Information

Audit Process- Welding (Supply Chain).

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Comments/ Recommendations:

Supplier Information and Review.

-

Company Name

-

Add location

-

When was the Company Established.

-

What is the the Business Characterization.

-

What is the Size of the Facility?.

-

Shift Length (hrs).

-

Are there any QA/QC Personnel on Staff

-

Is there a Certified Weld Inspector on Site?.

-

Is DCMA on Site?.

-

Is there ASNT Level I/II/III NDT Inspectors.

-

Are there any NAS- 410 NDT Inspectors on Staff?.

-

Does the Company Employ and Document any NDT Methods

-

Does the Company have Certified Welders on Staff

-

Does the Company have any Weld Supervisor's on Staff.

-

Does the Company have any Weld Engineers on Staff.

-

Does the Company have any MFG Engineers on Staff.

-

Does the Supplier presently do work for the Client?.

-

Quality Systems Approvals

-

Is there Separation in Reporting Duties for personnel responsible for Quality.

-

Does the Quality Control Inspector have the Authority to "Stop Work", the responsibility to Identify Quality Problems and Provide Recommendations.

-

Is there Objective Evidence of a Review Process of Certified Material Test Reports (CMTR) to ASTM Specifications. Note: If CMTR are not required to be kept of file per Contract Documents. the fabricator shall still show the capability of Reviewing the Reports.

-

Are materials identified and traceable as specified in the Technical Data Package (TDP). (Quality Program Receiving and Manufacturing Operations).

-

Do Purchase Orders for filler material specify the American Welding Society (AWS) Classification and Specification?.

-

Comments/ Recommendations:

Reference Library- All Reference Material Shall be to the Latest Published Version or Revision.

-

Does the Supplier have the Document "Aluminum Design Manual" from the Aluminum Association on File.

-

AMS-STD- 1595 (Qualification of Aircraft, Missile & Aerospace Fusion Welders) on File.

-

ANSI Z49.1 (Safety in Welding, Cutting and Allied Processes)

-

ASME Boiler and Pressure Vessel Code, Section V: Nondestructive Examination.

-

ASTM E 1444 (Standard Practice for Magnetic Particle Testing)

-

ASTM E1417 (Standard Practice for Liquid Penetrant Testing)

-

ASTM E1742 (Standard Practice for Radiographic Examination)

-

ASTM E164 (Standard Practice for Liquid UltrasonicTesting)

-

ASTM E1648 (Standard Reference Radiographs for Examination of Aluminum Fusion Welds)

-

AWS B1.11 (Guide for the Visual Examination of Welds)

-

AWS A3.0 (Standard Welding terms and Definitions)

-

AWS B2.1 ( Specification for Welding Procedure and Performance Qualification).

-

AWS B4.0 (Standard Methods for Mechanical Testing of Welds)

-

AWS D1.1 (Structural Welding Code- Steel)

-

AWS D1.2 (Structural Welding Code- Aluminum)

-

AWS D1.3 (Structural Welding Code- Sheet Steel)

-

AWS D1.6 (Structural Welding Code- Stainless Steel)

-

AWS D1.9 (Structural Welding Code- Titanium)

-

AWS D9.1 (Sheet Metal Welding Code)

-

AWS D17.1 (Specification for Fusion Welding for Aerospace Application)

-

AWS D17.2 (Specification for Resistance Welding for Aerospace Application)

-

AWS A2.4 (Standard Symbols for Welding, Brazing and Nondestructive Examination)

-

MIL-STD-2219 (Fusion Welding for Aerospace Application)

-

MIL-STD-271 (Requirements for Nondestructive Testing Methods)

-

MIL-STD-2035 (Nondestructive Testing Acceptance Criteria)

-

MIL-W-6858 (Welding, Resistance: Spot and Seam)

-

NADCAP welding documents (e.g., SAE AS 7110, NADCAP Requirements for Welding/Brazing)

-

NADCAP NDT Inspection Documents

-

NAVSEA Welding Standard 250-1500-1

-

NAVSEA Technical Publication S9074-AQ-GIB-010/248

-

NAVSEA Technical Publication S9074-AR-GIB-010/278

-

NAS-410 (Certification & Qualification of Nondestructive Test Personnel)

-

WS 33739 (Raytheon Process Specification for Aerospace Fusion Welding)

Certifications to:

-

Visual Inspection (VT)

-

Radiographic Inspection (RT)

-

Ultrasonic Inspection (UT)

-

Magnetic Particle (MT)

-

Dye Penetrant Inspection (PT)

Qualifications to:

-

ASTM E164

-

ASTM E1417

-

ASTM E1444

-

ASTM E1742

-

AWS QC1

Health and Safety

-

Is there an EH&S (Environmental Health & Safety) Officer or an Industrial Hygienist on Site?.

-

Is there objective evidence of a Welding Safety Program?

-

Is there objective evidence of Safety Training classes being conducted.

-

Is the facility environmentally controlled (i.e., fully heated and/ or air conditioned)

-

Is the relative humidity monitored and documented within the facility or the Welding Environment

-

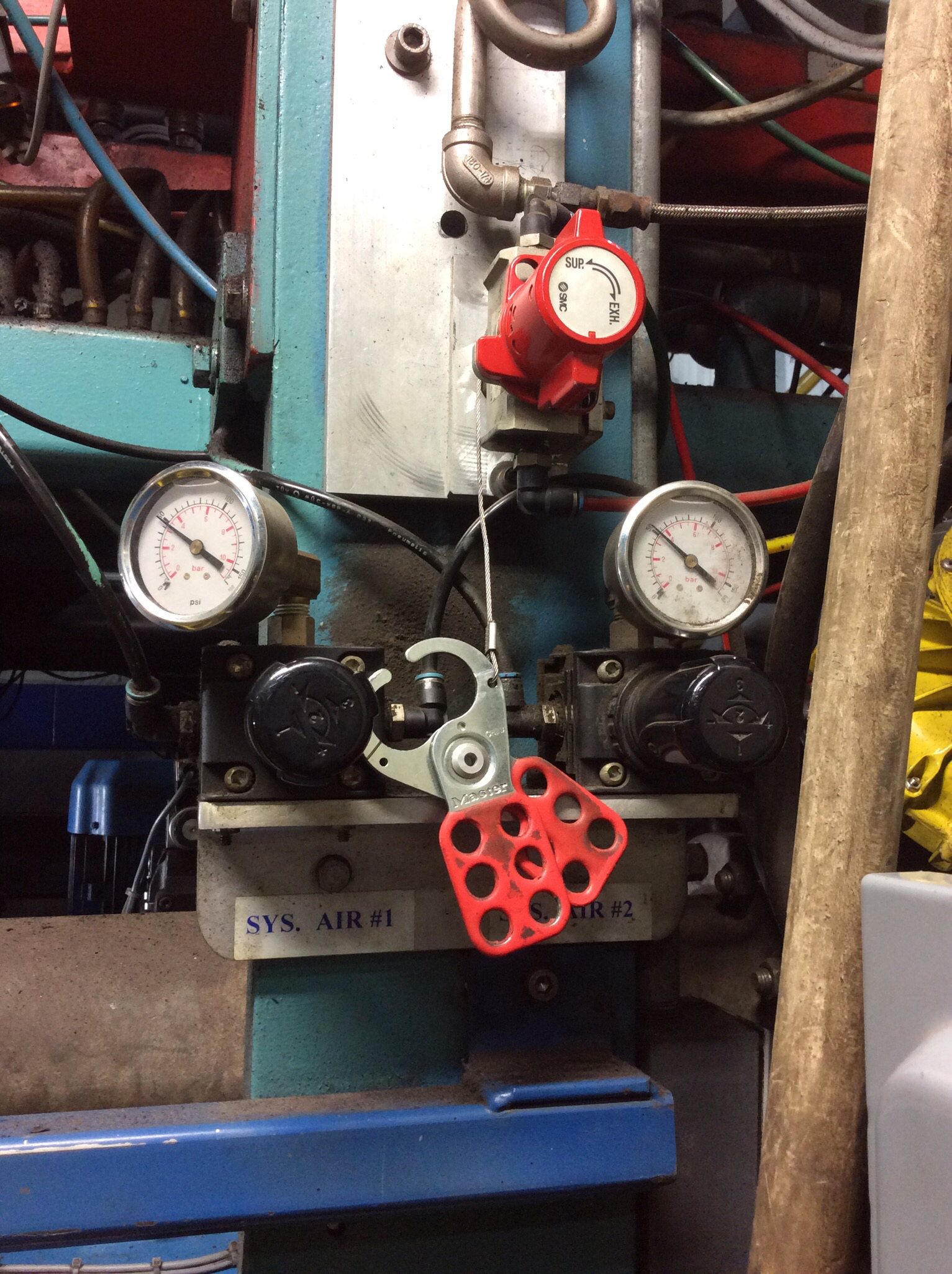

Does the facility have a welding gas distribution system?.

-

Are the Oxygen levels Monitored?.

-

Is there a facility Equipment List/ Capabilities Profile sheet available?.

-

Does the facility have lifting crane capacity within the welding area?

-

What type of lifting crane?.

-

Does the facility employ welding positioners.

-

Is there a designated area for weld and/or Base Material grinding?.

-

Is the Welding / Fabrication Area Safe, Clean and Orderly.

-

Are there Welding Fume Extractors

-

Are Pre and Post Weld heat treatments (PWHT) performed at the Facility

-

Are there Separate Work Areas for Stainless Steel, Titanium, CArbon Steel or Aluminum

-

Is Blast cleaning performed at the Facility

-

Is Base material or Weld metal Analyzed

-

Laboratory Info.

-

Does the organization perform leak testing

-

What Type of Process?.

-

Is there objective evidence of weld operator annual vision test

-

Is there objective evidence of weld inspector's annual vision test

-

Comments/ Recommendations

Quality Control- Documentation

-

Does the Organization have a Quality and Procedures Manual

-

Are Sub-Tier Suppliers Qualified by a documented evaluation?.

-

Do purchase orders for base material (Nuts, washers, Bolts, Bar Stock etc specify the Grade?.

-

Is the base material currently being used on the shop floor traceable to a Certified Mill Test Report (CMTR)

-

Do purchase orders for filler material specify the American Welding Society (AWS) classification and specification.

-

Is the filler material currently being used on the shop floor traceable to a Certified Mill Test Report (CMTR)

-

Do purchase orders for Paint specify it's Requirements

-

Is the paint currently being used on the shop floor traceable to a Test Report (CMTR)

-

Have controls been established to monitor the receipt of incoming Material.

-

Is a quality control program in effect to allow management to assess whether work is being performed according to specification?.

-

Is there objective evidence of correction of non-conforming material or work in process

-

Are weldments traceable to a Qualified or Certified Welder

-

Is the objective evidence that a welder/ weld operator has worked with a particulate process, material type and weld joint geometry within the last 6 months

-

Is there a formal Material Review Board (MRB) process established to disposition weld defects?.

-

Is there objective evidence to assure that welds are not obstructed by subsequent operations and are inspected prior to being covered up (e.g. witness/ inspection hold points on traveller).

-

Are Requests for Information (RFI's) necessary to resolve discrepancies and variations from contract requirements documented?.

-

Is there a procedure for processing revised or voided drawings

Quality Control- Welding Consumables

-

Are sub-merged arc welding (SAW) fluxes and filler wire properly identified?.

-

Is the Filler wire and Flux stored in a secure, clean and dry environment?,

-

Are Flux and Filler materials stored per manufactures recommendations?.

-

Are there established procedures for the proper storage and control of low hydrogen Shielded Metal Arc Welding (SMAW) electrodes.

-

When Low hydrogen filler metal is used from an Oven is the environment with in the storage oven measured?.

-

Are welding filler metal traceable to a Certified Mill Test Report (CMTR)

-

Are the welding consumables Heat No. And Lot No. documented on the Traveler/ Router (If required by the contract specifications)

-

Do the Welding Consumables meet the Contract Specifications?.

-

Is weld filler wire distribution Controlled?.

-

Are used weld filler wire disposed of After welding activities (e.g. Stub-end Box),

-

Is the welding filler wire sent to an independent Material's Lab for Testing and P.O. verification prior to being employed.

-

If the Organization mixes their own shielding gases are Calibrated Mixture Chambers used?.

Procedure Qualification Records (PQR's) and Welding Procedure Specifications (WPS's) are qualified in accordance with what Code:

-

AWS B2.1

-

AWS D1.1

-

AWS D1.2

-

AWS D1.3

-

AWS D1.6

-

AWS D9.1

-

AWS D17.1

-

AWS D17.2

-

ASME IX

-

NAVSEA

-

MIL-W-6858

What position(s) are Welders qualified in:

-

Groove Welds:

-

1G

-

2G

-

3G

-

4G

-

5G

-

6G

-

6GR

-

Fillet Welds:

-

1F

-

2F

-

3F

-

4F

-

5F

-

6F

-

Has the Organization engaged in DOD/ Military (MIL-STD) welding activities prior to this audit?.

Quality Control- Welding Operations

-

Does the Organization utilize Weld Chambers?.

-

Are O2 Analyzers Installed?.

-

Are O2 Levels verified within a purge gas/ Weldment environment?.

-

Are Pre-Weld, Inter-pass and Post-Weld Cleaning Requirements defined to the Welding Procedure Specification (WPS)

-

Is there objective evidence that surface condition and cleanliness of the weld joint fraying surfaces and filler metal has been examined prior to welding?.

-

Are Preheat, Inter-pass and Post-Weld heat treatment addressed on the Welding Procedure Specification (WPS)

-

Surface contacting Pyrometer

-

Temperature Crayons

-

Liquid

-

Pellets

-

Stickers

-

IR heat sensor

-

For automatic/ mechanized welding (as defined in AWS A3.0), are the weld settings used in production within range of those documented on the WPS or PQR?.

-

Is there an established Calibration Program for the calibration of Welding Supplies, Panel Ammeters, Panel Voltmeters, Wire Feeders, Positioners etc.

-

For semi-automatic welding (as defined in AWS A3.0), are the weld settings used in production within range of those documented on the WPS or PQR?.

-

Is there an established Calibration Program for the calibration of Welding Supplies, Panel Ammeters, Panel Voltmeters, Wire Feeders, Positioners etc.

Quality Control- Weld Inspection.

-

Are weld inspectors qualified and knowledgeable with the Specifications, which apply to the Fabricators work

-

Are written welding procedures in close proximity to and used by the Welders

-

Are tools or aids used for visual weld inspection.

-

Fillet Weld Gage's

-

Borescopes

-

Fiberscopes

-

Videoscopes

-

Are there Hold Points at the facility strictly devoted to weld inspection?.

-

Is there objective evidence of Visual (VT) weld inspection being performed Before, During and After additional Stress inducing Operations (e.g. straightening or heat-treating)

-

Is there a formal Material Review Board (MRB) established for disposition of non-conforming weldments.