Information

-

Project description

-

Contract No. GW

-

Contractor

-

Subcontractors on site

-

Conducted on

-

Prepared by

-

Location

-

Contractor's representative

1.0 Identification of services

-

1.1 Has a Dial Before You Dig (DBYD) enquiry been made?

-

1.2 Have utilities that are not members of DBYD been contacted?

-

1.3 Are records kept available on the work site?

-

1.4 Have DBYD records been validated by hand excavation?

-

1.5 Have cable identification methods been use?

-

1.6 For trenchless techniques, has “pot-holing” been performed to locate existing services?

-

1.7 Have private service lines been identified (eg. water pipe into a household) as these are not usually on DBYD plans.

-

1.8 Note that telecommunication lines cannot be relied upon to run in straight lines between access points.

2.0 General

-

2.1 Has a hazard and risk assessment on the assets been undertaken, with methods identified to ensure their protection?

-

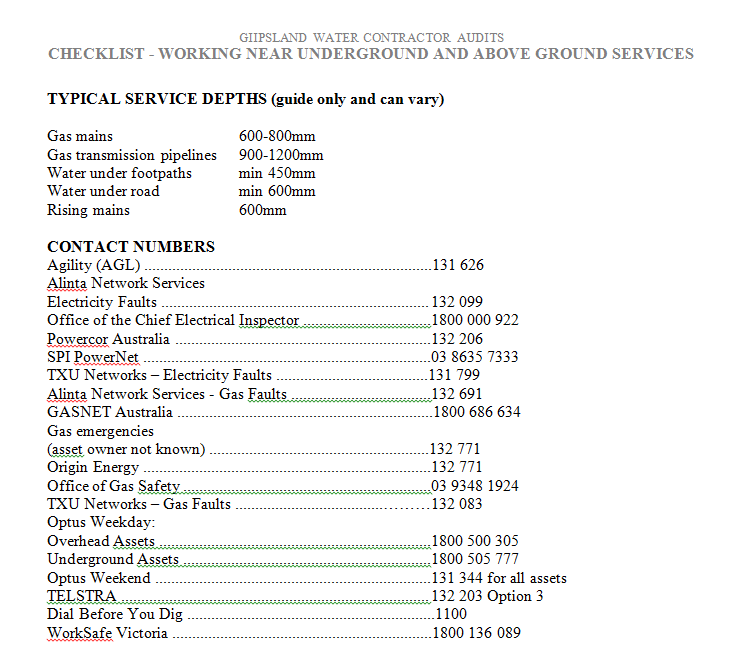

2.2 Is there a plan of action, should an emergency occur? Is this plan easily accessible and does it contain contact numbers?

-

2.3 If working underground, are relevant codes of practise for trenching and confined space entry being adhered to? (separate checklists)

-

2.4 If working near gas lines, is a fire extinguisher handy?

3.0 Location of work

-

3.1 If the work is being undertaken on public land, has the local council been notified?

-

3.2 If the work is being undertaken on or in the reserve of a VicRoads’ road, has VicRoads been notified and consent been given?

-

3.3 Are all road-opening permits kept on site?

4.0 Work near overhead services and utilities

-

4.1 Is work being undertaken “near” overhead services/utilities?

-

4.1.2 A spotter must be used, is a spotter being used?

-

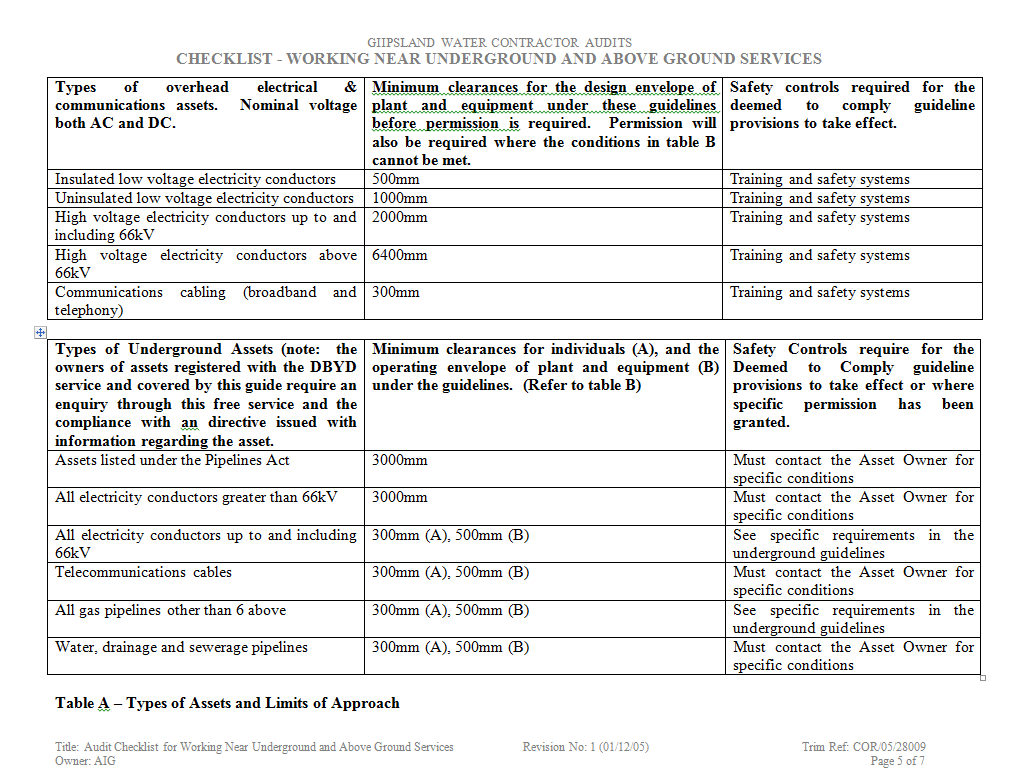

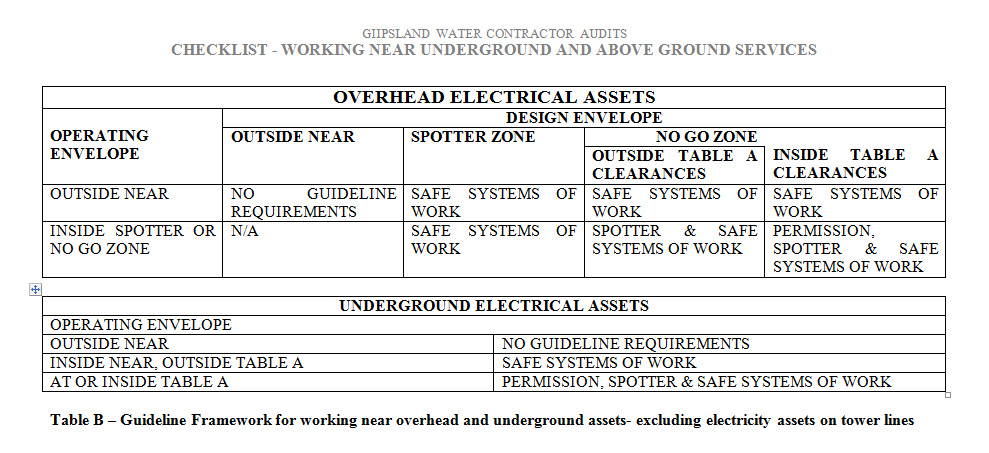

4.1.1 The term “near” refers to the following clearances:

• A distance of 6400mm from overhead cables 66kV and less

• A distance of 10000mm from overhead cables above 66kV -

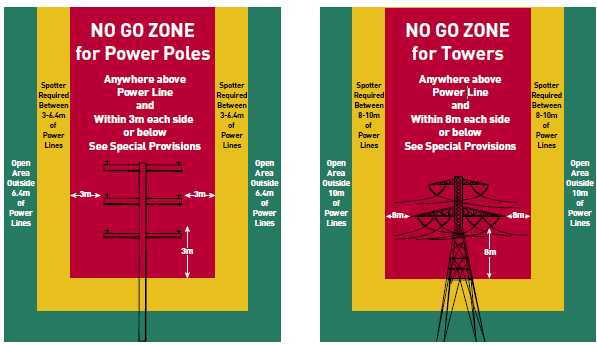

4.2 Is the design envelope (region of space accessible by any part of plant) able to encroach on the “no go zone”?

-

4.2.1 The term “no go zone” refers to the following clearances:

• 3000mm from overhead power cables on a pole and 8000mm from power cables on a tower. -

4.3 If the answer to either of the above is yes, the utility company must be notified before work commences unless a safe system of work has been developed in line with WorkCover guidelines. Refer to tables A&B (references)

Note: only a person competent in identifying and preparing a JSA for overhead and underground services shall assess compliance with the No Go Zone framework.

5.0 Working near underground services/utilities

-

5.1 Is work being undertaken “near” underground services/utilities?

-

5.1.1 The term “near” refers to the following clearances.

• A distance of 2000mm from an underground service

• A distance of 3000mm from an asset registered under the pipelines act or underground power cable greater than 66kV -

5.2 Is the design envelope (region of space accessible by any part of plant) able to encroach on the “no go zone”?

-

5.2.1 The term “no go zone” refers to the following clearances:

• 300mm for individuals and 500mm for plant and equipment

• 3000mm in the case of any underground assets registered under the pipelines act or a power cable with greater than 66kV -

5.3 Is the answer to either of the above 'yes'?

-

5.3.1 If the answer to either of the above is yes, tables A&B must be referred to and complied with. (References)

-

5.4 Excavations below assets should not be undertaken within a distance of 300mm below the asset located at the lowest level.

Note: only a person competent in identifying and preparing a JSA for overhead and underground services shall assess compliance with the No Go Zone framework.

6.0 Work near electricity

-

6.1 Is work being undertaken that involves excavation near a transformer pole on a single wire supply?

-

6.2 If so, no work shall encroach closer than 10 metres to the pole. A clearance of 300mm should be maintained for ordinary poles.

-

6.3 Poles such as traffic lights and street lights usually have underground power cables in the vicinity. Have these been identified?

7.0 Checklist for work near overhead/underground assets

-

7.1 For work “near” overhead and underground assets, have the following measure been implemented?

-

7.1.1 The presence, location, type and operating voltage/pressure of the asset has been positively determined by a competent person and all required safety systems are in place?

-

7.1.2 Job Safety Analysis (JSA) has been undertaken and all workers inducted into it?

-

7.1.3 Permission to work granted if necessary?

-

7.1.4 Persons instructed to avoid, wherever practicable, simultaneous contact between machines near assets and ground?

-

7.1.5 Controlling loads with non-conductive tag lines?

-

7.1.6 A spotter is being utilised?

-

7.1.7 A minimum 1 metre earthing chain is attached to the chassis of plant (for 66kV and less the chain should have 10mm links. For above 66kV 16mm links)?

-

7.1.8 An equipotential mat or 900x900x6mm clean, dry rubber mat is placed under an operator on ground in contact with plant (less than 22kV)?

-

7.1.9 An operator station is provided within the vehicle to eliminate step potential?

8.0 Plant and equipment

-

8.1 Are operation and maintenance manuals for all plant and equipment supplied and conforming to the current version of the OH&S Regulations?

-

8.2 Is a laminated quick reference guide for each piece of plant with clearly and permanently marked control panels provided?

9.0 Communication

-

9.1 Is a communications system in place?

-

9.2 This system must provide for emergency response. This could be direct to emergency services or via the operator’s base. If a spotter is being used a voice system of communications between plant operator and spotter is preferred (such as a two way radio). Otherwise another type of visual, audible system should be used.

10.0 Spotters

-

10.1 Have spotters completed a recognised training course?

-

10.2 Are spotters located effectively?

11.0 Asset and their owners

-

11.1 Is heavy machinery being used above an underground asset?

-

11.1.1 Minimum 1000mm cover should be ensured.

-

11.2 Is blasting being conducted within 30m of an underground asset?

-

11.2.1 The asset owner must be notified

-

11.3 Has any damage to assets been reported to their owners?

References

-

Table A

-

Table B

-

Important info

-

No go zones

Additional comments

-

Add additional comments

Action Required

-

Contractor is to review the comments, and consider the recommended actions within this Audit. The Contractor needs to demonstrate they are complying with their obligations as an employer, what specific remedial action they propose for this site, and if any overall modifications are required to their Health and Safety Plan / safety procedures / supervision. Prompt corrective action is required to eliminate any agreed deficiencies, and areas of any disagreement need to be further explored in writing. All “failed responses” need to be addressed/resolved.

Signatures

-

Gippsland Water responsible officer

-

Auditor

-

Contractor's representative