Title Page

-

Disclaimers:

The Specifications below, are to be used as a guide to complete a repair, to provide consistency with the quote procedure. An inspection should be undertaken to confirm full scope of works. The Contractor to confirm the scope of works and advise the relevant Building Surveyor if these works will require.

• Planning application

• Listed Building Consent

• Landlords Consent

A simple check can be made using https://historicengland.org.uk/

** If in doubt please consult Michelle Atkins – Michelle.Atkins@youngs.co.uk – 07811 336472 for clarification and advise the relevant Building Surveyor accordingly.

Asbestos register to be checked and advise relevant Building Surveyor if areas of works are not covered by the register.

• All relevant Permits, Traffic Management and Parking Dispensations are the responsibility of the Contractor:

• All rubbish and redundant materials are to be removed from site on completion of the works & disposed of. Only works detailed in this Report are to be included within your Quote/Estimate

**Any works/recommendations over and above as detailed within this document, should be submitted on a separate Quote/Estimate in the first instance**

Assume all Measurements to be approximate - All measurements should be confirmed by Contractor prior to submitting Quote /Estimate.

ANY SUB-CONTRACTORS USED MUST BE ON THE YOUNGS APPROVED LIST, AND LOG IN AND OUT OF PRONETT AS IF DIRECTLY EMPLOYED -

Site Name

-

Location

-

Date

-

Prepared by

Scope of Works

- Repair

-

Location on Site

-

Description of Repair

-

Specification for Proposed Repair

- Flooring Timber

- Flooring Sanding

- Flooring Carpet

- Flooring Ceramic Tiles

- Flooring Barrier Matting

- Flooring Accommodation Carpet

- Staff Bathrooms & WC's

- Flooring Altro

- Flooring Overlay Resin with Altro

- Internal Decorations

- Plastering

- Damp to Walls

- Cellar Walls & Ceilings

- Cellar Floors

- Cellar Drain Covers & Grates

- Cellar Hatch Doors

- Specialist Finishes (Saniclad)

- Internal Doors

- External Decorations

- External Doors

- Stair Nosings (Painted)

- Stair Nosings (Anti-Slip Edging)

- Sash Window Overhaul & Repair

- Timber WIndows

- Roofing - Pitched Tile/Slate

- Roofing - Flat Roof, 3 Layer Repair/Replacement

- Chimneys

- Pointing

- Timber Fencing

- Service Yard Gates

- External Metal Staircases

- External Timber Staircases

- External Paved Steps

- External Paving

- External Decking

- Car Park Surfaces

- Tarmac Repairs

- Car Park White Lining

- Electrical Works

- Fire Alarm Works

- External Lighting

- Boiler & Water Heater Replacement

- Tree Works

-

Flooring Timber:

Carefully lift defective timber flooring as identified on attached plan drawings/photos, supply and lay new to match existing. Inspect supporting joists and subfloor and carry out any remedial works, to provide sound base for new floor finishes.

Work to include new trims to doorways, upstands, drain covers etc, and all necessary trimming of doors, sanding, staining, and varnishing to match in with existing surfaces. -

Floor Sanding:

Allow to remove, store and refit all furniture, Cover fixed furniture and fixings with protective covering.

Sand and stain/lacquer timber flooring to the areas identified on attached photos/plan drawings.

Layer Seal with one full coat of Junkers ProSeal sealer and apply two full coats of Junkers ProTech clear/coloured lacquer.

Equal approved products should be agreed with relevant Building Surveyor prior to starting work.

All works to be completed outside normal working/trading hours and to be undertaken by experienced, specialist operatives. Care to be taken to use no toxic products and the work areas to be well ventilated during and after the works -

Flooring Carpet:

Allow for moving furniture and equipment for areas of works and refitting on completion.

Lift and dispose of carpet and underlay to identified areas.

Inspect and confirm suitability of subfloor for new covering. Carry out localised screed repairs, remove all projections and refix loose timber flooring as required. Survey and measure to ensure pattern match to adjacent carpets

Supply and lay contract quality carpet on new 42oz Hairfelt underlay, with joint seaming where required.

Allow for new gripper rods and aluminium door thresholds and hatch trims as required

Lay to manufacturer's instructions.

Ease, adjust and trim all doors as required

Make good to all works disturbed

Include site revisit for re-stretch as required -

Flooring Ceramic Tiles:

Allow for moving furniture and equipment for areas of works and refitting on completion.

Carefully take up and clear defective ceramic floor tiles to identified areas.

Cut out and remove all defective substrate and renew with WBP plywood screwed firmly down to subfloor with screws at not less than 300mm centres, to provide sound base.

Provide and lay new brand specification ceramic floor tiles, to existing floor levels, using waterproof adhesive, including waterproof grouting to finish and neat silicon sealant joint to all junctions

Make good to all works disturbed -

Flooring Barrier Matting:

Lift and dispose of barrier matting and underlay to identified areas.

Inspect and confirm suitability of subfloor for new covering.

Carry out localised screed repairs, remove all projections and refix loose timber flooring as required.

Supply and lay new Jaymart, Zigazaga Raw Umber, using waterproof adhesive

allow for jointing trims as required -

Flooring Accomodation Carpets:

Allow for moving furniture and equipment for areas of works and refitting on completion.

Lift and dispose of carpet and underlay to identified areas.

Inspect and confirm suitability of subfloor for new covering. Carry out localised screed repairs, remove all projections and refix loose timber flooring as required. Advise Building Surveyor of any major defects.

Survey and measure to ensure pattern match to adjacent carpets

Supply and fit Underlay to carpet to be 8mm thick PU (polyurethane Rebond), recycled foam 95-100kg/m3.

Supply and fit Felt Backed polypropylene twist carpet, neutral colour as required.

Fixings: Grippers nailed or glued to sub-floor.

New Aluminium door bars to all thresholds

Ease and adjust doors where required. -

Flooring Altro:

** CONFIRM ALL EQUIPMENT IS FULLY OPERATIONAL BEFORE REMOVAL **

Allow to Isolate all gas, electrical and water/waste supplies to kitchen/toilet equipment as required, and remove equipment to storage, in protected area

Carefully strip up and remove all existing floor finish. Make good any defective/damaged subfloor, including plywood, hardboard, and screed base layers.

Reinstate subfloor to original specification, to suit all existing floor levels.

Thoroughly prepare substrate, de-grease and make good to all defects, apply Latex Smoothing compound Ardex ARDITEX Na or similar in accordance with manufacturer’s instructions and lay new Altro Stronghold 30 R12 Dolphin slip resistant 3mm thick flooring, fixed using Altrofix 19 plus, 2-part polyurethane water resistant adhesive.

All joints to be cut in tight and type groove hot welded to match existing colour. To areas marked on the attached plan/photos.

Allow for all necessary detailing works including CF38R/CF20R 100 mm coved skirting to all wall junctions (Where required) include cleanable seal to all adjacent wall and floor finishes.

Replace all metal threshold strips to doorways and floor hatches/drain covers

Replace all kitchen / toilet equipment to original locations and reconnect all services and commission.

Include for all necessary testing of services and equipment following reinstalling into kitchen/toilets following flooring works.

Allow for carrying out this work in continuous shifts. (Including Out of Hours where applicable)

Allow for liaison with General Manager, staff and specialist sub-contractors as required for the completion of the works.

Ease, adjust and trim all doors where required. -

Overlay Resin with Altro

** CONFIRM ALL EQUIPMENT IS FULLY OPERATIONAL BEFORE REMOVAL **

Allow to Isolate all gas, electrical and water/waste supplies to kitchen/toilet equipment as required, and remove equipment to storage, in protected area

De-grease Resin floor using F balls degreasing product using a spinning disk to get a key, followed by using F balls one coat damp proofing membrane

Prime using a P141 primer, only primer that is guaranteed to stick to resin floor

Then lay a N.A. Ardex latex screed

Altro would be installed on top of that, using Altro recommended methods of installation using a F balls water resistant glue

Replace all kitchen / toilet equipment to original locations and reconnect all services and commission.

Include for all necessary testing of services and equipment following reinstalling into kitchen/toilets following flooring works.

Allow for carrying out this work in continuous shifts. (Including Out of Hours where applicable)

Allow for liaison with General Manager, staff and specialist sub-contractors as required for the completion of the works.

Ease, adjust and trim all doors where required -

Internal Decorations:

Provide all necessary plant, labour, and materials to complete the following works out of normal hours.

This is to include all access and health and safety equipment, Provide and display 'wet paint ' and other warning/ information signage as necessary, required for the safe completion of the works.

Protect all adjacent surfaces with dust sheets prior to starting work.

Thoroughly clean down the surfaces to remove all dirt grease and surface contaminants. Remove all blistered, poorly adhering, or otherwise defective coatings. Powdery and friable surface coatings should be completely removed by scraping, brushing, and washing. Allow the surface to fully dry before proceeding.

Where appropriate, rub down sound areas to produce the necessary 'key' for good adhesion and 'feather' broken edges of existing coatings. *Dust off.

Note*When rubbing down dry and/or dusting off wear a suitable face mask to avoid the inhalation of dust.

(See AkzoNobel Decorative Paints UK Site Work Instructions v9 Clause SW4.20 for further information.)

Priming

If surfaces remain powdery and friable after thorough preparation, they must be sealed with 1 coat of Dulux Trade Stain Block Primer.

Prime all sound bare areas and areas exposed by the removal of coatings with 1 coat of Dulux Trade Vinyl Matt of appropriate shade thinned up to 1-part Water to 5 parts of product as appropriate.

Making Good

Make good cracks, holes, and other imperfections with Polycell Trade Easy Sand Interior Filler. Allow such making good to dry out thoroughly. Rub down smooth to match surrounding area and *dust off.

Note*When rubbing down dry and/or dusting off wear a suitable face mask to avoid the inhalation of dust.

(See AkzoNobel Decorative Paints UK Site Work Instructions v9 Clause SW4.20 for further information.)

Finishing System

2 coats of Dulux Trade Vinyl Matt of selected shade.

Ceilings: seal all stained areas with a Zinsser Stain Blocker Paint, then apply two full coats of any of the following white acrylic polymer paints.

• Extreme, Scrubbable Matt, Crown Trade Clean Extreme Eggshell

• Dulux Diamond Matt. Colour: white

Walls: seal all stained areas with a Zinsser Stain Blocker Paint, then apply two full coats of any of the following acrylic polymer paints in colours to match the original.

• Extreme, Scrubbable Matt, Crown Trade Clean Extreme Eggshell

• Dulux Diamond Matt. Colour: white

Metal work: scrape back to firm edge, spot prime and apply one full undercoat and one full finish coat in matching colours.

Woodwork: spot prime and apply one full undercoat and one full finish coat in matching colours.

Varnished and stained surfaces:

Apply two full coats of lacquer or varnish in either clear or stained finish to match existing.

Remove all debris upon completion, wash down adjacent surfaces, and polish all glass and mirrors. -

Plastering:

Provide all necessary plant, labour, and materials to complete the following works out of normal hours. This is to include all access and health and safety equipment required for the safe completion of the works.

Protect all adjacent surfaces with dust sheets prior to starting work.

Hack off defective areas of plasterwork as identified in the drawings or photographs and clear from site.

Thoroughly brush down brickwork and seal with a solution of PVA adhesive and water before applying new two coat sand and cement rendering (to include waterproof additive) to complete area. Return when set and apply a smooth coat of finish plaster. Return when dry and seal with alkaline resisting sealer then decorate with two full coats of emulsion paint to match adjacent colour and finish.

Remove all debris upon completion and clean all adjacent surfaces. -

Damp to Walls:

Investigate cause of damp and resolve by using either of the below methods, to manufacturers specifications.

• Damp Proof Membranes

• Damp Proof Paint

• Cementitious Tanking

• Renovating Plaster

• Liquid Epoxy Damp Proof Membranes

• Anti-Mould Paint

• Anti-Condensation Paint

Remove all surface contamination and loose material from the affected surfaces back to brickwork or substrate to a height of 1m from floor level. Treat areas and restore finishes to match existing. -

Cellar Walls & Ceilings:

Liaise with General manager to provide clear working area.

Allow for decorating walls to cellar/cold room/spirit store. Thoroughly wash down all surfaces, using an approved anti-fungicidal wash, wire brush and scrape back to firm edge.

Prepare, filling minor defects as required, and apply 2 coats of Dulux Cellar Paint in either white or Black. (https://www.tradepaintdirect.co.uk/dulux-trade-mouldshield-cellar-paint.html).

Allow for decorating of ceiling to cellar/cold room/spirit store. Thoroughly wash down all surfaces and wire brush and scrape back to firm edge.

Prepare, filling minor defects as required, and apply 2 coats of Dulux Cellar Paint in white. (https://www.tradepaintdirect.co.uk/dulux-trade-mouldshield-cellar-paint.html). -

Cellar Floors:

Carefully break out defective areas of concrete flooring to cellar and repair with Watco 'Flowpatch' to manufacturers specifications.

All the surfaces must be -10°C or above and free from ice or water. The concrete to be treated must be at least four weeks old, completely dry, and free of contaminants. Grease or oil should be removed with Watco Bio D (or a similar emulsifying de-greasant) and the area thoroughly washed off and allowed to dry.

Priming

Is not usually required, but for open textured, or very porous high suction surfaces, such as sand and cement screed, use Watco Polyaspartic Primer to ensure a uniform finish and to prevent air entrapment bubbles. Watco Polyaspartic Primer should also be used to improve adhesion on smooth (but not power floated) concrete.

Metal – remove any rust or flaking material by disc grinding or wire brushing. Apply the coating immediately after preparation to the clean metal surface. Grease or oil can be removed using Watco Bio-D. Allow the metal to dry before coating

Bare concrete

Remove surface laitance, dust and any light dirt or grease deposits using Watco Etch & Clean. Watco Etch & Clean also etches smooth, bare concrete surfaces to provide a key. Flush with clean water and allow the surface to dry. For the removal of heavier deposits of oil and grease we recommend Watco Concroff®, again, flush with clean water and allow the surface to dry. Apply final coat of Watco Safety Coat Cold Cure to prepared surfaces as per manufacturer’s instructions. -

Cellar Drain Covers/Grates:

Carefully lift out grates to cellar floor drainage and thoroughly clean out channel and wash through prior to replacing. Supply and fit new grates. -

Cellar Hatch Doors:

Provide safety barriers, erect prior to starting work and maintain throughout the works

Carefully remove existing cellar drop doors and clean doors and frame.

Remove all ironmongery and set aside for reuse. Replace any defective sections of timber, ease and adjust as required to suit opening. Sand down all surfaces and apply three full coats of an approved preservative.

Wire brush all painted ironmongery, spot prime, and apply one undercoat and one finish coat in black.

Replace ALL hinges with matching, heavy duty items, and rehang doors.

Test and leave in full working order

Remove barriers and clean area. -

Saniclad Wall Finishes:

Carefully lift defective timber flooring as identified on attached plan drawings/photos, supply and lay new to match existing. Inspect supporting joists and subfloor and carry out any remedial works, to provide sound base for new floor finishes.

Work to include new trims to doorways, upstands, drain covers etc, and all necessary sanding, staining, and varnishing to match in with existing surfaces.

** CONFIRM ALL EQUIPMENT IS FULLY OPERATIONAL BEFORE REMOVAL **

Allow to isolate all gas, electrical and water supplies to kitchen equipment and remove equipment to safe storage.

Carefully remove all loose and broken wall tiles or defective plaster and clear. Repair substrate as required and prepare surfaces to receive white 2mm Saniclad wall cladding.

Allow for removal and replacement of all fittings and fixtures including electrical and gas, water, heating, and waste pipes. Where necessary include for replacement of all support or mounting brackets and clips.

Provide and install 2mm White Saniclad to complete area as specified. This item to include all necessary sealant to all junctions. Joints are to be kept to a minimum and to be made with purpose made Saniclad joining and finishing trims.

All bends and angles to be hot formed from one piece of cladding.

Polish all new work upon completion.

Allow to replace all kitchen equipment to original locations and reconnect all services and earth bonding, commission equipment and leave fully working.

Allow for carrying out this work in continuous shifts including night work.

Allow for liaison with General Manager, staff and specialist sub-contractors as required for the completion of the works.

Include for all necessary testing of services and equipment on completion. -

Internal, Fire door / door repairs:

Overhaul and repair doors and frames as detailed below:

Door repairs (carry out the following work to each door plus any additional items specified below)

Ease and adjust all edges including top and bottom rail to suit frame.

Adjust hanging position to correct uneven joints and to comply with FD30 specification to achieve a maximum gap 3mm

Replacement Door Closer to be Britton 2003 item, and adjusted so door closes correctly

Thumb turn locks to be fitted on staff accommodation and fire exit routes

Replace missing, broken or ‘over painted’ intumescent strips / smoke seals to door or frame.

Fix loose frames, fix loose and missing door stops and adjust lock keeps.

Remove loose beading to vision panels and re-fix to securely retain glass.

** Where required, glazing to be fire resistant, security rated, wire glazed **

Check and tighten all hinges and furniture, including door closers, latches, panic bar sets, and replace missing screws and leave in full working order.

Clear debris from top and bottom retaining holes, replace missing keeps and leave in full working order.

Re-fix loose magnetic door retaining equipment and test release function.

Fire door signage to be fitted as per Fire Risk Assessment

Sand down all surfaces, prime all bare timber and decorate all works disturbed to match existing using one undercoat and one full gloss coat. -

External decorations:

Allow for complete external redecoration to the areas marked on the attached plans and pictures.

Provide all necessary plant, labour, and materials, including all access and health and safety equipment, required for the safe completion of the works.

Areas around entrance and exit doors are to be scheduled for closed periods. Provide and display 'wet paint ' and other warning/ information signage as necessary.

Protect all adjacent surfaces with dust sheets prior to starting work.

Carefully wash / brush down all previously painted surfaces prior to redecoration.

Painted masonry: wire brush all defective areas, repair with sand and cement mortar, seal all loose, friable, and bare areas with 'Dulux Trade Weathershield Stabilising Primer' then apply two full coats of 'Dulux Trade Weathershield Smooth Masonry Paint' in colours to match the original unless directed by the relevant Building Surveyor.

Metal work: scrape back to firm edge, sand down, spot prime and apply one full undercoat and one full gloss finish coat in matching colours.

Woodwork: scrape back to a firm edge, cut out small areas of rotten timber and carefully fill with Permanent Joinery repairs wood filler "www.repair-care.co.uk"

Sand down, spot prime and apply one full undercoat and one full finish coat in matching colours.

NOTE: Larger areas of rotten joinery, to be scarfed in with new matching timber prior to decoration.

Varnished and stained surfaces:

Sand down to a smooth finish and apply two full coats of lacquer or varnish in either clear or stained finish to match existing.

Carefully remove all over painting from glazing, ease and adjust window openings, thoroughly clean all windows upon completion.

Report major defects, discovered during the works, to the relevant Building Surveyor -

External - replace doors:

Provide and hang new hardwood exit doors and frame.

New doors / frame to be purpose made by a specialist joinery workshop and not adapted from pre-made items.

All joints to be wedged mortise and tenon made with Cascamite waterproof adhesive. All glazing to be laminated safety glass retained with hardwood beading.

Sight lines of new doors to match existing but new pair to be uneven widths to provide better access. The exact dimensions to be agreed with the relevant Building Surveyor prior to construction.

Allow the sum of £500 for new door furniture.

Internal decoration to Doors

Carefully sand down all surfaces, prime bare timber and decorate completely all internal surfaces including frame, door panel and apply one undercoat and one gloss coat in original colours.

External decoration to Doors

Spot prime all bare timber and decorate all works disturbed with one undercoat and one gloss coat to match adjacent colours.

Decorate new doors, frame and all works disturbed with three full coats upon completion. -

Stair Nosing’s (Painted):

Carefully prepare and de-grease existing surfaces prior to starting work. Apply Armstead Endurance Anti Slip Floor Paint in White finish to nosing’s with at least 50mm on treads and 50mm on risers -

Stair Nosing’s (Anti-Slip Edgings/Inserts):

Carefully prepare and de-grease existing surfaces prior to starting work. Prepare step edge and fix to full step width www.safetread.co.uk/anti-slip-stair/stair-nosing White nosing’s. Fixed at every 200mm with countersunk screws -

Sash Window Overhaul & Repair:

Carefully remove all staff and parting beads, check condition and replace all damaged items.

Carefully remove sash pockets and set aside, cut sash cords, remove weights, and discard old cords. If sashes are hung on chains, carefully remove, clean, oil and set aside for reuse.

Remove sashes, check joints and glazing. Clamp, glue, and re-wedge all loose mortice and tenon joints, fit metal angle brackets to same and replace all defective putty. Check and oil pulleys fit new sash cords (or refit chains), refit sashes, weights, pockets and beading and leave in full working condition.

Replace all broken and cracked glass.

Replace defective or missing sash fasteners and lifts. Provide and fit restrictors to prevent full opening.

Internal decoration to Windows

Carefully sand down all surfaces, prime bare timber and decorate completely all internal surfaces including box frame, window board and all cover fillets with one undercoat and one gloss coat in original colours.

External decoration to Windows

Spot prime all bare timber and decorate all works disturbed with one undercoat and one gloss coat to match adjacent colours. -

Timber Windows:

Carefully remove rotten timber window frames as indicated on drawings/sketch/photos. Replace with new, timber frames and windows to include.

• Hardwood frames

• Trickle system with insect filter

• Glazed with 24mm double insulated glass units

• Internally glazed

• External white cills,

• Internal trim around frames

• White window boards.

• Frosted glass to match existing windows to bathroom/toilet where applicable.

• all opening windows to have key operated locks/sash stops and fire escape hinges where applicable.

• Sand down, spot prime and apply one full undercoat and one full finish coat in matching colours.

** Where required, glazing to be fire resistant, security rated, wire glazed **

Make good all disturbed internal & external walls/ceilings and decorate to match exiting. -

Roofing Pitched Tile/Slate:

• The Objective of Part L of the Building Regulations 2010 is to reduce the energy use in buildings by at least 25% compared with the 2006 regulations, which themselves were an improvement of 20% over the 2002 regulations.

• The regulations come into effect when 50% or more of the roof area is being refurbished. In simple terms, it means that the whole of that roof must be brought up to the thermal efficiency demanded by the current regulations.

• A strip and re-roof or even just the provision of a new layer of waterproofing, for example when striping and re-felting a flat roof, will usually necessitate the upgrading of the thermal performance of the roof.

• This will, in most refurbishment instances require the provision of additional thermal insulation to achieve an improved thermal efficiency (U value) in accordance with the regulations. If such an upgrade is not technically or functionally feasible or would not achieve a simple payback of 15 years or less, the element should be upgraded to the best standard that can be achieved

Allow for all access/edge protection requirements to complete works in accordance with Principal Safety Regulations.

Carefully remove plain clay/concrete tiles/Slates to pitched roof areas shown and set aside for reuse.

Dispose of all damaged and defective tiles/slates and clear from site.

Remove existing defective roofing battens and dispose of same including de- nailing rafters as required.

Carefully remove the existing flashings from chimney and gable upstand details.

Supply and fit new lead soakers to brick upstands/chimney and supply and fit new lead cover flashings to same including chasing into wall and repointing too same.

Supply and fit new Tyvek or similar breathable roof membrane allowing for overlapping to retained sarking felts.

Supply and mechanically fix new treated timber tile battens of size and profile to match existing.

OPTION - Reinstall salvaged tiles and allow for supplying and fitting new tiles - See Quantity to pitched elevations shown all to match existing.

OPTION - Supply and fit new slates of spec and size to match existing. - See Quantity to pitched elevations shown all to match existing

Sourced matching tiles from local salvage reclamation yards to match existing will be acceptable.

OPTION - Where applicable, all bonnet style hip and ridge tiles to be sourced from local salvage reclamation yards.

Bed and repoint all new/existing verge, hip, valley, and ridge tiles as applicable.

Clean out all adjacent gutters/rainwater goods whilst access equipment is in place - before & after photographs required.

Carry out water testing of repaired areas to confirm watertight repair.

Make good any disturbed/damaged internal areas -

Flat Roof - 3 Layer Repair/Replacement:

• The Objective of Part L of the Building Regulations 2010 is to reduce the energy use in buildings by at least 25% compared with the 2006 regulations, which themselves were an improvement of 20% over the 2002 regulations.

• The regulations come into effect when 50% or more of the roof area is being refurbished. In simple terms, it means that the whole of that roof must be brought up to the thermal efficiency demanded by the current regulations.

• A strip and re-roof or even just the provision of a new layer of waterproofing, for example when striping and re-felting a flat roof, will usually necessitate the upgrading of the thermal performance of the roof.

• Where whole roof replacements are to be undertaken a provisional sum of £5,000 should be allowed for decking – to be advised at time of works and re-measured on completion

This will, in most refurbishment instances require the provision of additional thermal insulation to achieve an improved thermal efficiency (U value) in accordance with the regulations. If such an upgrade is not technically or functionally feasible or would not achieve a simple payback of 15 years or less, the element should be upgraded to the best standard that can be achieved

Allow for all access/edge protection requirements to complete works in accordance with Principal Safety Regulations.

Note - All new feltworks to be installed shall be HP Soprema specification torch on roofing membranes or similar approved

Carefully remove old plant/equipment from site including isolating all electrical/services feeds and stripping back to internal junction box.

Carefully Sweep off existing roof areas shown, include all chippings and general debris and cart away from site.

Strip up all existing roofing felt finishes including verticals, back to existing structural roof decking.

Inspect roof timber and roof sub-structure, report any additional defective materials to the relevant Building Surveyor.

Include for stripping out defective decking in areas shown and cart away from site – See Quantity.

Replace with 18mm exterior quality plywood and treated soft wood firings as required, all mechanically fixed at min 150mm centres.

Reinstate roof structure with improved cut to fall in line with current building regulations relating to insulation etc, and apply for all any planning approvals which may be required to achieve the required U values

Prime completely exposed area of decking with Comar or similar approved bitumous high performance primer treatment Product and allow to dry.

Recover roof with 3-layer hot work works high performance, hot laid VCL layer, 120mm Purboard insulation fixed with PU adhesive, Sopravent Med layer, Soprema 500 Cap Sheet finish. Include for forming all upstand flashing details at any openings/extracts/rainwater outlets and perimeters with minimum 150mm upstand. extending under the ridge tiles where necessary.

Rake out brickwork joint and supply and fit new Code 4 lead cover flashings to all upstand perimeters, including repointing chase to brickwork/render on completion.

Supply and fit designated promenade tile walkways for maintenance to all roof mounted plant.

Clean out all adjacent gutters/rainwater goods whilst access equipment is in place and check for correct sizing -

Before & after photographs required

Carry out water testing of repaired areas to confirm watertight repair.

Make good any disturbed/damaged internal areas -

Chimney:

Raise scaffolding to chimney and carefully take down the top 12 courses of brickwork and clear. Provide new bricks to match existing and rebuild to original design and detail. Carefully point all new work to match original.

Allow 2 square metres of repointing to adjacent brickwork.

Include the sum of £500.00 for replacement of defective lead flashings.

Notify the relevant Building Surveyor scaffolding is erected and liaise re site inspection.

Clean down work area and remove any debris from adjacent gutters and strike scaffolding. -

Pointing:

This item is to include all necessary signage and H&S works required for the safe completion of the works. Liaise with the GM regarding the timing of this work.

Carefully rake out, by hand, all defective pointing to face brickwork to an even depth of 12 mm. Clean down surface area with a brush and clear all debris prior to repointing.

Replace all loose and broken bricks with new or salvaged items to match original.

Carefully repoint with gauged mortar of 6:1:1 mix and finish with a neat joint to match adjacent original brickwork.

Allow all necessary protection of the works during inclement weather.

Clear all debris upon completion. -

Timber Fencing:

Contractor to liaise with General Manage and Neighbours prior to starting works

Remove existing defective/damaged fence panels, gravel boards and posts. Maintaining boundary line and security of demise

Including for clearing any adjacent vegetation or debris as required for the safe completion of the works.

Excavate to a minimum depth of 600mm for posts, set 100mm x 100mm concrete/pressure treated timber post to match existing, using post mix concrete.

Supply and fit pressure treated fencing, installed to suit existing ground levels, and stepped appropriately, on top of 150mm gravel board (if required) to match adjacent and existing type and ground levels. -

Service Yard Gates:

Remove existing yard gates including both posts.

Supply and install new gate Frame timbers to be made of 100 mm x 100 mm pressure treated timber and include a matching head.

Frame posts to extend 600mm below ground and be set in post mix concrete. Making good surfaces on completion.

Provide and hang new pressure treated softwood framed ledged and braced gates with 100mm x 50mm framework and 18mm TG & V cladding.

Sand all surfaces and treat all new works with two coats of dark preservative.

New gates to be hung on 1 -1/2 pairs of 600mm heavy duty reversible hinges.

Provide and fit four number 300 mm black japanned straight barrel bolts two new gates. Fit bolt retaining eyes into concrete base and into head of timber frame.

Provide and fit one number digital entry lock to new gates. If the gates are the final exit from the service yard, push pads and signage to be fitted on both sides of gates -

External Metal Staircase:

Protect all adjacent areas throughout the work, always maintain fire exit routes.

Wire brush entire surface of all external metal fire escape stairs, handrails, and structures to remove rust/debris and loose paint. Report any defects to the Building Surveyor.

Structure and non-tread surfaces

Carefully prepare all previously painted surfaces including structural supports, handrails and underside of all treads and landings, NOT tread surfaces or landings. Spot prime all bare metal with alkaline resisting primer and decorate with one full undercoat and one full finish coat in black gloss.

Decorate all steps, landings and any other areas used as a walkway as follows:

Wire brush entire surface and spot prime any bare metal with 1 coat of Armstead Trade Prime Coat Metal Primer Zinc Phosphate.

Paint all tread surfaces with two coats of Armstead Endurance Anti Slip Floor Paint in Black finish.

Paint edges of all nosing’s, trip hazards or features with a neat contrasting strip of Armstead Endurance Anti Slip Floor Paint in White finish. This is to be 50mm deep on horizontal surface of tread and 50mm deep on vertical surface of tread -

Timber Staircases:

Investigate staircase for loose, damaged treads or risers, lifting any vinyl, carpet, underlay and gripper rods or runners as required.

Remove any handrails/balusters from stair stringers and newel posts. Include removing all fixings.

Remove all damaged stair treads and risers, inspect stair stringers, ensure both are not damaged or rotten and secure to wall with suitable length fixings. Replace like for like as necessary

Install new stringers to the header, the support beam under the outermost side of the landing, using heavy duty galvanised L-brackets and suitable fixing bolts.

Install a 100 x 50mm brace between the stringers for the top step and screw in place.

Fit the new risers to stringers. Using suitable wood glue and nails/screws as appropriate. Fill in the nail/screw holes with coordinating wood putty or filler ready to receive decorations

Set the treads in place Using wood glue to hold each tread in place while inserting three-inch trim head screws to stabilize them permanently. Screw the treads to each stringer, using two screws, one near the front and one near the back, spaced evenly across the width.

Fill in all visible holes on the top of the treads with matching coloured wood putty.

Install the 2No newel posts, top & bottom of stairs and securing with lag bolts.

Where fitted, install new balusters all spaced in accordance with current Building Regs.

Secure new rail fasteners into each newel post using suitable length screws. Set new railing in place. Secure new balusters to new railings -

External Paved Steps:

Lift and re-bed any loose paving, carefully prepare and degrease existing surfaces. Paint edges of all nosing’s, trip hazards or features with a neat contrasting strip of Armstead Endurance Anti Slip Floor Paint in White finish

This is to be 50mm deep on horizontal surface of tread and 50mm deep on vertical surface of tread -

External Paving:

Provide all necessary barriers and safety equipment required to cordon off the work area throughout the duration of the works, maintaining fire exits routes and disabled access. Remove barriers and thoroughly clean area upon completion.

Carefully lift all paving slabs to specified areas and set aside for reuse. Clear all defective, missing, and broken slabs and provide replacement to match existing.

Carry out all necessary repairs to substrate including raising levels to reinstate to original design and falls.

Re-lay paving slabs on minimum 50mm dry mix mortar bed and repoint with sand and cement mortar finish -

External Decking:

Erect safety barriers and signage prior to starting work.

Carefully strip up and clear timber decking/handrails and clear debris.

Inspect structural joists, supporting timbers/handrails and masonry structure supporting the decking and allow for repairs/replacement as required

** For commercial applications, 300mm (12 inches) on centre is the standard **

Treat supporting timbers with preservative and provide and lay new tantalised, minimum 124mm x 25mm timber decking to specified area, localised repairs to match existing width & depth.

Include for fixing with 75mm x 5mm Decking Screws in accordance with the manufacturer’s instructions and all necessary cutting and scribing around features/handrails.

All joints to be staggered

All steps to be fitted with anti-slip white edging strips, fixed every 200mm

For large, decked areas, anti-slip strips to be fitted to alternate decking boards

Clear all debris upon completion.

All works are to be carried out in accordance with the following:

BS 5268-2 Structural use of timber. Code of practice for permissible stress design, materials, and workmanship

BS EN 350-1 Durability of wood and wood-based products.

BS 5395-1:2000: Stairs, Ladders and Walkways. Code of practice for the design, construction and maintenance of straight stairs and winders

BS EN 350-1 Durability of wood and wood-based products -

Car Park Surfaces:

Replace defective tarmac surface wearing course in accordance with the following:

Cut out area of failed tarmac surface forming neat edge and excavate to a depth of 325mm.

Make up using 225mm of type 1 sub-base material and 70mm binder course prior to laying 30mm surface wearing course.

Apply hot pour jointing bitumen to all finished joints.

This item is to include all necessary signage and H&S works required for the safe completion of the works.

Liaise with the GM regarding the timing of this work.

Where the area identified affects any road markings of any kind the contractor shall include for replacing them with highway quality thermoplastic markings to original colour

and detail.

White Lining – Watco Roadmarker/Roadmarker Reflective Thermoplastic as used on Highways. -

Tarmac Repairs:

Replace defective tarmac surface wearing course in accordance with the following:

Break out area of failed tarmac surface and re surface with highway quality Tarmac finish

Where necessary make good to any potholes using 225mm of type 1 sub-base material and 70mm binder course of 28mm DBM prior to laying 30mm surface course.

Form a neat joint with the adjacent areas of tarmac and seal cut edges prior to laying new surfaces. Apply cold pour jointing to all finished joints.

This item is to include all necessary signage and H&S works required for the safe completion of the works. Liaise with the GM regarding the timing of this work.

Where the area identified includes road markings of any kind the contractor shall include for replacing them with Watco Roadmarker/Roadmarker Reflective Thermoplastic as used on Highway to original colour and detail. -

Provide all necessary plant, labour, and materials, including all access and health and safety equipment, and traffic management required for the safe completion of the works.

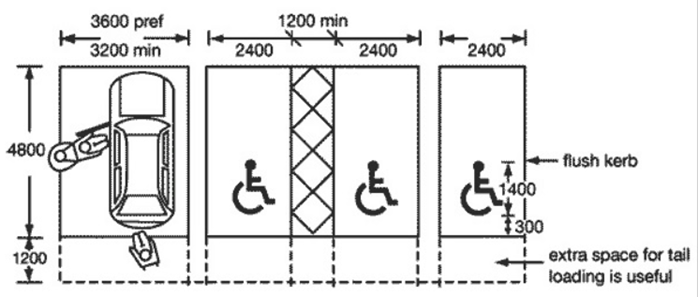

Using Thermal Lance to remove defective lining and prepare the surface to standard parking bays with a minimum size of.

• Standard bay 2.4m W x 4.8m L - White Lining – Watco Roadmarker/Roadmarker Reflective Thermoplastic

• Accessible bay 3.6m W x 6.6m L with 1.2m hatched area between bays, or to side of single bays

Accessible bays to have wheelchair symbol min height 1.4m - Yellow Lining – Watco Roadmarker/Roadmarker Reflective Thermoplastic to Accessible parking bays & hatching

In Gov’s guidelines, it states that 6% of parking should be allocated to disabled parking and gives instructions on how to effectively line and mark these spaces (this is something we specialise in at Designs & Lines).

As a rule, all disabled spaces should be at least 3.6m in width and 6.6m long. The car park markings should be coloured yellow and include a wheelchair icon (or ‘DISABLED ONLY’) to clarify the spot is intended for disabled badge holders.

All markings to satisfy BS EN 1436 (The European standard for road safety markings). -

Electrical Works:

A validation of the inspection of the existing distribution boards is to be carried out prior to installation of any new circuits. MCB/RCBO ratings and cable sizing & type to be checked and confirmed to be correct rating and type for circuit use.

All new installations shall be divided into separately controlled circuits, as required to maintain phase balance and phase distribution within the building, further sub dividing where necessary to ensure compliance with British Standards including earthing and equipotential bonding. Dedicated ‘clean earth’ systems shall be provided to all communications/AV equipment.

Electrical intake cupboards are to be kept clear of any combustible materials, smoke detection must be fitted and fire doors with intumescent strips.

All works to be carried out to current BS7671:2018+A2:2022 (Amendments) 18th Edition IEE Wiring Regulations, by competent personnel.

All warning and voltage signage to be clearly visible on disboards, and intake doors etc. Circuit charts to be updated for new circuits installed.

All relevant Test certificates to be submitted on completion of the works and uploaded to verisae. -

Fire Alarm Works:

Provide all necessary access equipment required for inspection of smoke & heat detector heads.

For all replacement devices, install dates on external sides of detector heads, (back of house only) and panel batteries with indelible pen or Dymo label, for ease of future checking and report any devices over 10 years old to the relevant Building Surveyor.

If a complete system is to be replaced, suitable temporary measures must be put in place to maintain original protection levels and agreed with the relevant Building Surveyor to meet Company H&S Policy.

Where possible identify E.O.L. devices

Mark all multifunction detectors with S = Smoke or H = Heat and date installed.

System to be tested following any replacement of devices, batteries, and/or wiring

All works to be carried out to BS5839-1:2017, and the relevant certificates submitted on completion and uploaded to Pronet -

External Lighting:

Test external lighting to all elevations, pathways, signage, and car park areas. Check time clocks / timers and/or sensor/photocell control functions and adjust as required.

Deflect any floodlights away from neighbouring properties and motorist’s direct line of sight. -

Boiler & Water Heater Replacement:

Carry out a water hardness check for the site to establish is a water softener is required to prolong the life of the equipment

Carry out validation investigation of water heater/boiler to confirm if a total replacement is required and no further repairs can be made to continue full operation of equipment.

A validation checks to be carried out on the Gas meter, pipework sizing, boilers, and water heaters to ensure suitability for maximum demand for installation. The heating (No of radiators to suit area size), hot water (supply and recovery) and all cookline appliances and gas fires on site.

All Gas/Water/Electrical services to be checked and confirmed against manufacturers requirements, to be correct size for any replacement equipment.

Flues to be checked for correct sizing, route, termination and if any high-level access is required.

Check all associated time clocks, controls, pumps, valves, thermostats, expansion vessels, TRV’s, gas interlocks, and/or emergency cut off systems, and pressurisation units to be checked for damage and verified as fully operational and correctly sized.

Ensure plant room has sufficient ventilation.

Boilers to be replaced on like for like basis in relation to KW/BTU output, manufacturer & model, and suitability for system requirements.

Where pipework is to be altered, all dead legs to be removed

Where a Keston boiler is to be replaced, look to replace with a Worcester, Ideal or Valliant equivalent wherever possible, including new frame kit and low loss header.

Water heaters to be replaced on like for like basis in relation to KW/BTU output, manufacturer & model, and suitability for system requirements. Lochinvar, Andrews are preferred manufacturers.

