Information

Information

-

Client:

-

Site:

-

Date:

-

Person Met:

-

Prepared by

Food Hygiene Rating (FHRS):

FHRS

-

Comments on FHRS score

-

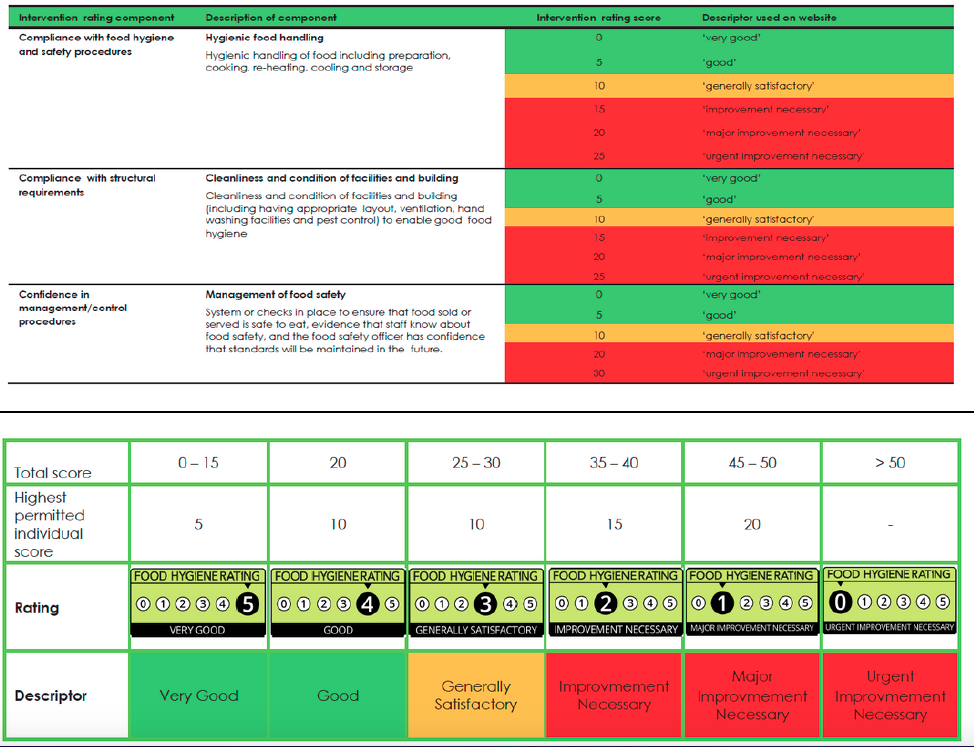

Food Hygiene Rating Score:

- 5 Stars

- 4-Stars

- 3-stars

- 2-stars

- 1-star

- 00-stars

-

0-15

-

20

-

25-30

-

35-40

-

45-50

-

This scoring guide defines the FHRS award that would be expected in the event of a live EHO inspection

-

Compliance with food hygiene and safety procedures: The hygienic handling of food by the Food Business Operator (FBO) in relation to food handling practices and procedures, staff personal hygiene, and effective temperature control. All necessary control measures in place to prevent cross-contamination and safe food preparation, cooking, re-heating, cooling and storage of food demonstrated.

- very good (0)

- good (5)

- generally satisfactory (10)

- improvement necessary (15)

- Major improvement necessary (20)

- Critical Improvement required (25)

-

Preparation and handling of foods (cross contamination):

-

undefined

-

Temperature Control:

-

undefined

-

Personal Hygiene:

-

undefined

-

Compliance with structural requirements: Cleanliness and condition of faciliites and building (including having and appropriate layout, ventilation, handwashing facilites, changing faciliites, effectve waste management, sufficient hot water and pest control) to enable good food hygiene.

- very good (0)

- good (5)

- generally satisfactory (10)

- improvement necessary (15)

- Major improvement necessary (20)

- Critical Improvement required (25)

-

Pest Control:

-

undefined

-

Design and provision of structure and facilities:

-

undefined

-

Cleaning and Hygiene:

-

undefined

-

Confidence with with management and control procedures: The systems or checks in place to ensure that food sold or served is safe to eat, evidence that staff know about food safety, and the food safety officer has confidence that standards will be maintained int he future.

- very good (0)

- good (5)

- generally satisfactory (10)

- improvement necessary (15)

- Major improvement necessary (20)

- Critical Improvement required (25)

-

Food Safety Management Systems (FSMS), Due Diligence and implementation:

-

undefined

-

Food Safety Training:

-

undefined

Food safety:

-

Food Safety: comments or observations that affect food safety at the restaurant?

FOOD SAFETY

1.0 CONTAMINATION CONTROLS

-

1.1 Is separation of RAW and RTE foods in the kitchen adequate to control microbial contamination risks and are probe wipes available and do staff know how to use and disinfect?

-

1.2 Is food handled correctly to minimise the risk of contamination and no foods exposed to excessive risk of contamination (Ph, Ch, Mb or All)?

-

1.3 Is the separation of known allergens (14 Major) adequate?

2.0 HACCP FOOD SAFETY MANAGEMENT

-

A spot check of all documented DD information and a visual check of procedures and practices.

-

2.1 All food safety control records maintained correctly and in a consistent manner. The records are stored in an orderly manner for monitoring purposes, to ensure that all CCP's adequately controlled to offer an effective due diligence defence and Is there an approved supplier list on site?

-

Documents viewed:

-

2.2 Is there an up-to date and verified modular / product specific HACCP plan representative of the operation and products on offer?

-

Documents Viewed

-

2.3 All food businesses must have an Allergen Management System (AMS) that controls risk from allergen in the business especially 14 Major allergens. The AMS should included the Caterer HACCP, Allergen Risk Assessment• Practical Allergen Management• Allergen Communication.

-

Allergen Procedures:

3.0 CLEANING AND DISINFECTION

-

3.1 All all parts of the structure of the food preparation area, tables, equipment, and ancillary areas maintained in a clean condition?

-

3.2 All food preparation equipment is stored and maintained in a clean hygienic condition and fit for purpose?

-

3.3 The Pot-wash area and dishwasher / area is clean, clear segregation between clean and dirty equipment, All cleaning equipment is stored and maintained in a clean hygienic condition, sufficient hot water and sanitiser ?

4.0 PEST MANAGEMENT

-

Uncontrolled Pest infestation is a significant cause of restaurant closure, it is vital that pest issues are managed correctly

-

4.1 Are the premises free from infestation and from any visible signs of pests, have they been spotted and are pest issues suitably managed on site, have the recommendations on the pest control report been actioned. Are there sufficient EFK's provided and sited correctly and are subject to a planned maintenance and cleaning?

5.0 PERSONAL HYGIENE

-

Are team members changing gloves, washing hands, working in a safe manner to ensure that all food is produced to the safest and highest standard. WHB to be stocked with liquid antibacterial soap, Hot and cold water and drying facilities - suitable signage to be provided. Not consuming food or drink in kitchen.

http://www.food.gov.uk/sites/default/files/multimedia/pdfs/publication/fitnesstoworkguide09v3.pdf -

5.1 Are hand wash facilities sufficient, fully stocked with supplies and operating at an approximate temperature of between 40°C and 45°C? and are team members using the Wash hand-basin (WHB) effectively?

-

5.2 Are the personal habits of all team members suitable and sufficient at time of audit are they following the personal hygiene rules not picking at food or 'double dipping'. It is advised that disposable gloves are used for the direct handling of ‘ready to eat’ foods, If gloves are worn they must not be overused or misused in a manner to cause cross-contamination?

-

5.3 Are all kitchen personnel (food handlers) complying with the company policy on uniform, jewellery, hats and suitably coloured plasters?

6.0 WASTE AND REFUSE

-

6.1 Internal Storage: refuse is stored in a hygienic manner in the catering areas, storage bins are suitable and/or fitted with foot operated lids as required?

-

6.2 Housekeeping: The refuse is regularly removed from the catering areas so that no unacceptable build-up of refuse occurs?

-

6.3 External Storage: refuse is stored in bins fitted with a lid. The storage area is generally clean and tidy with no spillages or overflows of refuse likely to attract pests?

7.0 FOOD PREMISES DESIGN, CONSTRUCTION AND EQUIPMENT

-

The site shall be of suitable size, location, construction and design to enable the production of safe and legal products. It shall be suitably maintained and controlled to ensure that conditions hazardous to food safety (e.g. pest infestation) do not occur.

-

7.1 All structural surfaces are in good repair and comply with the requirements of food safety legislation. Ceilings, walls, doors and windows are sound and in good repair. All preparation and work surfaces are smooth, impervious?

-

7.2 Adequate standards of lighting are provided to all work areas. All light fittings are correctly designed and in good repair. Are light diffuser covers fitted in food preparation areas?

-

7.3 Adequate ventilation is provided to the kitchen areas to ensure a comfortable and safe working environment. The optimum temperature for comfort within a catering establishment should be 19°C to 23°C.

8.0 STORAGE AND LABELLING

-

All food must be stored at the correct temperature and labelled with the correct 'use-by' or 'best-before' date to meet both legal and company requirements.

-

8.1 Are all items suitably stored under the right conditions, labelled and dated in the fridge?

-

8.2 Are all items suitably stored, labelled and dated the freezer?

-

8.3 Are all items suitably stored, labelled and dated in the dry stores. The area is orderly with sufficient storage space and no foodstuffs stored on the floor. Opened packages are correctly protected within suitable containers. Is all food is adequately covered and protected from contamination during storage?

-

8.4 Good stock rotation is evident with the F.I.F.O. system being operated and no out of date foods being identified (following 3-day rule unless authorised)?

9.0 FOOD SAFETY ISSUES NOTED AT SITE

-

Food Safety Issue No.

-

undefined

-

Identify food safety issue:

FOH:

-

Front of House: Comments that affect FOH and the safe service of drinks.

10.0 FRONT OF HOUSE (FOH) CAFE AND BAR SERVICES

-

10.1 Are all areas of the bar and front of house area clean and tidy?

-

10.2 Are the controls in place suitable for the safe serving of ice (is the ice machine clean and suitable for the operation are scoops stored in clean containers)?

Training:

11.0 COMPLIANCE TRAINING

-

Comments on training:

FOOD SAFETY TRAINING

-

11.1 As a minimum has the General Manager and Head Chef achieved appropriate food safety training having achieved 'Level 3' within a reasonable period. Have staff have received appropriate food safety training with high risk food handlers trained to 'Level 2', within the required 3-month period??

-

11.2 Have on the spot knowledge checking questions been answered satisfactorily (are staff aware of the allergen controls in place, asking customers do they have any allergens and location of allergen information)?

Swab Testing:

-

ATP is an organic chemical and used as a hygiene indicator . A failed swab test result will affect the score for either cleaning (structure/equipment) or personal hygiene (hands).

PERSON OR EQUIPMENT TESTED

-

SWAB TEST RESULTS

SWABBING

-

Person or Equipment

-

RLU result