Title Page

-

Vessel Serial Number

-

Customer Name

-

Date

CES 5 Yearly Vessel Planned Maintenance Checklist

-

Customer address

-

Functional Location

-

Vessel size

-

Vessel Contents

-

Vessel ZZ number

-

Vessel ZZ number:

-

Work order number

-

Name

-

Signature

To be completed by maintenance manager or equivalent:

-

Checked by:

-

Sign

-

Date

Equipment Checklist

-

VESSEL SERIAL NUMBER:

EQUIPMENT CHECKLIST

-

Pressure safety valves (PSV) & pressure relief valves (PRV) - New tags fitted

-

Bursting discs (BD) - Visual check of outlets - Re-tag

Complete this section with details of all PSV, BD (where applicable) and PRV up to the battery limit. -

PSV, BD or PRV?

- PSV1

- PSV2

- PSV3

- PSV4

- BD1

- BD2

- PRV1

- PRV2

- PRV3

- PRV4

- PRV5

- PRV6

-

PSV/BD/PRV size:

-

Make:

-

Model:

-

Setting:

-

Install Date

-

Is 3-way valve piped correctly - Centre port? Refer to CESSUP-09-07-GSP

-

Are all valves labelled in accordance with P&ID?

-

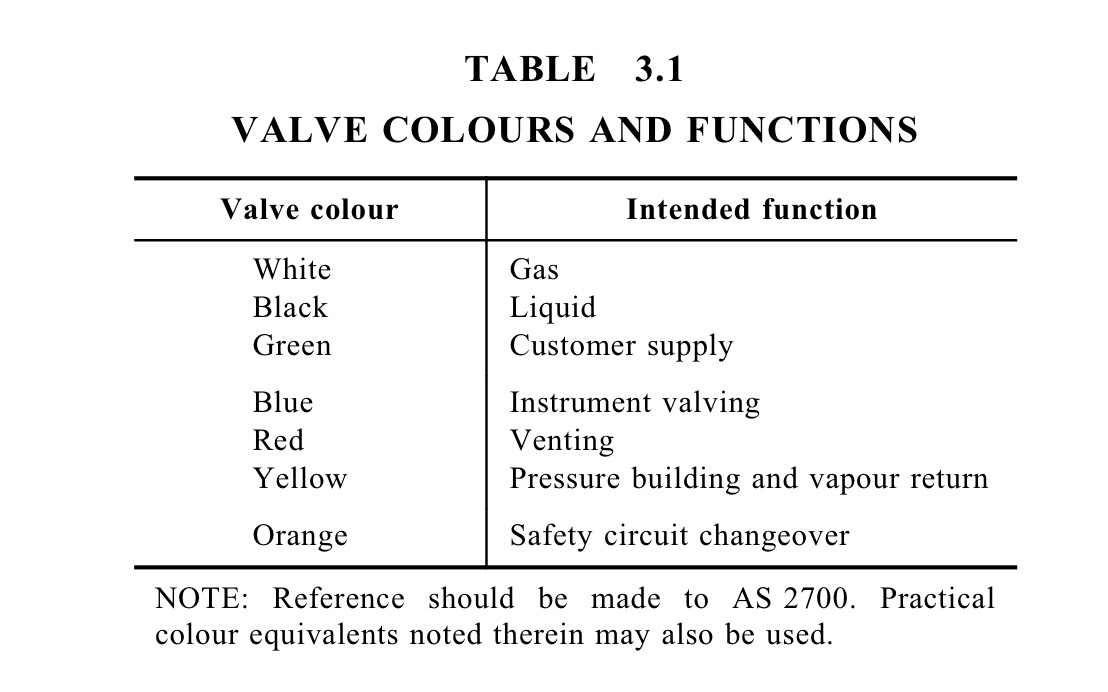

Are all valves colour-coded handles and valve stems? (REFER AS1894)

-

Table 3.1 - Valve Colours and Functions

Please use with reference to AS 1894-1997 -

Are all valve handles satisfactory?

