Title Page

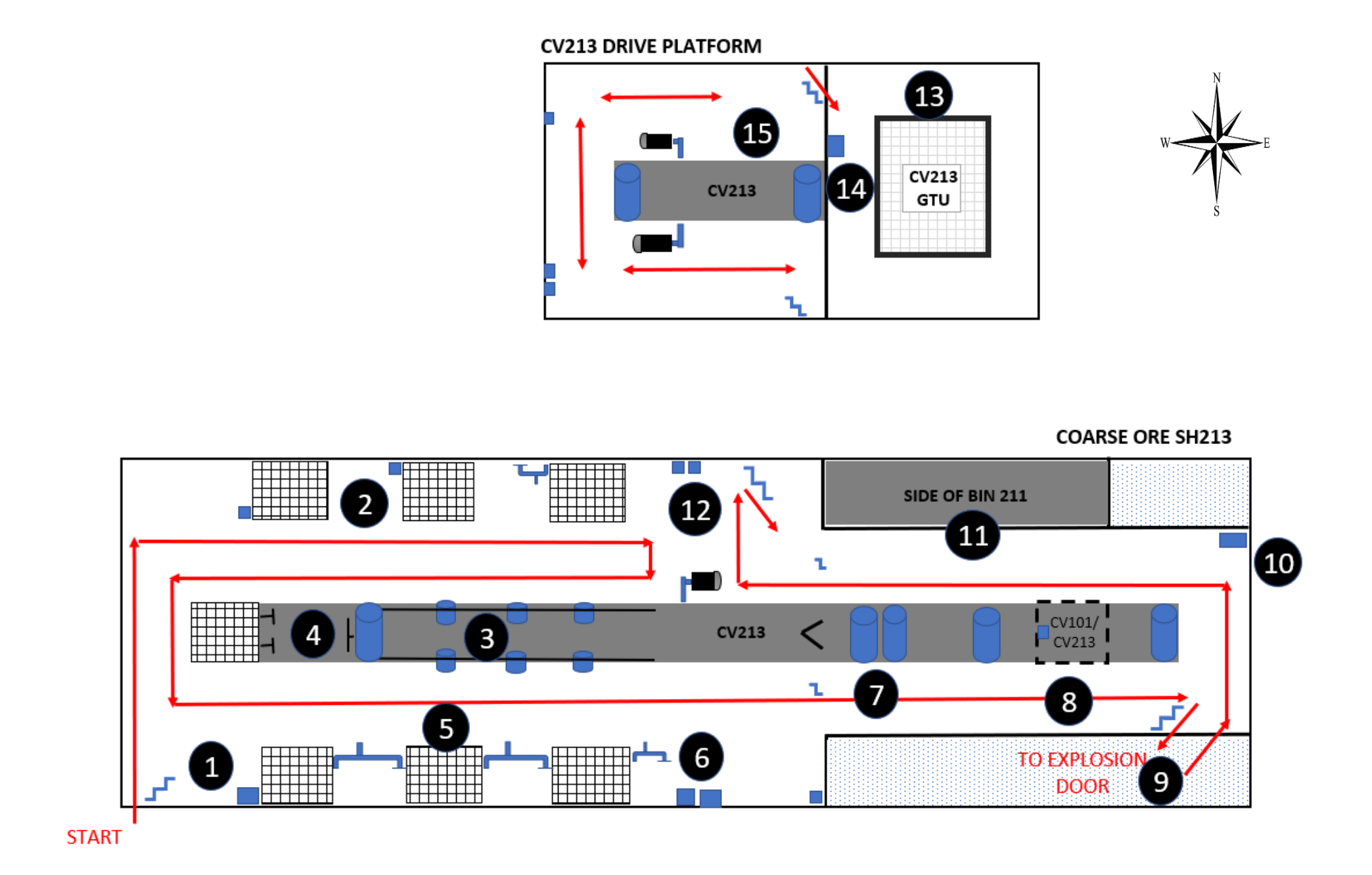

-

Site conducted

-

Date

-

Prepared by

-

Checked By

-

Approved By

-

Location

-

Preparation and Information

START – Coarse Ore Ground

-

Coarse Ore Ground

-

Pedestrian Shedder: Corrosion, rust or build up on roof

-

Have you raised a Notification?

-

SP205 and Local Start: Clearly labelled, bogged? working in auto?

-

Have you raised a Notification? Add Notification Number:

-

Pedestrian Shedder: Corrosion, rust or build up on roof

-

Fire Extinguisher: Unobstructed & bagged?

-

Report to Chubb

-

Have you raised a Notification? Add Notification Number:

-

PPE Box: Stocked

-

Additional Comments/Notes

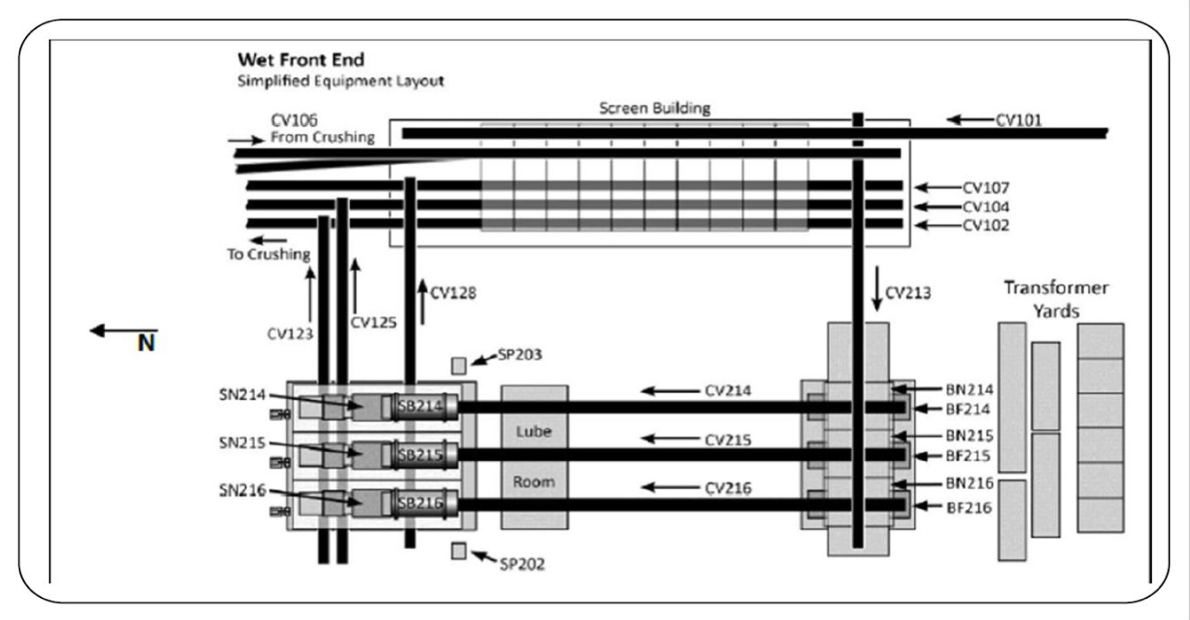

Coarse Ore Tail CV214, CV215, CV216

-

Coarse Ore Tail Diagram

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Check the following on all 3 Trains:

-

Tail CV214, CV215, CV216: Tail pulley, scrapers, belt, safety in drop zone from apron feeder above

-

Dribble Conveyor: Build up in roller catches, condition of chute, tail pulley and bearing housing, belt, guarding & gridmesh

-

*Know location of drive and local start button (west side) and tilt

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Additional Comments/Notes:

Coarse Ore Apron Feeder Level

-

Fire Extinguisher: Unobstructed & bagged? If not, report to Chubb

-

Check the following on all 3 Trains:

-

Apron Feeder: Tail pulley and grease from bearing housing, bin condition from CV213, spillage at tail, guarding

-

Drive, Gearbox, Local Start: Excessive/unusual noise, smells, leaks,

-

Moisture trap is not discoloured, ID plaque clearly labelled

-

Head Chute: Check build up inside head chute, tilt probe is in place, chute condition, door is working and securely closed

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Fire Extinguisher: Unobstructed & bagged? If not, report to Chubb

-

Additional Comments/Notes:

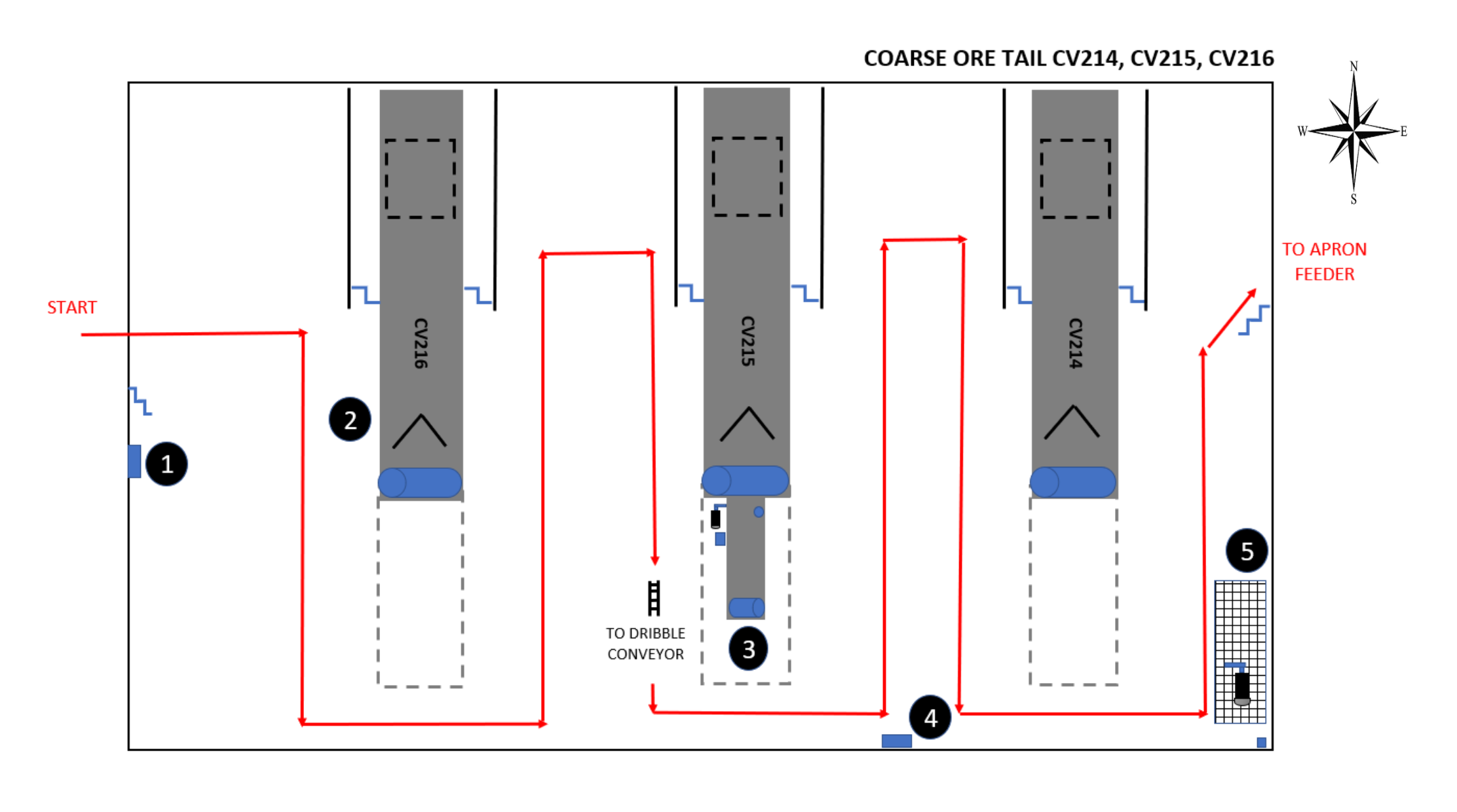

Coarse Ore CV213/SH213

-

Start at South West Stairs of SH213

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

SH213 & CV213 Local Start Button: ID plaque clearly labelled

-

BN214, BN215, BN216: Loose/missing liners

-

SH213: bogy wheels and rails free of build up, condition of condition & signs of belt drift, primary scraper effective

-

Bump Stops: In place and not damaged

-

BN214, BN215, BN216: Loose/missing liners

-

Process Water Lines: Leaks, water available/lines blocked?