All safety temperature and pressure relief valves to all pressurised and sealed systems, shall be installed with a tundish on discharge with suitable waste pipe i.e., at least one size larger than the valve. The waste pipe shall be routed to drain externally. Where located in a basement or below the natural drainage level, the waste pipe shall be routed to a catch tank, which shall contain a sump pump to remove any discharge to the natural drain.

After the final flushing through of the heating and/or cooling system, a suitable corrosion inhibitor is to be added during the filling of the system. Supply and install a proprietary dosing pot. Supply a certificate to record the dosing chemical, the quantity of chemical installed, the dosing percentage required, and the dosing percentage installed.

A raw flush should be carried out on the heating system unless a power flush is included on manufacturer’s instructions.

CO detector to be installed where required.

Ensure no combustible materials are stored within the plant room, and all redundant pumps, valves, water heaters and boilers etc are removed and disposed of correctly -

Tree Works:

Carry out relevant searches to establish if trees are subject to a Tree Preservation Order or are situated within a Conservation Area.

Quote to include application for consent from the Local Planning Authority before any works commence.

Seek written permission from any neighbouring property for access and works to any trees within their boundary.

All Works to be completed only by NPTC trained and qualified Arboriculture certified operatives, using rope and harness techniques, chainsaws, chippers, and various hand tools where applicable.

Canopy Reduction to previous pollarding points and removal of any dead wood.

If root systems are to be removed, complete tree felling should be carried out, and roots ground back as far as possible to prevent tripping hazards.

Waste will be disposed at a licensed facility unless otherwise specified.

Where possible all wood chippings will be spread along car park boundary borders to reduce waste costs.

With any tree or shrub works, care must be exercised to ensure that no nesting birds are disturbed under the Wildlife and Countryside Act 1981, Countryside and Rights of Way Act 2000 and the European Habitats Directive 1992/Nesting Birds Directive. The ‘Bird Nesting Season’ is from March until August inclusive. If any works are requested to be carried out within these months, perform bird nesting checks prior to the work commencing. If active nests are found, the tree/shrubs must not be worked on and inform the relevant Building Surveyor of this immediately

Tree Felling

Where trees are to be felled their stumps should also be removed to prevent suckering, either by use of a chemical stump killer, physical stump removal or stump grinding to main root plate into fine sawdust to prevent tripping hazards in public areas.

Crown Thinning

This reduces the density of the tree’s crown without changing the overall shape and size of the tree. Thinning reduces the amount of foliage and allows more light through the canopy or crown. The amount of thinning proposed should be specified as a percentage (%) of the leaf area (usually no more than 30%).

This is useful for letting more light into gardens and windows

Crown Lifting

This means removing lower branches to increase the clearance between the ground and the crown. Identify the

branches you wish to remove or specify a height above ground level to which you wish to “lift” the crown.

Useful for allowing more light into gardens Prevents low branches obstructing paths, drives etc.

Crown Reduction

The tree crown is reduced by shortening branches, and so changes the overall size and shape of the tree. Reductions are usually carried out all round the outer parts of the crown to maintain a balanced shape, but seldom should it

include cutting through the main stem.

The amount of reduction proposed should be stated in terms of the intended height and spread of the tree after pruning (rather than what percentage (%) of the overall crown is to be removed).

Partial reduction may be useful for preventing branches contacting buildings, roofs, and guttering

Pollarding or re-pollard

This is a traditional form of tree management and involves the removal of all the branches. It should not be used on large trees that have not previously been pollarded, for large wounds created initiate serious decay in mature and maturing trees. It is not suitable for certain species as very heavy pruning may kill some species while others will be stimulated to produce a proliferation of very dense re-growth of shoots from each wound.

Formative pruning and training Pruning trees when young (formative pruning) may reduce the need for major pruning in middle age and in maturity. The need to prune middle age and mature trees is frequently determined by their position in the landscape. There are occasions when changing land use (e.g., building or highway development) may make extensive pruning necessary.

Crown clean

This is the removal of dead wood, crossing branches and any defective or damaged branches from within the crown for health and safety. -

Staff bathrooms & Toilets

Carefully remove, bath, bath panel, shower cubicle, WC, Cistern, and basin including taps and waste, over bath shower. And replace with specification below as required.

Wash Basin

A fixed impervious, durable, and easily cleansable wash hand basin. It should be provided with a supply of hot and cold water with local isolation. The wash hand basin should be a minimum of 560mm x 430mm and installed with an overflow with all associated wastewater drainage systems and must have a tiled or similar waterproof splash back, with all joints to the wash hand basin being flexible and waterproof.

Bath or shower

A fixed impervious, durable, and easily cleansable bath or shower. It should be provided with a supply of hot and cold water with local isolation. A bath should have minimum dimensions of 1700mm x 700mm, a shower should have minimum dimension of 800mm x 800mm. Both must be installed with all associated wastewater drainage systems and must have a tiled or similar waterproof splash back, with all joints between the unit and surface being flexible and waterproof.

Toilet

A fixed impervious, durable, and easily cleansable toilet that is properly connected to a foul drainage system. With a dual flush cistern (4L & 6L) with local isolation.

Extract Ventilation

In accordance with Approved Document F of the Building Regulations 2006 -

Quantity / Area

-

Photo of Defect

-

Repair Sign Off on Completion

-

undefined

Specialist Surveys

-

Structural Survey Required

-

To carry out a structural survey of the area detailed within this report and indicated on supporting documents

Report to include.

• Observations,

• Recommendations

• Detailed repair specification,

• Fully detailed CAD drawings showing scope of works suitable for contractor quoting purposes.

• Remedial works required

Required Site visits

• Initial site visit

• During works to be agreed

• On completion

• Final Structural Engineer sign off once works are completed to confirm works have been completed as per design, and building is structurally sound. -

Asbestos Survey Required

-

Marked Up Plans / Sketch Showing Areas Requiring Inspection