Title Page

-

Site conducted on

-

Conducted on

-

Weekly Checklist

-

Prepared by

Daily Task Schedule

-

Attached is the daily tasks assigned to site staff. Please review when required and sign off that they have been completed

-

Signature

Week Task Schedule

Fire Call Point Checks

-

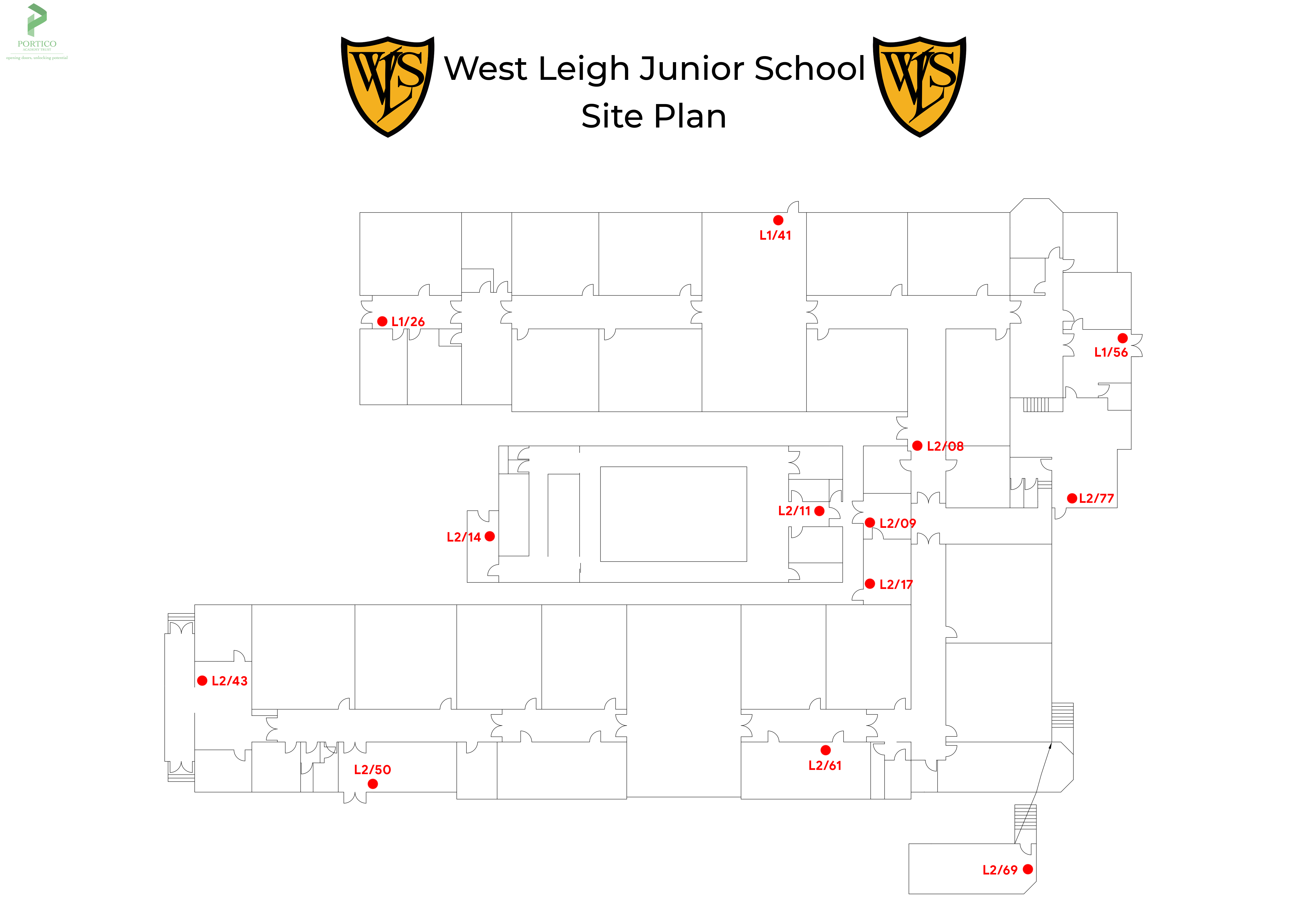

See below attachment for Fire Call Point schedule

-

See below map for all Fire Call Points in the building

-

Test fire alarm call point (minimum 1 point per week)

-

Why did a point not get tested?

-

What point was tested? (Zone and Point, e.g. L2/54)

- L1/56 - Reception

- L2/77 - Staff Room

- L2/69 - Basement (Dungeon)

- L2/08 - Year 4/6 Exit

- L2/09 - Pool Plantroom

- L2/17 - Boiler Plantroom

- L1/11 - Swimming Pool Rear Entrance

- L1/14 - Swimming Pool Front Entrance

- L2/61 - Year 6 Kitchen

- L1/50 -Library

- L2/43 - Year 5 Bag Store

- L1/26 - Outside ICT Suite

- L1/41 - Lower School Hall Exit

-

When was the point completed?

-

Additional points tested?

-

What additional points were tested? (Zone and Point, e.g. L2/54)

- L1/56 - Reception

- L2/77 - Staff Room

- L2/69 - Basement (Dungeon)

- L2/08 - Year 4/6 Exit

- L2/09 - Pool Plantroom

- L2/17 - Boiler Plantroom

- L1/11 - Swimming Pool Rear Entrance

- L1/14 - Swimming Pool Front Entrance

- L2/61 - Year 6 Kitchen

- L1/50 -Library

- L2/43 - Year 5 Bag Store

- L1/26 - Outside ICT Suite

- L1/41 - Lower School Hall Exit

Green Break Glass Checks

-

Main Office

-

Reception Double Doors

-

Staff Room

Disabled WC Emergency Pull Cord Test

-

Pull the cord to sound the alarm, and then reset it from the small panel. If no sound is heard or it cannot be reset, the unit has failed

-

Year 6 Disabled WC

-

Check intruder alarm and report faults

-

Check standard and emergency lights and report faults

-

Check external lighting and report faults

-

Check CCTV system and report faults

-

Inspect boiler pipes, valves, insulation and general surfaces in the boiler house and or individual boilers

-

Check flow and return water temperature for hot water calorifiers (flow temperature should be at least 60⁰C; return temperature should be at least 50⁰C)

-

Run any infrequently used taps and showers to reduce legionella risk for 2 minutes

Internal Climbing Frame

-

Structure - Bending, warping, cracking, loosening, breaking or vandalism

-

Structure

-

Surface - Finish Protective coating missing, rust or other corrosion, cracks

-

Surface

-

Consumable Items such as Chains/Ropes - Missing, bent, broken, loosened, worn, frayed, twisted, open hooks

-

Consumable Items such as Chains/Ropes

-

Fixings - All fixings are secured

-

Fixings

-

Edges - Protrusions, sharp points, sharp edges

-

Edges

-

Pinch or Crush Points - Exposed mechanisms, joints or moving parts

-

Pinch of crush points

-

Guard/Hand, Rails/Swing Barrier - Bending, missing, bent, broken, loosened, worn

-

Guard/Hand Rails/Swing Barrier

-

Welding - Joints (noticeable signs of corrosions/cracks)

-

Welding

-

Access - Missing or broken rungs, steps or treads

-

Access

-

Swing and Other Seats - Missing, damaged or loosened

-

Swing and other seats

-

Foundations - Cracked, loose in the ground, exposed

-

Foundations

-

Trip points - No trip points or obstructions within play zone

-

Trip points

-

Remove weeds from site (rotation basis, front of school one week, rear of school the following week)

-

Ensure mats are cleaned (dry, sweep etc.) under water coolers

-

Check all windows, including window locks and glazing, for damage

-

Check classroom chairs for bottom supports

-

Area checking?

-

Any replacements needed?

-

Conduct a maintenance check of grounds, fences, boundary walls and gates

-

Check fire extinguishers are in position and ready for use

-

Inspect drains, gullies, manhole chambers for blockages. Remove blockages where possible. Report any need for further rodding, jetting or cleaning

-

Remove any leaves or rubbish from the roofs. Inspect flat roofs and report defects and/or damage likely to cause failure in or water ingress