Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

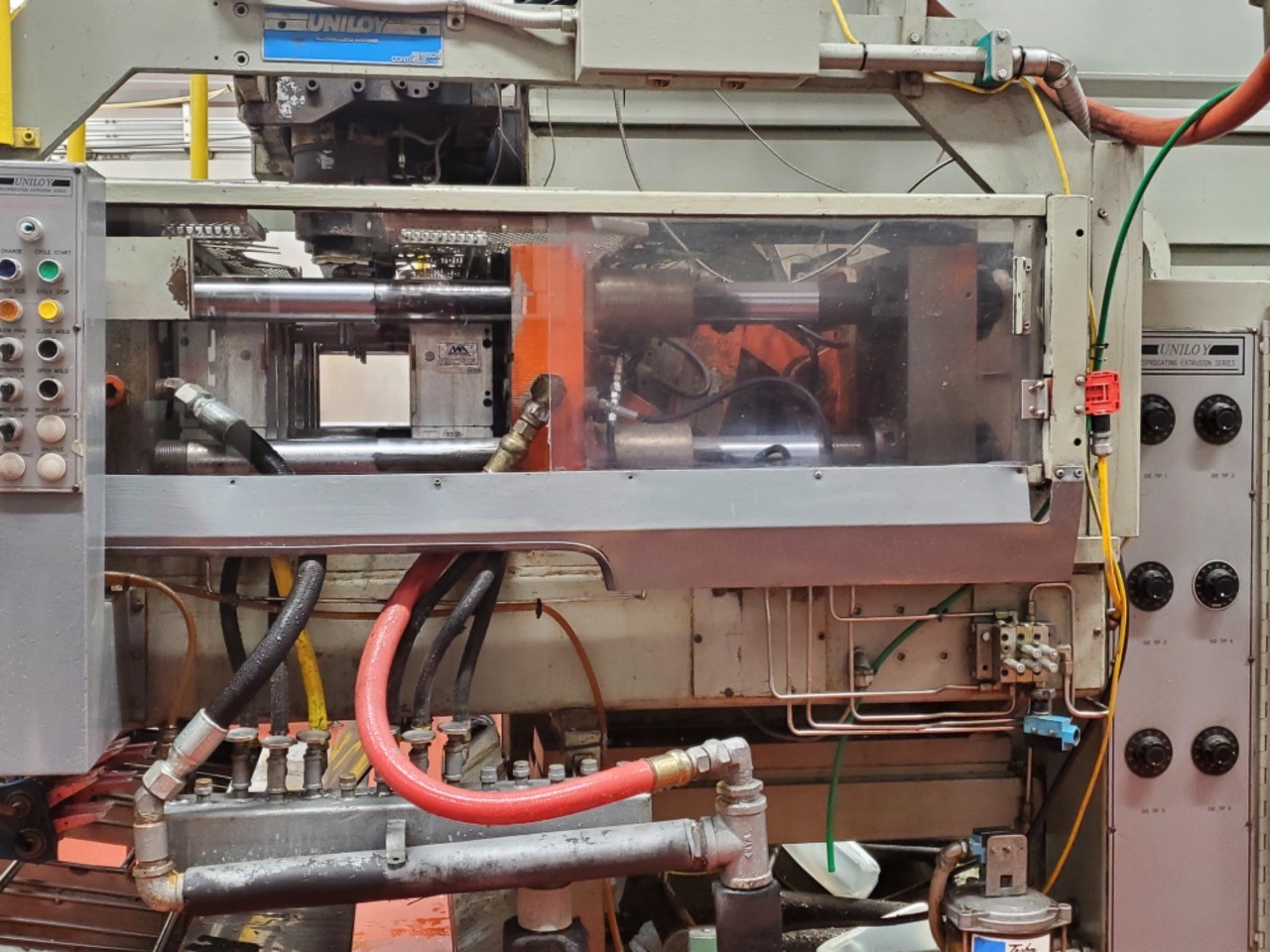

Blow Mold Start Up & Restart

-

At Machine Screen (HMI) Clear any/all Alarms that are shown

-

Turn on Hydraulic Power (temp should reach between 80 - 100 degrees) before starting machine

-

Cycle Swing Arms 3 to 5 times to ensure fingers opening and closing in right locations

-

While cycling swing arms, make sure cooling bed and trimmer running, if not check and move to correct position (from Manual to Automatic)

-

Turn on Extruder

-

Make sure plastic/parison coming from all heads as evenly as possible

-

After parisons reach cooling bed plate, push Cycle Start button

-

When molds close, pull parison/purge off of cooling bed with hook pole and move aside to cool

-

Monitor tail lengths on next several shots and if necessary, hold Charge button to ensure tails are long enough for swing arm fingers to grab

-

If you have a second person helping you, have them check the cooling bed for mis-aligned bottles and clear them and either grind bottles off the cooling bed or run into the Regrind buckets

-

Run bottles through Trimmer after tails look good and you think they'll trim (3 to 5 shots at least)

-

Monitor tail lengths, bottle drops to cooling bed and trimming for several minutes before moving on to next start up or task