Title Page

-

Conducted on

-

Prepared by

Tools

Torches/ Cutting

-

Cutting Torch gauges/regulators

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Torch tanks<br><br>Check oxygen and fuel level in tanks. If your tanks are empty or low replace/ refill tanks.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Cutting Torch hoses<br><br>Check hoses for cracking, leaks or damage. Report any defects in hoses to service supervisor.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

90 Degree cutting torch

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Straight cutting torch

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Long cutting tip

-

Restock welding supplies so that you have them when needed on a service job

-

Short cutting tip

-

Restock welding supplies so that you have them when needed on a service job

Hand Tools

-

Labyrinth seal snap ring pliers

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

3/4" Impact Gun

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

1" Impact Gun

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Flow Meter

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

18/1 Torque Multiplier

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

3/4" Drive torque wrench

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

1/2" Drive torque wrench

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

1" Drive 7/8" Hex socket

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

10,000 PSI Hydraulic pressure gauge QTY:2

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

10,000 PSI Hydraulic pressure gauge hoses QTY:2

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

1" Drive 1" Hex socket

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

24v Test light

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

1" Drive Extension 4" long

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Thin Head Wrenches:3/4", 13/16", 7/8", 15/16", 1", 1 1/16", 1 1/8", 1 3/16", 1 1/4", 1 5/16", 1 3/8", 1 7/16",1 1/2", 1 9/16", 1 5/8", 1 11/16", 1 3/4", 1 13/16", 1 7/8", 1 15/16", 2", 2 1/8", 2 1/4",

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Threading Taps: 3/8-16, 7/16-14, 1/2-13, 9/16-12, 5/8-11, 3/4-10, 7/8-9, 1-8, 1 1/8-7, 1 1/4-7

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Tap Handle

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Grease Gun

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Chipper knife gauge<br>

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Deutsch Connector Set<br>

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

Welding

-

Miller trailblazer welder/ Generator<br><br>Check engine oil level and coolant level, inspect positive and negative electrode connections, check function of GFCI outlets, fuel filter, glow plugs, air filter

-

What is the issue with the tool?

-

When was the last service done on the welder. You should keep a log of the oil changes and services done to the welder.

-

Hours on weler

-

Suitcase welder<br><br>Check MIG gun for defects in the liner, tip, trigger and gas nozzle. Check for proper operation of wire feeder.

-

What is the issue with the tool?

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Welding leads<br><br>Check for cracking/damaged/melted casing, exposed wires, broken connectors, or any defects in the leads that could cause harm or quality defect. report any defects immediately as this is a safety concern.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Carbon Arcing torch<br><br>

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Welding/ Cutting blankets<br><br>Check for holes in welding/ cutting blankets. if there is any holes or tears in blanket notify service supervisor.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Welding rods

-

Restock welding supplies so that you have them when needed on a service job

-

Argon gas bottle<br><br>check level of argon gas. If low, replace or refill bottle.

-

Restock welding supplies so that you have them when needed on a service job

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

MIG Wire

-

Restock welding supplies so that you have them when needed on a service job

Air Compressor and accessories

-

Air Compressor<br><br>Inspect drive belts, check oil level in engine, check oil level in compressor (should be half way up sight glass), quick connectors, air filter, oil filter (change oil according to manufacturers recommendations),

-

What is the issue with the tool?

-

Add media

-

When was the last service done on the welder. You should keep a log of the oil changes and services done to the welder.

-

1/2" Air Hose 50'

-

What is the issue with the tool?

-

Add media

-

3/8" Air hose 50'

-

What is the issue with the tool?

-

Add media

Porta Power

-

30 Ton porta power cylinder

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Large manual porta power pump

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

60 Ton porta power cylinder

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Small manual porta power pump

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Pneumatic porta power pump

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

Rigging and Lifting

-

1.5 ton chain hoist<br><br>Check chain links, body, hooks and clasps for defects. If the clasp is missing or damaged in any way the chain hoist can not be used until it is repaired.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

List the serial number of the chain hoist.

-

3 ton chain hoist<br><br>Check chain links, body, hooks and clasps for defects. If the clasp is missing or damaged in any way the chain hoist can not be used until it is repaired.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

List the serial number of the chain hoist.

-

5/8" Shackle QTY: 2

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

3/4" Shackle QTY: 2

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

1" Shackle QTY: 2

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

1" Ratchet tie down

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

Lifting chains<br><br>Check chain links, hooks and clasps for defects. All lifting chains NEED to have a permanently attached tag from the manufacturer certifying the chain and have a maximum weight. If the chains do not have a permanently attached tag then you CAN NOT use the chain for lifting. If the hook is not a grab hook then the hook is required to have a clasp. If the clasp is missing or damaged in any way the chain can not be used until it is repaired.

-

What is the issue with the chain?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

List the serial numbers of the lifting chain. The serial number is located on the tag that is permanently attached to the chain.

-

1" x 3' Lifting Straps QTY: 2<br><br>Lifting straps need to be inspected for rips, tears, cuts or abrasions. The strap can not be soaked in oil or any substance that can compromise the integrity of the strap. If there is any defects with the straps then the strap needs to be replaced and can not be used.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

List the serial numbers of the lifting straps. The serial number is located on the tag that is permanently attached to every lifting strap.

-

1" x 6' Lifting Straps QTY: 2<br><br>Lifting straps need to be inspected for rips, tears, cuts or abrasions. The strap can not be soaked in oil or any substance that can compromise the integrity of the strap. If there is any defects with the straps then the strap needs to be replaced and can not be used.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

List the serial numbers of the lifting straps. The serial number is located on the tag that is permanently attached to every lifting strap.

-

2" x 6' Lifting Straps QTY: 2<br><br>Lifting straps need to be inspected for rips, tears, cuts or abrasions. The strap can not be soaked in oil or any substance that can compromise the integrity of the strap. If there is any defects with the straps then the strap needs to be replaced and can not be used.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

List the serial numbers of the lifting straps. The serial number is located on the tag that is permanently attached to every lifting strap.

-

2" x 8' Lifting Straps QTY: 2<br><br>Lifting straps need to be inspected for rips, tears, cuts or abrasions. The strap can not be soaked in oil or any substance that can compromise the integrity of the strap. If there is any defects with the straps then the strap needs to be replaced and can not be used.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

List the serial numbers of the lifting straps. The serial number is located on the tag that is permanently attached to every lifting strap.

-

3" x 8' Lifting Straps QTY: 2<br><br>Lifting straps need to be inspected for rips, tears, cuts or abrasions. The strap can not be soaked in oil or any substance that can compromise the integrity of the strap. If there is any defects with the straps then the strap needs to be replaced and can not be used.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

List the serial numbers of the lifting straps. The serial number is located on the tag that is permanently attached to every lifting strap.

-

3" x 10' Lifting Straps QTY: 2<br><br>Lifting straps need to be inspected for rips, tears, cuts or abrasions. The strap can not be soaked in oil or any substance that can compromise the integrity of the strap. If there is any defects with the straps then the strap needs to be replaced and can not be used.

-

What is the issue with the tool?

-

Add media

-

Fill out purchase requisition form and turn into service supervisor so that the tool can be ordered.

-

List the serial numbers of the lifting straps. The serial number is located on the tag that is permanently attached to every lifting strap.

Crane

-

When was the last documented inspection of the crane performed?

-

Cable<br><br>Inspect the cable for fraying, stretched, kinked or broken strands. Report any defects to the service supervisor immediately. If a defect is found you must lock out the crane and tag it until it is fixed.

-

Describe the issue found with the crane cable and upload pictures.

-

Add media

-

Remote and electronics<br><br>Inspect the buttons on the remote. Cycle through the functions and make sure that they all work. This will also test the solenoids to make sure they work.

-

Describe the issue found with the remote and electronics and upload pictures.

-

Add media

-

Hydraulics<br><br>Inspect all the hydraulics for leaks. Verify pressure gauge is working. Cycle through the functions with the levers and verify everything is working properly. If any leaks for defects are found lock out the crane and tag it until the defects are fixed.

-

Describe the issue found with the hydraulics and upload pictures.

-

Add media

-

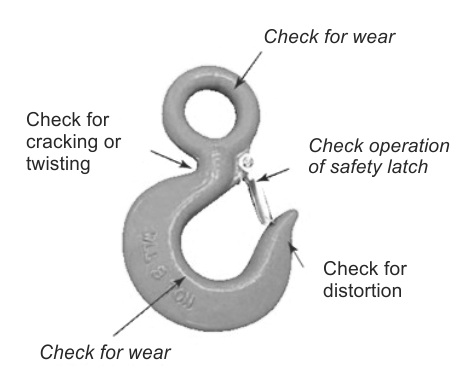

Hook and hook block<br><br>Inspect the hook and hook block for defects. The look for wear on the hook. If the hook is missing the clasp or the clasp is damaged in any way you must lock the crane out and tag it until the hook is fixed. Look for wear on the pulley on the hook block.

-

Describe the issue found with the hook and hook block and upload pictures.

-

Add media

-

-

Boom and frame<br><br>Inspect the boom.Make sure the pivot and slide points are greased and not bound up. Extend the boom and look for cracking in the boom. Inspect the pulley at the end of the boom for any defects. If any defects are found with the boom and boom frame you must lock out the crane and tag it until the defects are fixed.

-

Describe the issue found with the boom and frame and upload pictures.

-

Add media

-

Outriggers<br><br>Inspect outriggers for defects. Make sure pivot and slide points are greased and not bound up. Check hydraulics for leaks and defects.

-

Describe the issue found with the outriggers and upload pictures.

-

Add media

-

Safety limit switches<br><br>Cycle functions to engage safety limit switches. Verify switches are in good working condition. If the safety limit switches are not in good working condition you must lock the crane out and tag it until the hook is fixed. Look for wear on the pulley on the hook block.

-

Describe the issue found with the out figgers and upload pictures.

-

Add media

Safety Gear

-

first aid kit

-

what is the issue with your first aid kit?

-

Notify service supervisor if you do not have a first aid kit issued to your truck or it is missing.

-

Water fire extinguisher

-

Chemical fire extinguisher

-

Check fire extinguisher for damage. There should be an inspection tag on the fire extinguisher with the expiration date and the inspection date. Verify that your fire extinguisher is within the date on the inspection tag. If it is not then select the complaint option and describe the complaint.

-

Per DOT regulations, every commercial vehicle is required to have a permanently mounted fire extinguisher that meets DOT requirements.

https://www.gpo.gov/fdsys/pkg/CFR-2011-title49-vol5/xml/CFR-2011-title49-vol5-sec393-95.xml -

Spare Fueses

-

Spare fuses are required by the DOT to be present on all commercial vehicles. You must have at least one of each size fuse used on the vehicle.

https://www.gpo.gov/fdsys/pkg/CFR-2011-title49-vol5/xml/CFR-2011-title49-vol5-sec393-95.xml -

Road flares or safety triangles

-

Road flares or safety triangles are required by the DOT to be present on all commercially driven motor vehicles.

https://www.gpo.gov/fdsys/pkg/CFR-2011-title49-vol5/xml/CFR-2011-title49-vol5-sec393-95.xml -

Welding PPE

-

If you are missing any welding PPE please notify service supervisor.

-

Welding PPE includes but not limited to leather welding gloves, appropriate welding helmet, and leather welding jacket. Welding PPE is required by terex to be used whenever welding is performed. Please describe any missing, damaged or not issued welding PPE.

-

Hard Hat

-

A hard hat is required on some job sites so it is required to be on every service truck so that it is available when required.

-

Reflective vest

-

A reflective vest is required on some job sites so it is required to be on every service truck so that it is available when required.