Air Door Inspection SWI

-

The purpose of this SWI is to provide sufficient procedure and information for performing planned OFFLINE mechanical inspections on the Underground air doors. This procedure applies to the Underground power machine door. Approximately 2 hours. Document number: 10000413598 Effective date: 11/01/2024 Document owner: UG AM Superintendent Site name: Kennecott Underground Department: Asset Management

Please see attached the SWI for Underground 4WK Air Door OFFLINE Mechanical Inspection -

Please read above attached the SWI for Underground, 4WK Air Door OFFLINE Mechanical Inspection

Conducted

-

Conducted on

-

Inspected by

-

Inspected by

-

Work Order number

-

Location

-

Qualification: Mechanics - Trained, competent and authorized for the task.

-

Qualification: Operator - Trained, competent and authorized for the task.

-

Required: Lifting equipment

HEALTH, SAFETY & ENVIRONMENTAL CONSIDERATIONS

Contact with Electricity

-

Contact with Electricity

Please follow below CRM controls

• Electrical Isolation and Lockout

• Verification of Zero Energy

Ergonomics

-

Maintain correct body posture while working on the equipment

Pinch points

-

Manual lifting and handling

Pinching fingers between equipment

Please follow below the controls -

Maintain good communication

Slip, trip, and falls

-

• A high standard of housekeeping shall be always maintained to prevent trip hazards.

• Be wary while walking around the pumps, motors, and other live equipment as the area might be slippery. -

Use appropriate PPE

Work instructions

1. PRE-START PREPARATIONS & ISOLATION (MUST FOLLOW C1 ISOLATION PROCESS)

-

1.1 Identify and control the hazards using the TRACK

-

1.2 Prepare material and tools:<br>Ensure that you have the necessary equipment/tools available at the site:<br>- Required Materials<br>- Required PPE<br>- Maintain good housekeeping<br>Proper Inspection of all tools and equipment

2. LOCK OUT, TAG OUT & TRY OUT

-

2.1 Follow the Lock out, tag out and try out procedures. <br>Inform the maintenance supervisor or team lead of the scope of work and that work about to start.

-

“HOLD POINT”

Leader and team members (Subject Matter Expert - SME) must verify the critical control(s) where a critical risk exists.

3. DOOR INSPECTION AND MAINTENANCE

-

3.1 Confirm all door frame bolt (to the ribs, roof & floor) locations are not damaged or missing.

-

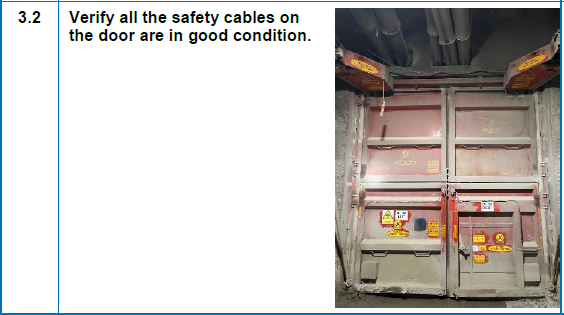

3.2 Step instruction

-

3.2 Verify all the safety cables on the door are in good condition.

-

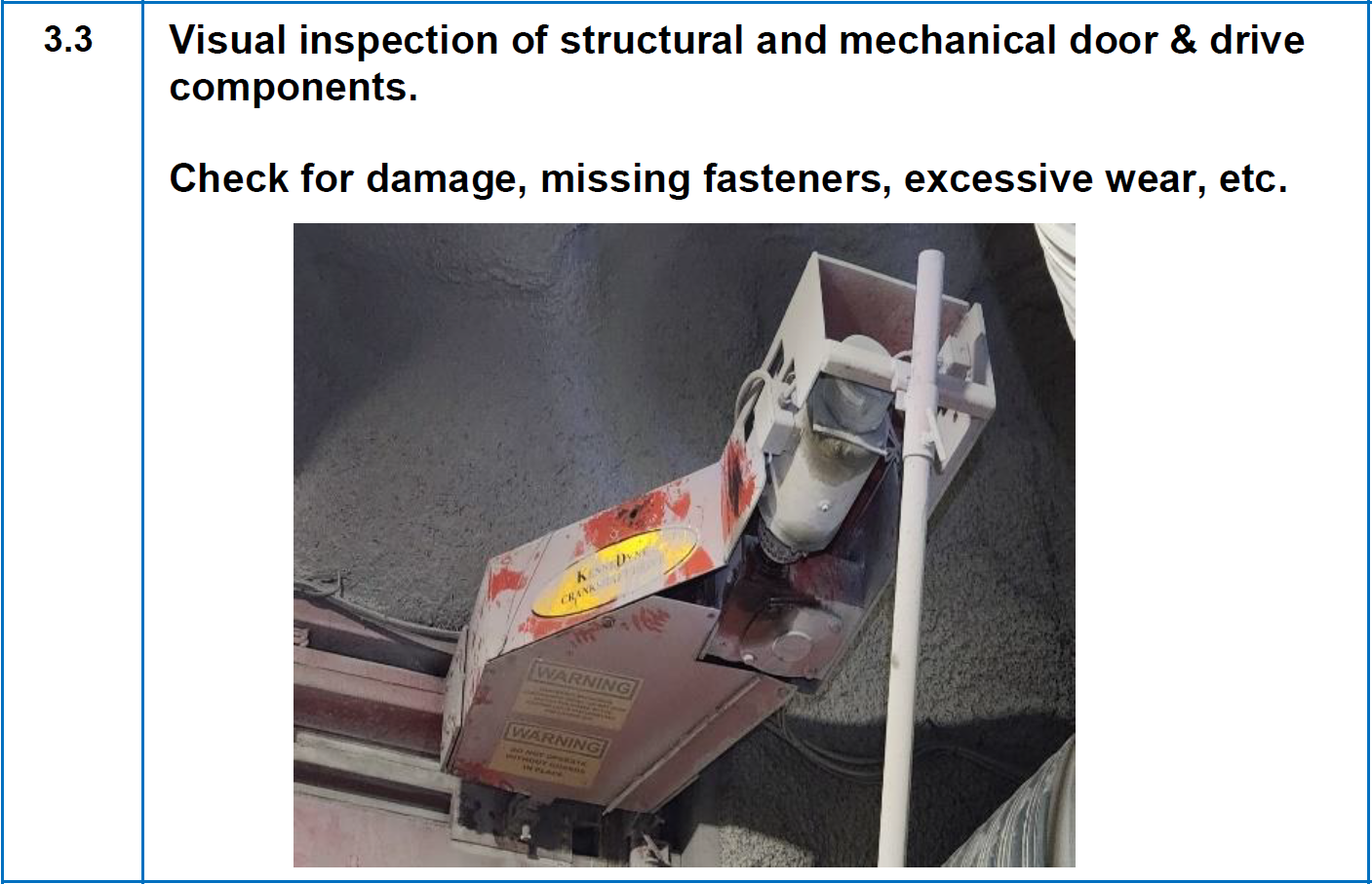

3.3 Step instruction

-

3.3 Visual inspection of structural and mechanical door & drive components.<br>Check for damage, missing fasteners, excessive wear, etc.

-

3.4 Grease door leaf & column hinge knuckles.

-

3.5 Step Instruction

-

3.5 Lubricate the chain with a drying chain or open gear lubricant suited for roller chains.<br>It is imperative that the lubricant used is the type that will dry, completely.

-

3.6 Check the ratcheting chain tensioner on the drive units to make sure it has not reached the end of its stroke. If the Chain and sprockets are worn and needs replacement, please put in a notification for the same.

-

3.7 If it has bottomed out, the chain will need to be tightened. Check step 3.7 for instructions.

4. TASK COMPLETION

-

4.1 Equipment Identification<br>Install any identification tags that may have been removed during head set up.<br>Cleanup area and discard of old parts properly.<br>• Scrub oil or grease on floor.<br>• Wash and squeegee floor.<br>• Crush any canister filters.<br>• Put oily waste in an oily waste dumpster.<br>• Dump trash bins<br>• Other

-

4.2 Replace Removed Items<br>If any covers, identification tags, heat trace, insulation, grounding, grating, handrails or toe kicks were removed in the performance of this job, they must be reinstalled before the job is considered complete.

-

4.3 Clean any used specialty tools and return them to their specified location.

-

4.4 Is the task fully completed? Notify the control room that the Air Door inspection is completed, and it is back in operation.

-

4.5 Report any defects to the supervisors and the planning team. Any repair done must also be recorded.

-

4.6 Please make notes on the document if there are recommendations to improve the work or procedure.

-

ADDITIONAL COMMENTS:

-

Signature

-

Signature