Information

-

Hoist number

- Hoist 1

- Hoist 2

- Hoist 3

- Hoist 4

- Hoist 5

- Hoist 6

-

Make and Model

-

Name Of operator conducting inspection

- Ernie

- Vince

- Luke Blackadder

- Brayden Read

- Chris

- Talmon

- Frank

- Ben

- Jon

- Garry

- Luke M

- Greg

- Kevin

-

Conducted on

-

Location

-

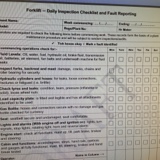

Operators are required to check the following items before commencing work. These records from the basis of a plant maintenance procedure and will be subject to random inspections/audits.

-

Inspect the following items to ensure plant is safe to use.

If plant is defective and determined to be unsafe to use than the operator shall tag-out and report the problem to the workshop or their supervisor for further advice. -

Rating for inspection of plant as follows:

1. Safe to use GREEN

2. Fault detected, but safe to use YELLOW (Note: Do not use if there is risk of harm to worker(s) or plant damage!)

3. Unsafe to use, Tag-out and report RED

1. Plant Checklist

1. CHECK WARNING STICKERS AND COMPLIANCE PLATE

-

2. Operators instruction manual available?

-

3. Compliance plate attached and legible?

-

4. Operating controls clearly displayed?

-

5. Check for any maintenance tags (damage to hoist or switchboard)?

-

6. Emergency shut-off switch is available and functioning correctly?

2. LIFTING EQUIPMENT

-

1. Lifting flexible steel wire cables and sheaves visually inspected for wear or damage?

-

2. Inspect all support lifting arms and adjustment locks for proper operation and damage?

-

3. Inspect rubber pass for wear or damage?

-

4. Inspect up-right safety locking mechanisms for security and working effectively?

-

5. Inspect all moving parts to ensure they are in good condition?

3. HOIST GUARDING

-

1. Inspect all goods are fitted correctly and secure?

4. HYDRAULICS

-

1. Check hydraulic reservoir is full to level indicated?

-

2. Hydraulic cylinders are not leaking and in good condition?

-

3. Hydraulic hoses not damaged or brittle, no loose connections or damaged fittings?<br>Not worn with wire braid exposed?

5. WORK AND LIFTING ZONE

-

1. Check lift area is clear of obstructions before commencing work (Particularly when lifting and lowering vehicles)?

6. DETAILS OF PLANT OPERATOR

-

Name and signature of operator

- Ernie

- Vince

- Luke Blackadder

- Brayden Read

- Chris

- Talmon

- Frank

- Ben

- Jon

- Garry

- Luke M

- Greg

- Kevin

-

Name and signature of operator checking plant