Information

-

Project description

-

Contract No. GW

-

Contractor

-

Subcontractors on site

-

Conducted on

-

Prepared by

-

Location

-

Contractor's representative

1.0 Certifications and qualifications

-

Workers operating certain types of powered mobile plant without direct supervision must hold appropriate Worksafe certificates of competency. This includes the operation of slewing mobile cranes, non-slewing mobile cranes with greater than 3 tonne capacity, vehicle loading cranes with a capacity of 10 metre tonnes or more, fork-lift trucks (except pedestrian-operated types), boom-type elevating work platforms with a boom length of 11 metres or more, and truck-mounted concrete placing booms.

-

1.2 Ensure the Contractor has a copy and a register of certificates, and a review system to ensure all his employees and subcontractors on the site have the appropriate certificates where required.

-

1.3 Verify that the Contractor has checked to see that workers operating earthmoving plant such as front-end loaders, front-end loader/backhoes, skid steer loaders, excavators, dozers and draglines have an appropriate qualification card or certificate and the Contractor has determined employees have the necessary competency.

-

1.4 Contractors must have had operators show them their certificates and qualifications, and have recorded the details on the site register. If no formal certificates are required, ensure the Contractor has a process to determine employees have the necessary competency to safely operate the plant.

2.0 Operator training

-

2.1 Certificates of competency mean the operator has been assessed as generally competent to operate the classes of plant covered by the certificate. But it does not necessarily mean the operator is familiar with the particular make and model or the particular attachments being used with the plant.

-

2.2 Verify the Contractors system to ensure training in the particular plant and models they are using on site. Comment on system in use.

-

2.3 Verify how the Contractor makes sure operators are familiar with their machine and attachments, that they have the operator's manual and that they understand the safe operating procedures for the machine and the particular work. Detail in comments.

-

2.4 Has Contractor given operators training in the use of the particular machine/s they are operating?

3.0 Registration with WorkCover

-

Mobile cranes with a capacity of more than 10 tonnes and truck-mounted concrete placing booms must have a current plant registration with Workcover or an equivalent interstate authority before they can be operated in a workplace.

• Victorian plant registrations are valid for three years. -

3.1 Ensure the Contractor has a system that does not allow these items of plant to operate until he has sighted proof of current registration, and recorded the details on the site register. Check the expiry date and, make sure it is still current.

-

3.2 Is Contractors plant currently registered with WorkCover?

4.0 Maintainence and servicing of plant

-

Contractor must make sure plant is in a serviceable condition when it arrives on site. In the case of plant which has been hired or leased, Contractor must insist that the supplier provides him with a copy of the latest inspection and maintenance records.

-

4.1 Inspect Contractors system to ensure all the inspection and service checks recommended by the supplier are carried out at the recommended intervals immediately prior to arriving on site & during the time the plant remains on site.

-

4.2 Contractor must be able to produce records on any inspections and maintenance to plant carried out while the plant is under his management and control. Encourage contractor to have these available with the machine on site. Sight records.

-

4.3 Make sure the Contractors safety system will identify any unserviceable plant, and then has the plant taken out of operation until it is repaired or replaced.

-

4.4 Is Contractors plant properly maintained and serviced?

5.0 Reversing beepers

-

5.1 Review Contractors process which makes sure all trucks, mobile cranes and other types of powered mobile plant on site are fitted with properly operating devices to warn workers and the public who may be at risk from the plant moving. A combination of lights and reversing beeper is strongly recommended.

-

5.2 Is Contractors plant fitted with reversing beepers?

6.0 ROPS and FOPS

-

6.1 Tractors, rough terrain equipment or other powered mobile plant subject to the risk of overturning need a properly constructed and fitted roll-over protective structure (ROPS) to safeguard the operator from injury. Is ROPS required?

-

6.2 Likewise, if there is any danger of falling debris, the Contractor must have a suitable and robust falling objective protective structure (FOPS) to protect the operator. Is FOPS required?

-

6.3 Is plant fitted with ROPS and FOPS (if necessary)?

7.0 Safe operation of plant

-

7.1 Ask Contractor how he ensures that plant is being used for the purpose it was designed for and operated in accordance with the supplier's recommendations, the operator's manual, and good practice.

-

7.2 Where, for any reason, the plant is to operate outside its normal conditions or in an abnormal environment, how does the Contractor make sure that additional hazards have been identified and any risk associated with this has been properly controlled? Detail in comments.

-

7.3 Are lifting hooks on backhoe buckets etc. properly designed?

8.0 Work near powerlines

-

8.1 Is the Contractor working near power lines or towers(see below)?

-

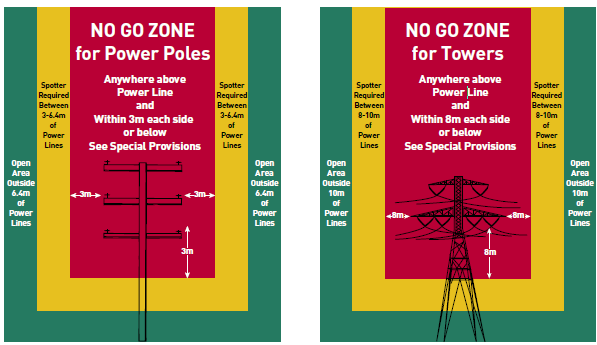

8.1.1 Is there a safe distance between powerlines and cranes, earth moving equipment, elevating work platforms, hoists, scaffolds and portable ladders? Observe “no go zone” safe clearances

-

8.1.2 An on site work meeting and risk assessment prior to commencing work is required. Check documentation.

-

8.1.3 For work within the yellow region shown below, a dedicated safety observer is required. Is this in place?

-

8.1.4 No work is permitted within the red region (shown below) of any live power line without written permission from the power authority (TXU). Check permit.

-

8.1.5 For scaffolds, the no go zone clearances are 5m above or below, and 4.6m beside any power line on POLES. Clearances are from the top of any guard rail or part of the scaffolding.

-

Proceed to next section

-

Clearance zones for power poles and towers

9.0 Use of safety harnesses

-

If the occupants of a basket are not safeguarded with a harness, a sudden failure of the knuckle joint at the end of the boom can throw them to their death.

-

9.1 Are safety harnesses being used where necessary?

-

9.2 Have Harnesses (Safety belts, individual fall arrest system, etc) been checked by Contractor for good condition and within date, to Australian Standards and on Plant?

-

9.3 Are Boom-type elevating work platforms (cherry pickers, travel towers, boom lifts etc) supplied with a safety harness and lanyard for each person working in the basket?

-

9.4 How does Contractor make sure safety harness’s are properly used at all times and are securely fixed to the proper anchorages when people are on the plant? Please comment<br>Training, toolbox meetings, regular supervision and inspections are vital.

10.0 Tractors

-

10.1 Does Contractor ensure the tractor has a roll over protective structures?

-

10.2 Has Contractor ensured employees are competent and trained in this tractor?

-

10.3 Does operator have a drivers licence if tractor used on roads?

-

10.4 Are power take off shafts guarded, noise monitored so it is not excessive?

-

10.5 Is tractor and equipment regularly maintained and serviced, with records?

-

10.6 Do employees make sure plant is left in a properly stowed safe configuration whenever it is unattended, keys stored securely? Do passengers only travel in cabin?

11.0 Forklifts

-

11.1 Does Contractor ensure forklift has a readable load chart?

-

11.2 Is FOPS fitted, (falling object protective structure)?

-

11.3 Has Contractor ensured warning devices such as beeper, flashing light, proximity indicator all fitted and working properly?

-

11.4 Does operator have the appropriate certificate of competency, specific model training?

-

11.5 Are daily checks done, pre work i.e. brakes, beepers, operation?

-

11.6 Can the workplace be designed to separate pedestrians from forklift areas?

-

11.7 Are loads lowered before travelling?

-

11.8 Is routine inspection, maintenance and cleaning carried out and documented?

12.0 Security of unattended plant

-

12.1 Does Contractor ensure employees make sure plant is left in a properly stowed safe configuration whenever it is unattended? Loads should never be left suspended.

-

12.2 Does Contractor ensure elevating work platforms and earthmoving plant are fully lowered when not in use?

-

12.3 Does Contractor where ever possible, park plant overnight within the properly secured confines of the building site? Or where this is not possible, make sure plant is secure against vandalism or joyriding.

-

12.4 Where it is necessary to leave plant adjacent to public roads or pedestrian areas, does Contractor make sure it is securely barricaded and, where appropriate, clearly marked with warning lamps overnight.

-

12.5 Is unattended plant properly secure?

Additional comments

-

Add additional comments

Action Required

-

Contractor is to review the comments, and consider the recommended actions within this audit. The contractor needs to demonstrate they are complying with their obligations as an employer, what specific remedial action they propose for this site, and if any overall modifications are required to their Health and Safety Plan / safety procedures / supervision. Prompt corrective action is required to eliminate any agreed deficiencies, and any areas of disagreement need to be further explored in writing. All “failed responses” need to be addressed/resolved.

Signatures

-

Gippsland Water responsible officer

-

Auditor

-

Contractor's representative