Title Page

-

Please Select

-

Conducted on

-

SSSTS Supervisor name

-

Site:

-

Sub-contractor

-

Location

-

Location where works will be carried out on site? (Level/ area)

-

Works to be carried out?

-

ADD GROUP PHOTO OF PERSONS ATTENDING SAFE START DAILY BRIEFING

Safe Working Environment

-

Do you have the correct Supervisor ratio?

-

Please upload evidence of supervisor training (SSSTS/ SMSTS)

-

State RAMS title for tasks being carried out?

-

Have you inspected all plant and equipment? (visual and documented inspections)

-

Confirm safe access/ egress to work area. (if NO then contact Dornan management)

-

Confirm all operatives are wearing correct PPE in accordance with Dornan requirements

-

Do you have sufficient barriers and warning signage in your work areas?

-

Do you need to use task lighting? If so, please ensure operatives are issued adequate lighting.

-

Is anyone taking medication or has health issues that may affect their works? Is there a plan in place to manage their works on site? (If yes please state plan)

-

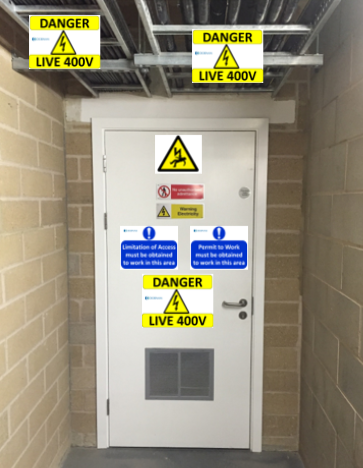

Do you need a permit to work? (Select permits needed)

- N/A

- Limitation of Access Electrical

- Sanction to Test

- Hot Works

- Step Ladder (Last Resort)

- OTHER (Please state)

-

Other permits (Please state)

Power Tools - HAV/ Noise/ Dusts

-

Will you be using power tools?

-

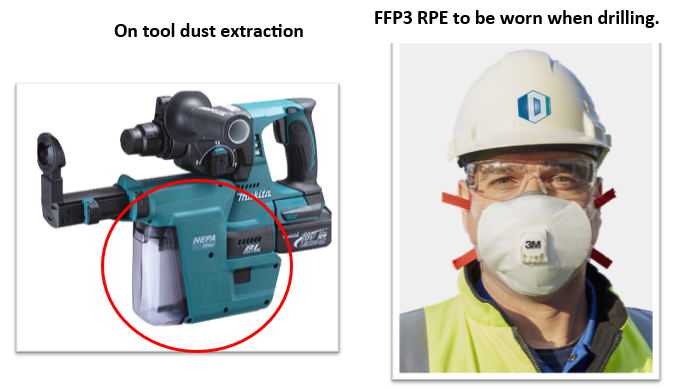

Hammer Drill - Use dust extraction, FFP3 RPE and ear protection

-

Max trigger time (minutes)

-

Chop Saw - Use safety goggles and ear protection

-

Max trigger time (minutes)

-

Impact Driver - Use ear protection

-

Max trigger time (minutes)

-

Angle Grinder - Use safety goggles and ear protection

-

Max trigger time (minutes)

-

Combi Drill (Concrete)- Use dust extraction, FFP3 RPE and ear protection

-

Max trigger time (minutes)

-

Reciprocating Saw: Use hearing protection and wear safety goggles

-

Max trigger time (minutes)

-

Multi Tool - Wear hearing protection

-

Max trigger time (minutes)

-

Jigsaw - Wear hearing protection

-

Max trigger time (minutes)

-

Band Saw: Wear safety goggles and hearing protection

-

Max Trigger time (Minutes)

Add additional tools.

-

Tool Type:

-

Max Trigger Time (Minutes)

What hazards are present?

-

Working from MEWP (IPAF needed)

-

- MEWPs to be operated by competent IPAF trained persons only.

- A thorough examination must be in date - A Dornan plant authorisation sticker must be displayed on equipment

- Daily documented inspection must be completed by IPAF trained operative

- Ensure chapter 8 barriers and warning signage is displayed to create exclusion zone

- A second competent person to be present in case of an emergency.

- Use on firm level ground only

- Do not exceed SWL of platform

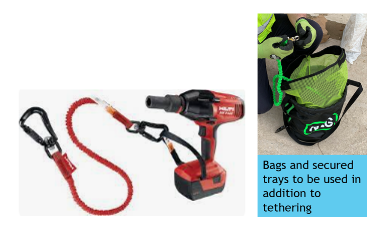

- Tools to be tethered as per Dornan’s To Tethering Policy.

- Operatives working at height to wear hard hat chin strap

- MEWP rescue plan to be in place

- Keys must be removed and stored in a secure place, and MEWPs disconnected from the power when not in use -

Working from Peco Lift or Power Tower (PAV)

-

- PAV's are to have a documented weekly inspection completed prior to use by a competent person.

- A Dornan plant authorisation sticker must be displayed on equipment

- PAV's Thorough Examination must be in date

- Familiarise with the manufacturer’s instruction manual.

- Emergency Lowering Tool must be in place for Peco - Ensure chapter 8 barriers and warning signage is displayed to create exclusion zone

- Brief operators on the dangers if confined overhead working.

- The platform is to be kept tidy at all times and used on firm and level ground.

- Do not stand on mid guard rails - Rescue plan must be in place for emergency situations -

Working from Podium (PASMA needed)

-

- All podium steps used on site must be PAS 250/BS 8620 compliant. - Ensure chapter 8 barriers and warning signage is displayed to create exclusion zone

- Podiums to be inspected and signed off by a competent PASMA trained person every seven days

- Do not overreach on podium

- Wheels must be locked

- Stabilisers must be in place and gate closed when in use -

Working from Delta Deck (PASMA needed)

-

- Delta Deck to be inspected and signed off by a competent PASMA trained person every seven days

- Daily visual inspection must be carried out by user

- Do not overreach or stand on guard rails whilst using delta Deck

- Safety gate must be closed when working on Delta deck

- Only use on firm level ground -

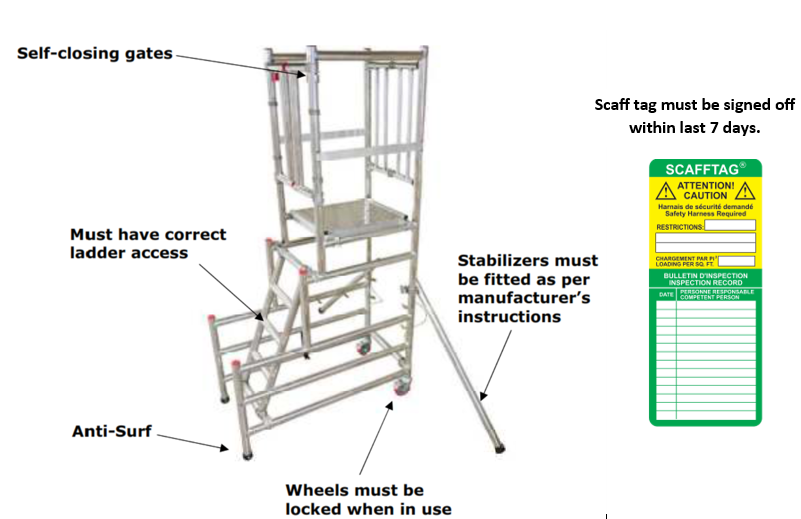

Podium Ladder (PASMA needed)

-

- Podium Ladder to be inspected and signed off by a competent PASMA trained person every seven days

