Title Page

-

Plant Name & Period Audit (ex. Richmond Beverage P1 6S Audit)

-

Period 6S Audit

-

Conducted on

-

Auditor

-

Location

-

Present During Audit:

-

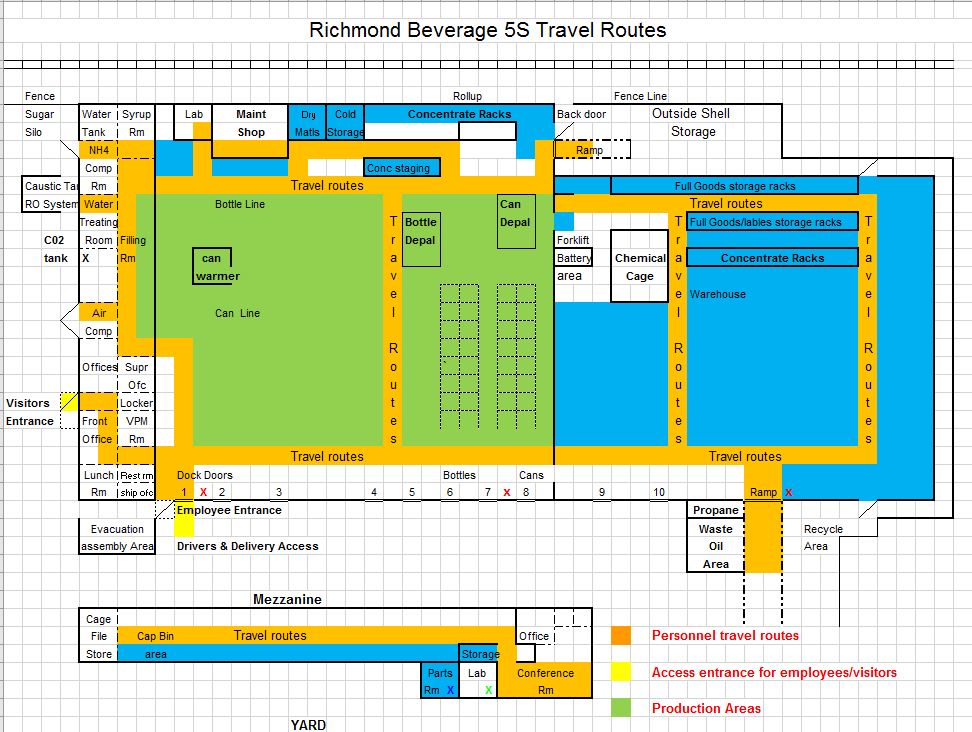

Travel Path

Warehouse/Shipping /Receiving

Warehouse/Shipping /Receiving

-

1) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

2) Needed equipment, tools, supplies & parts are present within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

3) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs, and surfaces free of debris (no oil, dirt, chips, etc.) and organized? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

4) equipment in the area is clean, free of dirt, grime, etc. There is evidence of the cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

5) All item locations are indicated, and items are in their proper location. Shelves and storage areas are organized, clearly divided and labeled. There are no uncertainties about where items are stored.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

6. GMP aisle ways, workstations, equipment, and location are clearly marked. Stairs, exits & aisle ways are clearly marked to facilitate work flow and escape routes. Lighting in the work area is bright and adequate.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

7) Visual organization methods are being used where appropriate (shadow boarding, floor markings, etc.) and tools are placed in a manner that minimizes unnecessary movements such as walking, bending, or reaching.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

8) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

9) Needed equipment, tools, supplies & parts are present and within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

10) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs and surfaces free of debris (no oil, dirt, chips, etc.) and organized.? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

Filling /Packaging /Palletizing

Filling/Packaging/Palletizing

-

1) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

2) Needed equipment, tools, supplies & parts are present within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

3) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs, and surfaces free of debris (no oil, dirt, chips, etc.) and organized? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

4) equipment in the area is clean, free of dirt, grime, etc. There is evidence of the cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

5) All item locations are indicated, and items are in their proper location. Shelves and storage areas are organized, clearly divided and labeled. There are no uncertainties about where items are stored.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

6. GMP aisle ways, workstations, equipment, and location are clearly marked. Stairs, exits & aisle ways are clearly marked to facilitate work flow and escape routes. Lighting in the work area is bright and adequate.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

7) Visual organization methods are being used where appropriate (shadow boarding, floor markings, etc.) and tools are placed in a manner that minimizes unnecessary movements such as walking, bending, or reaching.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

8) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

9) Needed equipment, tools, supplies & parts are present and within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

10) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs and surfaces free of debris (no oil, dirt, chips, etc.) and organized.? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

Maintenance / Utilities

Maintenance / Utilities

-

1) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

2) Needed equipment, tools, supplies & parts are present within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

3) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs, and surfaces free of debris (no oil, dirt, chips, etc.) and organized? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

4) equipment in the area is clean, free of dirt, grime, etc. There is evidence of the cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

5) All item locations are indicated, and items are in their proper location. Shelves and storage areas are organized, clearly divided and labeled. There are no uncertainties about where items are stored.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

6. GMP aisle ways, workstations, equipment, and location are clearly marked. Stairs, exits & aisle ways are clearly marked to facilitate work flow and escape routes. Lighting in the work area is bright and adequate.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

7) Visual organization methods are being used where appropriate (shadow boarding, floor markings, etc.) and tools are placed in a manner that minimizes unnecessary movements such as walking, bending, or reaching.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

8) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

9) Needed equipment, tools, supplies & parts are present and within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

10) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs and surfaces free of debris (no oil, dirt, chips, etc.) and organized.? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

11 )Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs and surfaces free of debris (no oil, dirt, chips, etc.) and organized.? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

11 )Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs and surfaces free of debris (no oil, dirt, chips, etc.) and organized.? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

Quality / Lab / Chemical Storage

Quality / Lab / Chemical Storage

-

1) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

2) Needed equipment, tools, supplies & parts are present within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

3) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs, and surfaces free of debris (no oil, dirt, chips, etc.) and organized? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

4) equipment in the area is clean, free of dirt, grime, etc. There is evidence of the cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

5) All item locations are indicated, and items are in their proper location. Shelves and storage areas are organized, clearly divided and labeled. There are no uncertainties about where items are stored.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

6. GMP aisle ways, workstations, equipment, and location are clearly marked. Stairs, exits & aisle ways are clearly marked to facilitate work flow and escape routes. Lighting in the work area is bright and adequate.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

7) Visual organization methods are being used where appropriate (shadow boarding, floor markings, etc.) and tools are placed in a manner that minimizes unnecessary movements such as walking, bending, or reaching.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

8) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

9) Needed equipment, tools, supplies & parts are present and within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

10) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs and surfaces free of debris (no oil, dirt, chips, etc.) and organized.? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

General Office / Exterior Plant

General Office / Exterior Plant

-

1) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

2) Needed equipment, tools, supplies & parts are present within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

3) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs, and surfaces free of debris (no oil, dirt, chips, etc.) and organized? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

4) equipment in the area is clean, free of dirt, grime, etc. There is evidence of the cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

5) All item locations are indicated, and items are in their proper location. Shelves and storage areas are organized, clearly divided and labeled. There are no uncertainties about where items are stored.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

6. GMP aisle ways, workstations, equipment, and location are clearly marked. Stairs, exits & aisle ways are clearly marked to facilitate work flow and escape routes. Lighting in the work area is bright and adequate.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

7) Visual organization methods are being used where appropriate (shadow boarding, floor markings, etc.) and tools are placed in a manner that minimizes unnecessary movements such as walking, bending, or reaching.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

8) All the unnecessary items in the work area are removed to proper storage. The only items present are those needed for production or current project.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

9) Needed equipment, tools, supplies & parts are present and within the work area. Unnecessary items are removed to proper storage. Only current / necessary documents are present in the work area.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

10) Does the area have trash, rubbish, etc. that should be disposed of? Floors, walls, stairs and surfaces free of debris (no oil, dirt, chips, etc.) and organized.? There is evidence of cleaning being performed in a constant manner. Checklist for cleaning is posted, visible and current.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

General Items

General Items

-

1) Have all employees had 5S Training (Review training documents)

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

2) Has periodic 5S inspections been performed?

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

3) Were all items on previous audit corrected (Review plant Prev. 5S audit)

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

4) All employees are meeting their Monthly Alchemy Food Safety and Safety Training requirements.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

5) Is there documentation on the Plants Safety Record.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media

-

6) There is a strong indication the culture is improving.

- 0 - 1 Exceptions. Currently meets 5S expectations

- 2 - 3 Exceptions. Significant 5S progress has been made

- 4 - 5 Exceptions. There is evidence of activity, although improvements can be made

- 6 - 7 Exceptions. Activity taking place, yet there is no consistency or sustained effort visible

- 8 - 10 Exceptions. There is minimal evidence that 5S activity has occurred

- 11 + Exceptions. No evidence of activity being done

- Not Applicable - MUST provide comment

-

COMMENT:

-

Add media