Title Page

-

Conducted on

-

Prepared by

-

Location

FSP 4.1.1 Kitchen Daily Cleaning Schedule

Equipment

-

Dishwasher<br><br>Frequency - Daily | Technique - Clean surrounds | Chemical - All Purpose Cleaner

-

Kettle<br><br>Frequency - Every Batch | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Brat Pan<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Under bench Fridges<br><br>Frequency - Daily | Technique - Clean surrounds | Chemical - All Purpose Cleaner

-

Rational Ovens<br><br>Frequency - Daily | Technique - See SOP for cleaning | Chemical - All Purpose Cleaner

-

Grill Plate<br><br>Frequency - Daily | Technique - See SOP for cleaning | Chemical - All Purpose Cleaner

-

Stove Tops<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - KP Oven & Grill Cleaner

-

Deep Fryers<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - KP Oven & Grill Cleaner

-

Mixer<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - KP Oven & Grill Cleaner

-

Hot boxes<br><br>Frequency - As required | Technique - See SOP for cleaning | Chemical - All Purpose Cleaner

-

Pulp Master<br><br>Frequency - As required | Technique - See SOP for cleaning | Chemical - All Purpose Cleaner

Environmental

-

Benches<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Shelfs <br><br>Frequency - Daily | Technique - Clean surrounds | Chemical - All Purpose Cleaner

-

Sinks<br><br>Frequency - As required | Technique - Remove soil & clean | Chemical - All Purpose Cleaner/Sanitizer

-

Hand wash basin<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner/Sanitizer

-

Dry Store<br><br>Frequency - Daily | Technique - Clean surrounds | Chemical - All Purpose Cleaner

-

Floors<br><br>Frequency - As required | Technique - Remove soil & wash | Chemical - All Purpose Cleaner/Degreaser

-

Walls<br><br>Frequency - Daily | Technique - Clean & Sanitize | Chemical - All Purpose Cleaner

-

Drains<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Bins<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Door- handles / Flaps<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

Refrigeration

-

Freezer / Cool room<br><br>Frequency - As required | Technique - Clean surrounds | Chemical - All Purpose Cleaner

-

Blast Chillers<br><br>Frequency - As required | Technique - Clean surrounds | Chemical - All Purpose Cleaner

-

Ice Machines<br><br>Frequency - Daily | Technique - See SOP for cleaning | Chemical - All Purpose Cleaner

Dishwasher Temperature

-

Time temperature taken

-

🔴 Temperature does not meet requirements. Corrective action must be noted.

-

Corrective action notes

-

🔴 Temperature does not meet requirements. Corrective action must be noted.

-

Corrective action notes

-

Enter employee name and signature

-

Comments/Corrective Actions

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.1.2 Retail outlet Daily Cleaning Schedule

-

Hot Display / Bain Marie<br><br>Frequency - Daily | Technique - Remove spills & clean | Chemical - All Purpose Cleaner

-

Cold Display<br><br>Frequency - Daily | Technique - Remove spills & clean | Chemical - All Purpose Cleaner

-

Carvery<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Sinks<br><br>Frequency - As required | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Benches<br><br>Frequency - As required | Technique - Clean & Sanitize | Chemical - All Purpose Cleaner/Sanitizer

-

Drains<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Floors<br><br>Frequency - As required | Technique - Remove soil & wash | Chemical - All Purpose Cleaner/Degreaser

-

Bins<br><br>Frequency - As required | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Under bench Fridges<br><br>Frequency - Daily | Technique - Remove spills & clean | Chemical - All Purpose Cleaner

-

Cool room & fridges<br><br>Frequency - Daily | Technique - Remove spills & clean | Chemical - All Purpose Cleaner

-

Hand Sink<br><br>Frequency - Daily | Technique - Clean & Sanitize | Chemical - All Purpose Cleaner/Sanitizer

-

Toaster<br><br>Frequency - Daily | Technique - Clean loose soils | Chemical - All Purpose Cleaner/Sanitizer

-

Point of Sale (POS)<br><br>Frequency - Daily | Technique - Clean surrounds | Chemical - All Purpose Cleaner/Sanitizer

-

Coffee Machine<br><br>Frequency - Daily | Technique - As per manufacturers instructions | Chemical - N/A

-

Coffee Blender<br><br>Frequency - Daily | Technique - As per manufacturers instructions | Chemical - N/A

-

Walls (shoulder height)<br><br>Frequency - Daily | Technique - Clean & Sanitize | Chemical - All Purpose Cleaner

-

Ovens<br><br>Frequency - Daily | Technique - Remove spills & clean | Chemical - All Purpose Cleaner

-

Walls Frequency - Daily | Technique - Clean & Sanitize | Chemical - All Purpose Cleaner

- √

- X

- N/A

-

Door- handles / Flaps Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

- √

- X

- N/A

-

Ice Machines<br><br>Frequency - Daily | Technique - Remove soil & clean | Chemical - All Purpose Cleaner

-

Enter employee name and signature

-

Comments/Corrective Actions

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

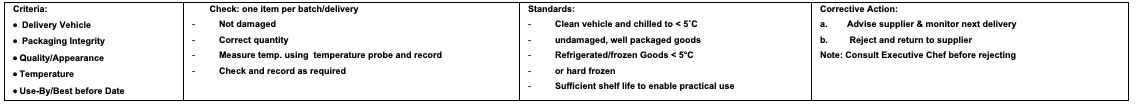

FSP 4.2 Receipt of Incoming Goods

-

-

Select Date

-

Enter Supplier Name

- Alaska Crab

- Andrews Meat

- Baron Bakery

- Continental Patisserie

- Farmer Joes Chicken

- Fresh Ness

- Game Farm

- Grumpy Baker

- Hoshi Sushi/Heng

- Loftus Cakes

- Milkman

- Magnetic Foods

- M&G Seafood

- The Brasserie Bread

- The Bread Spread

- UncleTony's

- Exotic Cuisine

- Vilis Pies

- Smith's Snackfoods

- De Bortoli Wines

- EH Palmer

- Lion Dairy and Drinks

- OTHER

-

Product

-

Quality /Appearance pack condition

-

NON-Conforming Temperature

-

Enter action taken

-

Enter employee number and sign

-

Use/By or Best Before Date/Doc Num

-

Corrective Action taken if required

-

Accept/Reject Incoming goods

-

Enter name and signature of employee

-

Date

-

Manager/Supervisor or authorised signatory

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.3 Process Temperature Log

- TEMPERATURE LOG

Function / Event

-

Enter function/event name

Process

-

Select Heat Process (multiple selections available)

- Sealing

- Cooking

- Re-heat

-

-

Enter product name

-

Start Time

-

Finish time

-

-

Enter product name

-

Start Time

-

Finish time

-

-

Enter product name

-

Start Time

-

Finish time

Cooling Log

-

Cooling Steps

Safe cooling: Temperature after 2hrs must be at or below 21°C Temperature after a further 4hrs must be at or below 5°C -

Enter product

-

-

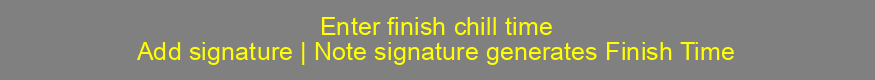

Enter employee number and signature. ◾ NOTE: Signature generates start of chill time and must be applied. ◾ Must be completed at start of process or within 30 minutes of start.

-

-

Enter employee number and signature ◾ NOTE: Signature generates start of chill time and must be applied. ◾ Must be completed at start of process or within 30 minutes of start.

-

-

Enter corrective action

-

Employee name and signature

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.4 Food Temperature Check Form

-

1. Please check prior to commencement of service and during service

2. Hot Food Items Must Be Held Over 60 degrees C

3. Cold Food Items Must Be Held Between 1-4 degrees C

Temperature check

-

Select Day

- Monday

- Tuesday

- Wednesday

- Thursday

- Friday

- Saturday

- Sunday

-

Enter outlet name

-

Item being checked

-

Type of temperature check

-

Select time

-

Enter any comments

-

Enter employee name and signature

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.5 Fridge/Freezer Temperature Record Sheet

-

NORMAL OPERATING TEMPERATURE

Refrigerators +5c or less

Freezers between -15c or more

If kitchen is closed please write closed in signature field. Do not leave blank -

Week ending

Unit Check

-

Select day

- Monday

- Tuesday

- Wednesday

- Thursday

- Friday

- Saturday

- Sunday

-

Select date

-

Location

-

Fridge/Freezer number

-

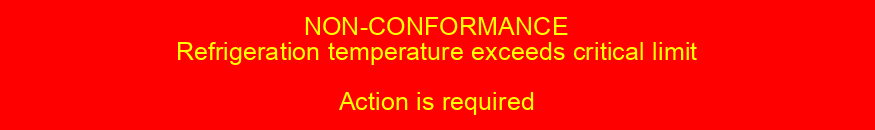

AM Temperature

-

-

Enter corrective action comments

-

Enter employee name and signature

-

PM Temperature

-

PM Temperature

-

-

Enter corrective action comments

-

Enter employee name and signature

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.6 Food Service Temperature Log

- Service Log

-

Date

-

Function

-

Covers

-

Food Service Time and Temperature Process

First Line

-

-

Time

-

-

Time

-

-

Time

-

-

Time

Second Line

-

-

Time

-

-

Time

-

Slide to temperature

-

-

Time

-

-

Time

-

Enter employee name and signature

-

Enter executive chef name and signature

-

Instructions Please compete all sections as required.

If retention sample is required protein from main e.g. Function over two hundred persons, please retain one sample of each item served and return to the main kitchen ensuring that it is labelled correctly and identifying the function and date.

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.7 Monthly Temperature Probe Calibration

-

Partially fill a container with broken ice. A vacuum flask is best but an ice bucket may be used. Wet the ice with a small amount of water and allow to stand for at least 30 minutes for temperature to equalise.

Some melting ice must remain when the test is done. Insert the tip of the probe into the ice/water mixture and leave for 3 minutes before taking the probe reading.

A reading of between -1c and +1c is acceptable. -

Boil water and insert the tip of the probe into the boiling water. A reading of between 99c and 101c is acceptable.

-

Select Month

- January

- February

- March

- April

- May

- June

- July

- August

- September

- October

- November

- December

Device

-

Probe number or location

-

Enter any corrective action notes

-

MASTER THERMOMETER

-

Employee name and signature

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.8 Pest Maintenance Report Log

-

🔹 For severe pest infestations:

Area should be cleared of food and food contact items until area is treated.

🔹 Any food from area should be checked for contamination and/or discarded.

🔴 After treatment there may be an increase in activity this is common:

Review treated area after a few days

Clean area of any contaminants

Pest Sighting

-

Date Sighted

-

Floor/Level

-

Area/Department

-

Select type of pest or OTHER and type in

- Cockroach

- German Cockroach

- Rodent

- Fly

- Fruit Fly

- Bee/Wasp

- Ants

- OTHER

-

Type in pest type

-

Where sighted

-

Enter name and signature of person making report

-

Name and signature of pest controller

-

Treatment date

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.12 Supplier Audit Report

-

Select supplier or OTHER and type in

- Alaska Crab

- Andrews Meat

- Baron Bakery

- Continental Patisserie

- Farmer Joes Chicken

- Fresh Ness

- Game Farm

- Grumpy Baker

- Hoshi Sushi/Heng

- Loftus Cakes

- Milkman

- Magnetic Foods

- M&G Seafood

- The Brasserie Bread

- The Bread Spread

- UncleTony's

- Exotic Cuisine

- Vilis Pies

- Smith's Snackfoods

- De Bortoli Wines

- EH Palmer

- Lion Dairy and Drinks

- OTHER

-

Supplier Type

-

NSW Food Authority Licence Sighted

-

Expiry Date

-

HACCP Certification Sighted

-

Expiry Date

-

Product Liability Insurance Current

-

Expiry Date

-

Pest Maintenance Schedule Current

-

Expiry Date

-

CCP Monitoring check, Process Flow and verify documentation

-

CCPs/Comment

-

QCPs/Comment

Facility Observations

-

-

Audit Outcome Further Action Required Y/N Follow Up date ___________________

-

Select Date or note time frame below

-

Supplier Representative Signature

-

Supplier Representative Signature Position

-

Australian Turf Club Representative Signature

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.13 Unfit Food Report

-

For receipt of goods and or customer complaints.

Immediate action must be taken in the event of a complaint arising from any kind of unfit food.

Return to the Executive Chef with all details completed immediately. -

Manager

-

Nature of the incident or unfit food (please describe briefly)

-

When Discovered

-

Reported to:

-

Was the food processed in your establishment?

-

Select supplier or OTHER and type in

- Alaska Crab

- Andrews Meat

- Baron Bakery

- Continental Patisserie

- Farmer Joes Chicken

- Fresh Ness

- Game Farm

- Grumpy Baker

- Hoshi Sushi/Heng

- Loftus Cakes

- Milkman

- Magnetic Foods

- M&G Seafood

- The Brasserie Bread

- The Bread Spread

- UncleTony's

- Exotic Cuisine

- Vilis Pies

- Smith's Snackfoods

- De Bortoli Wines

- EH Palmer

- Lion Dairy and Drinks

- OTHER

-

Date of delivery

-

-

-

Has the Executive Chef been informed?

-

Please attach relevant cleaning documentation, temperature monitoring forms, and other relevant documentation. Photograph/Scan acceptable.

-

I declare that the details entered on this form are correct to the best of my knowledge: 🔹 Please type in name and then sign. 🔴 Signature generates date and time stamp and must be applied.

-

Tap for supplier instructions

- Tap for supplier non-conformance report

-

Supplier Name

Supplier Non-conformance report

-

Suppliers Company Name:

-

Address:

-

Enter date

-

Food Safety Contact:

-

Phone:

-

This form must be completed and returned with page one within 48hrs to Gerry Maher, Executive Chef. You may contact him on telephone number 0404 880008.

Please detail your reply below

-

How did the non-compliance occur?

-

What is your corrective action?

-

What is your current HACCP status?

-

Copies of your most resent relevant food safety documentation must accompany your reply.

Further information, or action, may be required, depending on the customer’s position and the seriousness nature of the complaint -

Date Received

-

Signature:

-

Closed Y / N<br><br>

-

Executive Chef

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

Supplier Non-conformance report

-

Select Supplier

- Alaska Crab

- Andrews Meat

- Baron Bakery

- Continental Patisserie

- Farmer Joes Chicken

- Fresh Ness

- Game Farm

- Grumpy Baker

- Hoshi Sushi/Heng

- Loftus Cakes

- Milkman

- Magnetic Foods

- M&G Seafood

- The Brasserie Bread

- The Bread Spread

- UncleTony's

- Exotic Cuisine

- Vilis Pies

- Smith's Snackfoods

- De Bortoli Wines

- EH Palmer

- Lion Dairy and Drinks

- OTHER

-

Suppliers Company Name:

-

Address:

-

Enter date

-

Food Safety Contact:

-

Phone:

-

This form must be completed and returned with page one within 48hrs to Gerry Maher, Executive Chef. You may contact him on telephone number 0404 880008.

Please detail your reply below

-

How did the non-compliance occur?

-

What is your corrective action?

-

What is your current HACCP status?

-

Copies of your most resent relevant food safety documentation must accompany your reply.

Further information, or action, may be required, depending on the customer’s position and the seriousness nature of the complaint -

Date Received

-

Signature:

-

Closed Y / N<br><br>

-

Executive Chef

Issue Date 01/01/2020 | revision Date 01-01-2022 | Prepared by AFSIC | Authorized by ATC

FSP 4.14 Corrective Action Log

-

Date

-

Non-compliance

-

Corrective action required

-

Who

-

When? Completion Date

-

Amendments to Plan?

-

Employee name and signature