Title Page

-

To be completed by Project Supervisor or Nominated person weekly from the start of construction work on site. Completed forms are to be kept readily available (preferably on site) for the duration of construction works, after which time shall from par of the CDM Health & Safety file.

-

Sensible Monitoring Audit Completed By:

-

Site Manager:

-

Contract Number:

-

Project Title:

-

Conducted on

General

-

Any H&S actions identified shall be entered onto Audit / Inspection Action Log and brought to the urgent attention of the appropriate personnel as soon as possible. Contractor / Project Manager to be notified of actions required / taken.

-

1) Is there a Method Statement / Risk Assessment / Permit to Work available on site for the activity?<br>a) Has it been briefed out and signed for?

-

Comments:

-

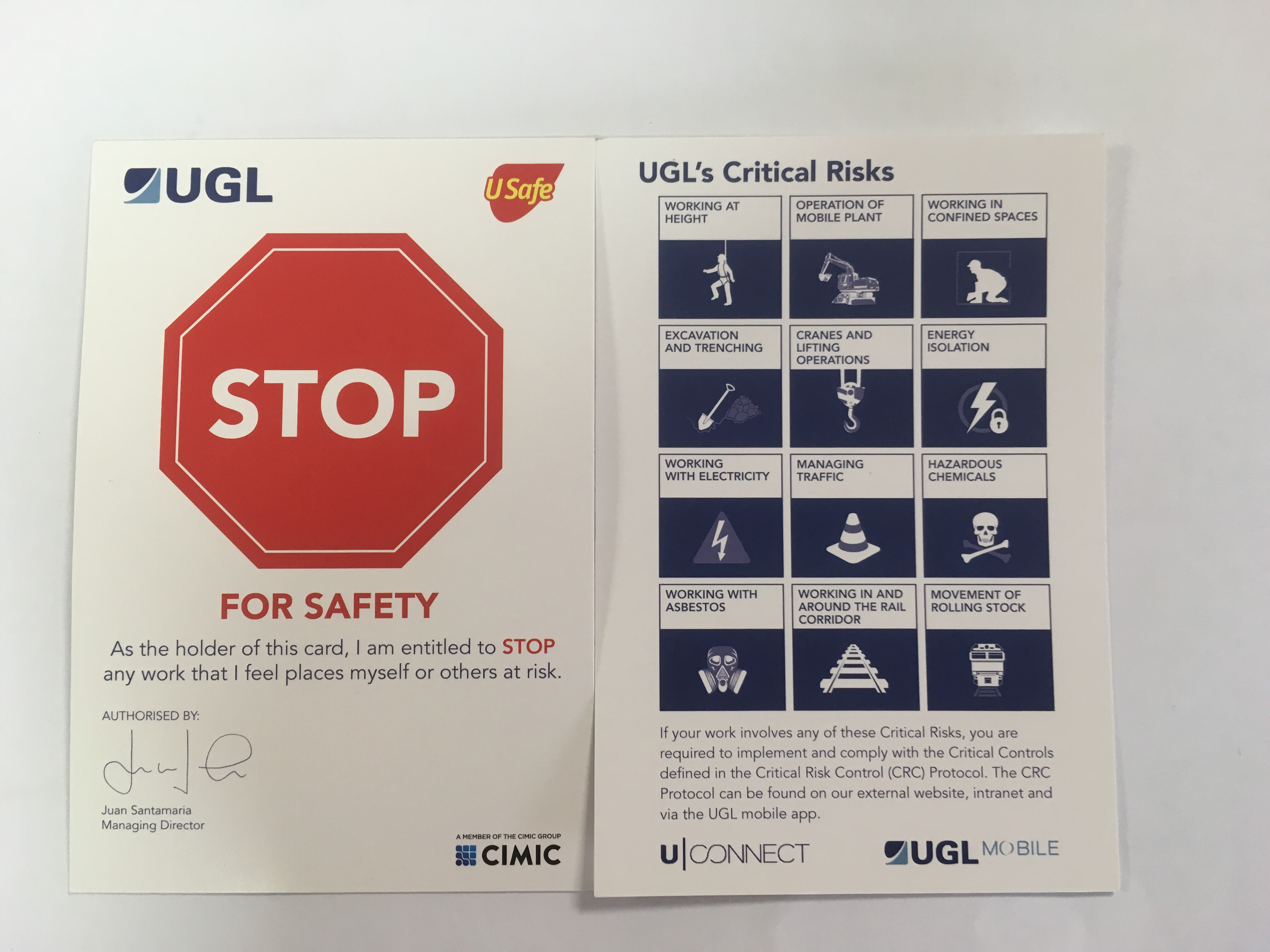

Attach any images relevant to question 1 here.

-

2) Are the Emergency Procedures available on site?<br>a) Are all operatives aware of them?<br>b) Are the Emergency Procedures adequate and do all personnel understand them?<br>c) Have foreseeable emergencies been identified?

-

Comments:

-

Attach any images relevant to question 2 here.

-

3) Have all Operatives been inducted to the Project and received EUSR training?<br>a) Are all operatives competent to perform the task?<br>(Check CITB, CSCS cards, training records etc.) Confined Spaces entry training, breathing apparatus, medically fit.

-

Comments:

-

Attach any images relevant to question 3 here.

-

4) Are the welfare facilities adequate and is there appropriate first aid provision on site?<br>(Numbers of Appointed persons / First Aiders, Location / Contents of Kit)

-

Comments:

-

Attach any images relevant to question 4 here.

-

5) Is the correct PPE for the task being worn? <br>(Check condition, age, storage, training)

-

Comments:

-

Attach any images relevant to question 5 here.

-

6) Is the site tidy and free from trip hazards and is there safe access and egress available for all?

-

Comments:

-

Attach any images relevant to question 6 here.

-

7) Are all operatives competent to perform the task?<br>(Check CITB, CSCS cards, training records etc.) Confined Spaces entry training, breathing apparatus, medically fit.

-

Comments:

-

Attach any images relevant to question 7 here.

-

8) What specified risks exist which classify the work are as a confined space?<br>a) Can the task be avoided?

-

Comments:

-

Attach any images relevant to question 8 here.

-

9) Are the emergency procedures adequate and do all personnel understand them?<br>a) Have foreseeable emergencies been identified?

-

Comments:

-

Attach any images relevant to question 9 here.

-

10) Has a system of communication been agreed between those inside the confined space and those outside?

-

Comments:

-

Attach any images relevant to question 10 here.

-

11) Are any vehicle / plant exhaust fumes likely to enter the confined space?

-

Comments:

-

Attach any images relevant to question 11 here.

-

12) Is breathing apparatus checked / tested / inspected prior to entry?<br>(Recorded)

-

Comments:

-

Attach any images relevant to question 12 here.

-

13) Are atmospheric tests carried out at the start of every shift and during activities?

-

Comments:

-

Attach any images relevant to question 13 here.

-

14) Are atmospheric monitors within their calibration date, batteries checked, tested prior to entry?

-

Comments:

-

Attach any images relevant to question 14 here.

-

15) Is there safe access / egress to and from the confined space?

-

Comments:

-

Attach any images relevant to question 15 here.

-

16) If required, are there an adequate number and type of fire extinguishers on site and are they in appropriate locations?

-

Comments:

-

Attach any images relevant to question 16 here.

Pipe Entry

-

17) Is safe access to the pipeline provided?<br>E.g. suitably footed ladder.

-

Comments:

-

Attach any images relevant to question 17 here.

-

18) Have powered access trolleys undergone maintenance / safety checks prior to use?

-

Comments:

-

Attach any images relevant to question 18 here.

-

19) Are warning notices and personnel posted at each open end of the pipe?

-

Comments:

-

Attach any images relevant to question 19 here.

-

20) Is a shatterproof torch / headlamp, face mask / respirator, rescue line, air sampler analyzer and suitable Breathing apparatus available on site?

-

Comments:

-

Attach any images relevant to question 20 here.

-

21) If an entry of more than 60m is to occur, are two people on powered trolleys used?

-

Comments:

-

Attach any images relevant to question 21 here.

-

22) Has the pipeline profile been consulted prior to the commencement of the work?<br>(Gradients, dips, turns)

-

Comments:

-

Attach any images relevant to question 22 here.

-

23) Is working time in the pipe limited?<br>(Is this documented and time of entry record)

-

Comments:

-

Attach any images relevant to question 23 here.

-

24) Are ropes / harnesses inspected prior to use?<br>a) Do harnesses have a valid test certificate, SWL indicated?

-

Comments:

-

Attach any images relevant to question 24 here.

Sign Off Audit

-

Print Name:

-

Signature:

-

Project Manager Name:

-

Signature:

-

Designation:

-

Select date