Information

-

Environmental Services Division: [Check the applicable operation]

- Collection Operations

- Processing Operations

- Injection Operations

- NORM Injection Operations

- Industrial Disposal Facility Operations

- Permian Basin Operations

-

Specialty Cleaning Systems Division: [Check<br>the applicable operation]

-

Facility Location/ Address:

-

Facility Manager:

-

Conducted On:

-

Evaluation Prepared By:

-

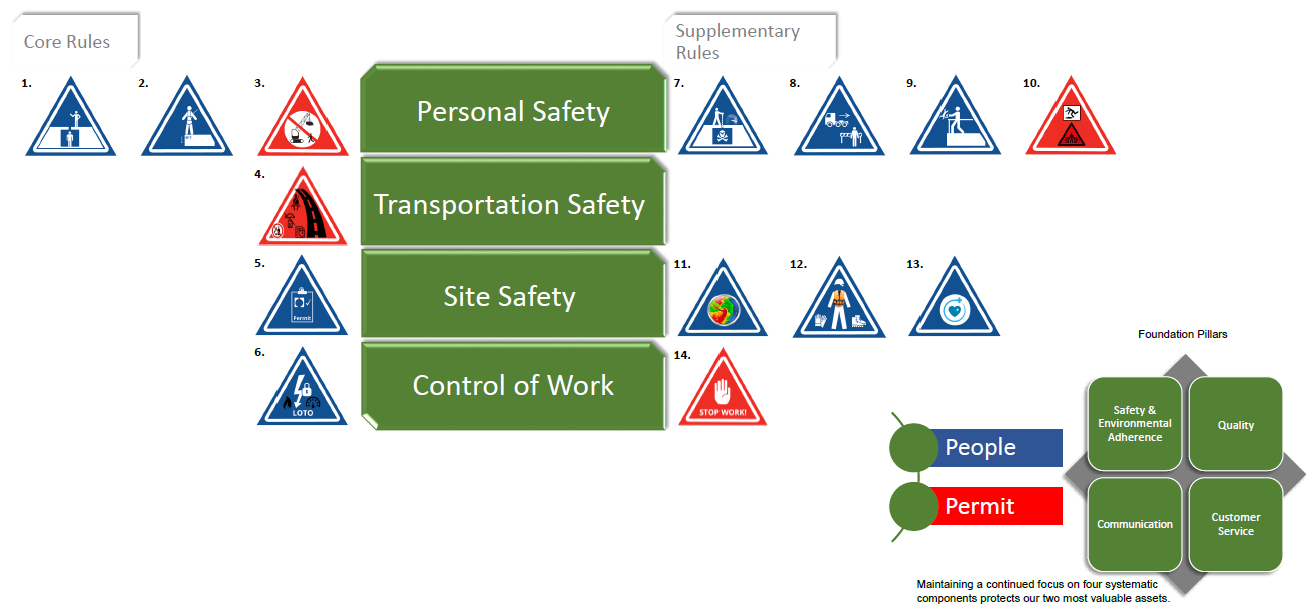

In support of a sustainable culture with a centered focus on Safety and Environmental Adherence, Quality, Communication and Customer Service we have developed this Annual Facility Inspection. The purpose of the inspection is to have local management annually review the topics in relation to each facility and share their findings with the EHS Department to acknowledge compliance strengths and/or developmental gaps and plans of action for closure. Each tilted section offers an input of “Coaching Comments and/or Recognition”. Please use such to provide directional guidance or positive acknowledgement supportive of the review. Evaluation closure is subject to the completion of any action items deemed required by the facilitator and/or the EHS Department.

Instructions:

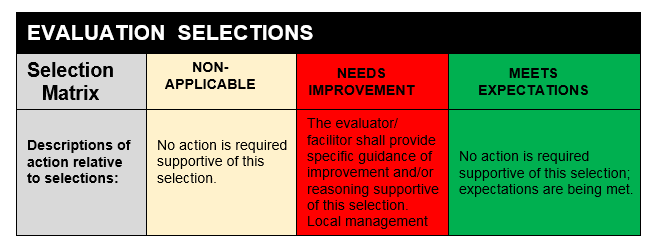

1. Open each tilted section by selecting "Yes"

2. Read through the baseline questions

3. Make a selection of "Meets Expectations", "Needs Improvement" or "Non-Applicable".

Some items will require dates and/or a reference of supportive materials

4. For each "Needs Improvement" selection a comment is required

Comments shall address improvement plan, responsible party and expected closure date

5. Questions were written to provide the auditor with guidance of baseline requirements that are of standard compliance from a Federal and/or State requirement and dependent on facility operations and/or employee exposures.

The quality of your feedback is essential to the success of this program, sustainability of our facilities, development of our personnel and safety culture. -

EVALUATION SELECTIONS

-

List by name any personnel present as a participant during this inspection:

-

The facilitator shall check the box to acknowledge they have reviewed the intent of this evaluation and the process with any personnel whom will been named as participants:

PREVIOUS INSPECTION DATA

-

Have all previous findings from other "Self-Verification" evaluations been addressed and/or closed?

-

Identify incomplete items, persons and/ or departments that are responsible for closure and expected closure dates

-

"Self-Verification" participation - Has your location achieved a successful percentage of completion for this calendar year (minimum of (2) conducted per month (24) annually)

-

Provide reasoning of performance and mitigation plan to close gap of below annual target

-

Provide number of "Self-Verification(s)" completed for this calendar year

1.0 OFFICE WORK AREAS

-

Does this inspection include work areas such as those identified in 1.0

-

Is the required OSHA Job Safety and Health Protection Poster displayed in a prominent location visible to all employees <br>

-

Is the Summary of Work-Related Injuries and Illnesses (OSHA Form 300A) posted during the months of February, March and April<br>

-

Are office machines cords kept off floor to prevent tripping

-

Are desk and file cabinet drawers kept closed when not in use

-

Are emergency exits clearly marked and properly illuminate

-

Are emergency evacuation routes posted

-

Are emergency telephone numbers posted and readily available in case of an emergency

-

Has an annual emergency drill been conducted

-

Enter the date of the last annual emergency drill on record

-

Has the facility's Hurricane Preparedness and Evacuation Plan been updated for this season/ calendar year

-

Enter the date of the last recorded update on record

-

Are items such as lockers, file cabinets, bookcases and shelves secured

-

Are heavy objects stored on lower shelves

-

Are emergency lights operational

-

Are designated smoking areas clearly marked

-

Is the facility equipped with fire extinguisher or proper fire defense equipment and is it stored properly

-

Has the fire alarm system been inspected in the past (12) months-<br>Inspection must be documented (verify)

-

Are gutters and downspouts in place and secured

-

Are exterior lights operational

-

Area Photograph(s)

-

Comments

2.0 FIRST-AID STATIONS

-

Does this inspection include equipment such as those identified in 2.0

-

Are first-aid kits available and adequately stocked

-

Is a first-aid log maintained for supplies issued

-

Are emergency eye wash stations available

-

Are portable emergency eyewash stations capped, labeled, within service date and easily accessible

-

Is an emergency shower available and operable

-

Is at least one employee on each shift currently qualified to render first aid in the event such is needed

-

Provide name(s) of persons trained in first-aid

-

Is there a occupational clinic and hospital for medical care near your facility

-

Name of Occupational Clinic and Hospital:

-

Area Photograph(s)

-

Comments

3.0 SAFETY MEETING

-

Does this inspection include a review of material as titled in 3.0

-

Is a completed daily safety meeting form present

-

Does the form identify a topics relevant to the work task and/or environment <br>

-

Are the topics aligned with the prior shifts Section 0.16 - Post Shift Evaluation

-

Are safety meeting forms filed/ maintained with an electronic copy on the Company's server within the "Safety Records" (Daily) folder

-

Posting Photograph(s)

-

Comments

4.0 (JSEA) JOB SAFETY ENVIRONMENTAL ANALYSIS/ PRE-JOB PLANNING

-

Does this inspection include a review of material as titled in 4.0

-

Is a JSEA written by use of the Company's current form and present for the task being performed

-

Does the JSEA cover environmental concerns and hazards

-

Is the JSEA signed by all personnel involved in the task including the PIC (Person in Charge)

-

Have all task affiliated risks identified been properly mitigated

-

Has each mitigation been assigned to an individual or group

-

Have proper work permits been signed and acknowledged by all effecting parties

-

Are SSE(s) identified on the JSEA

-

Is a Mentor assigned and noted

-

Is Stop-Work-Authority (SWA) addressed and noted on the JSEA

-

If applicable to task; i.e. Fall Protection or Confined Space Entry is rescue plan posted and in place

-

Posting Photograph(s)

-

Comments

5.0 BEHAVIOR BASED SAFETY

-

Does this inspection include a review of material as titled in 5.0

-

Is the S.H.I.N.E process being utilized

-

Are all personnel familiar and participating

-

Are the cards being properly completed (observed behavior, corrective action if applicable and/ or recommendations)

-

Is the PIC encouraging the process and reviewing observations daily

-

Are cards being filed for record following the PIC review

-

Photograph(s)

-

Comments

6.0 SHORT SERVICE EMPLOYEE

-

Does this inspection include a review of employee status as titled in 6.0

-

Has each SSE completed the Company's Verification of Competency Orientation

-

Has each SSE been assigned a mentor identified on the JSEA as well

-

Can each SSE identify their mentor

-

Are performance evaluations being conducted routinely on SSE employees - Section 36.1 - Employee Performance Reviews

-

Do total number of SSE's exceed 20% of crew (1 to 5 ratio) shall not exceed unless a variance approved by the company and/or the client

-

Photograph(s)

-

Comments

7.0 GENERAL WORK ENVIRONMENT

-

Does this inspection include an area such as what's identified in 7.0

-

Are all work areas clean, sanitary and orderly

-

Are work surfaces kept dry and appropriate means taken to assure the surfaces are slip-resistant

-

Is combustible scrap, debris and waste stored safely and removed from the work area promptly

-

Is all regulated waste, as defined by different agencies, discarded according to Federal, state and local regulations

-

Is waste properly stored and are the appropriate containers used

-

Are the minimum number of toilets and washing facilities provided and maintained in a clean and sanitary fashion (20 or less (1) and 20 or more (1) toilet seat and (1) urinal per (40) workers)

-

Are all work areas adequately illuminated

-

Are pits and floor openings covered or otherwise guarded

-

Have all confined spaces been evaluated for compliance with 29 CFR 1910.146 - signage posted accordingly

-

Are aisles and passageways kept clear and marked as appropriate

-

Are wet surfaces covered with non-slip materials

-

Are holes in the floor, sidewalk, or other walking surface repaired properly, covered, or otherwise made safe

-

Is there safe clearance for walking in aisles where motorized or mechanical handling equipment is operating

-

Are materials or equipment stored in such a way that sharp projections will not interfere with the walkway

-

Are changes of direction or elevations readily identifiable

-

Are aisles or walkways that pass near moving or operating machinery, hazardous operations, or similar operations arranged so employees will not be subjected to potential hazards

-

Is adequate headroom provided for the entire length of any aisle or walkway

-

Are standard guardrails provided wherever aisle or walkway surfaces are elevated more than 30 inches (76.20 centimeters) above any adjacent floor or the ground

-

Are safe walkways/ bridges provided over conveyors and similar hazards

-

Are floor openings guarded by a cover, a guardrail, or equivalent on all sides (except at stairways or ladder entrances)

-

Are all elevated surfaces beneath which people or machinery could be exposed to falling objects provided with standard 4-inch (10.16 centimeter) toe boards

-

Is the glass in windows, doors, glass walls, etc., subject to possible human impact, of sufficient thickness and type for the condition of use

-

Are grates or similar type covers over floor openings such as floor drains designed to allow unimpeded foot traffic or rolling equipment

-

Are manhole covers, trench covers and similar covers, and their supports designed to carry a truck rear axle load of at least 20,000 pounds (9,072 kilograms) when located in roadways and subject to vehicle traffic

-

Do standard stair rails or handrails on all stairways have at least four risers

-

Are all stairways at least 22 inches (55.88 centimeters) wide

-

Do stairs have landing platforms not less than 30 inches (76.20 centimeters) in the direction of travel and extend 22 inches (55.88 centimeters) in width at every 12 feet (3.6576 meters) or less of vertical rise

-

Do stairs angle no more than 50 and no less than 30 degrees

-

Are step risers on stairs uniform from top to bottom

-

Are steps slip-resistant

-

Are stairway handrails located between 30 inches (76.20 centimeters) and 34 inches (86.36 centimeters) above the leading edge of stair treads

-

Do stairway handrails have at least 3 inches (7.62 centimeters) of clearance between the handrails and the wall or surface they are mounted on

-

Where doors or gates open directly on a stairway, is a platform provided so the swing of the door does not reduce the width of the platform to less than 21 inches (53.34 centimeters)

-

Are stairway handrails capable of withstanding a load of 200 pounds (90.7 kilograms), applied within 2 inches (5.08 centimeters) of the top edge in any downward or outward direction

-

Where stairs or stairways exit directly into any area where vehicles may be operated, are adequate barriers and warnings provided to prevent employees from stepping into the path of traffic

-

Are signs posted, when appropriate, showing the elevated surface load capacity

-

Are surfaces that are elevated more than 30 inches (76.20 centimeters) provided with standard guardrails

-

Is a permanent means of access and egress provided to elevated storage and work surfaces

-

Is material on elevated surfaces piled, stacked, or racked in a manner to prevent it from tipping, falling, collapsing, rolling, or spreading

-

Are all exits marked with an exit sign and illuminated by a reliable light source

-

Are the directions to exits, when not immediately apparent, marked with visible signs

-

Are doors, passageways or stairways that are neither exits nor access to exits, but could be mistaken for exits, appropriately marked "NOT AN EXIT," "STOREROOM," etc.

-

Are exit signs labeled with the word "EXIT" in lettering at least 5 inches (12.70 centimeters) high and the stroke of the lettering at least l/2 inch (1.2700 centimeters) wide

-

Are exit doors side-hinged

-

Are all exits kept free of obstructions

-

Are at least two means of egress provided from elevated platforms, pits, or rooms where the absence of a second exit would increase the risk of injury from hot, poisonous, corrosive, suffocating, flammable, or explosive substances

-

Are there sufficient exits to permit prompt escape in case of emergency

-

Are exit doors able to be opened from the direction of exit travel without the use of a key or any special knowledge or effort when the building is occupied

-

Area Photograph(s)

-

Comments

8.0 FIRE PROTECTION

-

Does this inspection include equipment such as what's identified in 8.0

-

Is your local fire department familiar with your facility, its location and specific hazards

-

Are an adequate number of fire extinguishers available

-

Are the fire extinguishers properly spaced (travel distance every 50 feet or less) and mounted (carrying handle placed 3-1/2 to 5 feet above the floor) with regards to compliant height and signage requirements

-

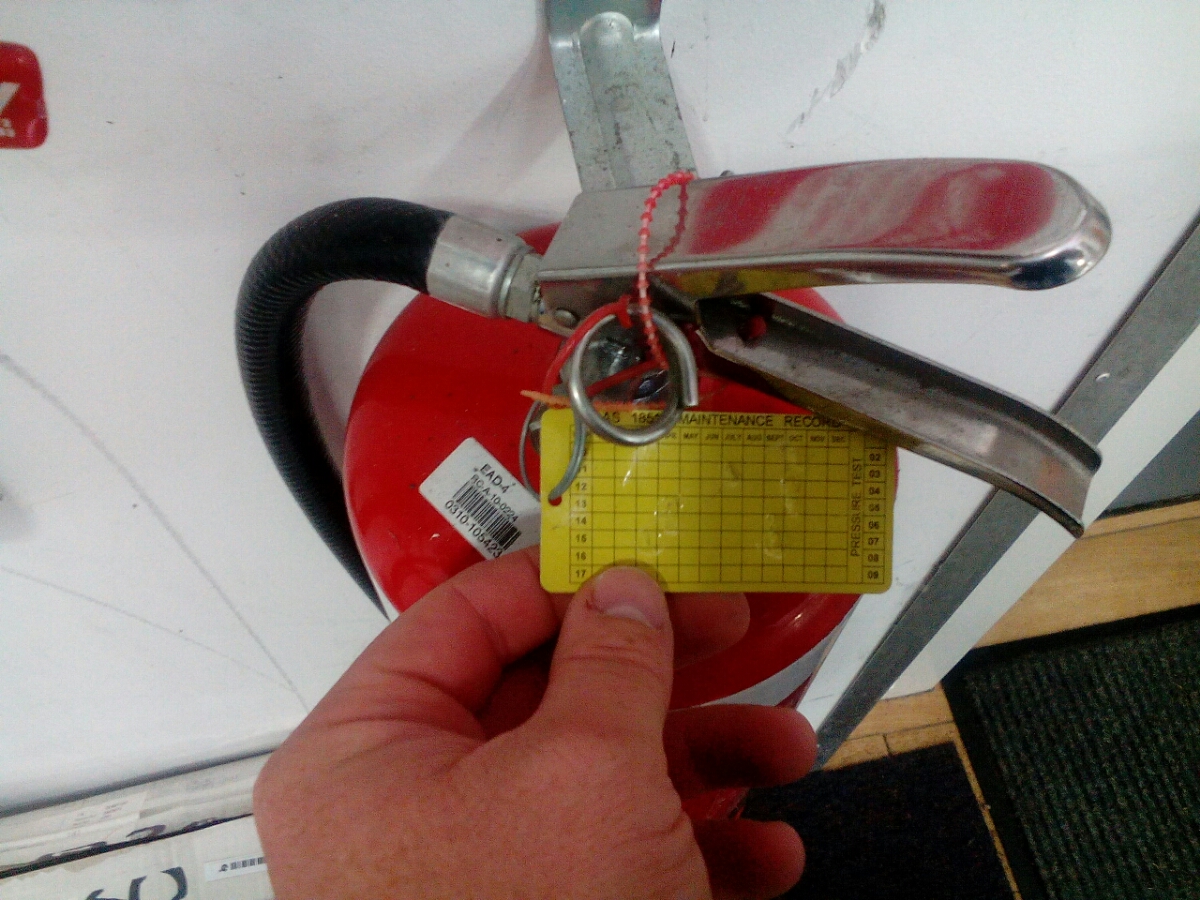

Have the fire extinguishers been inspected (annual and monthly inspection)- verify documentation

-

Enter the date reflective of the most recent annual inspection

-

Are fire extinguishers recharged regularly and inspected on a monthly basis with record of inspection

-

Are fire exits and extinguishers free of obstructions

-

Are cigarette containers specifically designed for cigarette butts and positioned away from combustible materials

-

Is combustible and flammable material properly stored away from ignition sources

-

Are combustible and flammable storage areas clearly marked

-

Are emergency exits clearly marked and properly illuminate

-

Are emergency evacuation routes posted

-

Are emergency telephone numbers posted and readily available in case of an emergency

-

Are employees periodically instructed/ refreshed in the use of fire extinguishers and fire protection procedures

-

Area Photograph(s)

-

Comments

9.0 FALL PROTECTION

-

Does this inspection include any hazard such as what's identified in 9.0

-

All practical options to eliminate the need to perform elevated work from heights have been explored

-

Fall protection risk and hazards are identified on the task related JSEA

-

A rescue plan has been developed and all equipment needed to execute is readily available and on site

-

All fall arrest equipment/ systems being utilized are in good condition and have been inspected prior to use

-

Has an annual equipment inspection been conducted and is a registry being maintained

-

Enter the date reflective of the most recent annual inspection

-

Fall protection system(s) being utilized allow workers to tied off 100% of the time

-

Anchor point vertical of the user

-

Anchor point(s) are capable of supporting 5000lbs

-

Photograph(s)

-

Comments

10.0 OPEN HOLE: Openings 2" or greater located in any walking or working surface

-

Does this inspection include any hazard such as what's identified in 10.0

-

Open holes have been properly barricaded and/or covered

-

Barricades have a top rail and middle rail: top rails of each barricade are at least 42" in height and are capable of withstanding a load of at least 200lbs applied in any direction

-

A 4" kick plate/ toe board, or third rail no more than 4" above the decking is installed if personnel are working below<br>

-

Open holes that cannot be immediately barricaded after exposure are monitored by an attendant (hole-watch) with no other duties and is equipped with fall protection at all times

-

Photograph(s)

-

Comments

11.0 DROPPED OBJECTS

-

Does this inspection include any hazard such as what's identified in 11.0

-

Dropped objects risk and hazards have been identified on the task related JSEA

-

Suitable bins are provided for small, loose objects such as off-cuts, welding rod stubs, nuts and bolts, etc.

-

All hand tools are secure and restrained from free falling

-

The area below is adequately barricaded and personnel have visual warnings to increase awareness to anyone wanting to enter

-

The upper level work area is tidy and all loose material, pieces of scrap, unwanted tools and equipment are removed and positioned safely out of the way

-

Photograph(s)

-

Comments

12.0 ELECTRICAL

-

Does this inspection include any hazard such as what's identified in 12.0

-

Are electrical enclosures such as switches, receptacles, junction boxes, etc., provided with tight-fitting covers or plates<br>

-

Are all disconnecting switches and circuit breakers labeled to indicate their use or equipment served<br>

-

Are all energized parts of electrical circuits and equipment guarded against accidental contact by approved cabinets or enclosures

-

Are all unused openings (including conduit knockouts) in electrical enclosures and fittings closed with appropriate covers, plugs, or plates

-

Are all components free of missing or loose parts

-

Are all electrical cords in use clear of damage and in a serviceable condition

-

Do extension cords have a grounding conductor

-

Are hand held electrical tools marked with a sticker that reads- IGNITION SOURCE

-

Are there any extension cords through walls, doors, ceilings, under rugs or mats - such practices are not approved

-

Electrical panels marked to indicate servicing voltage

-

Are exposed wiring and cords with frayed or deteriorated insulation repaired or replaced promptly

-

Are flexible extension cords and cables free of splices or taps

-

Are electrical appliances such as vacuum cleaners, hand held tools, portable fans, ice machines, vending machines, etc., grounded

-

Are portable electrical tools and equipment grounded or of the double insulated type

-

In wet or damp locations, are electrical tools and equipment appropriate for the use or location or otherwise protected

-

Is the location of electrical power lines and cables (overhead, underground, under floor, other side of walls, etc.) determined before digging, drilling, or similar work is begun

-

Is the use of metal ladders prohibited where the ladder or the person using the ladder could come in contact with energized parts of equipment, fixtures, or circuit conductors

-

Is sufficient access and working space provided and maintained around all electrical equipment to permit ready and safe operations and maintenance (36" or 3 feet)

-

Is low voltage protection provided in the control device of motors driving machines or equipment that could cause injury from inadvertent starting

-

Is each motor disconnecting switch or circuit breaker located within sight of the motor control device - Emergency Shutdown

-

Are employees prohibited from working on energized lines or equipment

-

Photograph(s)

-

Comments

13.0 GRINDERS/ ABRASIVE WHEEL TOOLS

-

Does this inspection include any equipment such as what's identified in 13.0

-

Do all grinders have the manufactures guards in place: control handle, disc guard and auto shut-off switch

-

Is double eye protection being utilized when grinding; i.e. safety glasses or goggles with a face-shield

-

On a stationary bench/ pedestal grinder - Is the work rest used and kept adjusted to within 1/8 inch (0.3175 centimeter) of the wheel

-

On a stationary bench/ pedestal grinder - Is the adjustable tongue on the top side of the grinder used and kept adjusted to within 1/4 inch (0.6350 centimeters) of the wheel

-

On a stationary bench/ pedestal grinder - Do side guards cover the spindle, nut and flange and 75 percent of the wheel diameter

-

Are bench and pedestal grinders permanently mounted

-

Is each electrically operated grinder effectively grounded

-

Are new abrasive wheels visually inspected and ring tested before they are mounted

-

Are work areas barricaded or a barrier used to protect other employees when grinding operations are active

-

Are grinders unplugged/ de-energized when not in use and/or when left unattended

-

Equipment Photograph(s)

-

Comments

14.0 WELDING, CUTTING AND BRAZING

-

Does this inspection include any task such as what's identified in 14.0

-

Are "Metal Fume" respirators available to welders

-

Are cylinders legibly marked to clearly identify the contents or type of gas

-

Are compressed gas cylinders secure and safe for operation

-

Are cylinders, cylinder valves, couplings, regulators, hoses and apparatuses kept free of oily substances

-

Are cylinders properly stored at a minimum of distance of 20 feet (6.1 m) or by a noncombustible barrier at least 5 feet (1.5 m) high having a fire-resistance rating of at least one-half hour

-

Are "No Smoking" signs posted in the compressed gas cylinder storage area

-

Are compressed gas cylinders kept clear of ignition sources

-

Are regulators removed and valve-protection caps put in place before moving cylinders, unless they are secured on special trucks

-

Before a regulator is removed, is the valve closed and gas released

-

Are regulator/ fuel sources shut-off and pressures released when not in use and/or when left unattended

-

Are liquefied gases stored and shipped valve-end up with valve covers in place

-

Are fittings inspected for leaks and properly tightened (confirm with soap and water solution in spray bottle)

-

Are portable tinted barriers available in the welding/ cutting area

-

Are Arc Welding machines grounded

-

Are used drums, barrels, tanks and other containers thoroughly cleaned of substances that could explode, ignite, or produce toxic vapors before hot work begins

-

Are employees exposed to the hazards created by welding, cutting, or brazing operations protected with PPE and clothing

-

Is suitable fire extinguishing equipment available for immediate use

-

Are electrodes removed from the holders when not in use

-

Is a check made for adequate ventilation in and where welding or cutting is performed

-

Are combustible floors kept wet, covered with damp sand, or protected by fire-resistant shields

-

When the object to be welded cannot be moved and fire hazards cannot be removed, are shields used to confine heat, sparks and slag

-

When working in confined places, are environmental monitoring tests done and means provided for quick removal of welders in case of an emergency

-

Are fire watchers assigned when welding or cutting is performed and must remain on location for a duration of (30) minutes following hot-work is complete for fire prevention purposes

-

Is grounding of the machine frame and safety ground connections of portable machines checked periodically

-

Is red used to identify the acetylene (and other fuel-gas) hose, green for the oxygen hose and black for inert gas and air hoses

-

Photograph(s)

-

Comments

15.0 CONFINED SPACE

-

Does this inspection include any hazard such as what's identified in 15.0

-

Has a rescue plan been developed, discussed, documented and posted prior to entry

-

Are confined spaces thoroughly emptied of any corrosive or hazardous substances, such as acids or caustics, before entry

-

Are all lines to a confined space that contain inert, toxic, flammable, or corrosive materials closed by valve, disconnected or double isolated and relieved of pressure and/ or separated before entry<br><br>* A flammable gas, vapor or mist in excess of 10% of its’ lower flammable limit (LFL)<br>* An oxygen deficient atmosphere containing less than 19.5% oxygen by volume or an oxygen enriched atmosphere containing more than 23.5% oxygen by volume<br>* Airborne combustible dust at a concentration that meets or exceeds its LFL (airborne combustible dust which obscures vision at five feet or less)<br> • An oxygen-deficient atmosphere has less than 19.5% available oxygen. Any atmosphere with less than 19.5% oxygen shall not be entered. This is an atmosphere that is Immediately Dangerous to Life and Health (IDLH) without an approved self-contained breathing apparatus (SCBA).<br><br>

-

Are all impellers, agitators, or other moving parts and equipment inside confined spaces locked out if they present a hazard

-

Is either natural or mechanical ventilation provided prior to confined space entry<br>

-

Is adequate illumination provided for the work to be performed in the confined space<br>

-

Has the appropriate atmospheric tests been performed to check for oxygen deficiency, toxic substances and explosive concentrations in the confined space before entry

-

Is the atmosphere inside the confined space continuously monitored and frequently documented during work (should be posted)<br>

-

Before entry has the confined space entry supervisor approved the space safe for entry and documented such on the entry log

-

Is there a trained and equipped standby employee positioned outside the confined space, whose sole responsibility is to watch the work in progress, sound an alarm if necessary and render assistance<br>

-

Is the standby employee appropriately trained, comfortable and equipped to handle an emergency (can they explain their role and method of communication) <br>

-

Is approved respiratory equipment required if the atmosphere inside the confined space cannot be made acceptable <br>

-

Photograph(s)

-

Comments

16.0 HIGH PRESSURE CLEANING

-

Does this inspection include any task such as what's identified in 16.0

-

Is the appropriate approved PPE being used during blasting and cleaning procedures

-

Is the operator(s) standing in a position that is safe and allows full control of the water jetting equipment without body strain

-

Is there a safety observer ready to shut down the system in the event of an emergency or a malfunction

-

Are the pressure jetting guns or lances equipped with a fast acting hold-to-activate device that when deactivated, will stop the flow of high pressure water (direct control of the operator)

-

Is the operator wearing personal protective clothing and equipment on their body, hands, arms, legs and feet, including the metatarsal area

-

Has all the equipment been inspected prior to beginning the process; i.e. guns, gauges, whip checks, hoses, etc.

-

Are fittings and valves properly secure

-

Are the hoses marked with the following information: manufacturers identification, date of manufacture and maximum operating pressure

-

Is the equipment being used including guns, foot control devices, hoses and nozzles suitable for use with greater than or equal to the maximum operating pressure of the high pressure pump

-

Is the jetting/ blasting system depressurized and secured when not in use and/or when left unattended

-

The area is properly barricaded and also visual warnings signs have been posted to increase awareness of the hazards associated with entering the area

-

Is the cleaning procedure being performed in a well ventilated area

-

Are environmental practices being followed

-

Photograph(s)

-

Comments

17.0 SCAFFOLDING

-

Does this inspection include any equipment such as what's identified in 17.0

-

Has the scaffolding been inspected and tagged approved for use

-

Is the scaffolding equipment equipped with the appropriate guard rails and work platforms

-

Is the staging surfaces level, smooth and free of obstructions (proper footing in place)

-

For any personnel assigned to work from scaffolding, do they maintain current the correct credentials; i.e. use and inspection training

-

Has the planning for such work been documented and reviewed by use of the JSEA process

-

Equipment Photograph(s)

-

Comments

18.0 LADDERS

-

Does this inspection include any equipment such as what's identified in 18.0

-

Are all ladders maintained in good condition, joints between steps and side rails tight, all hardware and fittings securely attached, and moveable parts operating freely without binding or undue play

-

Are ladders inspected for damage before use

-

Are non-slip safety feet provided on each metal or rung ladder, and are ladder rungs and steps free of grease and oil<br>

-

Are the labels on ladders readable/ legible not deteriorated

-

Are portable metal ladders legibly marked with signs reading "CAUTION - Do Not Use Around Electrical Equipment" or equivalent wording<br>

-

Are employees instructed not to use the top step of ordinary stepladders as a step

-

When portable rung ladders are used to gain access to elevated platforms, roofs, etc., does the ladder always extend at least 3 feet (0.9144 meters) above the elevated surface

-

Are employees required to secure the base of a portable rung or cleat type ladder to prevent slipping, or otherwise lash or hold it in place

-

Are employees instructed to only adjust extension ladders while standing at a base (not while standing on the ladder or from a position above the ladder)?

-

Equipment Photograph(s)

-

Comments

19.0 HOSES

-

Does this inspection include any equipment such as what's identified in 19.0

-

Are the hoses marked with the following information: manufacturers identification, date of manufacture and maximum operating pressure

-

Are hoses in good, safe working condition

-

Are secondary protectors in place, i.e. safety pins and whip checks

-

Are the gaskets for each connection inspected and replaced if worn, distorted or too soft

-

Are hoses laid out so that they will not obstruct the pathway of employees

-

Are hoses flushed and/or a decontaminating process completed prior to storage or preparation for travel

-

Is secondary containment utilized at connection points

-

Are connections inspected before use and routinely while in use

-

Equipment Photograph(s)

-

Comments

20.0 PORTABLE HAND TOOLS AND EQUIPMENT

-

Does this inspection include any equipment such as what's identified in 20.0

-

Are only tools and equipment owned by the Company used at the workplace and is such in good condition

-

Are hand tools, such as chisels, punches, etc., which develop mushroomed heads during use, reconditioned or replaced as necessary<br>

-

Are broken or fractured handles on hammers, axes and similar equipment replaced promptly

-

Are worn or bent wrenches replaced

-

Are tools stored in a dry, secure location where they cannot be tampered with

-

Is there adequate lighting in all areas including exterior

-

Are grinders, saws and similar equipment provided with appropriate safety guards

-

Are portable circular saws equipped with guards above and below the base shoe

-

Are rotating or moving parts of equipment guarded to prevent physical contact

-

Are all cord-connected, electrically operated tools and equipment effectively grounded or of the approved double insulated type

-

Area Photograph(s)

-

Comments

21.0 PERSONAL PROTECTIVE EQUIPMENT

-

Does this inspection include any protective requirement that would fall under what's identified in 21.0

-

Has an annual PPE assessment been performed for the location/ operation

-

Enter the date of the last annual PPE assessment

-

Are employees being provided PPE designed and adequate to exposures; initially free of charge to the employee

-

Is PPE being used appropriate for the task

-

Is PPE being utilized as written on task planning documentation; i.e. JSEA

-

Are employees who wear corrective lenses (glasses or contacts) wearing only approved safety glasses, protective goggles, or use other medically approved precautionary procedures

-

Are the respirators (NIOSH) approved for this particular application - National Institute for Occupational Safety and Health<br>

-

Is all PPE maintained and stored in a sanitary condition and ready for use

-

Are adequate work procedures, PPE and other equipment provided and used when cleaning up spilled hazardous materials

-

Are appropriate procedures in place to dispose of or decontaminate PPE contaminated with, or reasonably anticipated to be contaminated

-

If any observed PPE does not meet the criteria above please identify:

- Respiratory Protection CFR 1910.134

- Eye Protection ANSI Z87.1, CFR 1910.133

- Hand Protection Proper to Task, CFR 1910.138

- Body Protect Proper to Element Exposure

- Foot Protection ASTM F2412-05, CFR 1910.136

- Head Protection ANSI Z89.1, CFR 1910.135

- Fall Protection CFR 1910.269

- Hearing Protection CFR 1910.95

-

Equipment Photograph(s)

-

Comments

22.0 NOISE

-

Does this inspection include any hazard such as what's identified in 22.0

-

Are there areas in the workplace where continuous noise levels exceed 85 decibels<br>

-

Is there an ongoing preventive program to educate employees in safe levels of noise, exposures, effects of noise on their health and the use of personal protection - Is such discussed routinely

-

Is approved hearing protective equipment (noise attenuating devices) available to every employee working in noisy areas

-

Are employees utilizing hearing protection equipment

-

Have work areas where noise levels make voice communication between employees difficult been identified and posted

-

Add media

-

Comments

23.0 HAZARD COMMUNICATION/ RIGHT TO KNOW

-

Does this inspection include (GHS) Globally Harmonized System materials as what's identified in 23.0

-

The Right-to-Know refers to workers' rights to information about chemicals in their workplaces. The federal law that provides these rights is the OSHA Hazard Communication Standard (29 CFR 1910.1200). Private-sector employers must provide chemical information to their workers under the OSHA standard.

-

GHS stands for the Globally Harmonized System of Classification and Labeling of Chemicals. GHS defines and classifies the hazards of chemical products, and communicates health and safety information on labels and safety data sheets) goal is that the same set of rules for classifying hazards, and the same format and content for labels and safety data sheets (SDS) will be adopted and used around the world. An international team of hazard communication experts developed GHS.

-

Are SDS(s) present for all chemicals onsite

-

Are personnel aware of the location of the SDS(s)

-

Are personnel familiar with safety precautions regarding chemical usage

-

Is only the minimum amount of chemical in the area and/or properly contained

-

Are chemicals stored of in proper conditions; i.e. cabinets, elements, secured, combustibles, etc.

-

Is each container for a hazardous substance/ chemical (i.e., vats, bottles, storage tanks, etc.) labeled with product identity and a hazard warning in accordance with GHS standards (communication of the specific health hazards and physical hazards)?

-

If chemicals are in use; were safe usage procedures included on the JSEA up to and including emergency procedures

-

Area Photograph(s)

-

Comments

24.0 RIGGING

-

Does this inspection include any task or equipment such as what's identified in 24.0

-

Are all slings and rigging equipment inspected by a competent source (3rd Party w/ certificate of inspection) annually

-

Is all the rigging equipment equipped with legible identification tags

-

Are all the identification tags labeled with a working load limit

-

Is all rigging material inspected prior to use and the correct material for the task of which it is used

-

Are all rigging hooks equipped with a working safety latch

-

Are proper rigging practices being followed

-

Are only qualified riggers performing rigging duties

-

Equipment Photograph(s)

-

Comments

25.0 FORK-LIFT INDUSTRIAL TRUCKS

-

Does this inspection include any equipment such as what's identified in 25.0

-

Verify that the operator is current and up-to-date on their operating qualifications-<br>If the operator is not current they are immediately deemed unsafe to operate until training is brought current

-

Has a pre-use inspection been performed and is it documented-<br>Check for accuracy in regards to leaks (oil, air and water), appearance, signs and logos, safety equipment, lights, tires, etc.

-

Does each industrial truck have an operational warning horn, whistle or other device that can be clearly heard above normal noise in the areas where it is operated- <br>if not equipped or the device is not operational the equipment shall be serviced immediately as it is not in safe operating compliance <br>

-

Is the operator utilizing a safety belt/ seatbelt when operating

-

Is substantial overhead protective equipment provided on high lift rider equipment

-

Are industrial trucks operating where flammable gases, vapors, combustible dust or ignitable fibers present <br><br>

-

Are loads handled only within the rated capacity of the truck<br>

-

Operator follows correct procedures for an "unattended" vehicle; i.e. the vehicle is never left unattended with the engine running

-

Does the parking brake of the industrial truck prevent the vehicle from moving when unattended; meaning is it operable <br>

-

Are operators using ground guide personnel when maneuvering with in 10FT of any obstacle

-

Equipment Photograph(s)

-

Comments

26.0 CRANES AND EXCAVATORS

-

Does this inspection include any equipment such as what's identified in 26.0

-

Verify the annual inspection of the crane is current-<br>If the equipment has not been inspected by a professional inspection firm in the past (12) months this equipment is deemed unsafe and shall be locked out of service

-

Enter most recent date of the Certificate of Annual Inspection on file

-

Multiple crane information can be entered here

-

Enter most recent date of the Certificate of Annual Inspection on file

-

Provide mitigation plan to achieve compliance - If an annual is overdue the Crane must be locked out of service until a certificate of achievement is obtained

-

Verify that the operator is current and up-to-date on their operating qualifications-<br>If the operator is not current they are immediately deemed unsafe to operate until training is brought current

-

Does the equipment have an operational warning horn, whistle or other device that can be clearly heard above normal noise in the areas where it is operated- <br>if not equipped or the device is not operational the equipment shall be serviced immediately as it is not in safe operating compliance

-

Has a pre-use inspection been performed and is it documented-<br>Check for accuracy in regards to leaks (oil, air and water), appearance, signs and logos, safety equipment, lights, glass, track condition, cable condition, etc.

-

Is there a designated "Signal Man" to provide the operator hand signals and are they identified on the JSEA

-

Is the equipment staged properly for safe lifting or operating practices; i.e. adequate swing radius, safe boom angle at least 3'FT from the boom stops, etc. <br>(If "NO" specify in the comments section and provide media)

-

Has the operator identified and marked a perimeter around the swing radius of the equipment as to warn personnel-<br>The swing radius shall be barricaded in such a manner as to prevent an employee from being struck or crushed during cab maneuvering operations<br>IF NOT- all operations shall cease until changes to gain compliance are made

-

Are there any obstructions which block the operators line of sight

-

Are operators using ground guide personnel when maneuvering with in 10FT of any obstacle

-

Is the operator utilizing a safety belt/ seatbelt when operating

-

Operator follows correct procedures for an "unattended" vehicle; i.e. the vehicle is never left unattended with the engine running and not locked out

-

Is the operator utilizing "Radio" communications to support signaling when operating

-

Is the operator familiar with lift planning and requirements beyond the use of a JSEA (Section 10.14 - Lift Plan Permit 2.0) and is there evidence of such being practiced

-

Equipment Photograph(s)

-

Comments

27.0 SKID LOADER

-

Does this inspection include any equipment such as what's identified in 27.0

-

Has a pre-use inspection been performed and is it documented-<br>Check for accuracy in regards to leaks (oil, air and water), appearance, signs and logos, safety equipment, lights, tires, etc.

-

Verify that the operator is current and up-to-date on their operating qualifications-<br>If the operator is not current they are immediately deemed unsafe to operate until training is brought current

-

Does the equipment have an operational warning horn, whistle or other device that can be clearly heard above normal noise in the areas where it is operated- <br>if not equipped or the device is not operational the equipment shall be serviced immediately as it is not in safe operating compliance

-

Is the operator utilizing a safety belt/ seatbelt when operating

-

Operator follows correct procedures for an "unattended" vehicle; i.e. the vehicle is never left unattended with the engine running

-

Are operators using ground guide personnel when maneuvering with in 10FT of any obstacle

-

Equipment Photograph(s)

-

Comments

28.0 ATMOSPHERIC TESTING/ MONITORING

-

Does this inspection include any equipment such as what's identified in 28.0

-

Are the employees trained, competent and comfortable with using a gas monitor-<br>If any answer to the above is "NO" all associated work associated with monitoring shall halt until it is safe to proceed

-

Is there a (4) sensor gas detector(s) and/or VOC metering device(s) available and on-site

-

Model(s) and Serial Number(s) of the unit(s)

-

Has the gas detector(s) been bump tested prior to use that day-<br>Verify documentation!

-

What's the last date that a full calibration was performed on the gas monitor

-

Is the gas monitor(s) fully operational, charged and adequate for use/ exposure

-

Are the air samples being documented on an Air Monitoring Results Form-<br>Verify readings

-

Device Photograph(s)

-

Comments

29.0 ENVIRONMENTAL CONTROLS

-

Does this inspection include any equipment such as what's identified in 29.0

-

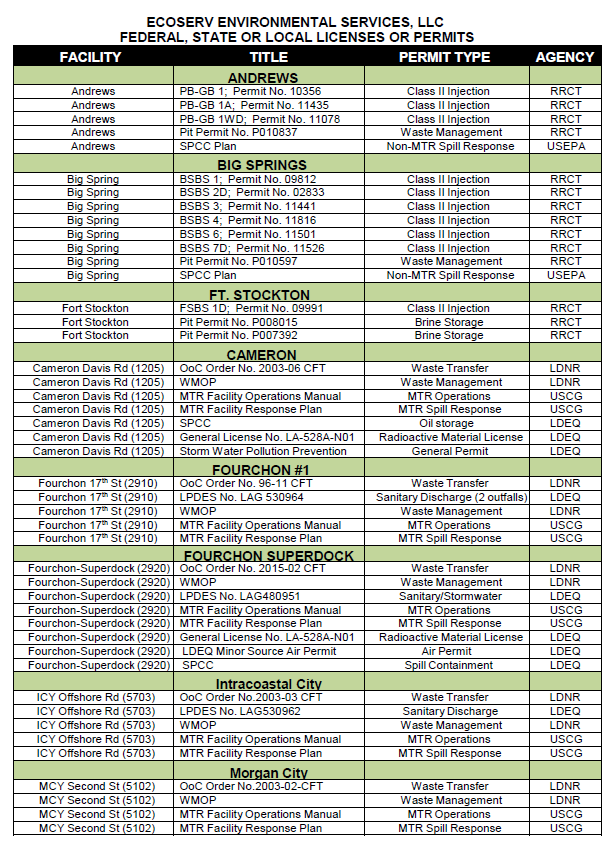

Environmental Services Federal, State or Local Licenses or Permit Reference Page #1

-

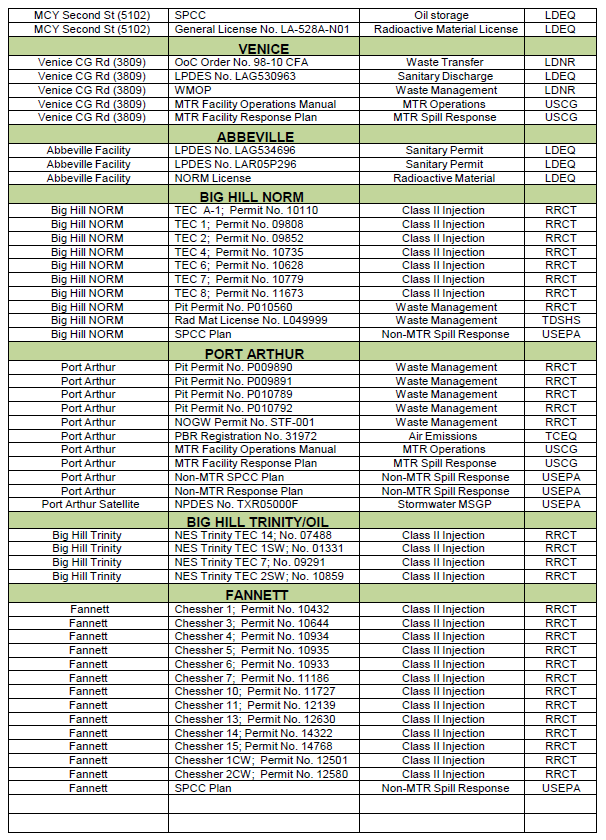

Environmental Services Federal, State or Local Licenses or Permit Reference Page #2

-

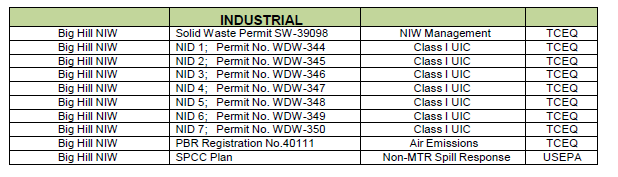

Environmental Services Federal, State or Local Licenses or Permit Reference Page #3

-

Are unusable chemicals, contaminated rags, used oil, etc. properly contained and scheduled for adequate disposal

-

Are recyclable materials being stored in a manner that they are available for pickup by a scheduled recycler on a regular basis

-

If applicable; is the Facility's Spill, Prevention, Control and Countermeasure (SPCC) plan current and being followed - (Verify) <br>

-

For applicable facilities; have all the employees been trained on the (SPCC) Plan and is it documented

-

Is the facility covered under a Storm-Water-Pollution-Prevention <br>Applies only to Cameron, Fourchon Superdock and Port Arthur Satellite Stockpile facility which falls under EPA MSGP, not TX MSGP<br>

-

Have the employees been trained with regards to storm water in the past (12) months <br>The employee training requirements of the EPA MSGP are not specific; EPA "recommends" annual training, but does not require it; this applies only to the Port Arthur Satellite stockpile facility, which has one employee, who has been thoroughly trained regarding the MSGP

-

Is the Facility visually monitoring storm water discharges at a minimum of (4) times per year<br>(1) documented monitoring report each quarter<br>Quarterly visual monitoring is done at the Port Arthur stockpile facility

-

Is storm water being adequately protected with a Best Management Practices (BMP) Plan <br>The Port Arthur satellite stockpile facility has a storm water pollution plan including BMP's

-

Are materials such as scrap metal, batteries, etc. stored properly according to the plan <br>(Area under cover protecting the environment for uncontrollable releases during weather)

-

Is the sewer treatment system being properly maintained on a regular scheduled basis-<br>Verify records of treatment additives that are being used; i.e. Chlorine tablets<br>(All of our facilities with package sewage units have maintenance contracts with local providers)<br>Package units at LA facilities discharge to waters of the State and are covered under an LPDES general permit.<br>Package units at TX facilities discharge to irrigation fields and do not require discharge permits.

-

Are waste manifest being properly reviewed for correct completion by trained representatives

-

Are waste manifest filed for record supportive of a collected sample prior to receipt of product

-

Verify the receipt of waste manifest protocols for compliance accuracy

-

Are all "transfer hoses and connections" properly identified, labeled for use and also locked with secondary pinned protection- visually inspect to verify condition

-

Are "Fill/ Full Level" of facility receiving tank(s) inspected for safe operating tolerance on a routine basis; i.e. gauges and/or alarms working - visually inspect to verify condition

-

Are "holding tank(s)" being routinely inspected for leaks and/or seepage - visually inspect to verify condition

-

Are "grounding station(s)" being inspected for proper grounding conditions/ adequate connections before transfer - visually inspect to verify condition

-

Are "transfer pumps" being routinely inspected; i.e. connections and integrity of pump housing

-

Are United States Coast Guard (USCG) requirements of a Marine Transportation-related facility (MTR) in compliance

-

Provide areas of improvement recognized, with a responsible party to address as well as a plan to achieve compliance

-

Are the regulatory requirements of State Agencies in compliance

-

Provide areas of improvement recognized, with a responsible party to address as well as a plan to achieve compliance

-

Are the regulatory requirements of Federal Agencies in compliance

-

Provide areas of improvement recognized, with a responsible party to address as well as a plan to achieve compliance

-

Is "emergency response equipment" available, operable and/or does assigned personnel know how to react given a situation where to arise

-

Are "Well Pressures" being inspected on a routine basis (daily) and such are within operating tolerance - visually inspect to verify

-

Has an annual emergency environmental drill been conducted; i.e. table top drill, physical walk-through etc.

-

Enter a date reflective of the most recent annual emergency environmental drill

-

Is the "delisted area" maintained in accordance with Waste Management Planning

-

Select all that have been found accurate in regards to compliance

- Storage is supportive of manifest on file

- Waste is properly segregated

- Spill protection is adequate

- Personnel have completed annual training

- Response planning is in order

-

Confirm the last time and date of inspection for the "delisted area"

-

Are storage times of waste compliant with planning prior to the waste being treated, disposed, or stored elsewhere

-

Area Photograph(s)

-

Comments

30.0 HOUSEKEEPING

-

Area Photograph(s)

-

Comments

31.0 SPECIALITY OR CRITICAL TASK

-

Area Photograph(s)

-

Comments

32.0 GENERAL SAFETY

-

The Company’s CORE Values and P.A.L.S. (Performance, Accountability, Life & Systems = Safe & Sustainable) Signage:

• Safety is No Accident- By design we protect our people and customers, focus on safety.

• Science Beyond Compliance- More than required, above and beyond, the right thing to do.

• We are People of Character- Self-respect, dignity, professionalism, integrity.

• One for All- Selflessness, family, accountability.

• No Status Quo- Rethink routine, innovation, ingenuity, creativity. -

Is the culture of management and personnel aligned with the Company’s P.A.L.S. Program; both the (10) Tools and (14) Fatal Risk Prevention Tools

-

Does the environment offers a designated area for food and drink consumption out of the work area

-

Are waste receptacles emptied regularly

-

Are food or beverages consumed only in areas where there is no exposure to toxic material or other potentially infectious materials

-

Are refrigerators maintained in a sanitary and safe for use condition; i.e. routinely cleaned and purged of expired contents

-

Are pre-use inspections being performed on all company owned pieces of equipment

-

Are pre-use inspections documented; i.e. leaks (oil, air and water), appearance, signs and logos, safety equipment, lights, tires, etc.

-

If applicable- does the facility have available gangways and such are being utilized in support of the standard (access to vessels 1915.74(a))

-

If applicable- Are all water coolers sealed and labeled with a date of liquid fill

-

Add media

-

Comments

33.0 ACTION ITEMS

-

Site Related

-

Management Related

-

Employee Related

-

Safety Related

34.0 ONSITE CONVERSATION/ CONCERNS

-

Comments

35.0 ACKNOWLEDGEMENT SIGNATURES

-

(PIC) Person In Charge Name

-

Name of Audit Facilitator