-

Are all valves operating ok and no leaks present?

-

Is thermocouple valve plugged?

-

Take vacuum reading?

-

How many microns?

-

Fit tag with date and reading to the thermocouple valve

-

Pressure indicator - BOC approved - blowout back (SPC-10-155-AU)

-

Pressure indicator - normal/safety valve/indication only labels

-

Pressure indicator - functional check of pressure indicator

-

Telemetry unit/contents indicator - BOC approved, where fitted - last test/zero check date/verify contents with BSC 1300 728 990

-

Fill connection - is a non-return valve present? Is it the correct fill connection?

-

Is a fill coupling dust cap fitted?

-

Fill connection condition - is it worn or cracked?

-

Fill connection - does the non return operate ok?

-

Fill connection - is a hose blowdown valve fitted?

-

Fill connection - is there a hose pressure relief valve?

-

Evacuation valve - is it plugged and wired?

-

Is the pressure build vapouriser condition ok?

-

Is the pressure building regulator condition ok and is orientation correct (vent hole must be pointing down so any moisture/water can drain out)?

-

Pressure building regulator - if any doubt about correct operation of regulator conduct functional test

-

Does vessel need cleaning?

-

Does vessel need painting?

-

Is the BOC logo legible and not faded?

-

Is there a product label visible?

-

Is the BOC telephone number visible and correct?

-

Is a first aid sign fitted?

-

Is the vessel ID number fitted and correct?

-

Is the vessel pipe work schematic fitted and correct?

-

Is a HAZCHEM placard fitted and is it legible and correct?

-

Is there a phone number on HAZCHEM and is it correct?

-

Is an 'OK Staff' tag fitted?

-

Does the pressure raising circuit operate correctly?

-

For LOX vessels, perform hydrocarbon test

-

Vessel tagged for last hydrocarbon test?

-

Last hydrocarbon test date:

-

Is the customer pipeline bracketed correctly with no visible damage?

-

Is a battery limit label fitted indicating BOC/customer ownership?

-

Statutory approval stamp registration number

-

Registration Number:

-

Is registration number highlighted in blue?

-

Is the condition of the 3-phase power outlet ok?

-

Is a RCD fitted at the 3-phase power outlet?

-

Please add any comments

Touch the plus symbol to the right to begin, add as many as required by tapping the plus symbol again.

Site Checklist

Site Checklist

-

Are there any other potential site hazards?

-

If a sloping site, is the placarding visible and legible?

-

Is vehicle protection adequate?

-

Is the vessel foundation in good condition?

-

For LOX vessels, is tanker hardstand in good condition? (crack/oil/grease)

-

Is the surrounding area free from oil and debris?

-

If fenced, is the fence secure and in good condition?

-

Is a water tap and hose present?

-

Is site lighting adequate?

-

Where applicable, is remote fill point in line of sight to vessel?

-

Take photos of current installation, including: - icing on vapouriser - vessel pipe work - any general defects - from distance of 20 minutes showing surrounding area

-

Comments:

Vessel Location Checklist

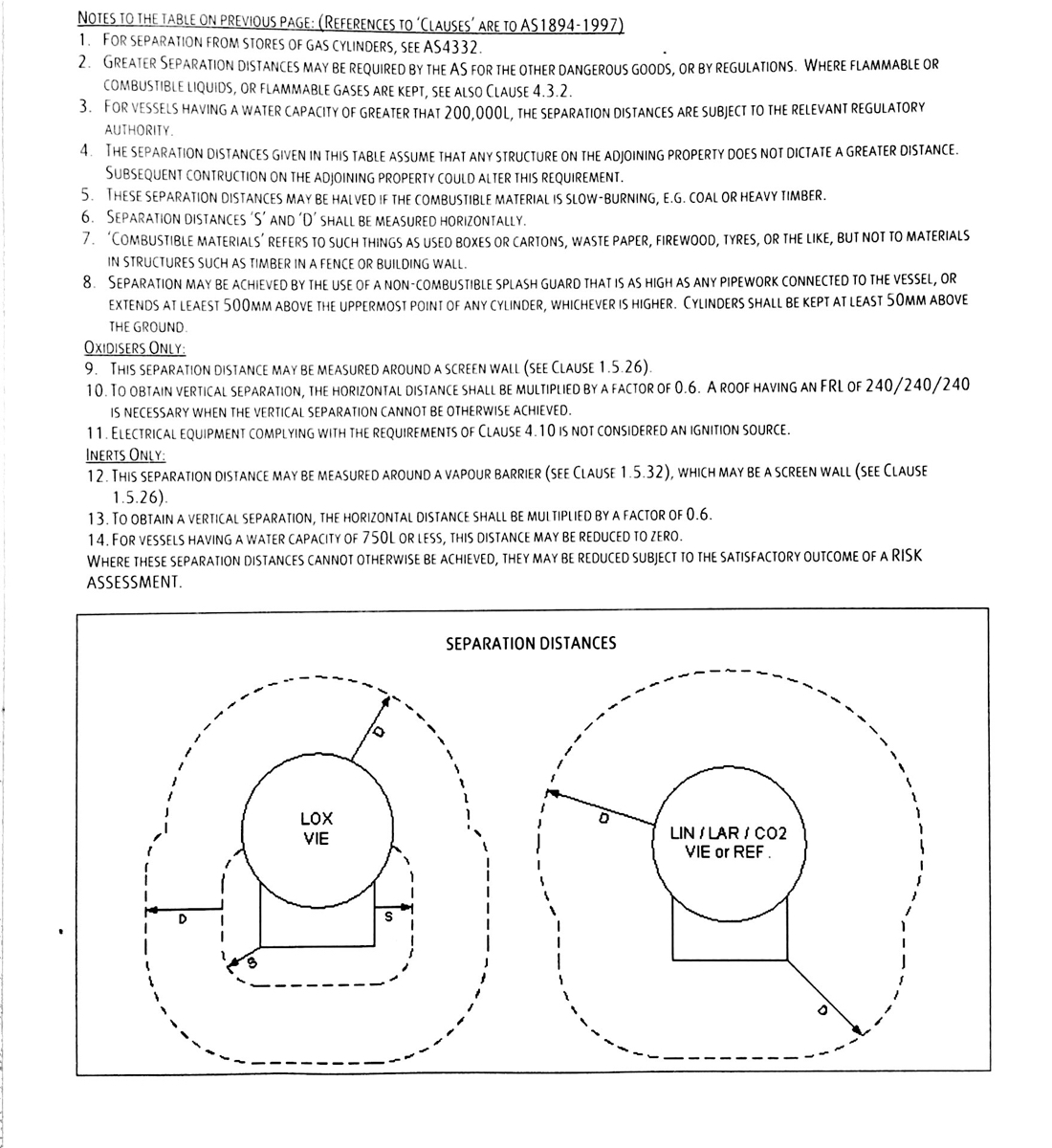

ITEMS FROM WHICH SEPARATION IS REQUIRED (See related notes in the next section)

-

Notes to the table below: (references to 'clauses' are to AS 1984-1997)

-

Oxidiser (LOX, N2O) or Inert (LIN, LAR and CO2) product?

-

Vessel Size

Minimum separation distance = 'S' + 'D' (metres), with reference to AS 1984 - 1997

-

Continuous section of pipeline containing flammable gas or liquid, not interrupted by fittings e.g. valves, unions, flanges<br><br>'S' = 1<br>'D' = 1<br>Total separation distance required = 2 metres

-

Building or structure with non-combustible exterior, or sprinklered building of other construction (see notes 8 & 14)<br><br>'S' = 1<br>'D' = 1<br>Total separation distance required = 2 metres

-

Property Boundary (see note 4) <br><br>'S' = 1<br>'D' = 1<br>Total separation distance required = 2 metres

-

Street, road boundary or car park, other than for authorised vehicles (see notes 9 & 10 or 12 & 14)<br><br>'S' = 1<br>'D' = 1<br>Total separation distance = 2m

-

Areas where open flames, smoking or other sources of ignition are permitted (see note 11)<br><br>'S' = 1<br>'D' = 1<br>Total separation distance required = 2m

-

Fixed installations of gases in cylinders (see notes 1, 8 & 14)<br><br>'S' = 1<br>'D' = 1<br>Total separation distance required = 2m

-

Other dangerous goods stores of other classes or subsidiary risks (see note 2) <br><br>'S' = 1<br>'D' = 1<br>Total separation distance required = 2m

-

Medium or high voltage electrical equipment greater than 415V e.g. substations, transformers or motor control centres (see notes 9, 10 & 11 or 12 &13)<br><br>'S' = 1<br>'D' = 3<br>Total separation distance required = 4m

-

Building or structure with combustible exterior (see note 14)<br><br>'S' = 1<br>'D' = 3<br>Total separation distance required = 4m

-

Process equipment and machinery that is not part of the installation (see note 15) <br><br>'S' = 1<br>'D' = 3<br>Total separation distance required = 4m

-

Fittings e.g. valves, unions and flanges in pipeline containing flammable gas or liquid<br><br>'S' = 1<br>'D' = 3<br>Total separation distance required = 4m

-

Openings to underground drains, pits, ducts, surface water drains or openings or systems below ground level<br><br>'S' = 1<br>'D' = 3<br>Total separation distance required = 4m

-

Openings in walls of adjacent buildings or structures (see notes 9 & 10 or 12 & 13)<br><br>'S' = 1<br>'D' = 3<br>Total separation distance required = 4m

-

Areas where personnel can congregate e.g. offices and lunchrooms (see notes 9 & 10 or 12 & 13) <br><br>'S' = 1<br>'D' = 5<br>Total separation distance required = 6m

-

Compressor or ventilator air intakes<br><br>'S' = 1<br>'D' = 5<br>Total separation distance required = 6m

-

Places of public assembly (see notes 9 & 10 or 12 & 13) <br><br>'S' = 1<br>'D' = 10<br>Total separation distance required = 11m

-

Areas of buildings where patients are confined to bed (see notes 9 & 10 or 12 & 13) <br><br>'S' = 1<br>'D' = 10<br>Total separation distance required = 11m

-

Solid combustible material (see notes 5, 7 & 10 or 12)<br><br>'S' = 1<br>'D' = 10<br>Total separation distance required = 11m

Minimum separation distance = 'S' + 'D' (metres), with reference to AS 1984 - 1997

-

Continuous section of pipeline containing flammable gas or liquid, not interrupted by fittings e.g. valves, unions, flanges<br><br>'S' = 2<br>'D' = 2<br>Total separation distance required = 4 metres

-

Building or structure with non-combustible exterior, or sprinklered building of other construction (see notes 8 & 14)<br><br>'S' = 2<br>'D' = 2<br>Total separation distance required = 4 metres

-

Property Boundary (see note 4)<br><br>'S' = 2<br>'D' = 2<br>Total separation distance required = 4 metres

-

Street, road boundary or car park, other than for authorised vehicles (see notes 9 & 10 or 12 & 14)<br><br>'S' = 2<br>'D' = 2<br>Total separation distance required = 4 metres

-

Areas where open flames, smoking or other sources of ignition are permitted (see note 11)<br><br>'S' = 2<br>'D' = 2<br>Total separation distance required = 4 metres

-

Fixed installations of gases in cylinders (see notes 1, 8 & 14)<br><br>'S' = 2<br>'D' = 2<br>Total separation distance required = 4 metres

-

Other dangerous goods stores of other classes or subsidiary risks (see note 2) <br><br>'S' = 2<br>'D' = 2<br>Total separation distance required = 4 metres

-

Medium or high voltage electrical equipment greater than 415V e.g. substations, transformers or motor control centres (see notes 9, 10 & 11 or 12 &13)<br><br>'S' = 2<br>'D' = 3<br>Total separation distance required = 5m

-

Building or structure with combustible exterior (see note 14)<br><br>'S' = 2<br>'D' = 3<br>Total separation distance required = 5m

-

Process equipment and machinery that is not part of the installation (see note 15) <br><br>'S' = 2<br>'D' = 3<br>Total separation distance required = 4m

-

Fittings e.g. valves, unions and flanges in pipeline containing flammable gas or liquid<br><br>'S' = 2<br>'D' = 3<br>Total separation distance required = 4m

-

Openings to underground drains, pits, ducts, surface water drains or openings or systems below ground level<br><br>'S' = 2<br>'D' = 3<br>Total separation distance required = 4m

-

Openings in walls of adjacent buildings or structures (see notes 9 & 10 or 12 & 13)<br><br>'S' = 2<br>'D' = 3<br>Total separation distance required = 4m

-

Areas where personnel can congregate e.g. offices and lunchrooms (see notes 9 & 10 or 12 & 13) <br><br>'S' = 2<br>'D' = 5<br>Total separation distance required = 7m

-

Compressor or ventilator air intakes<br><br>'S' = 2<br>'D' = 5<br>Total separation distance required = 7m

-

Places of public assembly (see notes 9 & 10 or 12 & 13) <br><br>'S' = 2<br>'D' = 10<br>Total separation distance required = 12m

-

Areas of buildings where patients are confined to bed (see notes 9 & 10 or 12 & 13) <br><br>'S' = 2<br>'D' = 10<br>Total separation distance required = 12m

-

Solid combustible material (see notes 5, 7 & 10 or 12)<br><br>'S' = 2<br>'D' = 10<br>Total separation distance required = 12m

Minimum separation distance = 'S' + 'D' (metres), with reference to AS 1984 - 1997

-

Continuous section of pipeline containing flammable gas or liquid, not interrupted by fittings e.g. valves, unions, flanges<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Building or structure with non-combustible exterior, or sprinklered building of other construction (see notes 8 & 14)<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Property Boundary (see note 4)<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Street, road boundary or car park, other than for authorised vehicles (see notes 9 & 10 or 12 & 14)<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Areas where open flames, smoking or other sources of ignition are permitted (see note 11)<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Fixed installations of gases in cylinders (see notes 1, 8 & 14)<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Other dangerous goods stores of other classes or subsidiary risks (see note 2) <br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Medium or high voltage electrical equipment greater than 415V e.g. substations, transformers or motor control centres (see notes 9, 10 & 11 or 12 &13)<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Building or structure with combustible exterior (see note 14)<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Process equipment and machinery that is not part of the installation (see note 15) <br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Fittings e.g. valves, unions and flanges in pipeline containing flammable gas or liquid<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Openings to underground drains, pits, ducts, surface water drains or openings or systems below ground level<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Openings in walls of adjacent buildings or structures (see notes 9 & 10 or 12 & 13)<br><br>'S' = 3m<br>'D' = 3m<br>Total separation distance required = 6 metres

-

Areas where personnel can congregate e.g. offices and lunchrooms (see notes 9 & 10 or 12 & 13) <br><br>'S' = 3<br>'D' = 5<br>Total separation distance required = 8m

-

Compressor or ventilator air intakes<br><br>'S' = 3<br>'D' = 5<br>Total separation distance required = 8m

-

Places of public assembly (see notes 9 & 10 or 12 & 13) <br><br>'S' = 3<br>'D' = 10<br>Total separation distance required = 13m

-

Areas of buildings where patients are confined to bed (see notes 9 & 10 or 12 & 13) <br><br>'S' = 3<br>'D' = 10<br>Total separation distance required = 13m

-

Solid combustible material (see notes 5, 7 & 10 or 12)<br><br>'S' = 3<br>'D' = 10<br>Total separation distance required = 13m

