Title Page

-

Site conducted

-

Quality Control Check Name

-

Conducted on

-

Account used

-

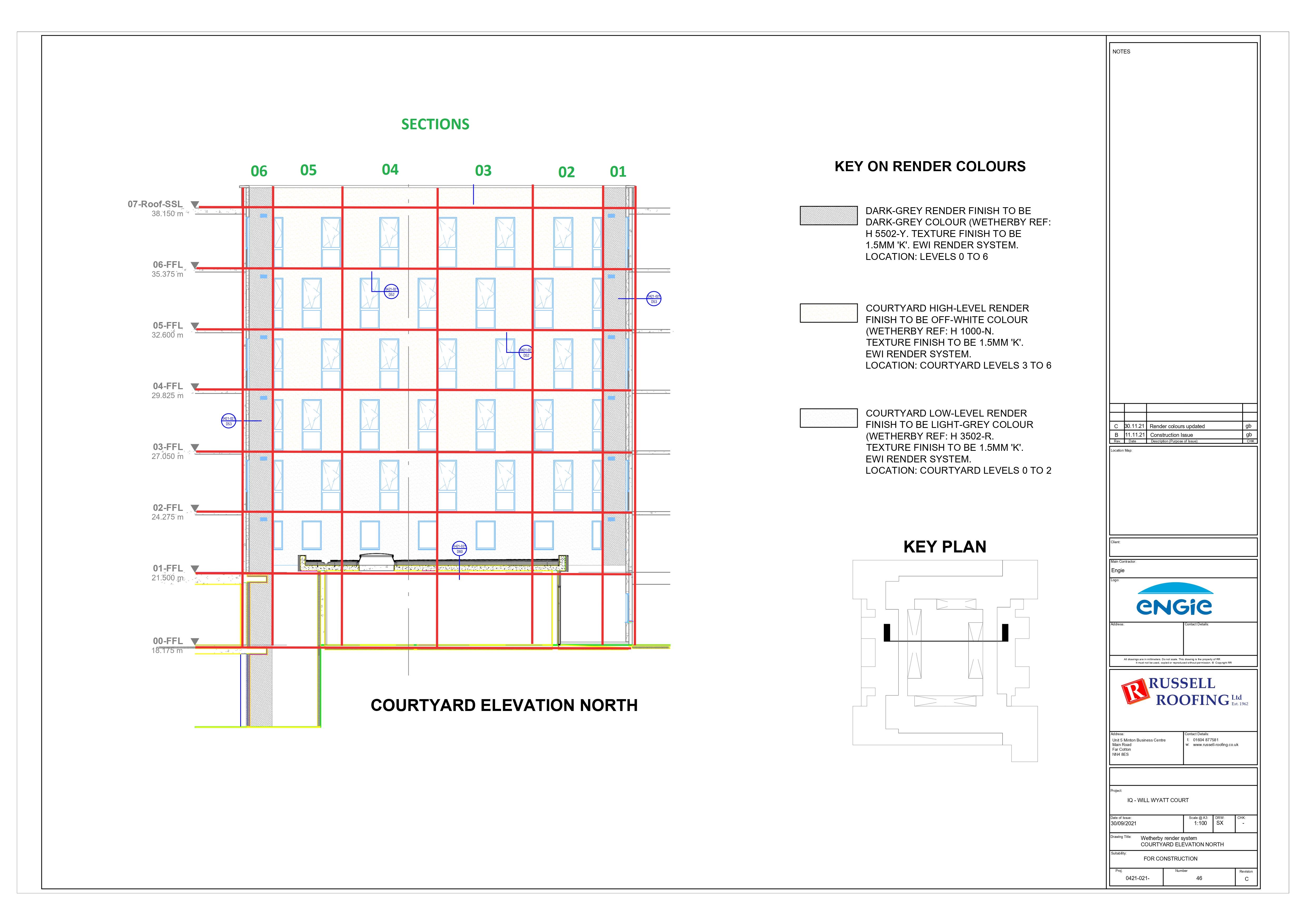

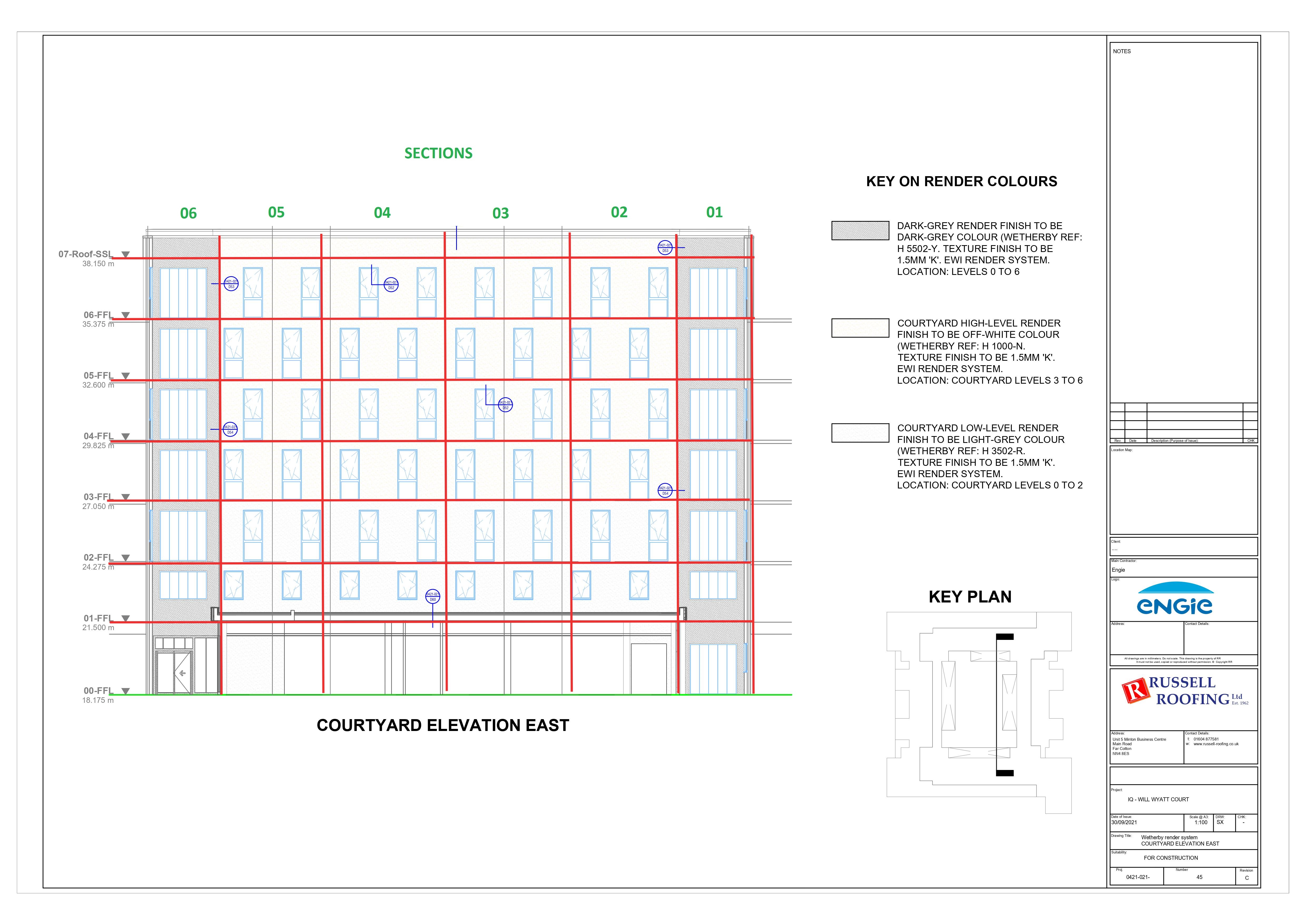

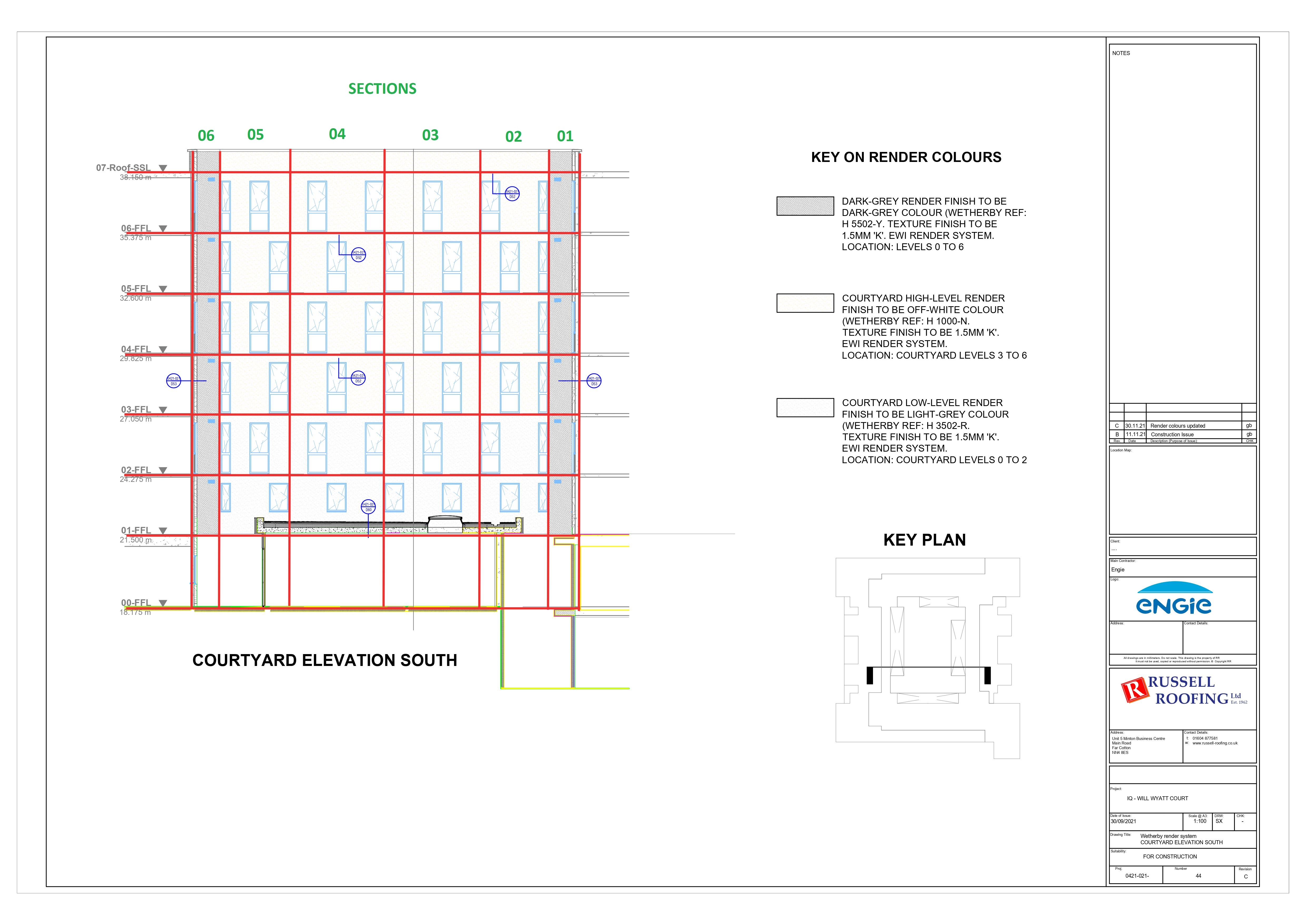

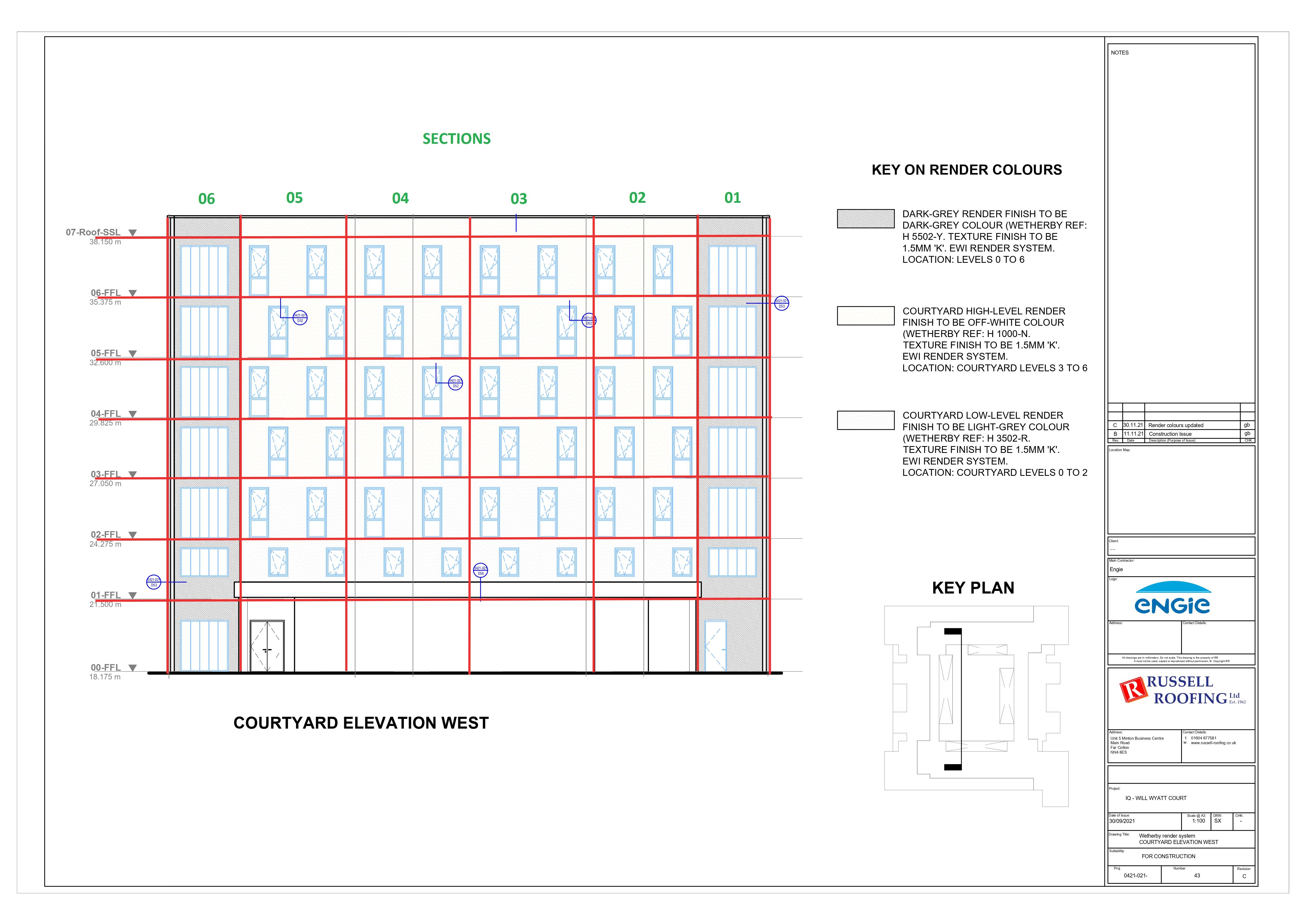

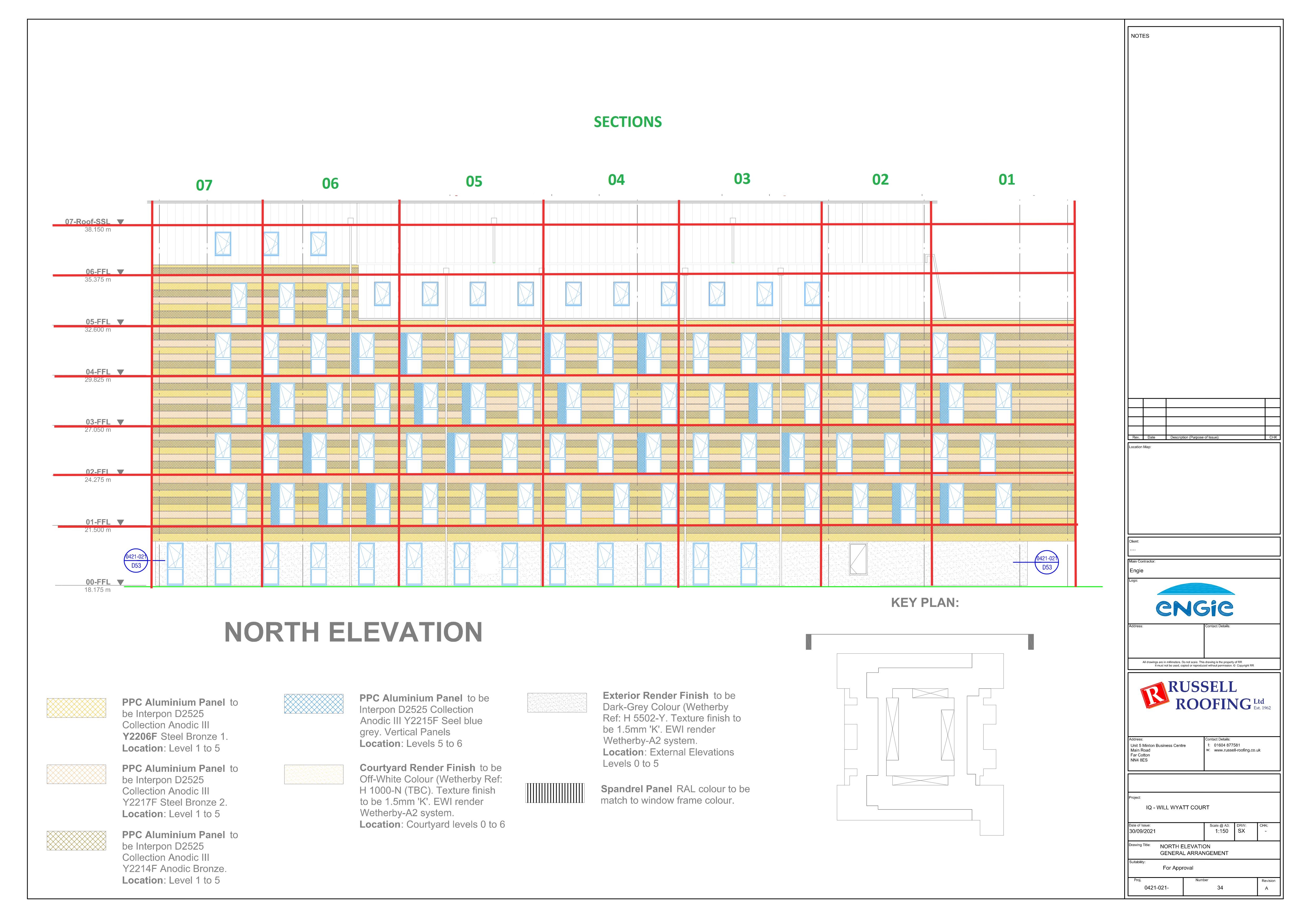

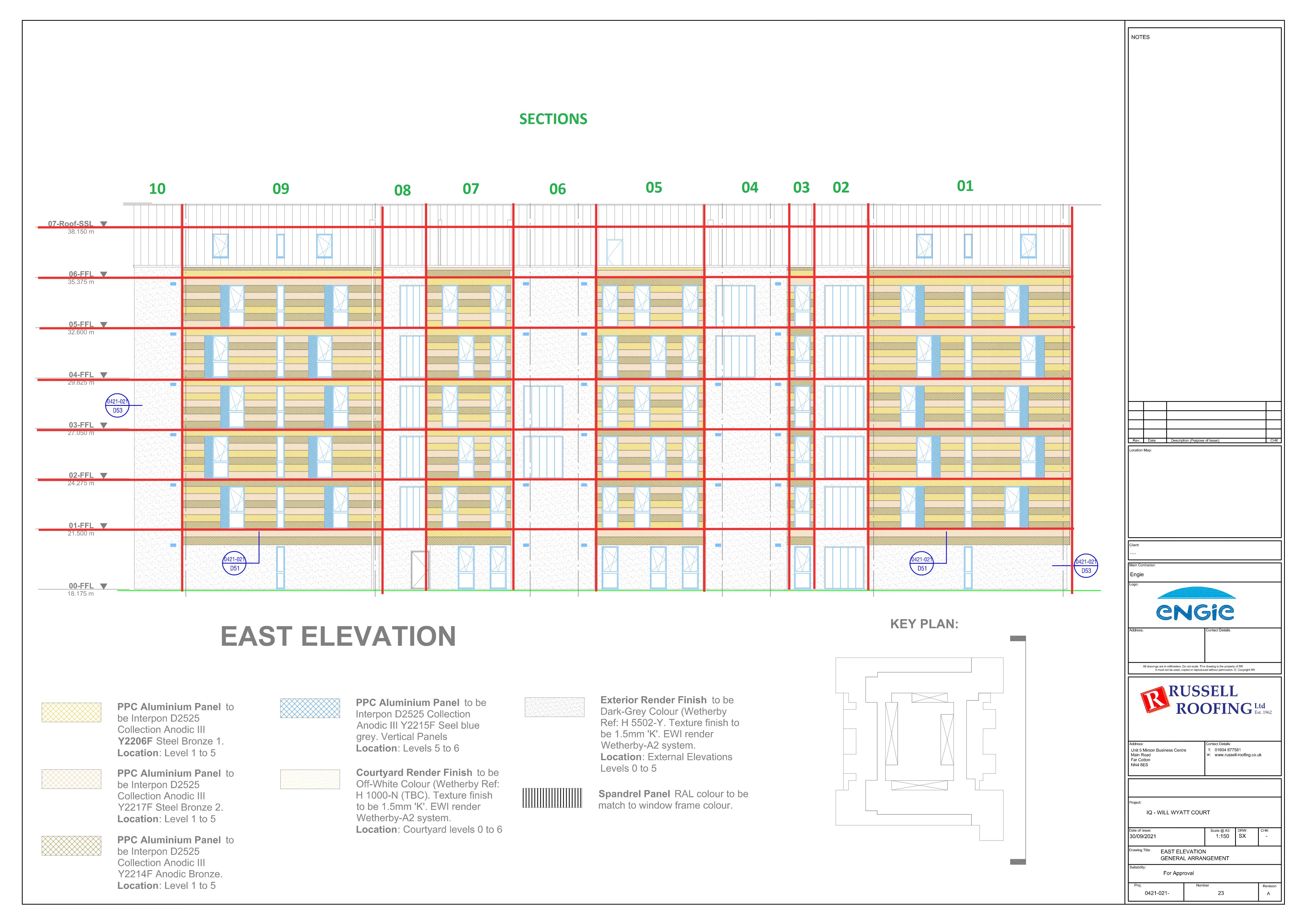

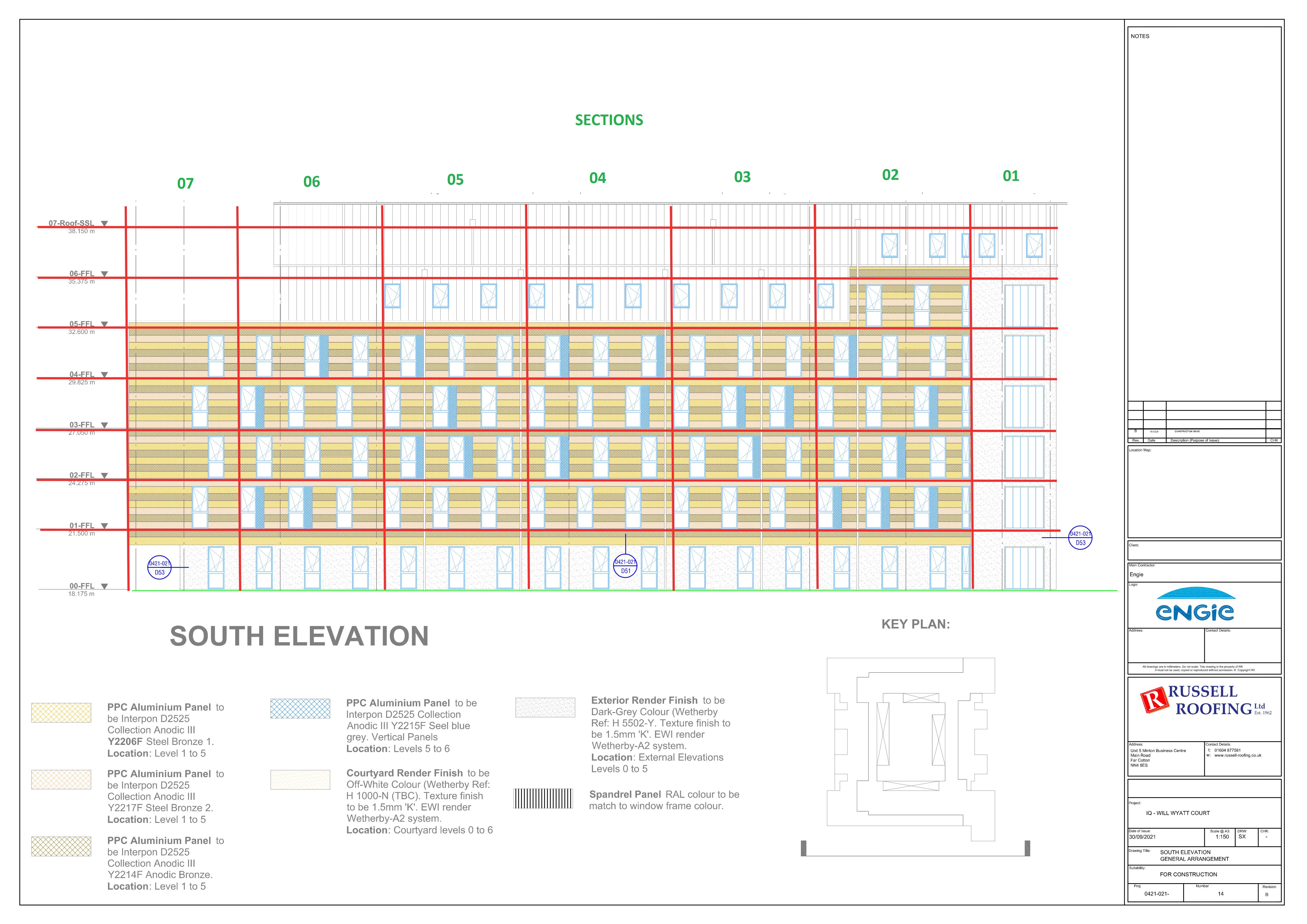

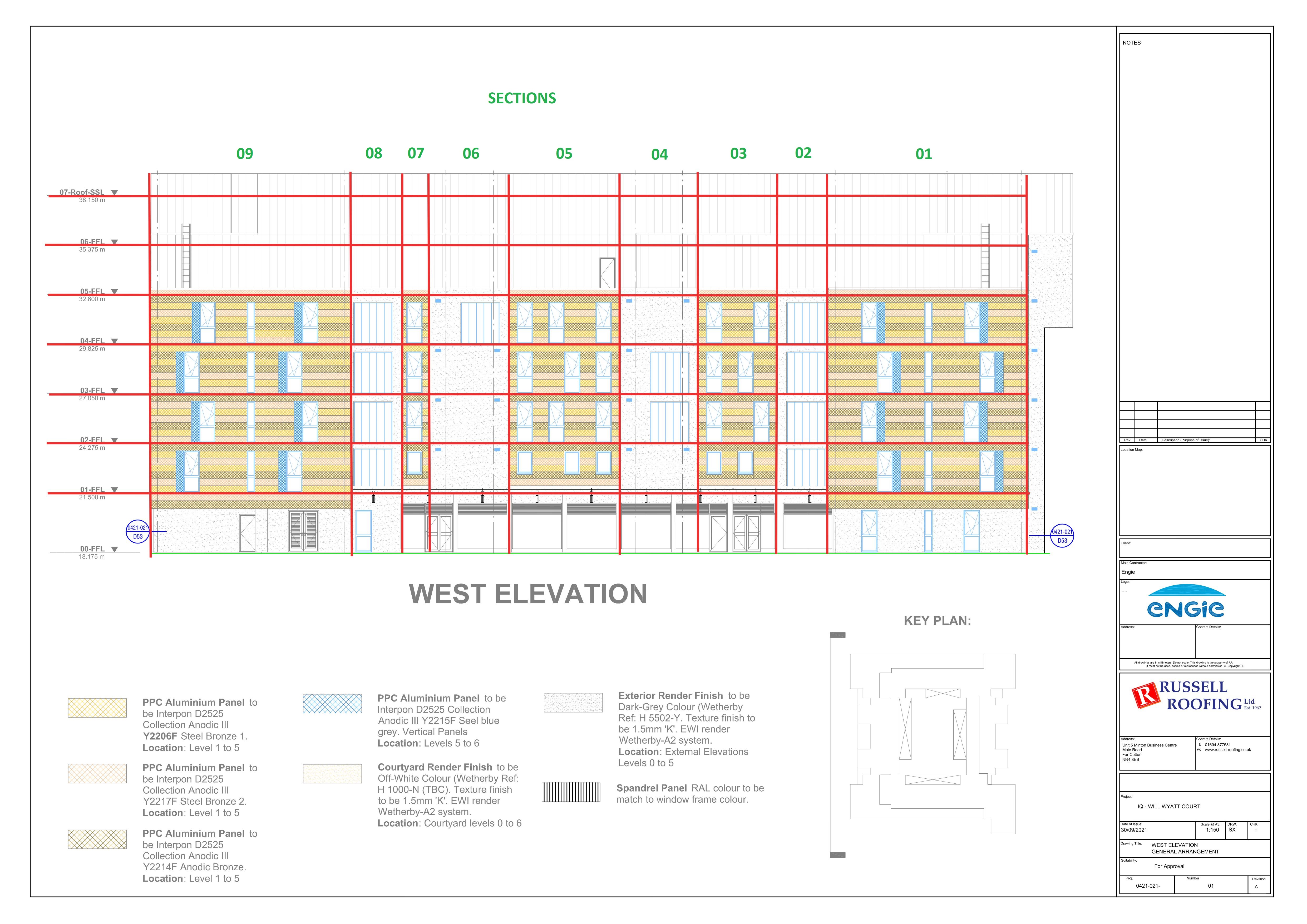

Elevation

-

-

-

-

-

-

-

-

-

Section(s)

Substrate (Panel Areas)

-

Is concrete cleaned and free of foreign objects?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Is the concrete surface fully suitable for proceeding and free from any areas requiring repairs?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

HOLD POINT - AFTER all of this element's works are fully complete and acceptable for this entire scaffold level / Elevation, take photos showing the element as a whole. Do not continue with works or this form until done.

Waterproofing / Sealing / EPDM / Wraptight (Panel Areas)

-

Has the EPDM been installed correctly around window perimeters as per Illbrook recommendations?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Is the wraptight breather membrane sealed at all joints and damage free? reference TS0421-021-01?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Are the wraptight laps at minimum 75mm overlap. Note; less than 75mm then Wraptight tape needs applying?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Has the wraptight at bottom of window/ EPDM been sealed with liquid wraptight?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Has the liquid Wraptight been applied to all penetrations and any holes?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

HOLD POINT - AFTER all of this element's works are fully complete and acceptable for this entire scaffold level / Elevation, take photos showing the element as a whole. Do not continue with works or this form until done.

Brackets

-

Are the Nvelope helping hand brackets installed correct with isolation packer? reference TS0421-021-04

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Are the Nvelope helping hand brackets fitted plum?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Are the correct anchor fixings being used for fixing helping hand brackets? reference TS0421-021-11

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Are the Nvelope helping hand brackets fixed at correct centres? reference TS0421-021-57

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

HOLD POINT - AFTER all of this element's works are fully complete and acceptable for this entire scaffold level / Elevation, take photos showing the element as a whole. Do not continue with works or this form until done.

Rails

-

Have the rail to helping hand brackets been fixed with the correct fixed points and sliding points? reference TS0421-021-57

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Are the vertical rails fitted correctly and plum?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Have the correct fixing been used to fix the rails to the helping hand brackets?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

HOLD POINT - AFTER all of this element's works are fully complete and acceptable for this entire scaffold level / Elevation, take photos showing the element as a whole. Do not continue with works or this form until done.

Cavity Barriers / Siderise

-

Have the vertical barrier brackets been fixed with correct spacings? 2 per unit fixed at 600mm centres 300mm from each end. reference RRL dwg 0421-021-96

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Have the horizontal barrier brackets been fixed with correct spacings? 3no per cut length at 400mm spacings? • Brackets must be installed at 400mm centres based on a 1200mm strip. For lengths ≤800mm 2no brackets must be used, with<br>spacing reduced pro-rata

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Are the barriers tightly abutted?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Has fire rated sealant been applied to any gaps at rear of barriers?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Has foil tape been applied at joints between vertical and horizontal barriers? reference RRL dwg 0421-021-96

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Horizontal barrier - is the required air gap of 25mm correct?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Do all vertical barriers take precedence over horizontal barriers? reference RRL dwg 0421-021-96

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Is the vertical barrier depth correct to allow for 10mm compression?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Has the osci been installed in the correct locations?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Has the osci been installed with foil tape applied to all perimeter edges?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

HOLD POINT - AFTER all of this element's works are fully complete and acceptable for this entire scaffold level / Elevation, take photos showing the element as a whole. Do not continue with works or this form until done.

Insulation / Duoslab

-

Has the correct size/type of insulation been used? reference TS0421-021-07

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Has the insulation been fixed correctly with 1 metal fixing & two polypropylene plates per board? reference RRL DWG 0421-021-72

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Is the insulation installed tightly / are any gaps filled?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

HOLD POINT - AFTER all of this element's works are fully complete and acceptable for this entire scaffold level / Elevation, take photos showing the element as a whole. Do not continue with works or this form until done.

Aluminium Panels and Flashings

-

Have the flashings been installed with fixed drill hole to centre & enlarged holes to remaining fixing points? reference RRL dwg 0421-021- 61

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Have the panels been installed with fixed drill hole to centre & enlarged holes to remaining fixing points? reference RRL dwg 0421-021- 61

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Are the panels / Flashing defect damage free?

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

Are the panel colours correct as per elevation drawings

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

On Completion of fixing the panel, Is the panel is clean and ready for sign-off

-

Please describe the nature of the issue

-

Please confirm the Section in which the issue is located (Refer to elevation plan on title page)

-

Has this now been rectified and reinspected?

-

Please describe what actions were carried out to rectify the issue

-

HOLD POINT - AFTER all of this element's works are fully complete and acceptable for this entire scaffold level / Elevation, take photos showing the element as a whole. Do not continue with works or this form until done.

Completion

-

Are there any other notes relevant to this particular Elevation/Scaffold Level not covered by the previous questions?

-

Are there any other photos relevant to this particular Elevation/Scaffold Level not covered by the previous questions?

-

Sign below to confirm that questions above have been answered truthfully and with all relevant due diligence having been carried out. Please include the person's name.

-

Russell Roofing Signature

-

EQUANS Signature