Information

-

A CCP is a step at which control can be applied and is essential in order to control the likelihood of introducing food safety hazards to and/or the contamination or proliferation of food safety hazards in the products or in the processing environment. The step must have critical limits separating acceptable to unacceptable. The critical limit is violated then the products are deemed unsafe. Each CCP needs to be monitored to ensure the control is operating as intended. Each CCP should have been challenge testing or validated. Critical to establishment of the CCP is the Hazard Analysis.

-

Internal Audit Date

-

Inspection Completed By (write your full name here)

-

Signature of Auditor

-

Has the auditor checked the following references ISO 22000 Technical Standard ISO/TS 22004 food safety management systems guidance on application of ISO 22000 section 7. Codex CAC/RCP hazard analysis and critical control point (HACCP) systems and guidelines for application. FSSC 22000 Certification Scheme Guidance Notes ISO 22002-1 Check List of requirements for CCPs (on our ISO server)

-

Has the auditor reviewed any other material relevant to this audit? Please list.

Executive Summary

-

Auditor Details

Auditor

-

Name

-

Position and experience with area to be audited

-

Executive Summary Write summary of audit here

Sifting Process

Sifting Process

HACCP

-

Photograph of HACCP section relating to defining procedure?

-

Does the HACCP define the food safety hazard to be controlled by the sifting step?

-

For the sifting step is the control measure defined?

-

Does the HACCP define the monitoring procedure?

-

Are clear steps available for the corrective actions to be taken if the critical limits are exceeded?<br>

-

Are responsibilities clearly defined?

-

Has the rational for chosen limits been established and documented?

SOP Procedure

-

Is a clear procedure written for the CCP step? Add photographs of the SOPs.

-

Is the procedure available to the Operators and Team Leaders

Training and Operator Knowledge

-

Are operators operating the CCP trained and know the requirements? check both training records and ask questions to operator at time of audit.

Records

-

Are records kept in a legible?

-

Were records accessible and quickly able to be shown to the auditor?

-

Are records stored appropriately archived and disposed of only after the end of the product shelf life?

-

Add some photos of records clearly showing the monitoring.

Monitoring

-

Is the CCP monitored? Sight > 10 records.

-

Does the monitoring match the SOP and the requirements of adequate time frame.

-

Is the monitoring process clearly defined in the SOP

-

Is the equipment calibrated?

Non conformances

-

Have any non conformances been raised in the sifting area. Are they addressed?

General Information

General Information

-

Does the auditor recognise any other process steps that could be CCP

Plastic Register - Upstairs

-

Date of Inspection

Plastic Register - Downstairs

-

Date of Inspection

Plastic Register - DOWNSTAIRS

Bin Jacks - LOW

-

-

Do all 3 Bin Jacks match the photo provided with no sign of damage or cracks?

-

Provide a photo of the bin jacks

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of all damaged jacks

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Bin Hoist Controller - LOW

-

-

Does the bin hoist controller match the photo provided with no sign of plastic damage or cracks?

-

Provide a photo of the bin hoist controller

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked bin hoist controller

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

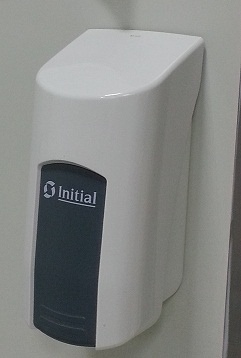

Sanitiser Dispenser - LOW

-

-

Does the sanitiser dispenser located next to the BIN HOIST match the photo provided with no sign of damage or cracks?

-

Provide a photo of the Sanitiser Dispenser

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Sanitiser Dispenser

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Sanitiser Spray Dispenser - LOW

-

-

Does the sanitiser spray dispenser located next to the SCOOP MACHINE match the photo provided with no sign of damage or cracks?

-

Provide a photo of the Sanitiser Dispenser

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Sanitiser Dispenser

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Does the sanitiser dispenser located next to the CANNING LINE EQUIPMENT BINS match the photo provided with no sign of damage or cracks?

-

Provide a photo of the Sanitiser Dispenser

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Sanitiser Dispenser

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Compressed Airgun - MEDIUM

-

-

Does the compressed airgun for the STICK MACHINE match the photo provided with no sign of damage or cracks?

-

Provide a photo of the compressed airgun

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked compressed airgun

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Does the compressed airgun for the CAN FILLER match the photo provided with no sign of damage or cracks?

-

Provide a photo of the compressed airgun

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked compressed airgun

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Do all 4 compressed airguns for the SEAMERS match the photo provided with no sign of damage or cracks?

-

Provide a photo of the compressed airgun

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of all damaged or cracked compressed airguns

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Tool Box - LOW

-

-

Do BOTH toolboxes match the photo provided with no sign of damage or cracks?

-

Provide a photo of both toolboxes

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of all damaged or cracked tool boxes

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Rubbish Bins - LOW

-

-

Does the downstairs rubbish bin match the photo provided with no sign of damage or cracks?

-

Provide a photo of the Rubbish Bin

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Rubbish Bin

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Canning Line Equipment Bins - LOW

-

-

Do all 9 Canning Line Equipment Bins match the photo provided with no sign of damage or cracks?

-

Provide a photo of the Canning line equipment bins

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of all damaged or cracked Canning line equipment bins

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Control Panels, Switches & Equipment Status Lights - LOW

Macro Ingredient Blender Control Panel, Switches and Status Lights

-

-

Does the Macro ingredient blender control panel and switches match the photo provided with no sign of damage or cracks?

-

Provide a photo of the control panel and switches

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked control panel and switches

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Does the Macro ingredient blender Status Light match the photo provided with no sign of damage or cracks?

-

Provide a photo of the equipment status light

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked equipment status light

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Canning Line Control Panels, Switches and Status Light

-

-

-

-

Do the control panel and switches for the Canning Line (Scoop, Can Filler, Seamers) match the photo provided with no sign of damage or cracks?

-

Provide a photo of the control panel and switches

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked control panel and switches

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Do the Canning Line (Scoop, Can Filler, Seamer) status lights match the photo provided with no sign of damage or cracks?

-

Provide a photo of the equipment status light

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked equipment status light

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Stick Machine Switches - LOW

-

-

Do the switches for the STICK MACHINE match the photo provided with no sign of damage or cracks?

-

Provide a photo of the switches

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked switches

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Scales

-

-

Do the scales located next to the stick machine match the photo provided with no sign of damage or cracks?

-

Provide a photo of the scales

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked scales

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Do the scales located on the canning line match the photo provided with no sign of damage or cracks?

-

Provide a photo of the scales

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked scales

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Two Way Radio - Walkie Talkie - LOW

-

-

Does the Two Way Radio (Walkie-Talkie) located next to the canning line control panel match the photo provided with no sign of damage or cracks?

-

Provide a photo of the Walkie Talkie

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Walkie-Talkie

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Bins for collecting Damaged or Test Cans - LOW

-

-

Does the damaged / test can collection bin match the photo provided with no sign of damage or cracks?

-

Provide a photo of the test can collection bin

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked test can collection bin

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Filter Clean-Out Bins

-

-

Does the filter clean-out bin match the photo provided with no sign of damage or cracks?

-

Provide a photo of the filter cleaning bin

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or filter cleaning bin

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Vacuum

Vacuum Hose - LOW

-

-

Does the vacuum hose located next to the DOWNSTAIRS AIRLOCK match the photo provided with no sign of damage or cracks?

-

Provide a photo of the vacuum hose

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked vacuum hose

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Does the vacuum hose located next to the SEAMERS match the photo provided with no sign of damage or cracks?

-

Provide a photo of the vacuum hose

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked vacuum hose

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Vacuum Attachments - HIGH

-

-

-

Do all vacuum attachments located near the DOWNSTAIRS AIRLOCK match the photo provided with no sign of damage or cracks?

-

Provide a photo of the vacuum attachments

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of all damaged or cracked vacuum attachments

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Do all vacuum attachments located near the SEAMERS match the photo provided with no sign of damage or cracks?

-

Provide a photo of the vacuum attachments

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of all damaged or cracked vacuum attachments

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Vacuum Holder -LOW

-

-

Does the Vacuum Holder located next to the DOWNSTAIRS AIRLOCK match the photo provided with no sign of damage or cracks?

-

Provide a photo of the Vacuum holder

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked vacuum holder

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Does the Vacuum Holder located next to the SEAMERS match the photo provided with no sign of damage or cracks?

-

Provide a photo of the Vacuum holder

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked vacuum holder

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Dustpans, Brooms Cleaning Stations

Blue Stations - LOW

-

-

Do all tools in the cleaning tool station located by the MACRO INGREDIENT BLENDER match the photo provided with no signs of cracks or damage?

-

Provide a photo of the cleaning station tools

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked cleaning station tools

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Do all tools in the cleaning tool station located by the DOWNSTAIRS AIRLOCK match the photo provided with no signs of cracks or damage?

-

Provide a photo of the cleaning station tools

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked cleaning station tools

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Do all tools in the cleaning tool station located by the SEAMERS match the photo provided with no signs of cracks or damage?

-

Provide a photo of the cleaning station tools

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked cleaning station tools

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

White Stations - HIGH

-

-

Do all tools in the cleaning tool station located by the CAN FILLER match the photo provided with no signs of cracks or damage?

-

Provide a photo of the cleaning tools

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked cleaning tools

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Do all tools in the cleaning tool station located by the SEAMER match the photo provided with no signs of cracks or damage?

-

Provide a photo of the cleaning tools

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked cleaning tools

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Do all tools in the cleaning tool station located by the METAL DETECTOR match the photo provided with no signs of cracks or damage?

-

Provide a photo of the cleaning tools

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked cleaning tools

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

Do all tools in the cleaning tool station located by the MAGNET match the photo provided with no signs of cracks or damage?

-

Provide a photo of the cleaning tools

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked cleaning tools

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

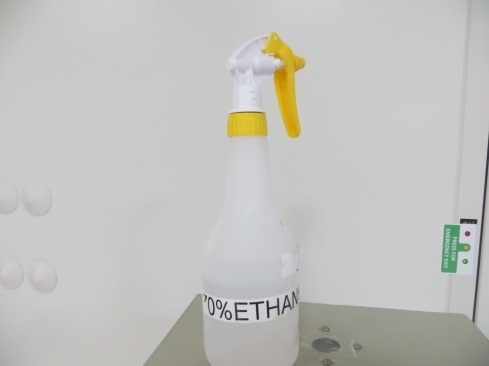

Ethanol Sprayers - Low

-

-

Do all 5 ethanol spray bottles downstairs match the photo provided with no sign of damage or cracks?

-

Provide a photo of the ethanol spray bottles

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked ethanol spray bottle

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Conveyor Drop Guards - High

-

-

Do all conveyor drop guards on the inside canning line match the photo provided with no sign of damage or cracks?

-

Provide a photo of the conveyor drop guards

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked conveyor drop guards

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Plastic Scoop Storage Bins - Low

-

-

Do all 5 Plastic Scoop storage Bins match the photo provided with no sign of damage or cracks?

-

Provide a photo of the plastic scoop storage bins

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Scoop storage bins

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Perspex Equipment Doors - Low

-

-

Do the perspex equipment doors for the STICK MACHINE match the photo provided with no sign of damage or cracks?

-

Provide a photo of the perspex equipment doors

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Perspex equipment Doors

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

-

Do the perspex equipment doors for the SCOOP MACHINE match the photo provided with no sign of damage or cracks?

-

Provide a photo of the perspex equipment doors

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Perspex equipment Doors

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

-

Do the perspex equipment doors for the CAN FEEDER match the photo provided with no sign of damage or cracks?

-

Provide a photo of the perspex equipment doors

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Perspex equipment Doors

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

-

-

Do the perspex equipment doors for all 4 SEAMERS match the photo provided with no sign of damage or cracks?

-

Provide a photo of the perspex equipment doors

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked Perspex equipment Doors

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Metal Detector - Display / Plastic Chute / Wide Outlet Funnel - HIGH

-

-

Does the metal detector's display, plastic chute and wide outlet funnel match the photo provided with no sign of damage or cracks?

-

Provide a photo of the Plastic components to the metal detector

-

Who inspected the item?

-

Any relevant comments

-

Provide a photo of the damaged or cracked plastic components to the metal detector

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments

Additional Plastic Items

-

Where any additional plastic items found downstairs?

-

What were the additional plastic items found

Additional Plastic Items Found

-

Take a photo of the additional plastic item

-

Report to the team leader about this item, so the technical manager can be informed and make a decision as to whether this item is necessary to production. If it is update the Glass and Plastic Register if not remove from inside.

-

Did the item have any cracks or damage?

-

Stop production immediately and report the damage to the team leader for NCR reporting

-

Isolate the area and collect as many shards as possible until major pieces can be cleared up. Keep all the pieces for analysis and pass them to the technical manager, who will make a decision based on risk analysis to restart the plant and quarantine any product

-

Who inspected the item?

-

Any relevant comments