Information

-

Location (nearest town)

-

Foreman

-

Cooperative Name

-

Conducted on

-

Work being performed

-

Prepared by

-

Location

-

Audit Guidance: -All unsafe acts shall be stopped immediately. -Field Observations shall include photos for both safe and unsafe operations. Photos should be annotated with what the observer is focused on at the time of the audit. -Any item marked as a deficiency shall have a photo (if possible) and a detailed description. -All comments should identify those crew members performing the task correctly and/or incorrectly. -Equipment being inspected shall be listed and/or have a photo with the unit number displayed. -All audits shall be reviewed with the PIC prior to departure from the site. Corrective actions shall be assigned with due dates and noted on the audit. -Any audits being forwarded to the client shall be reviewed by more than one safety team member prior to being sent.

-

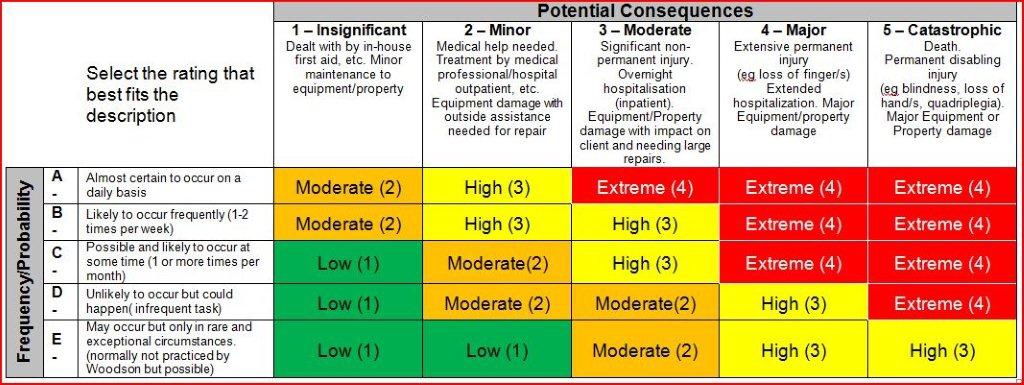

All audit findings shall have an assigned weight (1-4) assigned per the below matrix. Document the weighted number rating in the comment section associated with the applicable question.

Communication

-

Human Performance tools observed and bieng utilized correctly?

Procedures and Documents

-

Tailboard/Job Hazard/Driving assessment completed?

-

Paperwork (Private Motor Carrier License, Haz-Mat Registration, Vehicle Registration(s), Insurance Certificate, IFTA License & Stickers, Annual Inspections(s).392.2-396.17?

Work Practices

-

Proper PPE (Hard Hat, Glasses, Hearing Protection, leather or insulated gloves, FR, Safety Vest, Steel toe boots)?

-

Slip/trip and fall hazards identified and mitigated?

-

Are cell phones being use appropriately?

Supervision

-

Designated person in charge and documented?

-

Supervision verifying the job hazard analysis/job plan is being followed?

Change Management

-

JSA updated periodically and whenever work task changes? Time stamped at lunch?

External Influence

-

Heat/cold mitigation plan in use and documented?

System/Equipment Operation

-

If applicable, Is FR clothing being worn?

-

If applicable, 100% fall protection being utilized?

Management

-

Short service employee's identified and assigned mentors? On JSA? Proper colored hard hat?

-

incidents/near misses reported in a timely manner?

Design Configuration

-

Are appropriate DOT signs and cones in place?

-

Equipment properly barricaded when work is performed near live voltage or when grounded?

Summary and signatures

-

Positive observations. List crew members and specific items they are doing correctly:

-

# of Personnel-Personnel Present (first and last Names)

-

Number of Trucks

-

Number of Trucks Audited

-

Inspectors signature

-

Crew lead signature