Job description

-

The purpose of this SWI is to provide sufficient procedure and information for performing planned monthly offline visual inspection for the 4590 portal Air compressors. This procedure applies to the Underground 4590 Portal Air compressors.

4001SURF4590AIRCOM.AC01

4001SURF4590AIRCOM.AC02

4001SURF4590AIRCOM.AC03

4001SURF4590AIRCOM.AC04

Approximately 1 hours. File name: 10000399295 Task #: 325613 Effective date: 09/01/2024 Document owner: UG AM Superintendent, Underground Department: UG Asset Management Please see attached SWI for Underground Air Compressor 4Wk OFF INSPECTION. -

Please read above attached the SWI for Underground Air Compressor 4Wk OFF INSPECTION

Conducted

-

Conducted on

-

Inspected by

-

Work Order number

-

Location

-

Qualification: Mechanics - Trained, competent and authorized for the task.

HEALTH, SAFETY & ENVIRONMENTAL CONSIDERATIONS

Contact with Electricity

-

Contact with Electricity

Please follow below CRM controls

• Electrical Isolation and Lockout

• Verification of Zero Energy

Slip, trip, and falls

-

• A high standard of housekeeping shall be always maintained to prevent trip hazards.

• Be wary while walking around the pumps, motors, and other live equipment as the area might be slippery. -

Use appropriate PPE

Visibility and lightings

-

Use a headlamp or flashlight when working at the pump station

Force

-

• Regular rest

• Use appropriate tools.

• Avoid using brute force.

• Work in a team and ask for help from others -

Maintain good communication

Work instructions

1. PRE-START PREPARATIONS & ISOLATION (MUST FOLLOW C1 ISOLATION PROCESS)

-

1.1 Identify and control the hazards using the TRACK

-

1.2 Prepare material and tools:<br>Ensure that you have the necessary equipment/tools available at the site:<br>- Required Materials<br>- Required PPE<br>- Maintain good housekeeping<br>Proper Inspection of all tools and equipment

2. LOCK OUT, TAG OUT & TRY OUT

-

2.1 Follow the Lock out, Tag out and try out procedures. <br>Inform the supervisor the scope of work and that is about to start.

-

“HOLD POINT”

Leader and team members (Subject Matter Expert - SME) must verify the critical control(s) where a critical risk exists.

3. AIR COMPRESSOR DAILY CHECKS

-

3.1 Step Instruction

-

3.1 Check for leaks: Look for signs of escaping air around connections, hoses.

-

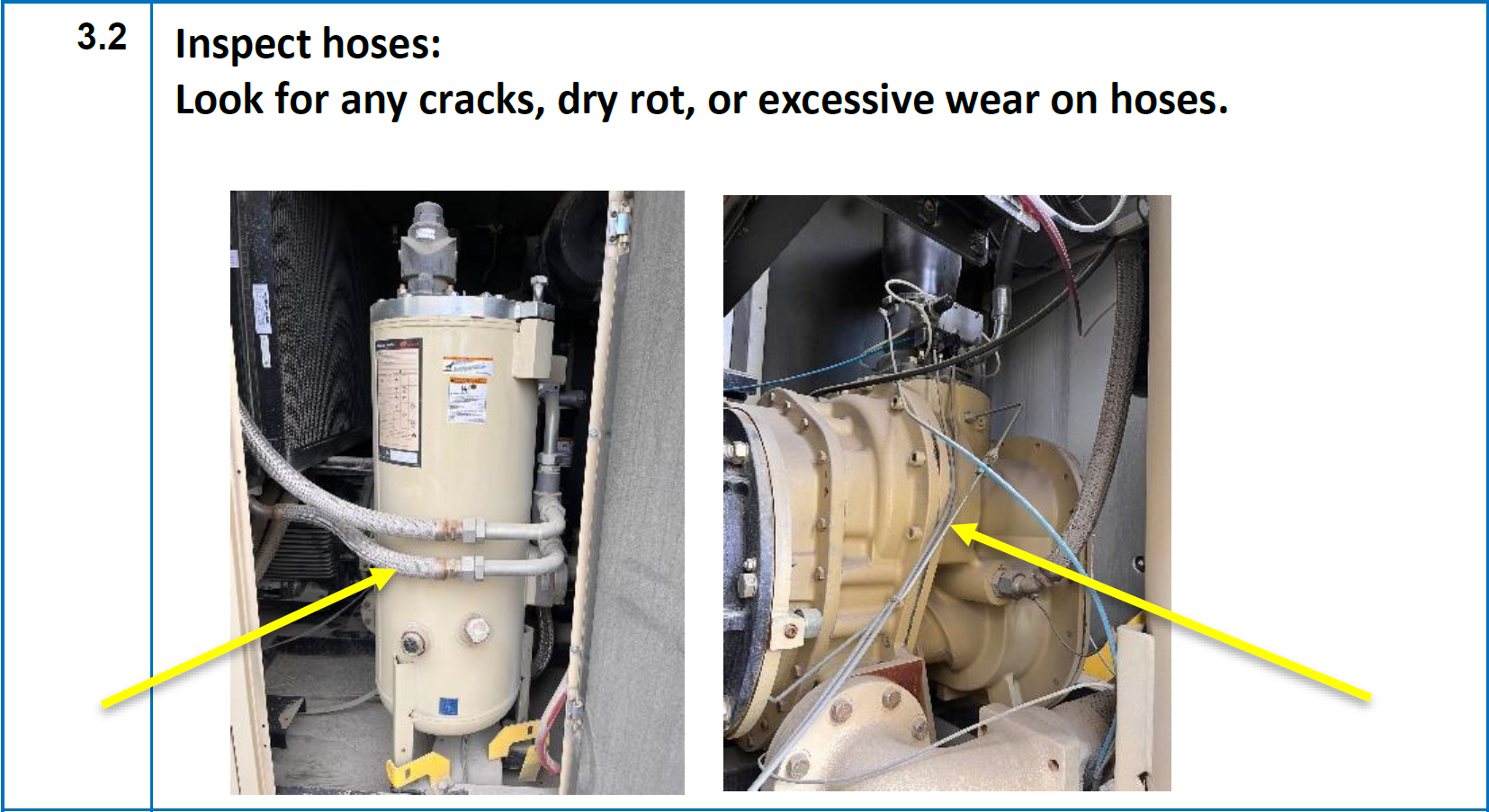

3.2 Step Instruction

-

3.2 Inspect hoses:<br>Look for any cracks, dry rot, or excessive wear on hoses.

-

3.3 Step Instruction

-

3.3 Check Pre-Package Filter for blockage.<br>• Look for any dirt or debris buildup that could restrict airflow.

-

3.4 Tighten loose fasteners: Regularly check and tighten any loose nuts, bolts, or screws on the compressor.

-

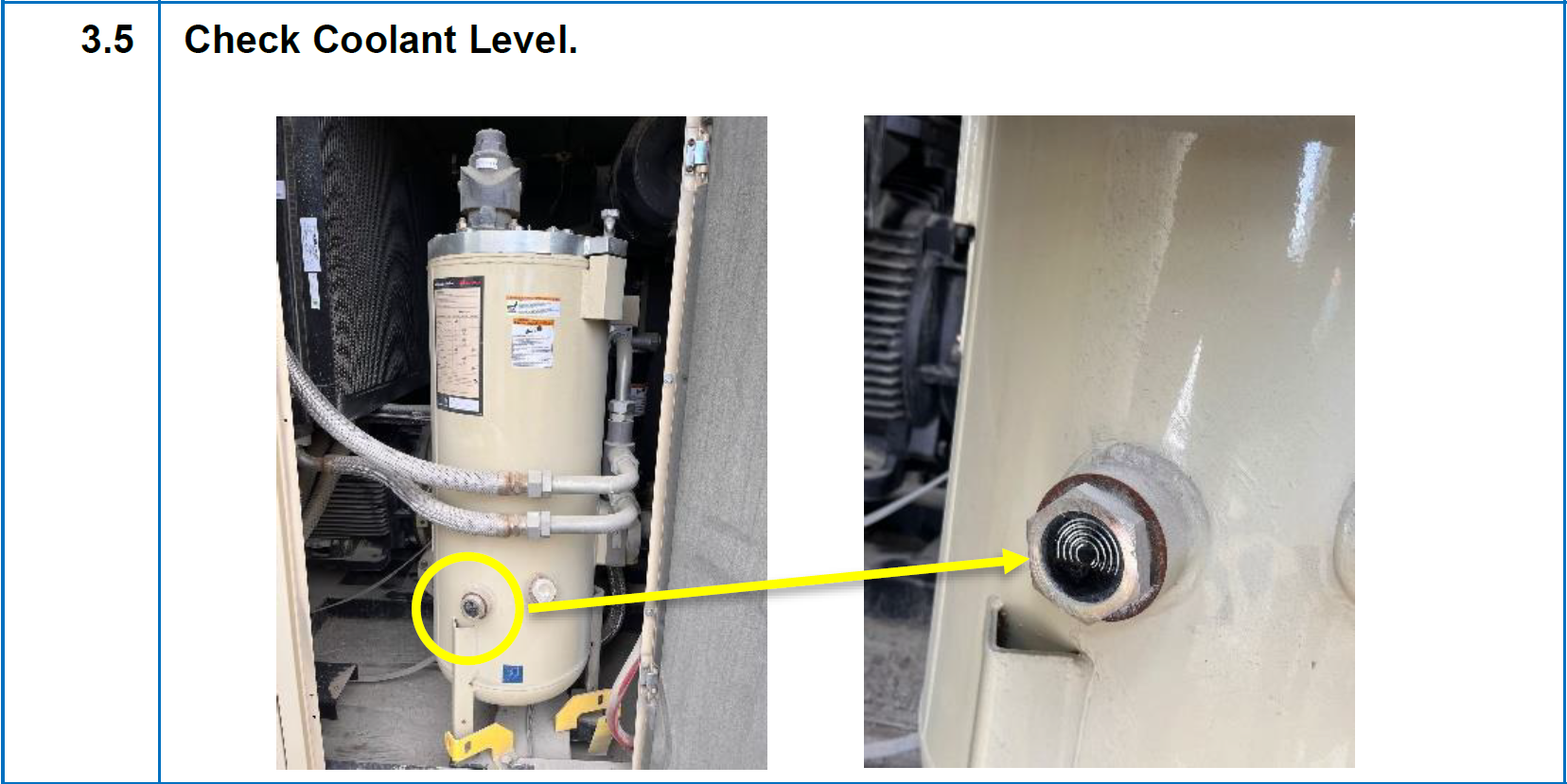

3.5 Step Instruction

-

3.5 Check Coolant Level.

-

3.6 Check Drain Valve operation.

4. PRESSURE READING

-

4.1 Step Instruction

-

4.1 Check the current pressure reading and record it.

-

4.1.1 Average Pressure

-

4.1.2 MIN Pressure

-

4.1.3 MAX Pressure

-

4.3 Capacity (%)

-

4.4 SMU (running hours)

-

4.5 Temperature

5. CONTROLLER INDICATOR

-

5.1 Step Instruction

-

5.1 When indicated by controller:<br>If the Indicator screen shows any warning sign for replacement, Then:<br>Replace Separator Element. <br>• Replace Oil filter.<br>• Replace Air filter. <br>Inform the supervisor ad create notification.

6. TASK COMPLETION

-

6.1 Clean work area of old or used parts.

-

6.2 Return all unused parts to the warehouse.

-

6.3 Clean and return all equipment and supplies to their proper location.

-

6.4 Clean any used specialty tools and return them to their specified location.

-

Caution:

Do not operate the equipment if you have no proper authority (license etc), Inform to operator to operate the equipment. -

6.5 Start the equipment and operate approx. 5-10 minutes to observe any defects.

-

Is the task fully completed?<br>Notify the underground shift supervisor that the 4590 portal Air compressor monthly visual inspections are complete, and it is back in operation.

-

6.6 Report any defects to the supervisors and the planning team.<br>Any repair done must also be recorded.

-

6.7 Please make notes on the document if there are recommendations to improve the work or procedure.

-

ADDITIONAL COMMENTS:

-

Signature