques are applied

* Provide job rotationand other alternative activities to reduce repetitive strain injuries

* Provide sufficient rest breaks for recovery -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Outdoor work

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Cease outdoor activity in inclement weather

* Only undertake acrivities not affected by the weather

* Outdoor workers to use subscreen and wear protective eyewear, hats with wide brim and long sleeve shirts and pants

* Outdoor workers must take plenty of fluids and rest between work sessions

* Where possible undertake work in shaded areas

* Workers ro be provided with UV protection (SPF30+) -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contact with hazardous chemicals/substances/atmospheres

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Where possible use non-hazardous paints and chemicals * Ensure current Safety Data Sheets (SDS) are obtained for all hazardous chemicals/substances and accessible on site

* PPE as prescribed in M/SDS for decanting is provided and used

* Ensure suitable respiratory protection & cartridge is selected as directed in SDS, inspect:

- Filters, seals, and valves

- Ensure filter and respirator are compatible

- Ensure respiratory equipment is regularly cleaned and maintained

- Inspect PPE for any sign of damage

- Replace filters if damaged, when resistance increases and as per manufacturer's instructions

Small spills:

- Shut off all possible sources of ignition

* Contain using sand and earth to prevent runoff into drains and waterways

* Collect and dispose of soiled material in a properly labelled airtight drum for disposal. Report any environmental incidents

* Ensure adequate ventilation

* For larger spills:

- Contain, take up with inert absorbent material (e.g. sand, soil)

- Place in secure labelled containers for disposal SKIN CONTAMINATION * Wear mandatory, task specific PPE * Use barrier cream and apply prior to handling hazardous substances * Wear gloves * Wash off all contact chemicals and paint as soon as practicable * Follow all manufacturers' recommendations as detailed on the SDS INHALATION ISSUES * Use a dust extraction system when using electric sanders * Whilst cleaning and or dusting/ a dusk mask must be worn P2 * EYE INJURY * Protective eyewear to be used when applying an hazardous substance or where the manufacturers' directions advise it

* Protective eyewear must also be worn when operating high pressure equipment -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 6. MIXING PAINTS

Potential Hazard: Muscular stress/musculoskeletal disorder (MSD)

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Where possible reduce the size/weight of items prior to handling

* Where any one item exceeds 20kgs then a lift aid or double lift assistance is required

* Use additional workers where repetitive handling of small items is required

* If hand unloading is required ensure that the correct handling techniques are applied

* Provide job rotationand other alternative activities to reduce repetitive strain injuries

* Provide sufficient rest breaks for recovery -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Exposure to hazardous chemicals/substances: occupational asthma, skin sensitisation, respiratory diseases, cancer

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Where possible change the process to minimize contact with and exposure to hazardous chemicals/substances

* Isolate or enclosse the process

* Use wet methods to reduce generation of dust or other particulates

* General dilution ventilation -avoid creation of hazardous atmosphere

* Ensure products are used as per label directions

* Ensure product is stored as per instructions on incompatible materials to be stored with or advise on potential hazardous degradation products -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Working with hand & power tools

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Ensure leads are not damaged - along the entire length of the lead and extension lead

* Ensure all equipment and leads are tested and tagged as required for use* Do not use electrical equipment in wet or damp areas

* Do not operate power tools in explosive atmospheres (i.e. presence of flammable liquids, gases or dust)

* Ensure operations manual is available, read and understood

* Pre-inspect and operate power tools as per manufacturer's instructions

* PPE worn as manufacturers recommendations

* Ensure equipment rated for atmospheric requirements (water, or explosion-proof for flammable zones)

* Ensure tool suitable for task, suited to the material. E.g.: steel, wood, MDF, masonry

- Not too powerful for task. E.g.: don't use larger tool than needed

- Sufficient power for task - excessive force not required

SAFETY DEVICES:

- Low impact tools where possible

- Single operation when trigger pressed

- Guards in place, undamaged, retracts and cover danger areas

- E-stops and other devices functional and tested

* Ensure tools are not carried in pockets or clothing (use sheaths, tool belts, etc.)

* Ensure Tool handles:

- Non-slip, good grip

- No sharp edges

- Guards or stoppers

- Clean, grease-free grips/handles. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Public and other worker safety

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Remove all non-essential persons from area

· Barricade area and place caution signs as needed. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 7. SURFACE PREPARATION & PAINTING (including sanding, caulking & patching)

Potential Hazard: Falls

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

ACCESS LADDERS:

* Use only access provided, do not climb on railings or other scaffolding components

* Use only ladders provided for access to scaffolds

* When on a ladder, do not over-reach. Descend ladder & re-position as required

* Do not carry materials when ascending/descending a ladder

* Always face ladder when using

* Do not use step ladders to gain extra height

* Remove ground level ladder when unattended to prevent unauthorised access

* Only competent scaffolder to make changes to scaffold:

- Do not remove any scaffold component e.g. handrails or boards

- Do not remove scaffold ties to support structure

MOBILE SCAFFOLD

* Level, plumb

* Casters locked before accessing, not moved when persons on scaffold

* Accessed by internal ladder only, do not climb on scaffold

* Clear of penetrations or floor edges (by at least 1metre where possible)

* Do not use steps or ladders on top of the work platform to gain extra height

* Do not move the scaffold with persons or materials on it.

* Before moving the scaffold ensure that it is clear of obstructions, both overhead and, at ground level

TRESTLE SCAFFOLD:

* Guardrails, toe board sides & ends are in place

* Erected as per manufacturer's specifications

* Purpose-designed pins

* Min 2 planks or 450mm wide

* Suitable span of plank (based on thickness). Example: Thickness of 38mm = 1.5m span, Thickness of 50mm = 2m span, Thickness of 63mm = 2.5m span)

PLATFORM LADDERS:

* Ensure industrial rating

* Non-slip treads

* Trestle back undamaged

* Suitable height hand rail (900mm)

* Triangular flat plate bracing

* Correct size for job (platform level)

* Large feet with non-slip mouldings

* If unfolding type, chains, rivets etc. are undamaged and functional

* Non-slip platform of sufficient strength for persons, tools and equipment. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Falls into openings

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

Holes or other openings through which a person can fall - Ensure:

- All holes or openings are protected/closed from falls immediately after creation

- Ensure the cover is secured to prevent movement

- Use signage or other clearly marked hazard alert to identify hazard. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Falling objects

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Maintain awareness of other people on scaffold

* Do not exceed the specified Safe Working Load of the scaffold

* Stack items to prevent sliding or toppling

* Use tether on tools/equipment where appropriate to prevent object falling

* Keep tools and other equipment away from edges

* Determine where items may fall (in case of uncontrolled release) and ensure all personnel are clear of that area

* Never work directly below other workers or where equipment is being placed above

* Use tool lanyards to pass tools to persons at height and ensure tools cannot fall onto workers below

* Ensure kickboards installed on elevated work areas to prevent tools falling off. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Use of hand/power tools

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Refer to step 6 (Working with hand & power tools) for controls. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Air under pressure

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Using high-pressure air can cause serious injury

* NEVER use compressed air for blowing dust off skin or clothing

* NEVER point the air hose at persons, or use to clean clothing, shoes, or any part of the body. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Fluid under pressure

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

Ensure:

- Spray gun hoses are routed as straight as possible to avoid kinking

- Any water condensate is drained from the compressed air system

- Satisfactory pressure for the operation of the spray gun

- Spray gun is held perpendicular to the surface area being sprayed at all times, with the airline held back away from the item

- Work arranged to minimise exposure. Be aware of wind direction, avoid spraying into wind (rotate work - not operator)

- Staggered work positions to avoid overspray of the operators

- Spray gun pointed only at the work - never at yourself or another person

- Spraying is not done in upward direction, as this directs spray into breathing zone and face. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contact with electricity

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Locate and maintain awareness aware of any power lines when working on ladders/trestles

* Locate and maintain awareness aware of any extension leads. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Repetitive, sustained tasks

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Avoid overreaching

* Job rotation

* Sufficient breaks

* Take regular breaks

* Do not overreach

* Maintain good posture avoiding awkward twisting and side bending

* Practice stretching throughout the shift

* Use alternate arms for painting, and direction of painting strokes (vertical/ horizontal) when possible

* Ensure tool handles have extendable handles -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Debris/dust

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure eye, breathing protection and protective clothing is worn. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Slips, trips & falls on the same level

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

Ensure:

* Non slip foot protection is worn

* Secure footing

* Safe access and egress

* Sufficient lighting

* Free of excess material

* Complete visibility of work area.

* When using plastic to protect floor surfaces cover the plastic with drop sheets, wet plastic will become very slippery. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Caulking & patching products

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Follow directions of use

* Consult M/SDS for the product

* Use PPE as per the product safety sheet

* Use with adequate ventilation

* Chemical resistant gloves for prolonged exposure. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 8. ON COMPLETION

Potential Hazard: Slips, trips, falls

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Clean up tools and any waste ensuring the site is left in clean and tidy condition

* Clean debris and ensure it is removed from area. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contact with electricity

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Disconnect power tool/extension leads from power point before winding up, so that you don't get a shock if the lead is damaged

* Inspect leads and power equipment for damage

* If safe to do so, remove isolation locks/tags and test appliance for function

Ensure:

- That no electrical appliances, light fittings, cables etc. have been damaged

- If damage suspected, do not turn power back on, seek advice from licensed electrician

- Reconnect services as required. Notify homeowner and/or site supervisor. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contamination of waterways and water catchment

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* All paint products may be harmful to aquatic life.

* Prevent contamination of sewers, drains and waterways by:

- Disposing of dried waste materials in approved landfill

- Dried empty cans can be recycled and should be disposed of via council metal recycling facilities

- Do not pour any leftover product down the drain

- Retain in a marked sealed container for future use of disposal via special chemical waste collection programs. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Public safety

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* If acceptable, remove barricades, contact supervisor and return as agreed.

* Store leftover paint in the original container with the label intact. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

PLANT / TOOLS / EQUIPMENT LIST

Plant/Tools/Equipment Required For The Job

-

Plant / Tools / Equipment are required to complete this job:

-

Plant / tools / equipment required:

Equipment / Tools / Plant

-

Make & Model

-

Photo of Equipment / Tools / Plant

-

List inspection and maintenance requirements

-

If a licence/ticket is required does the operator have a current licence/ticket

-

Photo of ticket/licence

HAZARDOUS SUBSTANCE LIST

- Hazardous Substance Details

-

Product Name:

-

Quantity on site:

-

Photo of current SDS

SITE SPECIFIC HAZARDS

-

Have you identified any further hazards on the job site?

Job Step

-

What job step does this hazard relate to?

-

Potential Hazard

-

Risk-Rating (IR) before control measures have been put in place<br>

Control Measures to Reduce Risk

-

Control measures used to reduce risk

-

Risk-Rating (RR) after control measures have been put in place.

-

Person responsible to implement control measures:

REVIEW & MONITOR

Review & Monitor

-

To ensure controls are implemented and monitored effectively:

* Toolbox /pre-work meetings will be undertaken

* Relevant persons will be consulted on hazards and contents of SWMS, work plans and other applicable information

* Control measures will be monitored throughout works:

- Spot checks

- Consultation

- Scheduled audits

- Corrective actions will be recorded and rectified in a timely manner SWMS will be reviewed and updated accordingly (in consultation with relevant persons)

Ensure all controls are reviewed as per the following:

* Controls fail to reduce risk adequately

* When changes to the workplace or work activity occur that create new / different risks where controls may no longer be effective

* New hazards identified

* After an incident involving work activities relevant to this SWMS

* During consultation with relevant persons indicate review is needed

* A Health and Safety Representative (HSR) requests a review in line with the requirements of the legislation. -

Review Number

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

Name & Initials

-

Date

RELEVANT LEGISLATION & CODES OF PRACTICE

State Specific References

-

State in which work is to be conducted:

- Victoria

- New South Wales

- Queensland

- Western Australia

- Tasmania

- Northern Territory

-

Select relevant Legislation and Codes of Practice

- VIC Occupational Health & Safety Act 2004

- VIC Occupational Health and Safety Regulations 2017

- VIC Dangerous Goods Act 1985

- VIC Electricity Safety Act 1998

- VIC Road Safety Act 1986

- VIC Road Safety (Traffic Management) Regulations 2019

- VIC Equal Oppportunity Act 2010

- VIC Equipment (Public Safety) Act1994

- VIC Equipment (Public Safety) Regulations 2017

- VIC Environmental Protection Act 2017

- VIC Heritage Act 2017

- VIC Heritage Regulations 2017

- VIC COP - Onsite Wastewater Management

- VIC CC Confined Spaces

- VIC CC First Aid in the Workplace

- VIC CC Hazardous Manual Handling

- VIC CC Hazardous Substances

- VIC CC Noise

- VIC CC Plant

- VIC CC Prevention of Falls in General Construction

-

Select relevant Legislation and Codes of Practice

- NSW Work Health and Safety Act 2011

- NSW Work Health and Safety Regulation 2011

- NSW Electrical Safety Act 2002

- NSW Electrical Safety Regulation 2013

- NSW Environmental Protection Act 1994

- NSW Environmantal Protection (Air) Policy 2008

- NSW Environmental Protection (Noise) Policy 2008

- NSW Environmental Protection Regulation 2008

- NSW Environmental Protection (Water) Policy 2009

- NSW Public Health Act 2005

- NSW Public Health Regulation 2018

- NSW Managing Noise & Preventing Hearing Loss at Work COP

- NSW Hazardous Manual Tasks COP 2011

- NSW How to Manage Work Health and Safety Risks COP 2011

- NSW Managing Risks of Hazardous Chemicals in Workplace COP

- NSW Managing Risk of Plant in the WOrkplace COP2013

- NSW Managing Risks of Falls at Workplace COP 2011

- NSW Managing the Work Environment and Facilities COP 2011

- NSW Electrical Safety Workplace COP 2013

-

Select relevant Legislation and Codes of Practice

- QLD Work Health and Safety Act 2011

- QLD Work Health and Safety and Other Legislation Amendment Act 2017

- QLD Work Health and Safety Regulation 2011

- QLD Electrical Safety Act 2002

- QLD Electrical Safety Regulation 2013

- QLD Environmental Protection Act 1994

- QLD Environmental Protection (Air) Policy 2008

- QLD Environmental Protection (Noise) Policy 2008

- QLD Environmental Protection Regulation 2008

- QLD Environmental Protection (Water) Policy 2009

- QLD Health Regulations 1996

- QLD Health Act 1937

- QLD Public Health Act 2005

- QLD COP Abrasive Blasting 2013

- QLD COP Confined Spaces 2011

- QLD COP Hazardous Manual Tasks 2011

- QLD COP How to Manage Health and Safety Risks 2011

- QLD COP Managing Noise and Preventing Hearling Loss at Work 2011

- QLD COP Managing Risks of Hazardous Chemicals in the Workplace

- QLD COP Managing Risks of Plant in the Workplace 2013

- QLD COP Managing the Risk of Falls at Workplaces 2011

- QLD COP Managing the Work Environamnet and Facilities 2011

- QLD COP Spray Paining and Powder Coating 2013

- QLD COP Work Health and Safety Consultation, Co-Operation and Co-Ordination 2011

- QLD COP Electical Safety - Managing electrical Riska in the Workplace 2013

- QLD Waste Reduction and Recycling Act 2011

- QLD Waste Reduction and Recycling Regulation 2011

- QLD Heritage Act 1992

- QLD Heritage Regulations 2015

- QLD Aboriginal Cultural Heritage Act 2003

-

Select relevant Legislation and Codes of Practice

- WA Occupational Safety and Health Act 1984

- WA Occupational Safety and Health Regulations 1996

- WA Dangerous Goods Safety Act 2004

- WA Dangerous Goods Safety (General) Regulations2007

- WA Electricity Act 1945

- WA Electricity Regulations 1947

- WA COP for persons working on or near energised electrical installations

- WA Health (Construction Work) Regulations 1973

- WA Environmental Protection Act 1986

- WA Environmental Protection Regulations 1986

- WA COP Abrasive Blasting

- WA COP First Aid Workplace Amenities and PPE

- WA COP High Pressure Water Jetting

- WA COP Managing Noise at Workplace

- WA COP Manual Tasks

- NCOP - Control of Hazardous Substances

- NCOP Inorganic Lead at Work

- WA COP Prevention of Falls at Workplace

- WA COP Spray Painting

- WA Environmental Protection Act 2005

- QLD Environmental Protection Regulations 1987

- QLD Dangerous Goods Safety Act 2004

- QLD Dangerous Goods Safety (General) Regulations 2007

WORKERS LICENCES / COMPETENCIEW/QUALIFICATIONS AND SIGN ON

Overall Risk Rating After Controls

-

Select risk rating

Worker Sign-off

-

This SWMS has been developed in consultation and cooperation with employee/workers and relevant Employer/Persons Conducting Business or Undertaking (PCBU). I have read the above SWMS and I understand its contents. I confirm that I have the skills and training, including relevant certification to conduct the task as described. I agree to comply with safety requirements within this SWMS including risk control measures, safe work instructions and PPE described.

Employee

-

Employee/Worker Name and Signature:

-

Job Role/Position

-

Employer/PCBU/Supervisor:

Licences/Competencies/Qualifications

-

Has the employee/worker completed any training or hold the licences required to complete this task?

-

Licence to Perform High Risk Work (operating certain plant, equipment)

-

Licence details

-

Photo of relevant licences

-

Training Organisation

-

Licence details

-

Photo of relevant licences

-

Construction Induction Card (or equivalent)

-

Licence details

-

Photo of relevant licences

-

Has the worker been provided with:

-

PPE

-

Traffic Management Plan

-

Other

-

Details

Additional Licences / Training

-

Licence details

-

Photo of relevant licences