Information

Audit Process- Welding (Supply Chain).

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Comments/ Recommendations:

EPP Mould Change/ Process Workcell Audit

-

Has the shift communication between groups been done? Verify with employee what the daily issues were.

-

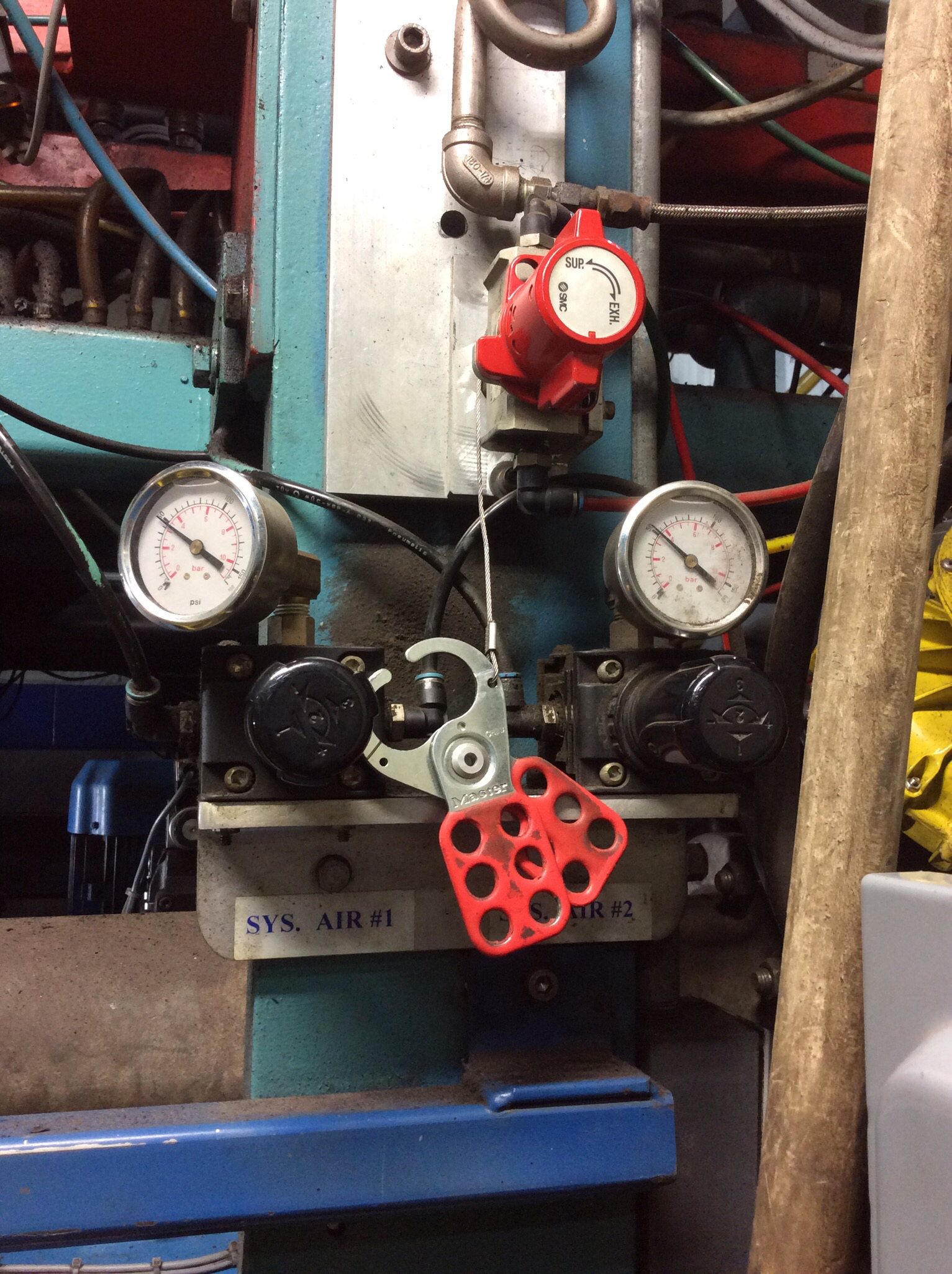

Is the machine locked out? Verify that machines being worked on have a lock belonging to every employee.

-

Are employees wearing proper PPE for groups?

-

Has the hoist inspection form been completed?

-

Is the walkie inspection complete?

-

Are the fillguns connected with correct airlines?

-

Review the machine platform. Is it clean and clear of hazards?

-

Are the safety gates closed and locked?

-

Is the conveyor chain connected? Review and ensure it is connected.

-

Have the fans and lights been turned off? Verify the equipment has been turned off after the mould change is complete.

-

Did the tool change start on time? Verify radio to review the start time (text message)

-

Was the tool ID scanned before the tool was installed? Ask a mould change team member.

-

Has the mould change check sheet been completed? Review form #3154 on Ipad to ensure it is complete.

-

Has the tool inspection sheet been completed in EAM? Check EAM system.

-

Is the TSCP correct on the mould change Ipad?

-

Are the material lines connected with the material? Review the lines to ensure it is connected.

-

Is the program running correct? Review the program on the machine. Ensure the correct program is running.

-

Is the process running to the master? Review the master settings and verify.

-

Is the process checklist complete? Review on process tech Ipad to ensure checklist is complete. Form #4750

-

Are the last off's complete for the tool removed? Verify last off's present.

-

Are the first off's complete for the tool installed? Verify first off's present at press.

-

Signature Teamleader or Designate: