Title Page

-

Store Number

-

Store Name

-

Date of Audit

-

Store Manager

-

Reason for visit

- High Loss

- High MFD

- RM Request

- Focus Store

- New Store

- Compliance Audit

- Count Follow Up

- Training

-

Net loss

-

Net loss as a percent of sales

-

Visit Number

- Visit 1

- Visit 2

- Visit 3

- Visit 4

- Visit 5

- Visit 6

- Visit 7

- Visit 8

- Visit 9

- Visit 10

-

Previous compliance score

Division

-

Select Division

Region

-

Select Region

- East Anglia

- East Midlands

- Liverpool & N Wales

- Manchester & Lancs

- North Midlands

- South Midlands

- West Midlands

- East Scotland

- North East

- North West

- South Yorkshire

- West Scotland

- W Yorks & E Lancs

- Yorkshire

- Central London North

- Central London South

- North East London

- South East

- South London

- Surrey & West Sussex

- West London

- Cotswolds

- Hampshire

- Northern Ireland

- Republic Of Ireland

- South Wales

- South Wales

- South West

- Thames & Avon

Open door modules completed by the stock manager

-

Does the store currently have a stock manager

-

Great store standards

-

Date completed

-

Stockroom systems & reports

-

Date completed

-

Management of voice

-

Date completed

-

Stock management

-

Date completed

-

Are there plans to complete any outstanding modules

-

Target date

-

Recommended completion date

-

Has the stock team leader completed all relevant open door modules

-

Date completed

-

Has anyone from the store attended a stock workshop

-

Compliance test required

-

Summary of actions and activities during visit

-

Training Oportunities

- Voice

- Wes Reports

- Root Cause Analysis

- Action Plans

- Objectives

- Scheduling

- Weekly Documentation

- Filing

- Reverse Flow

- Delivery

- Cash Office

- Breifings

- Feedback

- KPI Reports

- DPA

- Mis Match

- N/A

Delivery Receipt and Put Away-Last Two Weeks

-

Have delivery load seals been retained and filed

-

Photograph 4 load sheets with seals

-

Is the current delivery schedule accurate and up to date

-

Are All Ring Orders Released On The Day Of Receipt

-

Are All Deliveries Finalised Before The Next Available Delivery Window

-

If No Was This Due To A Missing Cage

-

Check 25 lines to see if these were put away to company standards (use recent QC checks)

-

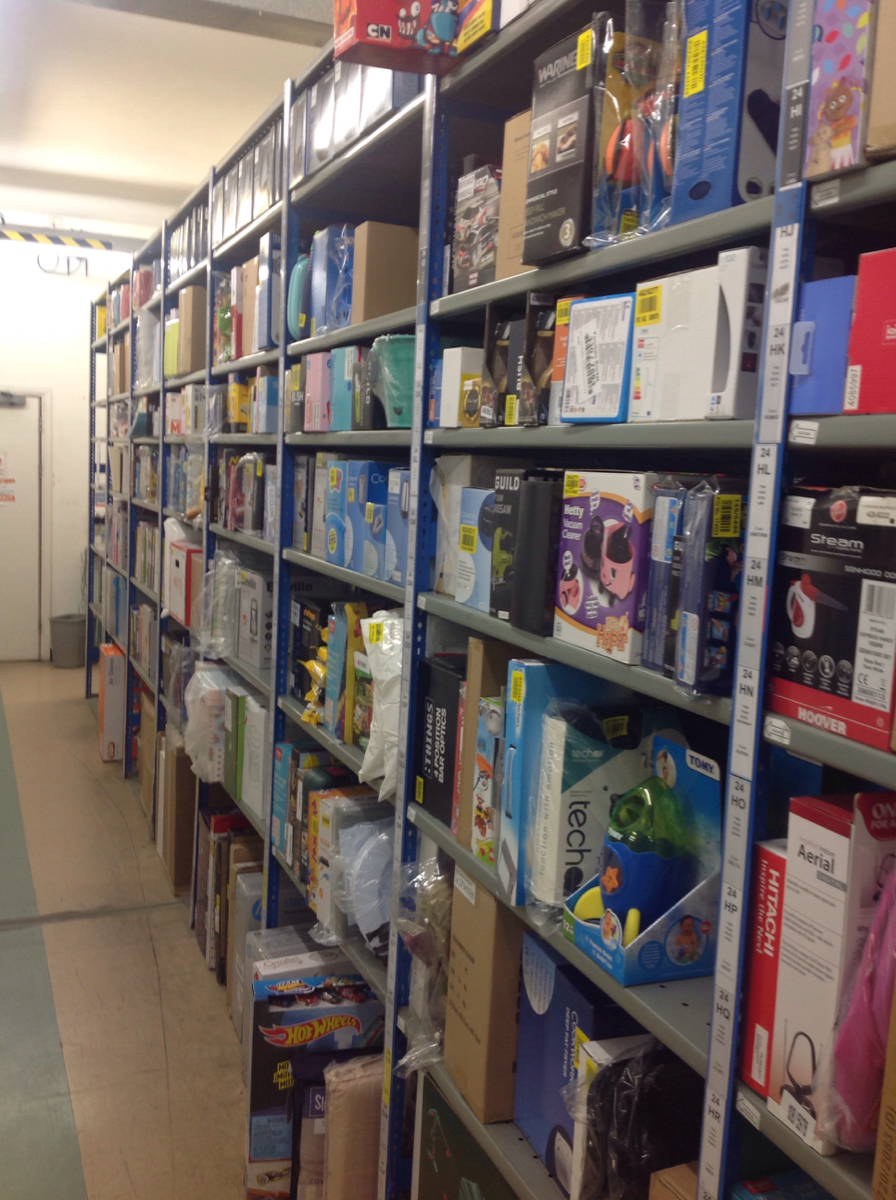

Photograph best aisle and worst aisle

-

From the last 2 weeks deliveries were any issues logged with the DC evidenced with reference numbers

-

If no were there any issues that should have been logged

-

Root cause

- Capabilty

- Process

- Behaviour

- N\A

Adjustments

-

Are adjustment codes being used correctly

-

Can the store provide evidence that locations are checked during any investigations

-

Is there any evidence of root cause analysis

-

Are short picks being checked on a daily basis

-

Root cause

- Capabilty

- Process

- Behaviour

- N\A

Fast track collection proposistion

-

Is Fast Track area set up correctly and within the 60 sec collection proposistion

-

Have all cancelled reservations been moved from the RPA

-

Spoke Store

-

Is the spoke receiving their transfers on time

-

Is this outside the stores control

-

Give an example of what has impacted this

-

Fast Track Area

-

Hub store

Fast Track delivery

-

Is the DPA area set up as per procedure

-

Check 15 FTD orders versus the manifest are they accurate

-

Are all code 15 adjustments being fully investigated

-

Check one Hub to Spoke transfer is it accurate (if possible)

-

Is the failed delivery process in place.

-

Are all collected products good and bad accounted for and processed correctly

-

From the last two weeks were all weekly checks conducted on the vans, fuel etc

-

Is the store validating fuel receipts against their TMC statement

-

From a check of one week can all fuel spend be validated

-

Has this been investigated

-

Root cause

- Ongoing investigation

- No investigation

- Investigated no outcome

- Investigated and resolved

Pending files

-

Is the returns file accurate

-

Is the view file accurate

-

Stores knowledge of mismatch

-

What education is required to gain knowledge around mis-match

-

Is the store actively maintaining the mis-match file

-

Root cause

- Capabilty

- Process

- Behaviour

- N\A

Reverse flow

-

Is there evidence to show that the store are reviewing the SASP report

-

Can all unprocessed damaged units be found

-

Are damaged items stored appropriately to prevent further damage occurring

-

Photograph returns area

-

Are yellow labels completed in full

-

Photograph incomplete or inappropriate reasons for fault

-

Is there evidence of the store utilising the repackaging tool kit

-

Root cause

- Capabilty

- Process

- Behaviour

- N\A

Cash

-

Are all monies secure with restricted access

-

Can the store provide evidence of investigation into T&B discrepancies (current period)

-

Are the T&B cash totals reconciled daily

-

Are weekly cash office audits taking place

-

Root Cause

- Capabilty

- Process

- Behaviour

- N\A

Housekeeping

-

Photograph Stock bench, security, DPA, bulk and staff lockers take others if appropriate

Meetings and action plans

-

Is the store on the high MFD programme

-

Is the high MFD strategy being followed correctly (check stores display plan-o-gram)

-

Photograph the Que system and one product wall

-

Is there evidence that weekly board meetings are taking place

Summary

-

We're there any commercial or customer impacts

-

Summarise commercial and customer impacts

-

Next steps

- Escalate to HRBP

- Escalate to Investigation Manager

- Follow up

- Copy sent to RM

- RM follow up required

- Copy sent to Paul Mitchener

-

Agreed Actions

Action Plan

-

Store to action

-

By When

Training opportunities

-

Who

- Stock Manager

- Stock Team Leader

- Colleague

- Store Manager

- CFM

- Store Manager

- CSM

- OPS Manager

-

What

- Process

- Planning

- Root Cause

- Reports

-

Which element

- Voice

- Wes Reports

- Root Cause Analysis

- Action Plans

- Objectives

- Scheduling

- Weekly Documentation

- Filing

- Reverse Flow

- Delivery

- Cash Office

- Breifings

- Feedback

- KPI Reports

- DPA

- Mis Match

- N/A

-

Completed By