Title Page

-

Asset being audited:

-

Address

-

Auditee:

-

E-mail address of Site Manager for Actions to be sent through to?

-

Auditor:

-

Date of Audit:

Introductions

Introductions and format of the audit

-

Introductions:

H&S Team

Site Team -

The purpose of this audit is to ensure that the council asset is meeting its statutory requirements with regards to Health & Safety across the Facilities department.

-

The audit is compiled to specifically look at the following areas:

Facilities Department

The Site Manager/Caretaker will be required to facilitate a full site inspection and to answer questions and provide documentary evidence on areas of compliance.

General Information

-

Name of Building Custodian?

-

Name of Caretaker/Site Manager?

-

Approximate age of the building?

General Notes

-

undefined

Physical Walkround

-

Carry out a physical 'walkround' of the site (to include all areas i.e. boiler house, plant rooms, offices etc.).

Compliance Questions

Section 1 - Water Hygiene

-

1.1 - Has a suitable and sufficient Legionella Risk Assessment been carried out for the premises, by a competent person?

-

1.1.1 - Who carried out the Legionella Risk Assessment?

-

1.1.2 - Date of Legionella Risk Assessment:

-

1.1.3 - Have any substantial changes been made since the last Risk Assessment was undertaken i.e. change of use, changes to the systems or services, changes to the management structure?

-

1.2 - Have all actions identified within the Legionella Risk Assessment been addressed?

-

1.2.1 - What management plan is in place to ensure all actions identified are addressed?

-

-

1.3 - Is someone identified as the Duty Holder (usually the Employer)?

-

1.3.1 - Name of Duty Holder?

-

1.3.2 - Has the Duty Holder got access to competent help and advice?

-

1.3.2.1 - Name of competent person/organisation?

-

1.4 - Is someone identified as the Responsible Person (usually the Building Custodian)?

-

1.4.1 - Name of Responsible Person?

-

1.4.2 - Has the Responsible Person received legionella awareness training (with refresher training every 3 years)?

-

1.5 - Is someone identified as the Deputy Responsible Person (usually the Site Manager/Caretaker)?

-

1.5.1 - Name of Deputy Responsible Person?

-

1.5.2 - Has the Deputy Responsible Person received legionella awareness training (with refresher training every 3 years)?

-

1.6 - Are there any stored potable (drinking) water tanks on site?

-

1.6.1 - Is there evidence that 6 monthly (Summer & Winter) water tank inspections are carried out by a competent person?

-

1.6.1.1 - Who carried out the tank inspections?

-

1.6.1.2 - When where the inspections carried out?

-

1.7 - Are there adequate measures in place to record all issues relating to water quality?

-

1.8 - Does the property purchase or use the services of a specialist water hygiene company?

-

1.8.1 - Name of water hygiene company?

-

1.8.2 - What level of service is purchased (usually listed in RA)?

-

Section 1 - Any other relevant deficiencies observed, not covered above?

-

Section 1 - Other relevant deficiencies observed, not covered above:

Section 2 - Asbestos

-

2.1 - Are there any known Asbestos Containing Materials (ACM's) on site?

-

2.2 - Has an Management Survey been carried out for the premises?

-

2.2.1 - Who carried out the Management Survey?

-

2.2.2 - Date of Management Survey:

-

2.3 - Is there evidence that the Management Survey is reviewed (as necessary)?

-

2.3.1 - Date of last review?

-

2.4 - Have all actions identified within the Management Survey been addressed?

-

2.4.1 - What management plan is in place to ensure all outstanding actions are addressed?

-

2.5 - As part of the Management Survey, has an MATERIAL risk assessment been produced?

-

2.6 - As part of the Management Survey, has an PRIORITY risk assessment been produced?

-

-

2.7 - Is there a Asbestos Management Plan for the building?

-

2.7.1 - Is the asbestos Management Plan reviewed every 12 months?

-

2.8 - Is someone identified as the Dutyholder for asbestos (usually the Employer)?

-

2.8.1 - Name of Dutyholder?

-

2.8.2 - Has the Dutyholder got access to competent help and advice?

-

2.8.2.1 - Name of Competent Person/Organisation?

-

2.8.2.2 - Has the Competent Person/Organisation received sufficient training?

-

2.9 - Is someone identified as the Responsible Person for asbestos (usually Building Custodian) ?

-

2.9.1 - Name of Responsible Person?

-

2.9.2 - Has the Responsible Person received asbestos awareness training?

-

2.10 - Is someone identified as the Deputy Responsible Person for asbestos (usually Site Manager/Caretaker) ?

-

2.10.1 - Name of Deputy Responsible Person?

-

2.10.2 - Has the Deputy Responsible Person received asbestos awareness training?

-

2.11 - Is there a printed copy of the Asbestos Register (containing plans/locations drawings/photographs) available at the main entrance to the building?

-

2.12 - Is there evidence that all contractors sign in and check the Asbestos Register prior to starting work?

-

2.13 - Are procedures understood, if asbestos is disturbed in the building?

-

2.14 - Are relevant employees that work in the building made aware of the presence and position of asbestos?

-

2.15 - Are Refurbishment Surveys commissioned prior to the commencement of any alteration works (buildings build prior to 2000)?

-

2.16 - Following any alteration works, are records updated accordingly?

-

Section 2 - Any other relevant deficiencies observed, not covered above?

-

Section 2 - Other relevant deficiencies observed, not covered above:

Section 3 - Gas & Boiler House Safety

-

3.1 - Is there evidence that 5 yearly testing of Gas Installation (Gas Installation Safety Report, Commercial Gas Testing and Purging Record & Schematic Diagram) is carried out?

-

3.1.1 - Who carried out the last 5 yearly Gas Installation test?

-

3.1.2 - Date of last 5 yearly Gas Installation test:

-

-

3.2 - Are all gas boilers subjected to an annual gas safety test?

-

3.2.1 - Who carried out the gas boilers annual gas safety test?

-

3.2.2 - Date of last gas boiler annual gas safety test:

-

-

3.3 - Is a gas shut off valve installed and are relevant staff aware of its location?

-

3.4 - Are boiler houses free of combustible materials?

-

3.5 - Is a suitable Carbon Monoxide detector fitted where gas appliances are present?

-

Section 3 - Any other relevant deficiencies observed, not covered above?

-

Section 3 - Other relevant deficiencies observed, not covered above:

Section 4 - Electrical Safety

-

4.1 - Is there evidence that periodic Electrical Installation Condition Reports (5 year fixed wiring tests) are carried out?

-

4.1.1 - Who carried out the Electrical Installation Condition Report?

-

4.1.2 - Date of last Electrical Installation Condition Report:

-

4.1.3 - Is the overall assessment of the electrical installation 'Satisfactory'?

-

Electrical Installation 'Unsatisfactory'

-

4.1.3.1 - Have all 'dangerous & potentially dangerous' observations identified within the Electrical Installation Condition Report been addressed?

-

-

4.1.3.2 - What Management Plan is in place to ensure any outstanding observations are addressed?

-

-

4.2 - Is there evidence that electrical appliances are tested (PAT/FAT) on a periodic basis?

-

4.2.1 - Who carried out the electrical appliance testing?

-

4.2.2 - Date of last electrical appliance testing:

-

4.3 - Electrical panels are clearly marked, are unobstructed and have restricted access?

-

4.4 - Cable management acceptable? (no split/taped cords)

-

4.5 - Any loose or damaged conduit/trunking?

-

4.6 - Is there suitable control over the use of personal electrical equipment?

-

4.7 - Do any power sockets appear to be overloaded?

-

4.8 - Is there evidence that an annual discharge (3 hour duration) test of emergency lighting is carried out?

-

4.8.1 - Who carried out the annual discharge test of emergency lighting?

-

4.8.2 - Date of annual discharge test of emergency lighting:

-

Section 4 - Any other relevant deficiencies observed, not covered above?

-

Section 4 - Other relevant deficiencies observed, not covered above:

Section 5 - Fire Safety

-

5.1 - Has a Fire Risk Assessment been carried out for the premises, by a competent person?

-

5.1.1 - Who carried out the Fire Risk Assessment?

-

5.1.2 - Date of Fire Risk Assessment:

-

5.2 - Is it more than 12 months since the date of the Fire Risk Assessment?

-

5.2.1 - Is there evidence that an annual review has been carried out?

-

5.2.2 - Date of annual review:

-

5.3 - Is it more than 3 years since the date of the Fire Risk Assessment?

-

5.4 - Have all actions identified within the Fire Risk Assessment been addressed?

-

5.4.1 - What Management Plan is in place to ensure all outstanding actions are addressed?

-

-

5.5 - Is there evidence that Fire Extinguishers are inspected/serviced on an annual basis?

-

5.5.1 - Who carries out the inspection/servicing of Fire Extinguishers?

-

5.5.2 - Date of last Fire Extinguisher inspection/service:

-

5.6 - Is there evidence that servicing of the Fire Alarm is carried out by a competent person on a regular basis?

-

5.6.1 - Who carried out the fire alarm service?

-

5.6.2 - Date of last fire alarm service:

-

5.7 - Is the building fitted with any specialist fire systems (i.e. Sprinklers, Wet/Dry risers, Automatic gaseous extinguishers, Smoke extract/ventilation, Fire/smoke dampers, Fire Shutters)?

-

5.7.1 - Sprinkler system?

-

5.7.1.1 - Is there evidence that the equipment has been inspected/serviced?

-

5.7.1.1.1 - Who carried out the inspection/service on this equipment?

-

5.7.1.1.2 - Date of last inspection/service:

-

5.7.2 - Wet/Dry risers

-

5.7.2.1 - Is there evidence that the equipment has been inspected/serviced?

-

5.7.2.1.1 - Who carried out the inspection/service on this equipment?

-

5.7.2.1.2 - Date of last inspection/service:

-

5.7.3 - Automatic gaseous extinguishing systems in kitchen?

-

5.7.3.1 - Is there evidence that the equipment has been inspected/serviced?

-

5.7.3.1.1 - Who carried out the inspection/service on this equipment?

-

5.7.3.1.2 - Date of last inspection/service:

-

5.7.4 - Automatic gaseous extinguishing systems in computer rooms?

-

5.7.4.1 - Is there evidence that the equipment has been inspected/serviced?

-

5.7.4.1.1 - Who carried out the inspection/service on this equipment?

-

5.7.4.1.2 - Date of last inspection/service:

-

5.7.5 - Smoke extract/Ventilation systems?

-

5.7.5.1 - Is there evidence that the equipment has been inspected/serviced?

-

5.7.5.1.1 - Who carried out the inspection/service on this equipment?

-

5.7.5.1.2 - Date of last inspection/service:

-

5.7.6 - Fire/Smoke dampers?

-

5.7.6.1 - Is there evidence that the equipment has been inspected/serviced?

-

5.7.6.1.1 - Who carried out the inspection/service on this equipment?

-

5.7.6.1.2 - Date of last inspection/service:

-

5.7.7 - Fire Shutters?

-

5.7.7.1 - Is there evidence that the equipment has been inspected/serviced?

-

5.7.7.1.1 - Who carried out the inspection/service on this equipment?

-

5.7.7.1.2 - Date of last inspection/service:

-

5.8 - Are regular fire evacuation drills carried out (at least every 6 months)?

-

5.8.1 - Date of last fire evacuation drill:

-

5.9 - Is the fire alarm remotely monitored?

-

5.9.1 - Remote monitoring of fire alarm is carried out by:

-

5.9.2 - Who is tasked with calling the fire brigade in a genuine emergency?

-

5.10 - Are external storage areas / waste bins, secured and located a suitable distance away from the main buildings?

-

5.11 - Does the asset have any electric vehicle charging points on site?

-

5.11.1 - Does the Fire Risk Assessment take into account any fire risks associated with charging electric vehicles?

-

Advise asset that their Fire Risk Assessment need to be reviewed, to ensure risks associated with charging electric vehicles is taken into account.

-

Section 5 - Any other relevant deficiencies observed, not covered above?

-

Section 5 - Other relevant deficiencies observed, not covered above:

Section 6 - Control of Substances Hazardous to Health (COSHH)

-

6.1 - Is there evidence of a COSHH inventory which identifies all hazardous substances used on site?

-

6.2 - Is there a system in place to request manufacturers hazard data sheets (MSDS's) for new products introduced in asset?

-

6.3 - Have COSHH assessments been carried out for all products, substances and processes?

-

6.4 - Have COSHH assessments been formally disseminated to relevant employees?

-

6.5 - Are COSHH assessments reviewed on a regular basis?

-

6.6 - List examples of hazardous substances observed on site:

-

6.7 - Has adequate information, instruction and training been provided for relevant employees using substances that may be hazardous to health?

-

6.8 - Are adequate cleaning procedures in place to control the spread of infections i.e. Flu, Norovirus, COVID etc.

-

6.9 - Are hazardous substances stored safely and suitably labelled (including Catering/Cleaning)?

-

6.10 - Is P.P.E. available (where required)?

-

Section 6 - Any other relevant deficiencies observed, not covered above?

-

Section 6 - Other relevant deficiencies observed, not covered above:

Section 7 - Lifts & Lifting Equipment

-

7 - Are there any lifts or lifting equipment?

-

7.1 - Is there a clear procedure to be followed in event of a person becoming trapped in the lift/equipment and are people competent to follow the procedure?

-

7.2 - Are lifts adequately serviced/maintained?

-

7.2.1 - Who carries out service/maintenance of lifts?

-

7.2.2 - Date of last lift service/maintenance:

-

7.3 - Is lifting equipment adequately serviced/maintained?

-

7.3.1 - Who carries out service/maintenance of lifting equipment?

-

7.3.2 - Date of last lifting equipment service/maintenance:

-

7.4 - Are all lifts/lifting equipment thoroughly examined at statutory intervals (every 6 months for people or 12 months for loads only) by a competent person.

-

7.4.1 - Who carried out the last lift/lifting equipment thorough inspection?

-

7.4.2 - Date of last lift/lifting equipment thorough inspection:

-

-

Section 7 - Any other relevant deficiencies observed, not covered above?

-

Section 7 - Other relevant deficiencies observed, not covered above:

Section 8 - Premises Management

-

8.1 - Are all windows above first floor fitted with suitable window restrictors?

-

8.2 - Is there a recent Tree Safety Survey (less than 2 years old)?

-

8.3 - Are work areas adequately lit?

-

8.4 - Is there adequate ventilation (fresh air) through work areas?

-

8.5 - Is there an adequate heating system installed in the building?

-

8.6 - Are arrangements in place for reporting defects to the building and remedial action carried out?

-

8.7 - Is the perimeter wall/fence/railings in a good state of repair?

-

8.8 - Is there an adequate provision of drinking water?

-

8.9 - Is there an adequate number of sanitary conveniences?

-

8.10 - Are all gates protected against trapping points (where necessary)?

-

8.11 - Are all doors protected against trapping points (where necessary)?

-

8.12 - Are all staircases fitted with handrails/guardrails?

-

8.13 - Is the building generally in a good state of repair?

-

Section 8 - Any other relevant deficiencies observed, not covered above?

-

Section 8 - Other relevant deficiencies observed, not covered above:

Section 9 - Housekeeping

-

9.1 - Are offices and other areas clean and tidy?

-

9.2 - Corridors/halls/walkways clear of debris and obstructions?

-

9.3 - What procedures are in place for dealing with spillages throughout the working day?

-

9.4 - Floor coverings in good condition? (No holes or curled edges)

-

9.5 - Are toilets kept clean and tidy?

-

9.6 - Floors, stairs and walkways have non-slip surfaces where appropriate?

-

9.7 - Waste bins are available and emptied regularly?

-

9.8 - Floors are free of holes, protrusions, loose boards and splinters?

-

9.9 - Items are stored correctly and empty boxes, etc are disposed of?

-

9.10 - Combustible materials are kept away from heat sources?

-

Section 9 - Any other relevant deficiencies observed, not covered above?

-

Section 9 - Other relevant deficiencies observed, not covered above:

Section 10 - Commercial Kitchen

-

10 - Is there any commercial catering equipment on site?

-

10.1 - Is there evidence that cleaning/testing of extraction fans/canopies is carried out periodically?

-

10.1.1 - Who carried out the last cleaning/testing?

-

10.1.2 - When was the last cleaning/testing carried out?

-

10.2 - Are the taps in the kitchen treated as little used outlets during periods of low usage and thoroughly flushed through accordingly?

-

10.2.1 - Who carried out the flushing?

-

10.3 - Are spray taps and pot wash spray heads in the kitchen cleaned and descaled every 3 months?

-

10.3.1 - Who carried out the descaling?

-

10.4 - Are maintenance records available for Catering machines (where applicable)?

-

Section 10 - Any other relevant deficiencies observed, not covered above:

-

Section 10 - Other deficiencies observed, not covered above:

Section 11 - Sewage/Water Treatment/Septic Tank and Oil Interceptors

-

11 - Are there any Sewage/Water Treatment/Septic Tank or Oil Interceptors on site?

-

11.1 - Is there evidence that tanks are being pumped out every 6 months?

-

11.1.1 - Who carried out the emptying of the tanks?

-

11.1.2 - Date of last tank emptying:

-

11.2 - Is there evidence that annual servicing of lift pumps is being carried out?

-

11.2.1 - Who carried the annual servicing of lift pumps?

-

11.2.2 - Date of last service of lift pumps:

-

Section 11 - Any other relevant deficiencies observed, not covered above?

-

Section 11 - Other relevant deficiencies observed, not covered above:

Section 12 - Car Parking and Vehicle/Pedestrian Segregation

-

12.1 - Are cars able to be parked safely?

-

12.2 - Is there adequate vehicle/pedestrian separation within the premises?

-

Section 12 - Any other relevant deficiencies observed, not covered above?

-

Section 12 - Other relevant deficiencies observed, not covered above:

Section 13 - Air Conditioning systems

-

13 - Are there any Air Conditioning units on site?

-

13.1 - Is there evidence that servicing of air conditioning equipment is carried?

-

13.1.1 - Who carried out the servicing of air conditioning equipment?

-

13.1.2 - Date of last service of air conditioning equipment:

-

Section 13 - Any other relevant deficiencies observed, not covered above?

-

Section 13 - Other relevant deficiencies observed, not covered above:

Section 14 - Oil Storage Tanks

-

14 - Are there any Oil Storage Tanks on site?

-

14.1 - Is there evidence that regular inspections of Oil Storage Tanks, Bunds, Pipework and surrounding areas is being carried out by a competent person?

-

14.1.1 - Who carried out the inspection of Oil Storage Tanks, Bunds, Pipework etc.?

-

14.1.2 - Date of last inspection of Oil Storage Tanks, Bunds, Pipework etc:

-

Section 14 - Any other relevant deficiencies observed, not covered above?

-

Section 14 - Other relevant deficiencies observed, not covered above:

Section 15 - Automatic Doors/Gates/Barriers

-

15 - Are there any Automatic Doors/Gates/Barriers on site?

-

15.1 - Is there evidence that regular servicing of Automatic Doors/Gates/Barriers is carried out?

-

15.1.1 - Who carried out the servicing of automatic doors/gates/barriers?

-

15.1.2 - Date of last service of automatic doors/gates/barriers:

-

Section 15 - Any other relevant deficiencies observed, not covered above?

-

Section 15 - Other relevant deficiencies observed, not covered above:

Section 16 - Lightning Conductor

-

16 - Is the building fitted with a lightning conductor?

-

16.1 - Is there evidence that inspection of Lightning Conductors is carried out at regular intervals (not exceeding 12 months)?

-

16.1.1 - Who carried out the annual inspection of the Lightning Conductors?

-

16.1.2 - Date of last inspection of the Lightning Conductors:

-

Section 16 - Any other relevant deficiencies observed, not covered above?

-

Section 16 - Other relevant deficiencies observed, not covered above:

Section 17 - Work Equipment

-

17 - Does the asset use any specialist equipment e.g. Scrubber Dryers etc. ?

-

17.1 - Is the work equipment assessed prior to purchase for its suitability and compliance with PUWER?

-

17.2 - Is the work equipment installed, located and used in such a way as to reduce the risk to users and others?

-

17.3 - Is the work equipment maintained and inspected?

-

Who carried out the last service/inspection?

-

When was the equipment last serviced?

-

17.4 - Where work equipment involves specific risks to H&S, is its use limited to competent persons?

-

17.5 - Have employees received suitable training to operate this machinery?

-

17.6 - Have risk assessments been carried out for the use of this equipment?

-

Section 17 - Any other relevant deficiencies observed, not covered above?

-

Section 17 - Other relevant deficiencies observed, not covered above:

Section 18 - Caretaker / Site Manager checks

-

Review Logbook (paper or electronic) to see if caretaker/site manager is carrying out their periodic checks.

-

18.1 - Daily Checks:

-

18.1.1 - Is there evidence that Means of Escape checks are carried out?

-

18.1.2 - Is there evidence that External Areas checks are carried out?

-

18.2 - Weekly Checks:

-

18.2.1 - Is there evidence that Fire Alarm test are carried out (using different call points, each week)?

-

18.2.2 - Is there evidence that Fire extinguishers checks are carried out?

-

18.2.3 - Is there evidence that Sprinkler tests (if applicable) are carried out?

-

18.2.4 - Is there evidence that flushing of infrequently used outlets is carried out?

-

18.3 - Monthly Checks:

-

18.3.1 - Is there evidence that Asbestos visual inspections (if applicable) are carried out?

-

18.3.2 - Is there evidence that Water temperature checks are carried out?

-

18.3.3 - Is there evidence that Calorifier temperature checks are carried out?

-

18.3.4 - Is there evidence that Emergency lighting (flick test) checks are carried out?

-

18.3.5 - Is there evidence that Fire door checks are carried out?

-

18.3.6 - Is there evidence that Disabled toilet alarm, Disabled refuge point alarm, Lift emergency alarm (if applicable) testing is carried out?

-

18.3.7 - Is there evidence that Evac equipment checks (if applicable) are carried out?

-

18.3.8 - Is there evidence that Housekeeping checks are carried out?

-

18.3.9 - Is there evidence that Ladder checks are carried out?

-

18.3.10 - Is there evidence that inspection of the external lighting is being carried out?

-

18.4 - Quarterly Checks:

-

18.4.1 - Is there evidence that shower heads and spray taps are cleaned & disinfected?

-

Section 18 - Any other relevant deficiencies observed, not covered above?

-

Section 18 - Other relevant deficiencies observed, not covered above:

Summary

Summary of audit

-

At the beginning of the report you will see two boxes marked 'Flagged Items' and 'Actions'.

-

A 'Flagged Item', indicates a major non-compliance and could mean your school is working unsafely or even breaking the law.

-

An 'Action', indicates issues identified during the inspection that require improvements.

-

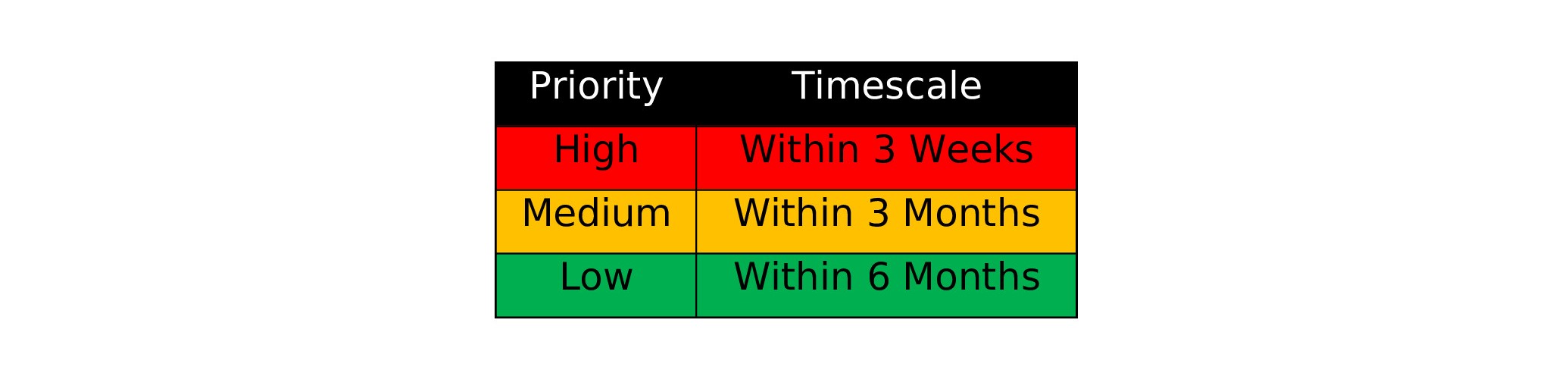

Timescales for addressing Actions:

Signature

-

Auditors Signature