- Daily visual inspection must be carried out by user

- Do not overreach whilst using podium ladder

- Safety gate must be closed when working on Mega Step Platform

- Only use on firm level ground -

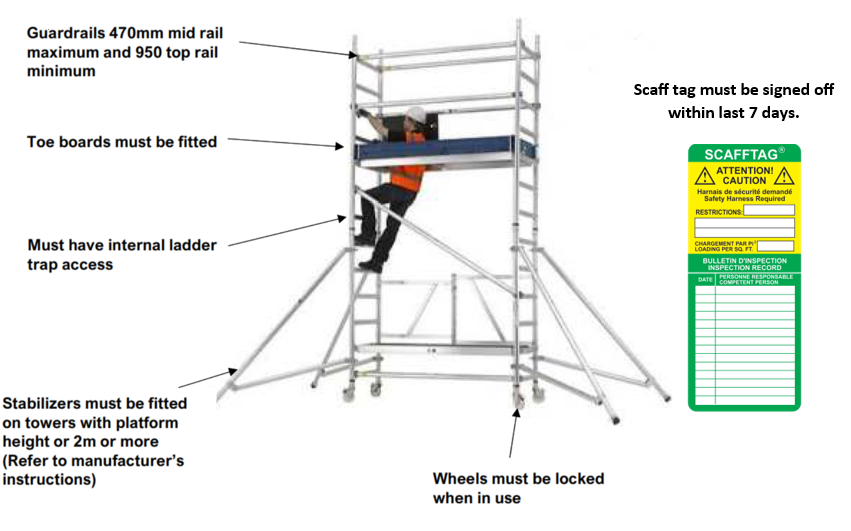

Mobile Tower (PAMSA required)

-

- All access towers will be erected, modified, or dismantled by a competent person who will hold a valid PASMA certificate.

- Must be inspected and signed off every 7 days at minimum by a PASMA trained operative - Mobile tower to be built in accordance with manufacturers instructions - Ensure chapter 8 barriers and warning signage is displayed to create exclusion zone

- Access equipment to be assembled with the top guard rails set a 950 minimum above the working platform, no unprotected gap greater than 470mm for the mid guard rail and toe boards must be fitted.

- Stabilisers to be fitted while using tower

- Wheels must be locked while using tower

- Climb ONLY through the hatch door internally to working platform level. Do not climb outside of the tower.

- Under No circumstance are operatives or materials to remain on any part of the access tower whilst being pushed to a new location.

- The height of the access tower is to be reduced to 4 meters prior to moving to a new location. -

Working from step ladder - LAST RESORT (Permit required)

-

- Step ladders must be used as last resort (UNDER PERMIT) and for short duration only

- Step ladders are to be inspected and signed off by a competent PASMA trained person and every seven days thereafter. A scaff tag must be signed off and attached to step ladder by the inspector.

- Ladders are to have a daily check sheet completed prior to use.

- All stepladders must be EN/BS 131 compliant for "professional" use

- Step ladders must be fibreglass (Non-Conductive)

- Ensure stepladders are in good condition and fully open before use. Do not use any stepladder with damaged or defective parts.

- Do not stand on top 3 treads of step ladder -

Working from Hop up? LAST RESORT (Permit required)

-

- Hop ups are to be inspected and signed off by a competent PASMA trained person and every seven days.

- A scaff tag must be signed off and attached by the inspector.

- Use industrial grade 400mm high hop up platforms minimum 600mm X 600mm wide.

- Hop ups must be fiberglass where there are live electrical services present

- Work durations to be kept short

- Only to be used as a last resort -

Poor lighting in work area?

-

- Use task lighting where there is poor lighting in work area.

- Do not attempt to work in areas with poor lighting. - In areas where task lighting cannot be utilised, Head torches must be used. -

Manual Handling

-

- Use mechanical aids (Pallet truck/ Trolleys) to transport materials

- Where mechanical aids cannot be used, manual handling exercise shall be limited, with task rotation utilised where necessary.

- Team lifting is to be undertaken for all large or awkward weights.

- Utilise TASK, LOAD, INDIVIDUAL, ENVIRONMENT -

Poor housekeeping/ Slips, Trips and Falls (Always Yes)

-

- Maintain good housekeeping by adopting a "clean as you go" approach

- Remove excess build up of materials to minimise trip hazards.

- All tools and materials should be stored out of emergency routes within demarcated work area - Ensure there are no trailing leads in work area -

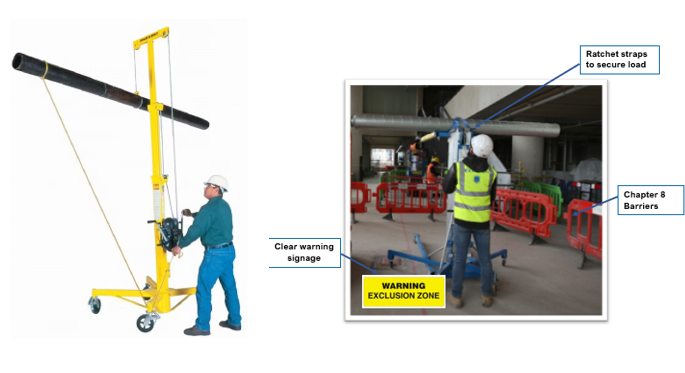

Lifting using Genie Lift/ Roustabout

-

- You MUST BE trained in use of Genie Lift or Roustabout.

- Genie Lift/ Roustabout to be used only for lifting materials.

- A thorough examination must be in place and in date

- A lift plan must be in place prior to works being carried out.

- All components to be visually inspected prior to use (refer to manufacturer’s instructions) and a documented record completed.

- Use on firm level ground, capable of withstanding the load.

- Materials will be correctly strapped.

- Ensure the load is evenly distributed and within the manufacturer’s SWL.

- Ensure area is suitably demarcated with warning signage displayed to prevent people below being struck by falling objects.

- Do not stand under or allow personnel under the machine when the load is raised.

- Equipment will be moved to work locations by 2 operatives.

- DO NOT move the equipment with a raised load. -

Drilling operations

-

- Use dust extraction drills. All drills must have a visual and documented inspection - Wear eye protection EN 166 and ear plugs EN 352 SNR 30+.

- FFP3 respiratory protection must also be worn when drilling

- A face fit test will be carried out for anyone using RPE

- All use of drilling tools and equipment must be carried out as per the Dornan HAV & Noise Register.

- Use battery drills to reduce trailing leads in work area -

Working around other trades?

-

- Ensure to coordinate so you works do not impeded on other trades

- Set up barriers and signage to let other trades know of your works

- keep your work area tidy and do not block escape routes - If you require to enter another trades work area, STOP and contact your supervisor -

Vehicle deliveries to site?

-

- Only trained banksman/ traffic marshal may accept deliveries

- Banksman/ traffic marshal must instruct driver

- Unloading shall be carried out by mechanical means where possible.

- Follow Dornan Delivery procedures

- Once unloaded, all materials will be manually distributed to the designated storage area using mechanical means

- At no time, will any operative attempt to carry out lifting of any materials which are beyond their own personal capabilities.

- Pallet trucks and other mechanical means to be utilised where possible

- Assess weather conditions and working environment before carrying out any manual handling tasks.

- Always assess weather conditions prior to receiving deliveries e.g. surface water or icy conditions -

Occupational health? (Noise, Dust, Vibration?)

-

- Follow HAV and Noise register trigger times

- Select the lowest vibration tool for task

- Wear hearing protection SNR 30+ and enclose activity to reduce exposure to others - Always use on tool extraction when drilling

- Wear FFP3 RPE when drilling or exposed to dusts - Face fit test required -

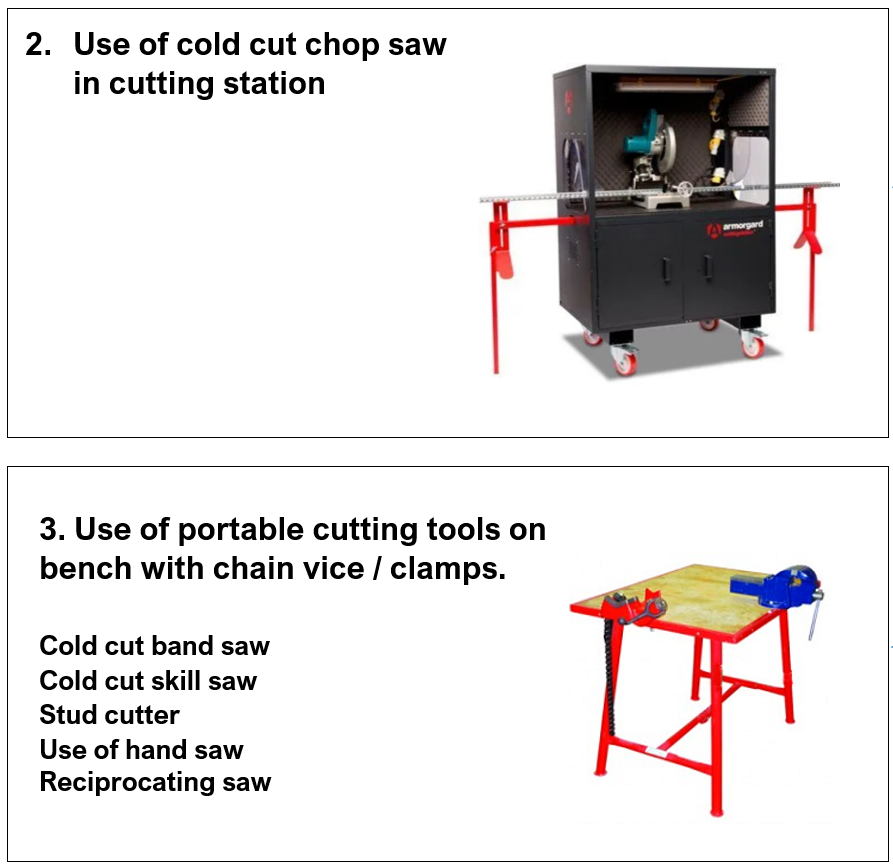

Cutting materials (Chop saw, Skill saw, Band Saw, Recip saw)

-

- Use cutting station to enclose cutting activity

- Set up barriers and warning signage alerting others of cutting activities

- Daily visual inspection must be carried out and weekly documented inspection on Weekly Tool Inspection Form.

- Clear all personnel from work area before raising or lowering the platform.

- All 110v equipment to be PAT tested within 3 months - Safety goggles and ear protection must be worn when carrying out cutting activities -

Sharp Objects (Metal studwork, unistrut, threaded bar)

-

- Inspect work area prior to starting work

- Ensure to wear minimum cut 5 safety gloves

- If working in ceiling or in wall, wear kevlar sleeves -

Hazardous substances

-

- Attend to and maintain high standards of personal hygiene.

- All COSHH items must be sealed when not in use and placed back in COSHH cabinets.

- COSHH waste must be disposed of in designated COSHH bins held on site.

- Wear PPE/ RPE stated within COSHH Assessment (Within RAMS) -

Live electrical & Mechanical systems

-

- TREAT ALL SERVICES AS LIVE

- Follow Dornan mechanical & electrical safety procedures

- Dornan AP to isolate/ energise only

- If access to risers, plant rooms or LV rooms are required, contact Dornan AP

- Do not tamper with any live mechanical or electrical system -Do not place tools or materials on live equipment -

Using abrasive wheels

-

- Use other safer means of cutting equipment where possible such as diamond blade chop saw or band saw

- Wear safety goggles and hearing protection

- Check that wheel is not damaged, expiry date has not been exceeded and there is no contamination of the wheel - Visual and documented inspection must be carried out on Dornan inspection form - Ensure material to be cut is secured in vice clamp - Fully inspect grinder - The handle and guard must be attached to grinder and use 2 hands to cut with grinder -

Welding

-

- Use fume extraction with carbon filter when welding mild steel

- FFP3 respirator to also be used which requires a face fit test certificate

- Suitable welding gloves, protective fire retarding clothing and welding mask must be worn when welding

- Welding screens to be erected to prevent others coming into work area and exposure to weld flash. All Operatives within work area to wear welding mask, Welding Apron and welding gloves. - Hot works permit must be place and a suitable fire extinguisher must be in immediate work area