-

Vessel Size

Minimum separation distance = 'D' (metres) with reference to AS 1894 - 1997)

-

Continuous section of pipeline containing flammable gas or liquid, not interrupted by fittings e.g. valves, unions, flanges<br><br>'D' = 1m

-

Building or structure with non-combustible exterior, or sprinklered building of other construction (see notes 8 & 14)<br><br>'D' = 1m

-

Property Boundary (see note 4)<br><br>'D' = 1m

-

Street, road boundary or car park, other than for authorised vehicles (see notes 9 & 10 or 12 & 14)<br><br>'D' = 1m

-

Areas where open flames, smoking or other sources of ignition are permitted (see note 11)<br><br>'D' = 1m

-

Fixed installations of gases in cylinders (see notes 1, 8 & 14)<br><br>'D' = 1m

-

Other dangerous goods stores of other classes or subsidiary risks (see note 2) <br><br>'D' = 1m

-

Medium or high voltage electrical equipment greater than 415V e.g. substations, transformers or motor control centres (see notes 9, 10 & 11 or 12 &13)<br><br>'D' = 1m

-

Building or structure with combustible exterior (see note 14)<br><br>'D' = 1m

-

Process equipment and machinery that is not part of the installation (see note 15) <br><br>'D' = 1m

-

Fittings e.g. valves, unions and flanges in pipeline containing flammable gas or liquid<br><br>'D' = 1m

-

Openings to underground drains, pits, ducts, surface water drains or openings or systems below ground level<br><br>'D' = 1m

-

Openings in walls of adjacent buildings or structures (see notes 9 & 10 or 12 & 13)<br><br>'D' = 1m

-

Areas where personnel can congregate e.g. offices and lunchrooms (see notes 9 & 10 or 12 & 13) <br><br>'D' = 2m

-

Compressor or ventilator air intakes<br><br>'D' = 2m

-

Places of public assembly (see notes 9 & 10 or 12 & 13) <br><br>'D' = 3m

-

Areas of buildings where patients are confined to bed (see notes 9 & 10 or 12 & 13) <br><br>'D' = 3m

-

Solid combustible material (see notes 5, 7 & 10 or 12)<br><br>'D' = 3m

Minimum separation distance = 'D' (metres) with reference to AS 1894 - 1997)

-

Continuous section of pipeline containing flammable gas or liquid, not interrupted by fittings e.g. valves, unions, flanges<br><br>'D' = 1m

-

Building or structure with non-combustible exterior, or sprinklered building of other construction (see notes 8 & 14)<br><br>'D' = 1m

-

Property Boundary (see note 4)<br><br>'D' = 2m

-

Street, road boundary or car park, other than for authorised vehicles (see notes 9 & 10 or 12 & 14)<br><br>'D' = 2m

-

Areas where open flames, smoking or other sources of ignition are permitted (see note 11)<br><br>'D' = 2m

-

Fixed installations of gases in cylinders (see notes 1, 8 & 14)<br><br>'D' = 2m

-

Other dangerous goods stores of other classes or subsidiary risks (see note 2) <br><br>'D' = 2m

-

Medium or high voltage electrical equipment greater than 415V e.g. substations, transformers or motor control centres (see notes 9, 10 & 11 or 12 &13)<br><br>'D' = 2m

-

Building or structure with combustible exterior (see note 14)<br><br>'D' = 2m

-

Process equipment and machinery that is not part of the installation (see note 15) <br><br>'D' = 2m

-

Fittings e.g. valves, unions and flanges in pipeline containing flammable gas or liquid<br><br>'D' = 2m

-

Openings to underground drains, pits, ducts, surface water drains or openings or systems below ground level<br><br>'D' = 2m

-

Openings in walls of adjacent buildings or structures (see notes 9 & 10 or 12 & 13)<br><br>'D' = 2m

-

Areas where personnel can congregate e.g. offices and lunchrooms (see notes 9 & 10 or 12 & 13) <br><br>'D' = 2m

-

Compressor or ventilator air intakes<br><br>'D' = 2m

-

Places of public assembly (see notes 9 & 10 or 12 & 13) <br><br>'D' = 3m

-

Areas of buildings where patients are confined to bed (see notes 9 & 10 or 12 & 13) <br><br>'D' = 3m

-

Solid combustible material (see notes 5, 7 & 10 or 12)<br><br>'D' = 3m

Minimum separation distance = 'D' (metres) with reference to AS 1894 - 1997)

-

Continuous section of pipeline containing flammable gas or liquid, not interrupted by fittings e.g. valves, unions, flanges<br><br>'D' = 1m

-

Building or structure with non-combustible exterior, or sprinklered building of other construction (see notes 8 & 14)<br><br>'D' = 1m

-

Property Boundary (see note 4)<br><br>'D' = 3m

-

Street, road boundary or car park, other than for authorised vehicles (see notes 9 & 10 or 12 & 14)<br><br>'D' = 3m

-

Areas where open flames, smoking or other sources of ignition are permitted (see note 11)<br><br>'D' = 3m

-

Fixed installations of gases in cylinders (see notes 1, 8 & 14)<br><br>'D' = 3m

-

Other dangerous goods stores of other classes or subsidiary risks (see note 2) <br><br>'D' = 3m

-

Medium or high voltage electrical equipment greater than 415V e.g. substations, transformers or motor control centres (see notes 9, 10 & 11 or 12 &13)<br><br>'D' = 3m

-

Building or structure with combustible exterior (see note 14)<br><br>'D' = 3m

-

Process equipment and machinery that is not part of the installation (see note 15) <br><br>'D' = 3m

-

Fittings e.g. valves, unions and flanges in pipeline containing flammable gas or liquid<br><br>'D' = 3m

-

Openings to underground drains, pits, ducts, surface water drains or openings or systems below ground level<br><br>'D' = 3m

-

Openings in walls of adjacent buildings or structures (see notes 9 & 10 or 12 & 13)<br><br>'D' = 3m

-

Areas where personnel can congregate e.g. offices and lunchrooms (see notes 9 & 10 or 12 & 13) <br><br>'D' = 3m

-

Compressor or ventilator air intakes<br><br>'D' = 3m

-

Places of public assembly (see notes 9 & 10 or 12 & 13) <br><br>'D' = 3m

-

Areas of buildings where patients are confined to bed (see notes 9 & 10 or 12 & 13) <br><br>'D' = 3m

-

Solid combustible material (see notes 5, 7 & 10 or 12)<br><br>'D' = 3m

Defect Action Report

Defect Action Report Further work required - SAP work order to be raised

-

Description of defect and action required. Touch 'Add Defect' or plus symbol to begin. Add as many defects as required

Defect

-

Description of defect and action required

-

Who is responsible?

-

Priority

Follow up action to be completed by maintenance manager and/or CES manager

-

Actioned by:

-

Action description: W/O No./email to etc

Part List

List of Parts Used During This Planned Maintenance

Safety Valves

-

Part number:

-

Quantity:

-

Work order number:

Pressure Relief Valves

-

Part number:

-

Quantity:

-

Work order number:

Additional Parts

-

Touch 'Add Part' or the plus symbol to start, then 'Response' to choose a part from the drop-down list. If the part is not listed, please select 'Other' in drop-down list

Part

-

Part description

- Bursting Discs

- Hydrocarbon Tag

- OK Staff

- Vacuum Tag

- Pressure Indicator Stickers

- Contents Gauge

- Valve Handle Paint

- Valve Labels

- Valve Stem Coloured Tape

- HAZCHEM Signs

- Pressure Indicators

- Contents Indicators

- Battery Limit Stickers

- Customer Isolation Stickers

- Valve Teflon Seats

- Other

-

Part number

-

Quantity

-

Work order number:

-

Product name/description

-

Part number

-

Quantity

-

Work order number: