Title Page

-

Division

-

Department/Outlet

-

Rooms / Areas (if applicable)

-

Date Inspected

Manager

-

Name

-

Position

Person(s) conducting the Inspection

-

Person

-

Name

-

Position

Workplace Heath and Safety Officer

-

Name

-

Position

-

Instructions for completion:

Complete one form.

Complete all areas in the Department/Outlet

Attach additional sheets if required

Set review date to verify identified actions completed

Filing instructions:

Original held at Department/Outlet.

Copy sent to Workplace Health and Safety Department.

General

-

Is the area tidy, clean and well kept?

-

Are all internal lights working correctly? <br>

-

Are all external lights working correctly?

-

Are there enough rubbish bins, and if so have they been emptied recently?

-

Are the general condition of walls, floors, floor coverings and ceilings good?

-

Is the temperature and ventilation appropriate?

-

Are the noise levels acceptable or measures taken where noise levels are excessive?

-

Are warning signs clearly visible and not faded?

-

Are corridors, hallways and stairs kept unobstructed?

-

Are stairs and passageways well lit?

-

Is there good visual contrast at changes in elevation e.g. steps?

-

Are steps in a good condition, including the edges of steps being non-slip?

-

Are handrails or balustrades provided where needed, and if so are they undamaged and safe and secure to use?

-

Are balustrades or handrails free from any nearby climbable objects?

-

Do ladders appear to be legal, compliant and safe to use?

-

Are entrances provided with wet weather mats?

-

Are there warning signs in place where wet or slippery floors were observed?

-

Are smoking areas at least 5 meters from a building entrance with signs displayed?

Emergency

-

Have emergency exit routes been identified and signage is visible?

-

Are emergency exit lights operational?

-

Are fire exits/doors in good condition, operable, unobstructed and not held open?

-

Are fire stairs free of obstructions?

-

Are fire door automatic closing devices operational?

-

Can evidence be presented as to when the last and next emergency evacuation drill was/will be conducted?

-

Are emergency evacuation diagrams, current and clearly visible?

-

Are all fire extinguishers, hose reels and hydrants sign posted and mounted and do they have clearings around them of at least one metre and is access clear?

-

Do all extinguishers, hose reels and hydrants have inspection tags that have been stamped within the last 6 months?

-

Do all hydrants have secure caps?

-

Are all smoke detectors operational and free of obstructions?

-

Have all staff been inducted into the department / outlet emergency evacuation procedures?

-

Have emergency wardens been assigned and trained in your department / outlet?

-

Have emergency alarms been checked and tested?

-

Has the main gas valve been identified, and have appropriate staff been made aware of its location and emergency shut-off procedure?

-

Is emergency equipment readily available e.g. eye wash, chemical spill kit?

Ergonomics

-

Have adequate storage facilities been provided? For example no improvised storage under benches or on floors.

-

Are areas free from obstruction or items sticking out into pathways?

-

Are items that are frequently used easily accessible?

-

If reaching up is necessary, is a step stool or similar device provided?

-

Have adjustable chairs been provided for workstations with a computer?

-

Have ergonomic aids been provided for computer workstations? For example foot rests and document holders.

-

Have lifting and moving devices (eg: trolleys) been provided for tasks requiring heavy manual work?

Electrical

-

Is all electrical equipment in good condition? I.e. no evidence of frayed, torn, broken or loose electrical leads or outlets.

-

Is there a current Test/Tag attached to every item of electrical equipment onsite not protected by an RCD?

-

Are power boards used instead of double adaptors or piggyback plugs?

-

Are leads secured and not potential trip hazards?

-

Are extension leads used only for temporary power?

-

Are liquids, chemicals and gasses stored away from electrical outlets of items?

-

Are all electrical cupboards/rooms/risers locked and free of combustible storage?

-

Are distribution boards sign posted, kept closed, kept free from obstruction and has access been restricted to authorised persons only.

-

Are any electrical leads lead away from areas that could cause damage to the lead, such as hot surfaces and doorways?

-

Are all electrical cords free from direct exposure to water or other liquids?

First Aid

-

Are first-aiders for the area appointed and trained? This may be staff not in your own area but elsewhere in the building.

-

Are the locations of first aid kits labelled, easily visible, easily accessible and known to staff?

-

Has a first aid cabinet caretaker been assigned?

-

Is the first aid cabinet contents regularly checked?

-

Is the contents of first-aid kits complete and within expiry dates?

Personal Protective Equipment (PPE)

-

Is personal protective equipment (PPE) provided where necessary, eg. gloves, face shield, respirators, hearing protection, safety glasses?

-

Is PPE worn when necessary?

-

Have staff been trained in the use, selection and maintenance of PPE? Comment:

-

Is PPE stored and maintained correctly?

-

Is PPE supplied to visitors in hazardous areas, eg. safety glasses?

Plant / Machinery / Equipment

-

Do operators have relevant licences / training for the plant and equipment they are operating?

-

Do operators of plant requiring WHSQ licences have copies on them?

-

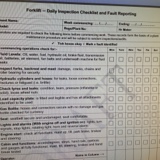

Have pre-starts been completed for all plant and equipment?

-

Have risk assessments been conducted and reviewed within 5 years?

-

Have nip points, v-drives, and chain drives been adequately guarded on machines e.g. compressors?

-

Have quick stops on rotating parts or blades been fitted, and are they in good working order i.e. bench grinders, meat slicers?

-

Are guards adequate for transmissions, gears, pulleys, belts, chain drives, guillotines and presses, etc?

-

Are emergency shut down switches located within easy access of the operator, clearly marked and colour coded?

-

Are fail safe, lock out switches provided where necessary and tested regularly?

-

Are Danger or Isolation tags used during maintenance and repairs?

-

Are hand-tools maintained and stored in good condition?

-

Are operating manuals (or instructions) available?

-

Are air receivers and compressors installed with pressure gauges and relief valves, and are these tested regularly?

Hazardous Chemicals & Dangerous Goods

-

Are there Safety Data Sheets (< 5 years old) for all materials used?

-

Are storage and handling practices in line with the Safety Data Sheets?

-

Do all staff have access to Safety Data Sheets in the area where the chemicals are used?

-

Are chemicals stored in defined areas away from food products or other items that could be contaminated?

-

Is the appropriate type of PPE available for chemicals used?

-

Are all containers with chemicals appropriately labelled?

-

Are chemicals that are taken from bulk storage put in appropriate containers and labelled appropriately? For example food or drink containers are not used to store chemicals.

-

Is absorbent material for chemical spills available?

-

Is the quantity of flammable liquids held for use kept to the minimum possible?

-

Are flammable liquids and other dangerous good stored appropriately and properly segregated?

-

Are there HAZCHEM / warning notices indicating the presence of flammable liquids / dangerous goods?

-

Are compressed air / gas cylinders stored in well ventilated areas and are they properly segregated?

-

Are cylinders adequately secured i.e. individually chained and not accessible to the public?

-

Are empty cylinders stored separately from full cylinders and are they adequately signed?

Staff Amenities

-

Are eating / drinking areas provided away from work areas?

-

Are general kitchen areas kept clean? For example removal of rubbish, cleaning of floors and surfaces.

-

Are storage cupboards and fridges kept clean and tidy?

-

Is there adequate provision of soap, dish cloths and towels?

-

Are appropriate fire extinguishers and fire blankets readily available?

-

Are toilet and washing facilities kept clean and hygienic?

-

Is there adequate provision of soap, hand drying facilities and toilet paper?

-

Are waste containers appropriately stored and correctly labelled? This includes recycling, chemical name/s and dangerous good labels.

-

Are waste bins clean and emptied regularly?

Workplace Kitchen / Catering Areas

-

Are kitchen tools such as knives kept sharp and are they appropriately stored?

-

Are staff appropriately clothed? For example no loose fitting clothing - long hair is confined and closed shoes.

-

Are kitchen utensils kept clean and are they appropriately stored?

-

Is guarding on moving parts adequate?

-

Are hot plates turned off when not in use or left un-supervised?

-

Are combustible materials and chemicals kept at a safe distance from hot surfaces and naked flames?

-

Are spill absorbents available for oil / grease spills?

-

Is there adequate provision of soap and towels?

-

Are range hoods and filters maintained in good condition?

-

Are airflow rates of the range hoods effective and comfortable for staff?

Traffic Management & Parking

-

Is there signage advising vehicles of the speed limits in the workplace?

-

Does the workplace have a documented site specific traffic management plan?

-

Does the workplace have physical barriers separating pedestrians and mobile plant?

-

Does the workplace have signage advising pedestrians where to walk and where not to walk?

-

Are traffic direction markings clearly visible?

-

Are wheel stops, bollards and columns highlighted?

-

Is parking area lighting operational?

-

Are surfaces free from potholes?

Swimming Pool Area

-

Does this location have a pool?

-

Are pool chemicals securely stored?

-

Are any climbable objects located near the pool fence?

-

Is the pool gate handle operating correctly and does the pool gate fully close and latch automatically?

-

Has the pool water been tested within the last week?

-

Are pool rules and CPR signage clearly visible?

-

Are water depth markings clearly visible?

-

Are pool suction fittings and plumbing grates/covers securely in place and in good condition?

Due Diligence

-

Are you a member of an industry body?

-

Do you subscribe to any industry specific publications that include safety issues within your industry?

-

Have you attended any industry training/seminars/professional development courses in the previous 12 months?