- Remove all combustible materials from work area - YOU MUST carry out 1 hour fire watch -

Soldering pipe

-

- Hot work permit must be in place - Remove all combustible materials or cover with fire retardant sheet - Barrier off area and display warning signage - Have suitable fire extinguishers in immediate work area - Full PPE must be worn - If soldering above head height then safety goggles must be worn - YOU MUST carry out 1 hour fire watch

-

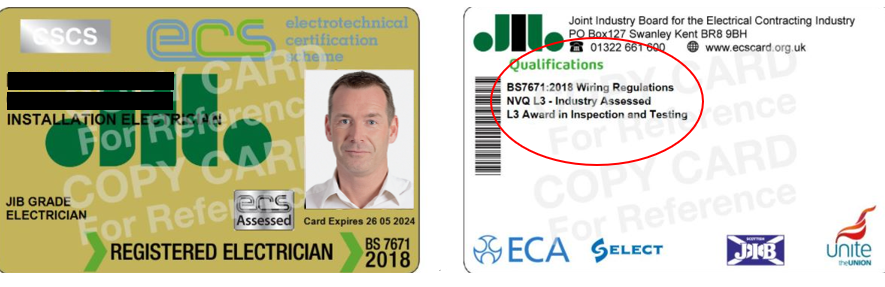

Electrical Testing

-

- You must be a ECS Gold Card Approved Electrician with C&G 2391 or equivalent - Obtain permit from Dornan AP - Only Dornan AP to isolate and energise systems. - Multifunction Tester must have in date calibration certificate - 4mm max test probes - Exclusion zone with warning barriers must be in place and warning signage displayed in accordance with Dornan's COHE

-

Pressure Testing

-

- You must obtain Pressure testing permit from Dornan Mechanical AP - Test gauge must have valid calibration certificate available - Where air tests are being carried out, pressure relief valve must be correct set on air compressors

- Area must be exclusion zone where test is being carried out - Barriers and warning signage must be on entry points to prevent unauthorised access to exclusion zone - Pressure test must not be left unattended at any point during test - Pipework must not be left under test over night -

Roof Works

-

- All roof works must be planned and coordinated on a daily basis.

- All roof works to be supervised at all times

- All operatives working on roof must be Dornan WAPE trained.

- All tools to be tethered on roof. All tools to be kept in tool bags when not in use.

- Step ladders are not to be used within 3m of the perimeter edge.

- Materials must be to a minimum and strapped down to prevent sail effects.

- Check weather conditions. -

Asbestos

-

- All persons must undertake approved asbestos awareness training prior to attending site. - Brief all operatives on asbestos locations affecting their work - If there is a likelihood of coming into close contact with asbestos then works must stop and Principal Contractor notified to have the ACM removed by a licenced asbestos removal company. - If there is an unintentional release of asbestos, follow Dornan’s Asbestos Emergency Procedure.

-

Other hazards present: (list hazard and control measures)

Sign off as conformation of briefing

-

Feedback from operatives

-

Supervisor 1 Signature

-

Add signature

-

Operative 1 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 2 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 3 signature

-

Add signature

-

Location:

-

Activities carried out:

-

Operative 4 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 5 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 6 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 7 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 8 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 9 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 10 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Need another SSSTS supervisor added?

- Yes

- No

- N/A

-

SSSTS Supervisor Name

-

Operative 1 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 2 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 3 signature

-

Add signature

-

Location:

-

Activities carried out:

-

Operative 4 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 5 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 6 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 7 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 8 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 9 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 10 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Need another SSSTS supervisor added?

- Yes

- No

- N/A

-

SSSTS Supervisor Name

-

Operative 1 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 2 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 3 signature

-

Add signature

-

Location:

-

Activities carried out:

-

Operative 4 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 5 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 6 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 7 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 8 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 9 signature

-

Add signature

-

Location:

-

Activities being carried out:

-

Operative 10 signature

-

Add signature

-

Location:

-

Activities being carried out: