Title Page

-

(CA) QA On-Site Food Safety Audit

-

Conducted on

-

Quality Assurance Department

-

For Retail Stores (i.e., Cataraqui Town Centre, Mississauga Hospital, TGH Catering), select "Higher Education / Retail" and then select "Bento Sushi Retail". Specify the province/territory followed by the retail store number and location in the text field provided.

-

Store

-

Store Banner

-

If banner is not available in the list provided, select "Banner is not listed here"

-

Province / Territory

-

Higher Education / Retail Store (Include store name and number)

-

Province / Territory

-

Specify the store number or location of the location being inspected. (i.e., If Aramark was selected, Store Number / Location: 1188 and if SSP was selected, specify whether the store being inspected is the 20316 or Pearson Intl Airport location). If there is no specific number or location, re-enter the location (i.e., Store Banner: University of Alberta Hospital, Store Number/Location: University of Alberta Hospital)

-

Store Number/Store Name

-

Chef Name(s):

-

If chef is unavailable at time of audit, input "N/A" under "Chef's Name"

-

Your phone's geolocation should automatically fill the Location field. If it does not, please tap on the location icon below and select the location. Do not type in the address manually.

-

Location

-

Inspect the store for compliance or non-compliance to the criteria. If the criteria standard is met, select “ Yes - In Compliance.” If not, select “No - Not in compliance”. If not available, select "N/A - Not Available" and if not applicable select "N/A - Not Applicable"

If store is not in compliance with the criteria, describe the non-compliance under "Notes" and take a photo by clicking “Image” underneath the criteria. Describe corrective actions performed with notes and/or photos if applicable.

For non-conformances that require QA Corporate attention, create an action by selecting “Actions” underneath the non-conforming criteria. Describe action to be done and describe non-conformance/action in further detail. Select an “Assignee” (i.e., If non-conformance requires action to be done by QA Specialists, QA Director, assign the task to the appropriate personnel). Select a Priority Level (Low, Medium, High) and a Due Date.

1-3. Front of Kiosk

-

Take a photo of the Kiosk

-

Is an allergen alert sign posted at the kiosk?

-

Is this a Wal-Mart location?

-

Are the Dash products available?

-

Take a photo of the showcase with the products on display.

-

Randomly select a product and measure the internal temperature of the product.

-

Are Bento At Home dry goods available on display?

-

Are there any dry goods expired at this location?

-

Select the product that is expired:

- Calrose Sushi Rice

- Goma Dressing

- Panko Bread Crumbs

- Pickled Ginger

- Rice Paper

- Roasted Seaweed Sheets

- Roasted Sesame Seeds

- Soy Sauce

- Sushi Rice Seasoning

- Wasabi Paste

- Other (Add Product in Notes)

Showcase(s) Temperature

-

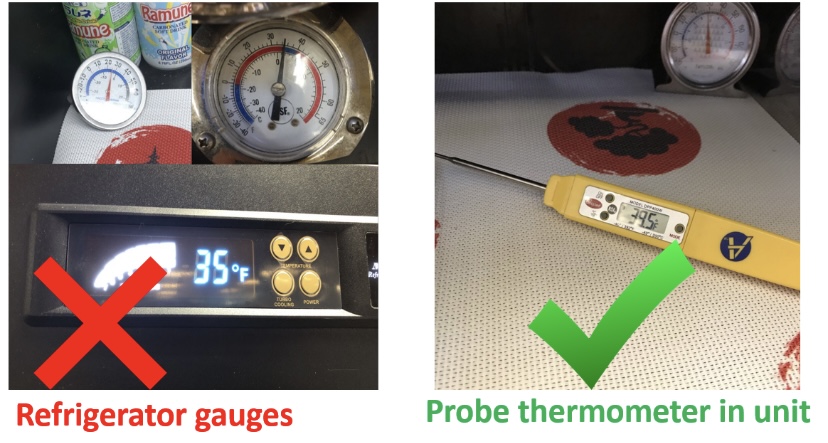

Check / measure & record the measurement for all showcase units. Take a photo of the showcase with the temperature shown on the probe.

-

1. Are the temperatures of showcase/s measured (less than or equal to) ≤4°C / 40°F? (1st Priority)

-

CAP Guide (Ver. 2022OC03):

1. If the cooling system of showcase is in defrosting process, check again temperature after 30 minutes to 1 hour.

2. If the showcase cooling is malfunctioning, move items from the malfunctioning refrigeration unit to another unit that satisfy the temperature requirements and inform the Store Management of the issue

3. If products has been sitting in showcase for unknown amount of time (i.e. two hours or more) discard all the products. -

2. Are finished products available in the showcase?

-

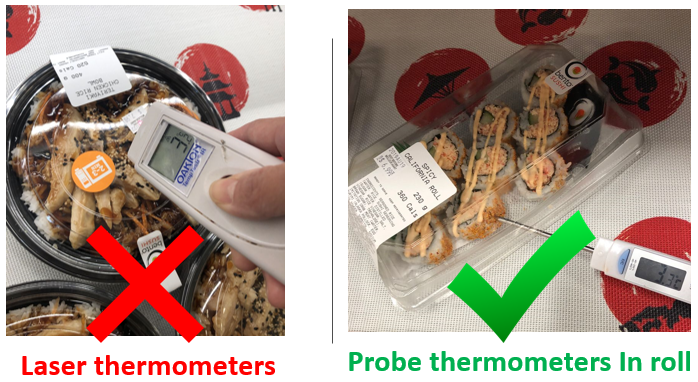

Randomly select three products. Measure & record the internal product temperature of the three products. Take a photo of the finished products with the probe inside the sushi. Temperature of the sushi must be visible in the photo.

-

2. (A101) Are all finished products displayed in the showcase measured at an internal temperature (less than or equal to) ≤4°C / 40°F? (1st Priority)

-

Finished Product Temperature

- Finished Product Temperature 4.1°C - 6°C

- Finished Product Temperature 6.1°C - 8°C

- Finished Product Temperature 8.1°C - 10.9°C

- Finished Product Temperature 11°C and above

- N/A - Not Applicable (Products not available at the time of visit)

-

CAP Guide:

1. Finished product(s) were immediately removed from the showcase for rechilling in the walk-in cooler / freezer to 4C / 40F or below

2. Re-train Chef on the proper chilling procedure and to take the product temperature with a calibrated / sanitized probe thermometer and ensure that the temperature of the finished products is at ≤ 4°C / 40°F before displaying them for sale.

3. If Finished products temperature was outside the required ≤ 4°C / 40°F because of insufficient chilling space in the refrigeration units, re-train Chef to re-organize the refrigeration units to allow for adequate space to chill products. If there’s not enough space, speak with Store Management to see whether or not additional chilling space can be provided elsewhere. -

Is SOP : Managing Chilling of Sushi & Other Products (CAN) available?

-

3. (B209) Is there a working probe thermometer (one used to measure finished product temperature) available for use?

- Yes

- No - Probe thermometer is not available

- No - Probe thermometer is not working

- N/A - Not Applicable

-

CAP Guide: Provide Chef with a calibrated probe thermometer and ensure there's one present in the operation at all times.

4-8. Finished Product Compliance

-

For the questions below, check the following: Are there any expired products on display? Are products made according to product recipes established in the Product Note (PN)? Are correct labels being applied to the finished products? Are finished products stamped with the correct number of days of shelf life?

-

4. (A119) Are all products on display within the Best Before Dates (i.e., not expired)?

-

CAP Guide:

1. Inform store managerment and supervisor, discard the products

2. Re-train Chef to check and discard finished products in the showcase (prior to start of shift) that are held / sold past the expiration date. -

Select which BBD non-compliance was observed on the products displayed

- No - Missing BBD sticker

- No - BBD is cut-off & not visible

- No - Product is expired

-

5. Are the products made according to the product recipes established in the Product Note (PN)?

-

CAP Guide:

1. Remove product from showcase and discard (Applying for the Products with extra ingredients not listed on the PN/ Products with non-approved ingredients)

2. Retrain Chef to make products according to the product recipes established in the most up-to-date Product Note (PN) -

Select which product recipe non-compliance was observed

- No - Missing ingredients

- No - Added extra ingredient(s) not listed on the PN (Immediately discard non-compliant products)

- No - Incorrect arrangement of component

- No - Used unapproved ingredients (Immediately discard non-cpmpliant products)

- No - Other

-

5a. Is BOT (Bento Operation Tablet) being used at this location?

-

Are the Cleaning Logs completed on the BOT?

-

Is the PN/Aztec code most updated version used in-store? (1st Priority)

-

CAP Guide (Ver. 2022OC03): Assign to Supervisor to print the most up-to-date Product Note (PN) /Aztec code and keep it at the store

-

Select which non-compliance related to the PN or Aztec Code was observed

- No - PN is not the most updated version

- No - Aztec code is not the most updated version

-

6. (B226) Are the correct labels being applied to the finished products? (i.e. California Roll is with California Roll label) (1st Priority)

-

"CAP Guide:

1. Inform store managerment and supervisor, replace the wrong labels with correct labels.

2. Re-train Chef to ensure and verify that correct labels are being applied to every package of finished product prior to displaying them for sale in the showcase. " -

7. (A119 & B226) Are finished products stamped with the correct best before date, expiration date / number of days of shelf-life? (1st Priority)

-

CAP Guide:

1. Inform store management and supervisor, replace the wrong labels with correct labels.

2. Re-train Chef to ensure and verify that correct labels are being applied to every package of finished product prior to displaying them for sale in the showcase. -

Select which non-compliance related to the best before date, expiration date / number of days of shelf-life was observed

- No - Sushi products were not stamped with correct number of days of shelf-life

- No - Side items products were not stamped with correct number of days of shelf-life

- No - Grab & go products were not stamped with correct number of days of shelf-life

- No - In-house dry goods were not stamped with correct number of days of shelf-life

-

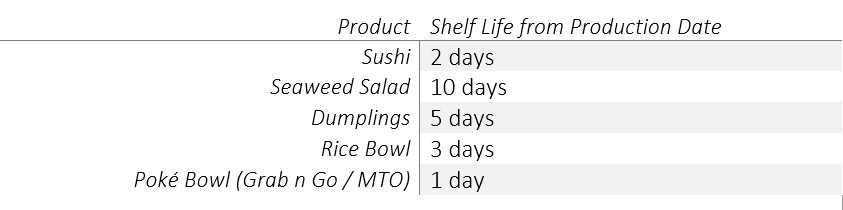

Guidance on Shelf Life

-

8. (LS103a) Does the finished product weight meet the net weight declared on the label?

-

Select which non-compliance related to product weight meeting the net weight declared on the label was observed

- No - Overweight

- No - Underweight

-

- CAP Guide: Re-train chef the importance of compliance with weight control. Overweight products means our product labels are incorrect because they are declaring nutrition facts for that specific weight. Non compliant weight of products can lead to customer complaints

-

CAP Guide (Ver. 2022OC03): underweight products need to be adjusted or discarded if cannot be fixed. Re-train chef on the important of compliance with weight control, non-compliance with weight of products can lead to customer complaints. Chefs need to use scales to random measure the first few rolls during rolling.

-

Take photos of finished product weights on scale after taring the weight of packaging, and compare with the net weight declared on the label to ensure compliance (Check a minimum of 3 products)

9-11. Refrigeration Equipment Temperature

-

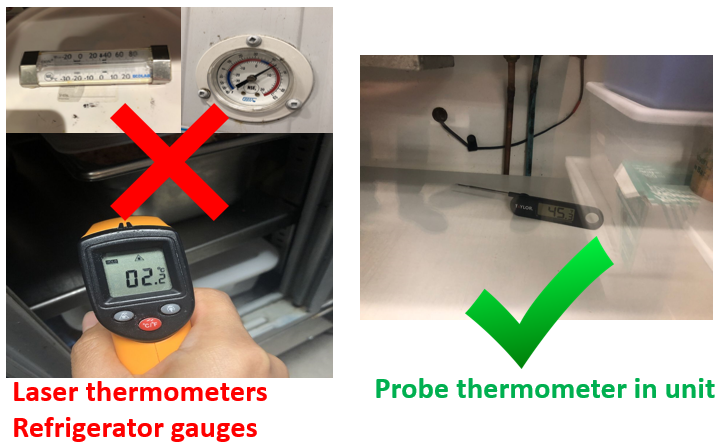

Check / measure & record the measurement for all raw material refrigerator units including walk-in coolers, reach-in coolers (minimum 2 units) and freezer units. Take a photo of the refrigerator with temperature shown on the probe

-

9. a) Are the temperatures of Walk-in cooler(s) and Reach-in cooler(s) measured at (less than or equal to) ≤4°C / 40°F?

-

Select the reason the Walk-in cooler(s) / Reach-in cooler(s) measured at less than ≤4°C / 40°F

- Cooler in Defrost

- Coolers temperature is set to the wrong range

- Other

-

Ensure that the cooler is in defrost. If the refrigerator unit is broken or requires maintenance, mark the question as non-compliance and reach out to QA.

-

Which Refrigeration Equipment Temperature is not complaint?

- Walk-In Cooler

- Reach-In Cooler

-

CAP Guide: If the temperature is measured above 4°C / 40°F, re-check the cooler's temperature after 1 hour to ensure that the unit is not undergoing defrost cycle and include another photo of the temperature taken during the re-check. If the temperature taken after 1 hour is still above 4°C / 40°F, record corrective actions (i.e., notified Store Management for repair/service, moved ingredients to another working unit, etc.)

-

9. b) Are the temperatures of Freezer(s) measured at (less than or equal to) ≤-18°C / 0°F?

-

Select the reason the Freezer(s) measured at (less than or equal to) ≤-18°C / 0°F

- Freezer In Defrost

- Temperature set to the incorrect range

- Other

-

Ensure that the freezer is in defrost. If the refrigerator unit is broken or requires maintenance, mark the question as non-compliance and reach out to QA.

-

Ensure that the freezer temperature is set to the correct range. If the refrigerator unit is broken or requires maintenance, mark the question as non-compliance and reach out to QA.

-

Describe the reason why the freezer temperature is non-compliant

-

10. (B209) Are working fridge thermometers available for all showcases, coolers, and freezers?

-

CAP Guide: report to Store Management and request for a new thermometer for the unit, etc.)

-

Select the fridge thermometers are not available

11-12. Acidified Sushi Rice pH

-

Select N/A if time of visit is out of operation hours where there is no chef. No score deduction.

-

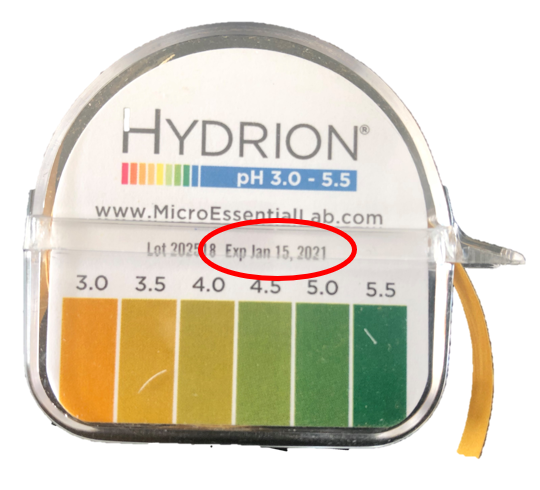

For pH TEST STRIPS: Check the pH test strips are not expired.

For pH METER: Check the pH meter is working (able to turn on) and calibrated. Make sure the pH buffer solution is not expired. -

11. (A134) Is the chef able to demonstrate how to complete pH testing (includes pH meter calibration and pH testing of the sushi rice)? (1st Priority)

-

Select the non-compliance related to pH testing which was observed

- No - Critical; Chef does not know how to test pH using pH meter

- No - Critical; Chef does not know how to test pH using pH test strips

- No - Critical; Chef does not know how to correctly take sample from rice bin (i.e., 5 points)

-

CAP Guide: Re-train chef on the proper pH testing using pH test strip/pH meter (Sobeys banner only - Sobeys / Safeway / Foodland)

-

12. (B238) Are pH test strips (or pH meter and pH buffer solution) available and in good working condition (ie. not expired, and/or functional and calibrated)?Y

-

Select the non-compliance related to pH testing materials being available and in good working condition which was observed

- No - pH test strip expired/damage

- No - pH test strip not available

- No - pH meter is not functional/can't be calibrated

- No - Expired buffer solution

- No - Buffer solution is not available

- No - pH meter is not available

- No - pH meter is not calibrated correctly

-

CAP Guide: Require replacing a working pH meter/pH buffer solution. Chef can use the pH test strip as the temporary back-up until getting the supply for pH meter/buffer solution.

-

CAP Guide (Ver. 2022.11.01) Request a new pH test strip ASAP and retrain chef the importance of pH testing for the rice using pH test strip.

-

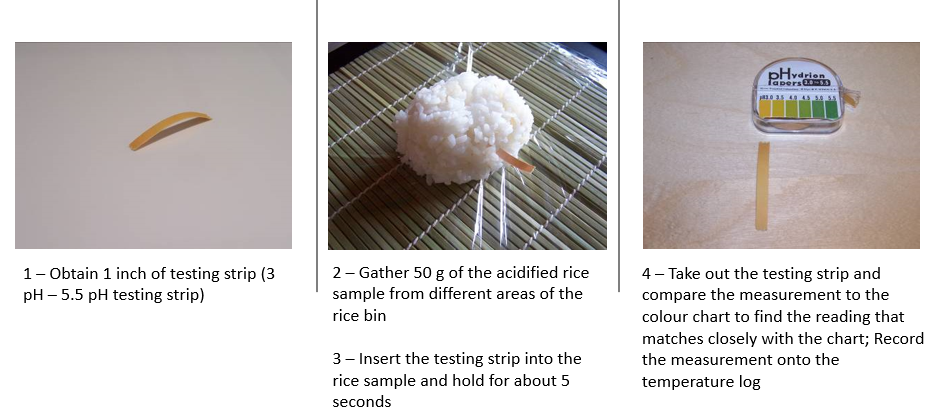

Randomly select a rice bin. Measure & record the pH of the rice under the criteria "Notes". Take a photo of the pH measured with the probe inside the rice. If using a strip, take a photo of the colour of the strip against the colour standard. pH of the sushi must be visible in the photo.

-

Select N/A if time of visit is out of operation hours where there is no chef and/or no rice available. No score deduction.

-

12a. (A134) Is the acidified sushi rice pH within the required standards according to requirements? I.e., 4.0 - 4.5 (≠ 4.5) when tested with pH test strip or 3.8 - 4.3 when tested with a pH meter (Sobeys banner only - Sobeys / Safeway / Foodland)

-

Sushi Rice pH

-

Sushi Rice pH

13-18. Food Handling

-

13. (C331) Is the chef following good hygiene practices?

-

Select the non-compliance related to good hygiene practices that was observed

- Yes

- No - Uniform is not clean

- No - Not following Bento uniform policy

- No - Chef is wearing jewelry

- No - Chef is wearing makeup

- No - Personal belongings are stored inside the kiosk (Not in designated area)

- No - Chef has long nails / artificial nails / nail polish

- No - Food / drinks are stored inside the kiosk (Not in designated area)

- No - Chef is not wearing safety shoes

- N/A

-

CAP Guide: Re-train chef on the spot on proper PPE that needs to be worn or changed, and jewelry needs to removed right away. Any artificial nail or nail polish needs to be removed before going back to work

-

Clean outer clothing is worn that is dedicated to the preparation of food, or an apron is worn; hair and beard restraints are used around exposed food and food-contact surfaces. Jewelry is removed from hands, wrists, face and any other areas that are not covered. No artificial nails or nail polish worn when handling food or food-contact surfaces.

-

14. (2) Is the chef able to demonstrate how to calibrate a thermometer correctly?

-

CAP Guide: Re-train chef using ice water method to calibrate a thermometer, 50% water with 50% ice, thermometer needs to reach within +/- 1°C, if the thermometer is higher than +/- 1°C, replace it with a new one

-

15. (14) Is the chef able to demonstrate how to calibrate a pH meter (Sobeys/Safeway/Foodland only)?

-

CAP Guide: Re-train chef on how to calibrate pH meter, please refer to SOP QFS 0011.01 Measuring Acidity of Sushi Rice Using pH Meters (CAN)

-

16. (A107) Are food items (excluding sushi rice) stored at room temperature for no more than 30 minutes? Temperature of food items should not (exceed) > 15°C / 59°F (1st Priority)

-

Measure the temperature of the food item. Specify the food item under the "Notes" . Take a photo of the food item with the thermometer probe inside the rice. The temperature of the food item must be visible in the photo.

-

Take the temperature of the food item stored at room temperature for more than 30 minutes

-

CAP Guide: Re-train Chef that prepared foods can only be left outside of the temperature controlled units for no more than 30 minutes. Food to be discarded if it stays out of the temperature controlled units for more than 30 minutes.

-

17. (B234) Is the sushi knife lubricant (vinegar/water dip) being used?

- Yes

- No - Not in use

- N/A - Ice water dip being used (Ensure ice is not fully melted)

- N/A

-

(B234) Is the pH of the knife dip solution measured at 3.5 or less?

- Yes

- No - Only water being use

- No - pH level is not at 3.5 or less

- No - Knife lubricant was not replaced / changed every two hours when needed

- N/A - Not Applicable

-

CAP Guide: Re-train chef when the sushi knife lubricant has pH high than 3.5, the vinegar method: fill 1 part of white vinegar to seven-part water, pH of solution should below 3.5. Or retrain chef when there is no ice in the ice water dip (Alberta water only).

-

Ice water or vinegar/water 1/7 ratio, pH should measure at 3.5 or less (Alberta only use ice water)

-

18. (A115) Is chef using right colour coded cutting boards? (1st Priority)

- Yes

- No - Incorrect colour coded cutting board being used

- No - Only one colour cutting board being used

- N/A

-

CAP Guide: Re-train chef blue cutting board is used for raw seafood and sushi contain raw seafood. Green and white can be used for all other ingredients and sushi.

19-24. Ingredients Storage

-

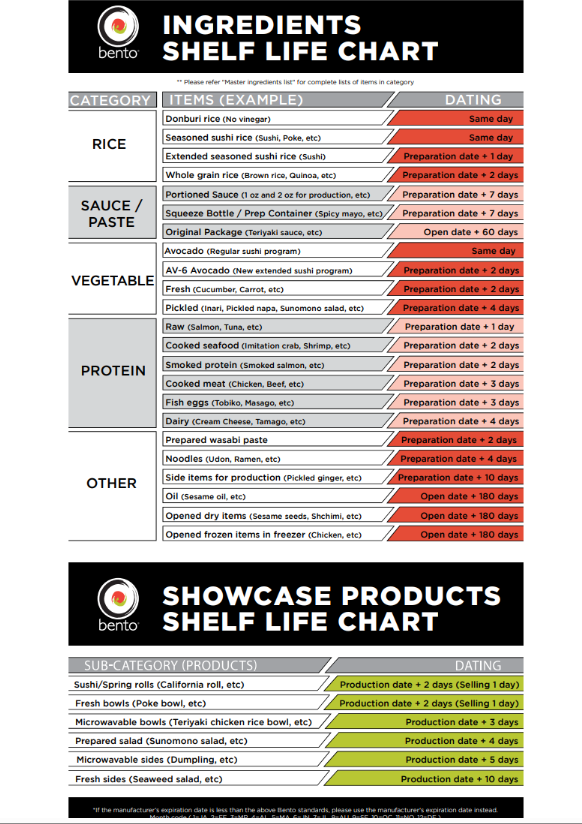

Ingredient Shelf Life Chart

-

19. (A121) Is the location using approved ingredients?

-

20. (B225 & C311) Are all prepared ingredients labeled with a common name, preparation date and use by date (where applicable)?

- Yes

- No

- N/A

-

Select the non-conformance(s) related to prepared ingredient labels which were observed

- No - Missing label

- No - Incomplete label (i.e., no name / preparation date / use by date)

- No - Incorrect shelf life being apply to the ingredients (Refer to Ingredient Shelf Life Chart)

- No - Incorrect label applied

-

CAP Guide: Re-train Chef to label each and every single prepared food item with its name, preparation date / use by and/or best before date(according to Ingredient Shelf Life Chart). Chef will verify that all prepared food items are properly labeled before finishing the work shift.

-

21. (A119) Are all ingredients used within the use by date / expiration date? Check that there are no expired ingredients?

-

Select the non-conformance related to use by date / expiration date / expired ingredients which was observed

- No - Fresh cut vegetable

- No - Condiments

- No - Sauce in squeeze bottle

- No - Prepared protein

-

CAP Guide: Expired ingredient are discarded at the spot, retrain chef does not use expired ingredients and chef is responsible to check all ingredient are in the use by date when the shift starts.

-

22. Are all delivered goods labeled with receiving dates?

-

CAP Guide: Re-train chef all receiving goods are required to write down the receiving date during receiving, it helps to track FIFO and traceability purposes

-

23. (C303) Are all vacuum packaged seafood items slit open prior to defrost?

-

CAP Guide: Retrain chef all thawing items need to slit open during thawing to avoid the growth of Clostridium botulinum bacteria in an aerobic environment

-

Ready-to-eat items are to be stored above frozen food and un-washed produce inside the storage unit.

-

24. (A115 & C307) Are raw materials separately stored from ready-to-eat items to minimize cross contamination risks? (1st Priority)

-

CAP Guide: re-organize the non-compliance items, discard all contaminated ingredients/ products, re-train chef all raw materials should not store above or next to ready-to-eat items

25-31. Sanitation

-

25. (B233 & A129) Are all required chemicals (sanitizer, detergent, hand soap) available at the location?

-

Select which chemical was not available

- No sanitizer

- No detergent

- No hand soap

-

CAP Guide: Require to replace any missing chemcial

-

1 – Turn the sanitizer dispenser on and let it run for 20 seconds before obtaining a sample

2 – Take 50 mL of sanitizer from the dispenser and let it sit for about 15 minutes or until it reaches room temperature

3 – Obtain 1 inch of the testing strip (QT10 – Quat Sanitizer; QT40 – AMFO Sanitizer)

4 – Immerse the testing strip into the sample solution, not foam surface, and hold still for 10 seconds (Hands should not be shaking as it will not give you an accurate measurement). Testing solution should be at 18°C - 24°C

5 – Take out the testing strip and compare the measurement to the colour chart to find the reading that matches closely with the chart. -

26. (A127 & A128) Does the sanitizer concentration (PPM) meet the standard? (1st Priority)

-

Select the non-conformance related to sanitizer concentration which was observed

- No - Sanitizer concentration is above the standard

- No - Sanitizer concentration is below the standard

-

CAP Guide: Retest sanitizer concentration (PPM), re-train the chef on how to properly collect sanitizer by turning on the sanitizer dispenser for 10 seconds and then collect sanitizer, sanitizer needs to be checked at room temperature without foaming

-

(3) Does the Chef know how to test sanitizer correctly?

-

27. (A125 & C325) Are all surfaces (food and non-food contact) of equipment kept clean, sanitized, dry and in good condition? (No cracks / grooves / broken)

-

Which equipment is not in good condition?

- 1. Cooking and Reheating Equipment

- 2. Refrigeration Equipment

- 3. Countertops / Processing tables

- 4. Sneeze guards

- 5. Hand washing sink

- 6. Compartment sink

- 7. Cabinets / Shelving units

- 8. Other

-

1. Cooking and Reheating Equipment:

- a. Rice Cooker

- b. Deep fryer

- c. Air fryer

- d. Induction cooktop

- e. Steam well

- f. Microwave

- g. Stove top & grill

- h. Other

-

2. Refrigeration Equipment:

- a. Showcase

- b. Reach-in Cooler

- c. Walk-in Cooler

- d. Blast Chiller

- e. Freezer

- f. Cold well on countertop

- g. Other

-

a. Showcase:

- i. Shelving

- ii. Air Vents

- iii. Ledges around the showcase unit

-

b. Reach-in Cooler:

- i. Sliding door tracks

- ii. DoorHandle

- iii. Door

- iv. Shelving

- v. Gasket

- vi. Other

-

c. Walk-in Cooler:

- i. Door Handle

- ii. Door

- iii. Shelving

- iv. Gasket

- v. Other

-

d. Blast Chiller:

- i. Door Handle

- ii. Door

- iii. Shelving

- iv. Gasket

- v. Other

-

e. Freezer:

- i. Door Handle

- ii. Door

- iii. Shelving

- iv. Gasket

- v. Other

-

CAP Guide: Sanitation issue: items need to be cleaned and require the supervisor to upload pictures after cleaning. Damage observed: Inform store management and supervisor, re-train chef when observing damage issue require to report to supervisor and store management require supervisor upload pictures after the issue has been address.

-

28. (A125, A123, B215, C321, C323, B235 & C315) Are all surfaces (food and non-food contact) of small wares kept clean, sanitized, dry and in good condition? (No cracks / grooves / broken)

-

CAP Guide: all non-compliance items need to be rewashed, and re-train chef the proper washing steps and/or how to properly store clean utensil after cleaning, rinse sanitize and air dry (all utensil handles should be face up and in one direction)

-

Which small wares are not in good condition:

- 1. Food Preparation Items

- 2. Food Storage Items

- 3. Miscellaneous Items

-

1. Food Preparation Items:

- a. Cutting Board

- b. Knife

- c. Mandolin

- d. Scissors

- e. Peeler

- f. Strainers

- g. Rice Scoops

- h. Rice Paddle

- i. Measuring Cups

- j. Knife Sharpener

- k. Serving Scoops / Tongs / Ladles

- l. Cutleries

-

2. Food Storage Items:

- a. Plastic Containers / Lids

- b. Stainless Steel Containers / Lids

- c. Rice Bin

- d. Squeeze Bottles

- e. Knife Rack / Holder

- f. Other

-

Check beneath refrigeration equipments, beneath compartment sinks, corners / crevices, walls, floors, ceilings, overhead fixtures such as signage / lighting, etc.

-

29. (B235, C315 & C335) Is the sushi kiosk in good repair and kept clean?

-

Select the non-conformances related to the sushi kiosk which were observed

- 1. Floors

- 2. Walls

- 3. Ceilings

- 4. Overhead signage

- 5. Ledges around the kiosk

- 6. Other

-

30. (B217, B219 & C319) Is the hand washing station easily accessible and fully equipped with the essential items (i.e., hot running water, cold running water, hand soap in dispenser, paper towel in dispenser, hand washing signage)?

-

(C319) What non-conformances with the hand washing station were observed

- No hot or cold running water

- No hand soap in dispenser

- No paper towel in dispenser

- No hand washing signage posted

- Hand wash station was blocked / obstructed / not easily accessible

- Food items stored in hand washing sink

- Hand wash sink is not clean

- Hand wash sink used for other purposes

- Other

-

CAP Guide: hand wash station was block/foreign material found in hand wash sink/ hand wash sink was used for other purpose. Re-train chef the important of hand wash sink should always accessible and use for hand wash only, any missing items should be replaced, require reporting store management and supervisor.

-

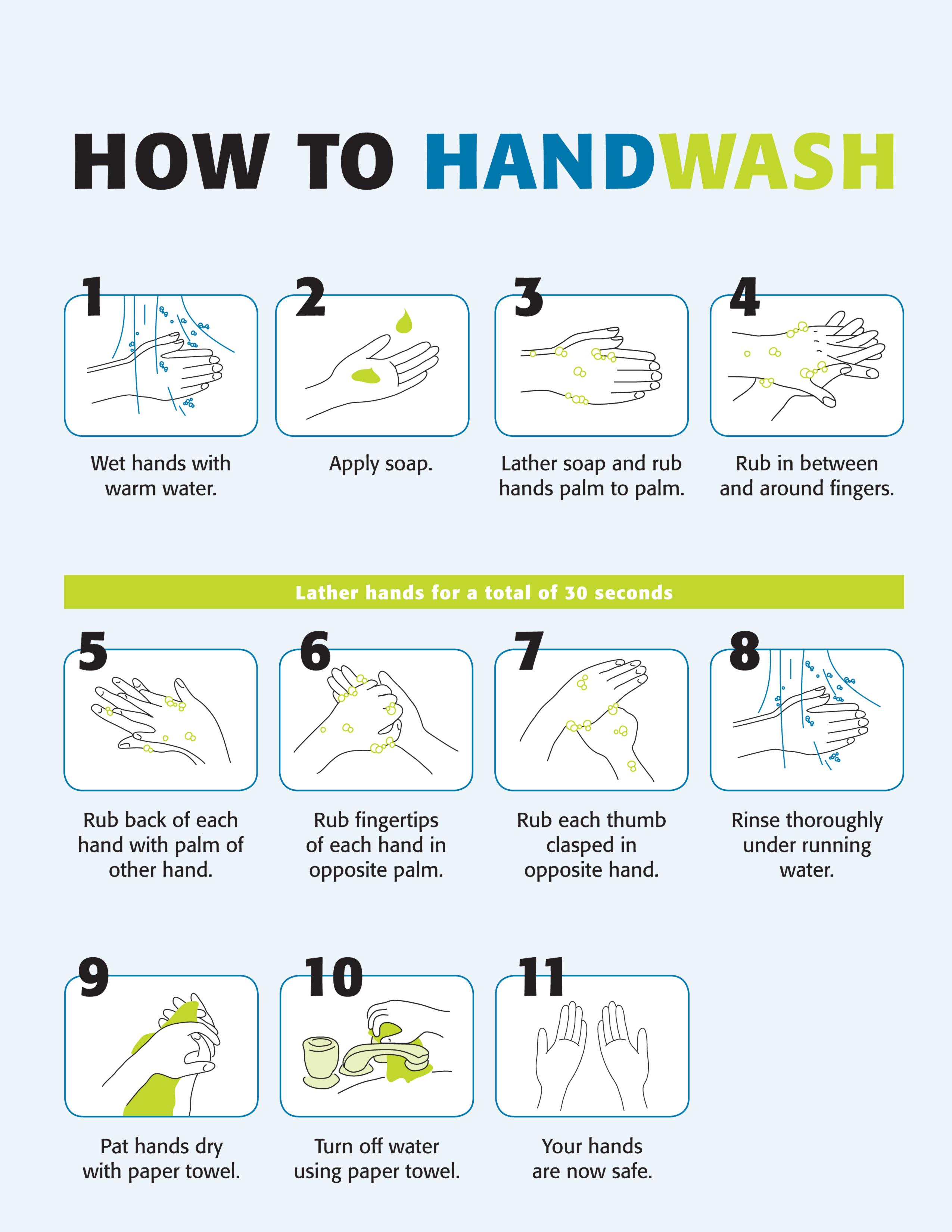

Proper Hand Washing Procedures

-

Select N/A if time of visit is out of operation hours where there is no chef. No score deduction.

-

31. (A131) Did Chef wash hands thoroughly before, after and in-between handling foods using the correct hand-washing procedure? (1st Priority)

-

Select the non-conformance related to handwashing which was observed

- No hand wash after picking up food / garbage from the floor

- No hand washing after exiting and re-entering the kiosk

- No hand wash in-between task / glove changes

- Not hand washing using the correct procedure

- No hand wash when required (Describe observations made under Notes)

-

CAP Guide: Re-train chef importance of hand washing, every time enter kiosk should wash hands, change gloves and when every time pick up garbage from the floor

32-36. Food Safety and Documentations

-

1. Check that the Bento Food Safety Training Checklist is completed with passing test scores (92%) and signatures or has the Bento Sushi Chef Training Certificate (issued from the LAB).

2. Check that there is a valid Food Handler Certification and that it is not expired. -

32. (B201 & BEN311) Are all food safety related documentations available for review? (1st Priority)

-

Select the non-conformance which applies to food safety related documents which was observed

- No - Incomplete food safety training checklist

- No - Food safety training checklist is without passing test scores

- No - Food safety training checklist not on-site

- No Food Handler Certificate on-site

- No - Food Handler Certificate is expired / not issued within the last 5 years

-

Take a photo of the non-conformance. Annotate the non-conformance on the photo.

-

CAP Guide: inform supervisor to provide missing documentation to kiosk and take picture(s) upload to 'action' on iAuditor

-

Take a photo of the completed Food Safety Training Checklist/ Lab Certificates

-

Take a photo of the Sushi Chef's Food Handler Certification

-

CAP Guide: inform supervisor to provide missing documentation to kiosk and take picture(s) upload to 'action' on iAuditor

-

Select the option(s) which applies to food safety related documents which was observed

- Yes - Completed LAB certificate available

- Yes - Completed food safety training checklist available

-

33. (A132) Is the Temperature & Food Safety Log completed correctly (i.e. not dry labbed) and verified by SV? (1st Priority)

-

Select the Temperature & Food Safety Log which was non-compliant

- Temperature & Food Safety Log (Safety Culture App)

- Temperature & Food Safety Log (Paper Version)

-

CAP Guide: missing record(s) during audit Section2. Instrument Calibration

• Calibrations of instrument not conducted at least once a week

• pH meter calibration was recorded on the log despite not having a pH meter available at the kiosk

• “X” was marked for non-compliance under the calibration, but no corrective action was recorded (Draw a line through the cell or record ‘N/A’ when entry is not available)

Section 3. sanitizer concentration

• Not indicating whether the sanitizer verified is from the ‘Spray Bottle or Sanitizer Bucket’

• Not checking or recording the sanitizer concentration for both the ‘Spray Bottle / Sanitizer Bucket’ and ‘Dispenser’

• Sanitizer concentration recorded as 200 ppm - 500 ppm, however, in the colour chart of the QT-40 test kit, there is a reading that lies between 200 ppm and 500 ppm, which is 400 ppm

• No corrective actions taken / recorded when the sanitizer concentration is out of deviation

Section 4. Product temperature

• Temperature checked with yesterday's product

• Record was complete advance (Temperature was recorded on the logbook, but not today’s product was made which consider as dry labbing)

• product temperatures higher than the limit and on the log was recorded as less than 4C which considered as dry labbing

section 5. refrigeration equipment temperature

• Temperature reading from the temperature sensor on the fridge ( the sensors were not calibrated regularly; the temperature can be inaccurate)

CAP Guide (Ver. 2022OC03): • Chef missing check the temperature of the products in refrigeration equipment

Section 6. Rice cooling

• The cooling of the rice must meet the time/temperature requirements [from 60oC (140oF) to 20oC (68oF) within 2 hours and from 20oC (68oF) to 4oC (40oF) within 4 hours for a total

Section 7. Rice Acidification

• pH >4.3, corrective action is more vinegar should add

• pH <3.8, corrective action is more rice from same batch of rice need added, or discard the rice (corrective action should be recorded)

• Recorded as 4.0~4.5, but the actual pH was 4.0, then on the logbook should be recorded as 4.0

Re-train chef how to record log correctly and require supervisor to take picture of following day’s records -

No Temperature & Food Safety Log (Paper Version):

- a. Temperature & Food Safety Log not completed at time of visit / audit

- b. Temperature & Food Safety Log completed in advance

- c. Temperature & Food Safety Log missing

- d. Temperature & Food Safety Log filled out incorrectly

- e. No corrective actions taken / recorded when required

- f. Supervisor / Manager did not verified / signed off as required

-

d. Temperature & Food Safety Log filled out incorrectly:

- Section 2 - Instrument Calibration

- Section 3 - Sanitizer Concentration

- Section 4 - Product Temperatures

- Section 5 -Refrigeration Equipment Temperature

- Section 6 - Rice Cooling

- Section 7 - Rice Acidification

-

Section 2 - Instrument Calibration:

- A) pH Meter

- B)Probe Thermometer

-

Section 3 - Sanitizer Concentration:

- A) Spray Bottle / Sanitizer Bucket

- B) Dispenser

-

Section 4 - Product Temperatures:

- A) Internal Product Temperature(s) After Chilling

- B) Internal Product Temperature(s)On Display

-

Section 5 - Refrigeration Equipment Temperature:

- A) Raw Material Fridge

- B) Showcase

- C) Freezer

- D) Blast Chiller

-

Which Log was used

- Yes - Temperature & Food Safety Log (Safety Culture App)

- Yes - Temperature & Food Safety Log (Paper Version)

-

Take a photo of the current Temperature & Food Safety Log. Annotate the non-conformance on the photo.

-

34. (A132) Is the Cleaning Log completed correctly (i.e. not dry labbed) and verified by SV? (1st Priority)

-

Select the Cleaning Log which was non-compliant

- Cleaning Log - Safety Culture App

- Cleaning Log - Paper Version

-

Select the section(s) of the Cleaning Log (Safety Culture App) which were non-compliant

- a. Clean #1 - Once a Day (Showcase)

- b. Clean #2 - During Operations

- c. Clean #3 - After Use

- d. Clean #4 - At the End of Day

-

Cleaning Log (Paper Version):

- a. Cleaning Log not completed at time of visit

- b. Cleaning Log completed in advance

- c. Cleaning Log missing

- d. Cleaning Log filled out incorrectly

- e. No corrective actions taken / recorded when required

- f. Supervisor / Manager did not verify / sign off as required

-

d. Cleaning Log filled out incorrectly:

- Section 2 - Clean - During Operations

- Section 3 - Clean - Once a Day

- Section 4 - Clean - After Use (Rice Cooker Pot)

- Section 5 - Clean - After Use (Containers for Raw Materials / RTE Items)

- Section - 6 - Clean - At the End of Day

-

Which Log was used

- Cleaning Log - Safety Culture App

- Cleaning Log - Paper Version

-

35. (A132) Does the store have a Hot Food Program

-

Does the kiosk have a dedicated probe thermometer for hot food? (avoid cross contamination risk with sushi)

-

Is the Hot Food Cooking, Reheating and Holding Log completed correctly (i.e., not dry labbed) and verified by SV? (Where applicable) (1st Priority)

-

Select the non-conformance related to the Hot Food Cooking, Reheating and Holding Log which was observed

- No - Log book was not completed

- No - Missing log book

- No - Log book was completed in advance

- No - Log book was filled out incorrectly

- No - Log book has not been verified by SV

- No - No corrective action taken / recorded when deficiencies were identified

-

CAP Guide:

• missing record(s) during the audit

• microwave cannot use as a hot holding unit

• the holding temperature was recorded one hour after finish cook time, products are cool already, product only allow to reheat once

• hot food raw material fridge temperature needs to be clean in AM and PM

• chef did not record afternoon production on the hot food logbook

• Re-train chef how to record log correctly and require the supervisor to take picture of following day’s records -

35a. Does the store have a Hot Food Program?

-

Take a photo of the current Hot Food Cooking, Reheating and Holding Log.

-

Does the kiosk has a dedicate probe thermometer for hot food? (avoid cross contamination risk with sushi)

-

Take a photo of the current Hot Food Cooking, Reheating and Holding Log.

-

36. (A132) Does the store Deliver products?

-

Does the kiosk have ice blankets / ice packs, and coolers for the delivery of products?

-

Is the DSD Temperature Log completed correctly (i.e., not dry labbed) and verified by SV? (Where applicable) (1st Priority)

-

Select the non-conformance related to the DSD Temperature Log which was observed

- No - Log book was not completed

- No - Missing log book

- No - Log book was completed in advance

- No - Log book was filled out incorrectly

- No - Log book has not been verified by SV

- No - No corrective action taken / recorded when deficiencies were identified

-

CAP Guide:

• missing record(s) during the audit

• microwave cannot use as a hot holding unit

• the holding temperature was recorded one hour after finish cook time, products are cool already, product only allow to reheat once

• hot food raw material fridge temperature needs to be clean in AM and PM

• chef did not record afternoon production on the hot food logbook

• Re-train chef how to record log correctly and require the supervisor to take picture of following day’s records -

Take a photo of the current DSD Log.

-

37. Steritech Audits - Have all noted deficiencies from previous audit been corrected?

-

*This is to ensure there are no 'Repeats' observed on future Steritech audits

38. Scale Calibration

-

Is there a scale found at the location?

-

Is scale functioning properly?

-

Weight Scale Reading With Standard Weight (RW) 200g (0.44 lbs), (g)

-

Difference (SW-RW), (± 0.5g)

-

39. (C339) Are refrigeration equipment fans in clean conditions? (No dust build-up)

-

40. (C318) Is Kevlar cut-resistant glove available and used as required (i.e., cutting of avocado, use of mandolin, cutting of fish, etc.)?

-

41. (701) Is a copy of the most recent Public Health Inspection record / signage available?

-

Take a photo of the Last Health Inspection Certificate

- Section 2 - Instrument Calibration

- Section 3 - Sanitizer Concentration

- Section 4 - Product Temperatures

- Section 5 -Refrigeration Equipment Temperature

- Section 6 - Rice Cooling

- Section 7 - Rice Acidification

-

42. (C330) Are personal items properly stored in designated areas away from food, utensils and equipment.

-

43. Positive Observation

- The kiosk is nice and clean

- All sushi on showcase is in the proper temperature range

- Sanitizer concertation is in the proper range

- Raw materials are separately stored from ready-to-eat items

- The chef was friendly with excellent customer service (i.e., always greeting & thanking customers for their purchase

- The chef was in proper uniform

- The chef was being very cooperative and taking corrective action on the spot

- Chef has proper PPE

- All ingredients are correctly labeled

- PN was updated version

- Chef is washing hands as required follow procedure

- Vacuum packs seafood is slit open prior defrost

-

44. Are there additional comments? If Yes, specify in the notes and attach photos.

-

C313

Foods and food-contact packaging are stored at least fifteen centimeters / six inches off the floor.

C307

Foods are properly protected from contamination. Foods in storage are properly covered unless cooling. Foods are protected from contamination during preparation and serving. No condensation is present above exposed food or food-contact surfaces. Proper serving practices are observed so that hands do not touch the food-contact or lip-contact surfaces of cups or utensils.

B221

Gloves are changed whenever damaged or torn. When handling exposed food, gloves are worn over bandages. Fingernails are kept trimmed.

C319

Manual warewashing facilities are properly maintained and operated; sinks are not used for dishwashing and food prep at the same time and sanitized between processes.

C329 Wipping cloth

Wiping cloths are kept clean and dry or else immersed in properly diluted sanitizer. Separate cloths are used for wiping food-contact and nonfood-contact surfaces.

C335/C337 floors,walls, ceilings

c335 Floors, walls, and ceilings are free of excessive dust, debris and standing water.

c337 Floors, walls and ceilings are smooth, easily cleanable, and in good repair. Exposed concrete blocks and bricks are sealed and smooth unless area is used only for dry storage.

C341

Lighting is adequate for cleaning and food handling tasks; lights are shielded or shatterproof above exposed food and food-contact surfaces, and above packaged food if the package integrity could be affected by broken glass.

C333 rest room

Restrooms used by food handlers are maintained clean with fixtures in good repair. Handwash sinks are supplied with readily available hot water, soap, disposable towels or heated-air hand drying device, covered trash can (in female or unisex restroom), and signed to remind employees to wash hands. Toilet paper available in stalls. Restroom doors leading directly into food preparation areas are self-closing.

B207

Proper cooling methods (placing foods in shallow pans, using chill blasters or cooling wands, etc.) are used for potentially hazardous foods. -

45. (C313, C307, B221, C319, C329, C335, C337, C335, C341, C333, B207) Additional Issues found?

Knowledge Questions

-

Choose 2 different questions to ask the Chef on site.

1. What is the "Food Temperature Danger Zone"?

Answer: 4°C - 60°C

2. Show/ explain to me the dishwashing procedure.

Answer: Pre-Scrape / Pre-Rinse - Wash - Rinse - Sanitize - Air Dry. Refer to SOP QFS 0001.

3. What is the colour code for cutting boards?

Answer: Blue should be used for raw seafood (eg raw salmon, raw tuna, etc.) and sushi containing raw seafood. Green/white cutting boards should be used for fruits, vegetables and sushi containing fruits and vegetables, as well as cooked proteins (eg shrimp tempura, smoked salmon, imitation crab sticks, etc.) and sushi containing cooked protein

4. Show me how to measure internal temperature of finished product.

Answer: The chef should check the thickest part of the food and 1 inch from the surface. The chef must know that all areas of a product must be at a safe temperature.

5. What is the difference between cleaning and sanitizing equipment and utensils?

Answer: Cleaning - Removing dirt or visible soil from a surface. Sanitizing - Removing bacteria to safe levels.

6. Quick cooling of hot products can be accomplished by what methods?

Answer: Ice-water bath; dividing food into smaller portions (i.e. using shallow pans instead of deep pans); using pre-chilled, shallow stainless steel pans; using refrigeration equipments to speed up cooling (i.e. walk-in freezer, blast chiller, refrigerators)

7. How can cross-contamination be best avoided?

Answer: Proper hand washing and glove changes during task changeover; Follow colour coding of cutting boards / tools; Stored ready-to-eat foods above raw products in the refrigerator; Wash and sanitize tools / utensils / equipment in-between task changeovers (especially when working from raw to ready-to-eat / cooked items)

8. When should you wash your hands?

Answer: Before starting work or donning a new pair of disposable gloves; in-between task changes; after returning from break / lunch break / washroom break; after handling garbage / washing dishes / chemicals.

9. What are some examples of how cross-contamination can occur?

Answer: Storing raw product on top of ready-to-eat foods in a refrigerator; Not following proper colour coding of cutting boards / tools; Not changing gloves / wash hands in-between task changes;

10. What are the main causes of foodborne illness?

Answer: Improper cooling of food; Improper hot holding of food; Inadequate reheating / cooking of food; Contaminated food / ingredient; Cross contamination; Infected food handler. -

Knowledge Question 1

-

Knowledge Question 2

-

CAP Guide: add notes of your observation which is not listed in the questions. Ex: expired Bento at-home products found on the shelves

-

Please enter your name and sign off below once all non-compliances have been reviewed with the Sushi Chef(s) on duty and corrective actions implemented

-

Sushi Chef(s)

-

If Sushi Chef is not available at time of audit, enter "N/A" under "Full Name" and sign "N/A" in signature field.

-

Supervisor