Title Page

-

Conducted on

-

Prepared by

-

FRANCHISEE

-

MARKET

-

Location

-

TECHNICAL FIELD TRAINER

-

FRANCHISE SUPPORT MGR

-

THE WHEEL TORQUE POLICY CHECKLIST

Checklist

WHEEL TORQUE PROCESS

-

When installing wheels, all lug nuts are hand-torqued to manufacturer’s specifications using a calibrated torque wrench. All wheels are then double-checked and signed off by a Buddy after a road test is completed

-

VERIFY TORQUE SPECIFICATIONS

-

Using the Store’s Wheel Torque Chart, verify the correct torque specifications for the vehicle

-

VERIFYING WHEEL TORQUE SPECIFICATIONS

-

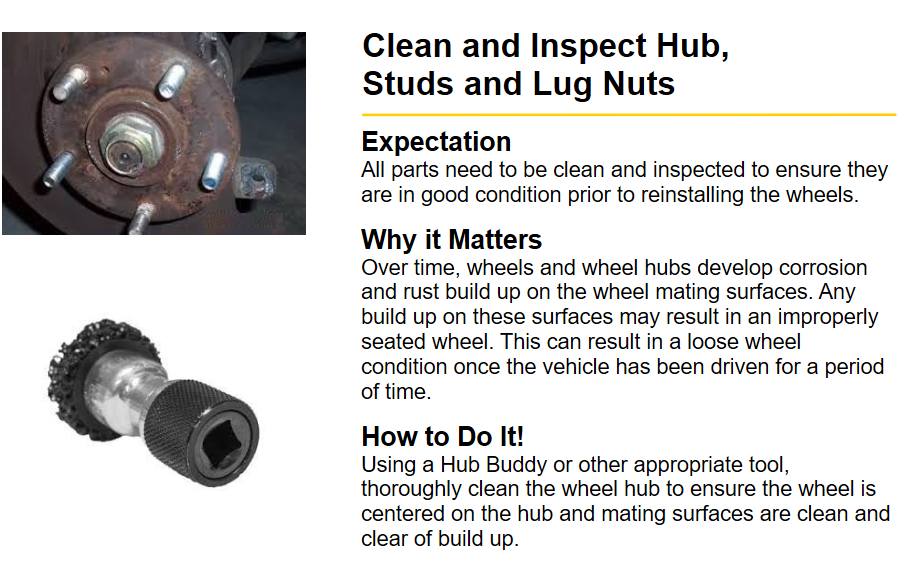

CLEAN & INSPECT HUB, STUDS AND LUG NUTS

-

Clean and inspect all hub, studs, and lug nuts

-

CLEANING & INSPECTING HUBS, STUDS AND LUG NUTS

-

HAND TIGHTENS LUG NUTS

-

Technician places the wheel on the vehicle and hand tightens lug nuts

-

HAND TIGHTENING LUG NUTS

-

TORQUE STICK

-

Technician uses a torque stick identified as the correct one for the vehicle application

-

PROPERLY USING TORQUE STICKS

-

TORQUE WRENCH

-

A Buddy uses a hand torque wrench, tightening lugs in a star pattern

-

PROPERLY USING TORQUE WRENCH

-

TEST DRIVE & RECHECK TORQUE

-

Technician tests drive vehicle and a Buddy rechecks the torque once the vehicle is returned to the Store

-

TEST DRIVING & RECHECKING WHEEL TORQUE

-

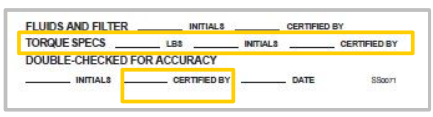

SIGN-OFF

-

Once the wheels are reinstalled, the vehicle is test driven and a Buddy checks that they are properly torqued, both the assigned Technician and Buddy must record and sign-off on the Courtesy Inspection with wheel torque specification used

-

DOUBLE CHECK FOR ACCURACY

-

SIGNING OFF ON DOUBLE CHECK FOR ACCURACY

-

Re-set torque torque wrench to zero and return to proper location

-

TORQUE STICKS AND WRENCHES RETURNED TO PROPER LOCATION

-

STORE MGR

-

SIGN AND ACKNOWLEDGE: WHEEL TORQUE POLICY AND PROCEDURE

-

TRAINER

EMPLOYEE

-

Technician

-

Technician

-

SIGN AND ACKNOWLEDGE: WHEEL TORQUE POLICY AND PROCEDURE