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Bend Pulley x 3: Free of build up

-

Vee Scraper: Touching but not cutting belt,

-

Drop Protection Mesh: Check for build up/rocks

-

CV101/CV213 Transfer Chute: Holes, spillage, impact rollers, loose/missing chute bolts, chute curtain, tail pulley

-

Upstairs to Explosion Door: *Know Location* Check door is closed, and proxy illuminated correctly. Check transfer chute condition

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Side BIN211 – Condition of structure, holes, spillage

-

-

Check All GTU Platforms: Guarding, gridmesh, pulleys, belt, *Know location of upper and lower limit switches*

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

CV213 Drive, Brake, Gearbox: Excessive/unusual noise, smells, leaks. Bend Pulleys free of build up, signs of belt drift

-

CV213 & PP213 (brakes) Local Start: ID plaque clearly labelled

-

Go downstairs to the tail of conveyors and walk up any belt to the top level of the Scrubbing Building

-

Additional Comments/Notes:

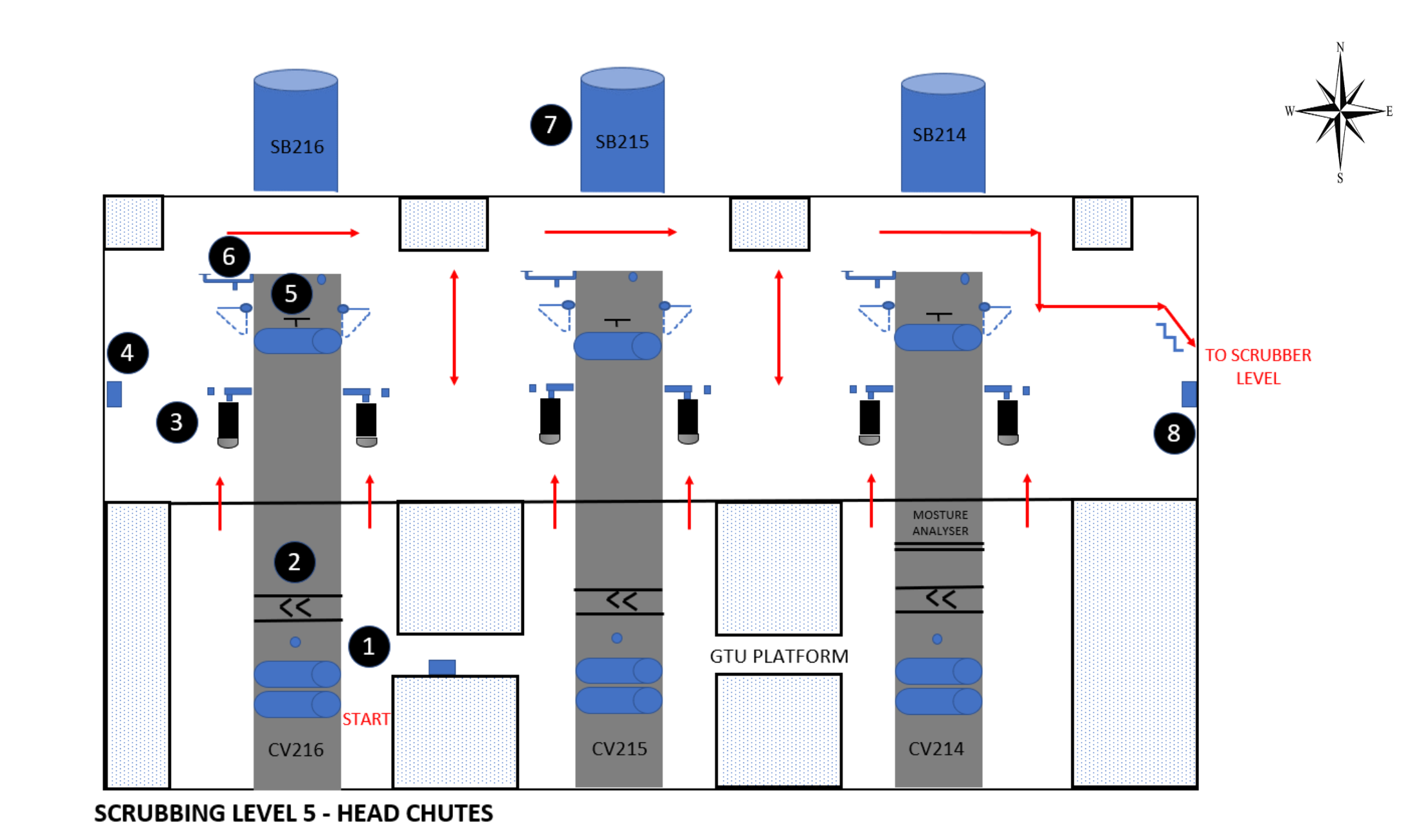

Scrubbing Level 5 – Conveyor Head Chutes

-

Scrubbing Level 5 – Conveyor Head Chutes

-

Start by walking up CV214, CV215 or CV216 from coarse ore side, checking the following on the way up:

-

*Note: There is 1 Moisture Analyser on CV214 only. Ops have no duties with this other than to know its location and ensure its free of build up*

-

Check the following on all 3 Trains

-

Conveyor: Belt, rollers, safety devices, tracking frames, build up on drop protection mesh, hungry boards & skirting

-

GTU Platform: Bend pulleys free of build up, signs of belt drift,

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Drive, Brake, Gearbox, Local Start: Excessive/unusual noise, smells, leaks. ID plaque clearly labelled

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Head Chute: Check build up inside head chute, tilt probe is in place, working and securely closed after inspection

-

Head Chute Spray Bar Water: Turned on, working, blocked, leaks

-

Top of Scrubbers: Visual inspection for damage

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Additional Comments/Notes:

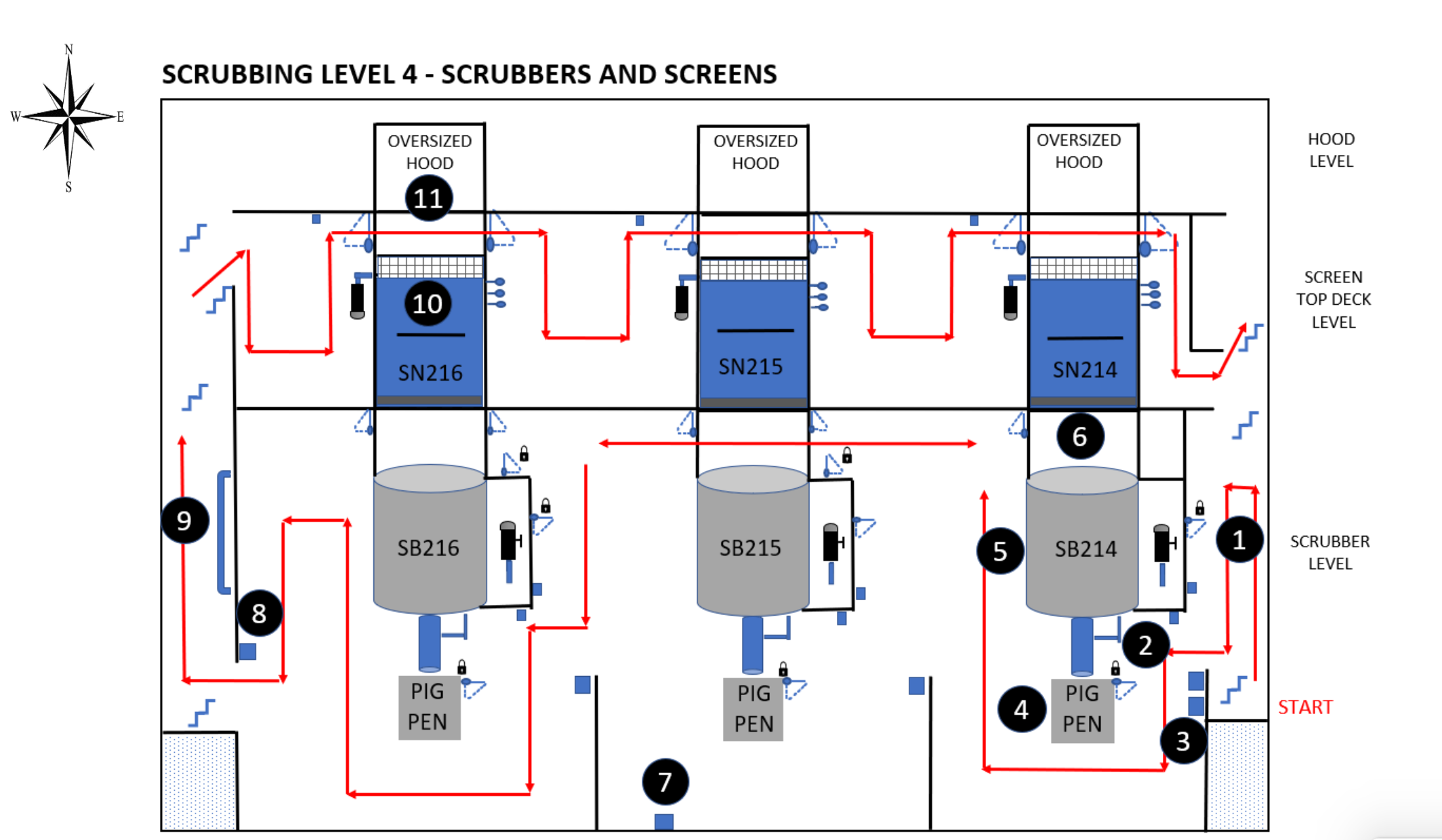

Scrubbing Level 4 - Scrubbers and Screens

-

Level 4 Scrubbers and Screens

-

Check the following on all 3 Trains

-

Access Gates: Secured with black locked

-

Drive, Gearbox, Clutch: No unusual/excessive leaks in area, know location and function of clutch lever

-

Scrubber Local Start: ID plaque clearly labelled

-

Inching Drive Panel: Used to inch scrubber when required

-

Gland water Lines: Leaks, corrosion

-

Trunnion Seals: Small amount of gland water should be leaking – if dry call fitters immediately. Report excessive grease leaks

-

Feed Chute: Holes, leaks, condition, spillage

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Pig Pen: Access gate black lock is on. Level of spillage, check for belt shavings – indicates head chute/scraper above is blocked

-

Grease Cabinet: Visual inspection of level, call fitters if low

-

Scrubber Drum: Check condition, holes, leaks

-

Scrubber Discharge and Cascading Chute: Loose liners/lifters inside chute is not blocked and free of damage

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Go down west side stairs do visual inspection under scrubbers then upstairs to SN216, SN215, SN214

-

Fire Water Line: Check line is clearly labelled and not leaking

-

Check the following on all 3 Trains

-

SN216, SN215, SN214:

-

Drive, Exciters & Drive Belts: No excessive noise, heat, smells

-

*Always check drive belts on start up. Local start clearly labelled

-

Screen Panels: Loose/missing panels/pegging rails

-

Spray Bars: Working, blocked, secure

-

Top Deck Strainers: Call control to check flow, flush if low

-

Top of Oversize Hoods: Visual inspection for damage

-

Additional Comments/Notes:

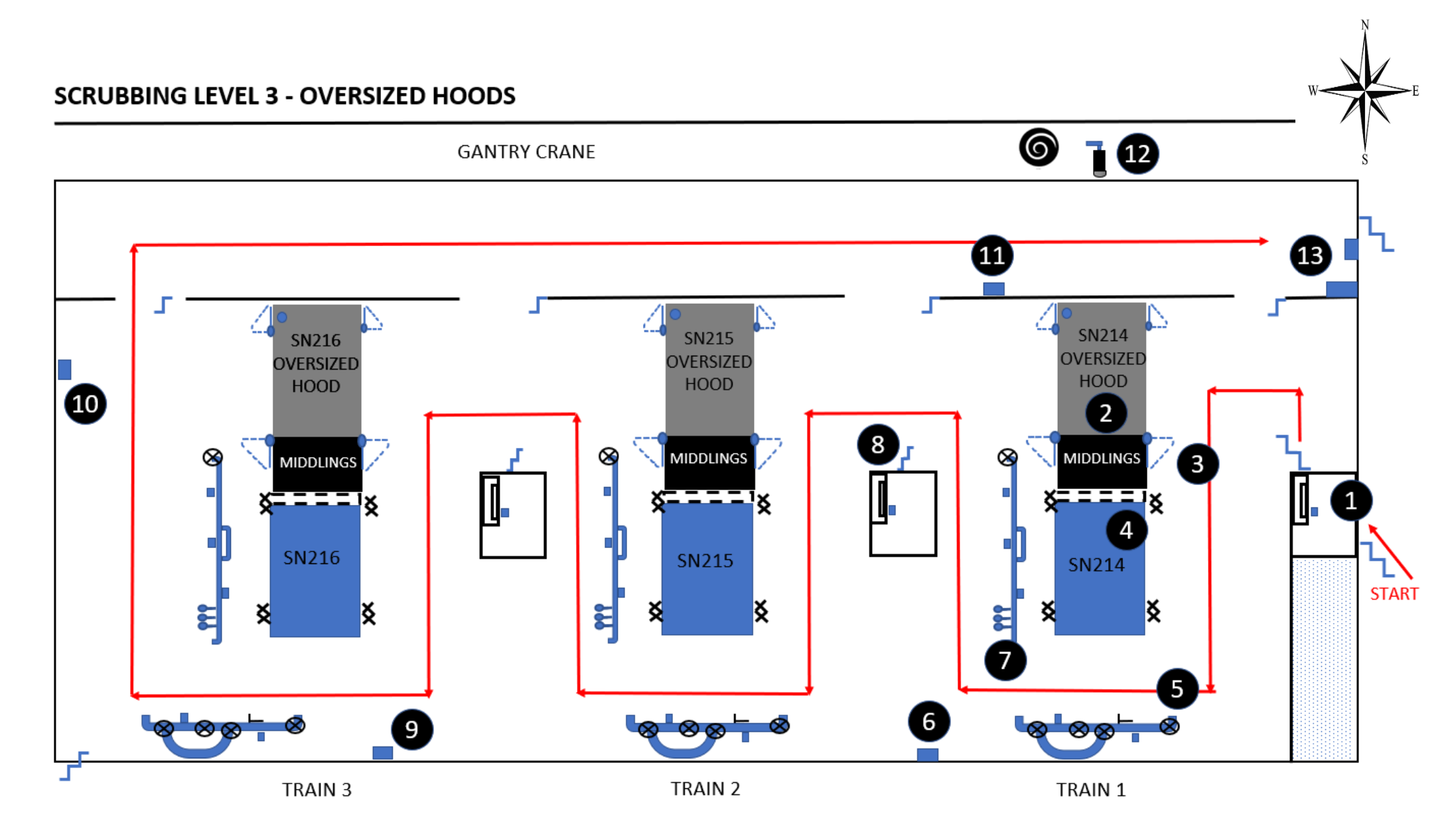

Scrubbing Level 3 – Oversize Hood

-

Check the following on all 3 Trains

-

SN214 Top Deck Water Lines and Drain: Check for leaks

-

Screen Isolation Frame: Structure, bolts, spillage

-

Oversize Hood: Structure, doors securely closed, know location of tilt probe, visually inspect inside for loose liners/billets or build up

-

Middlings Chute: Structure, doors securely closed, know location frame for holes/spillage

-

Screen Isolation Frame: Springs, structure, bolts, spillage

-

Top Deck Spray Bars: Call control to check flow is adequate and if not clean strainers and adjust valve accordingly

-

Head Chute Water Lines: Flow meter should read between 300-

-

600 cubes. If not, call control to check flow is adequate and adjust

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Bottom Deck Spray Bars: Call control to check flow is adequate and if not clean strainers and adjust valve accordingly

-

SN215 & SN216 Top Deck Water Lines and Drain: Check for leaks

-

Screen Isolation Frame: Structure, bolts, spillage

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Gantry Crane: Check reel, structure and drive are not damaged

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Gantry Crane Field Isolator: Check clearly labelled

-

Additional Comments/Notes:

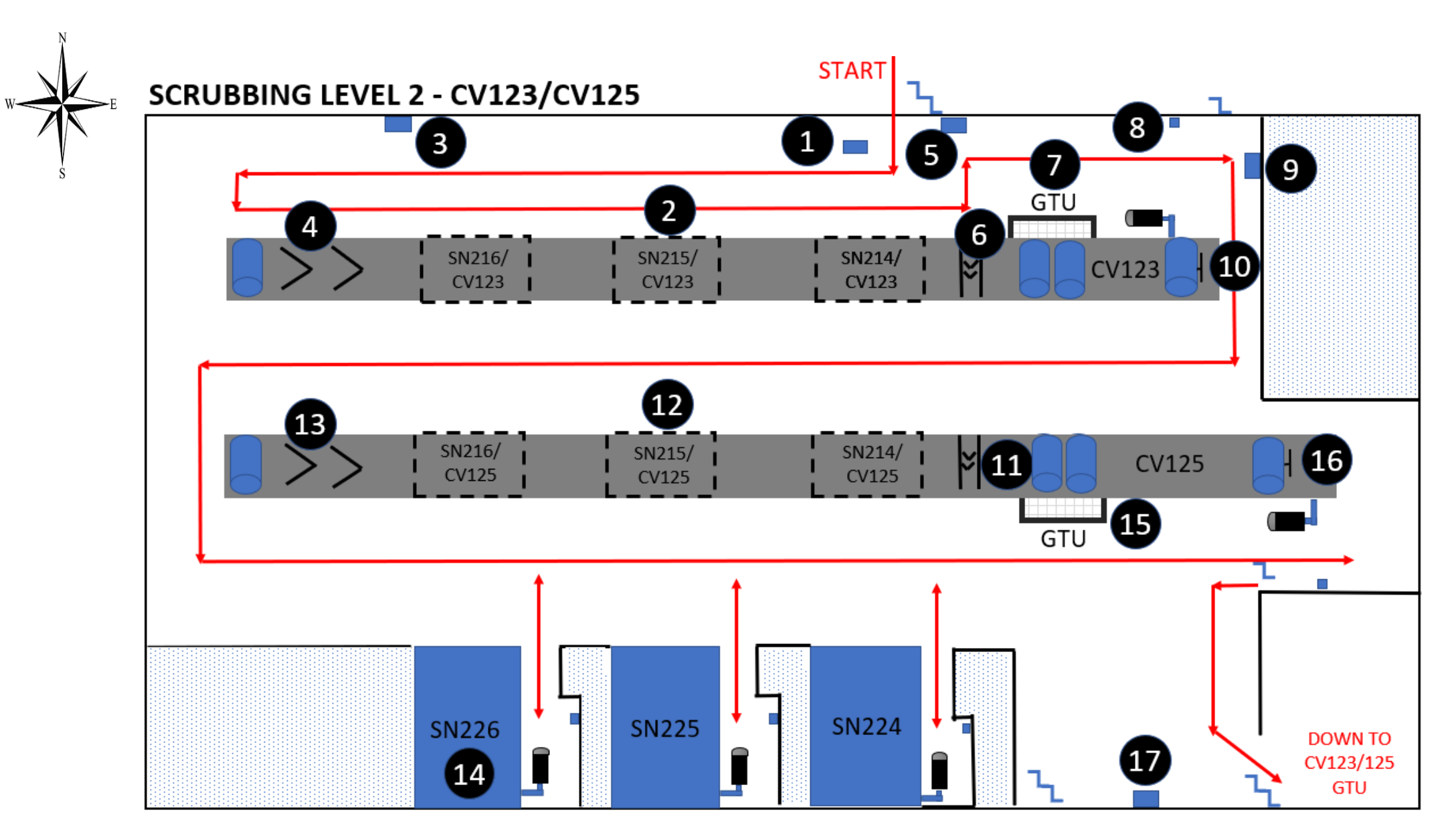

Scrubbing Level 2 - CV123 and CV125

-

Scrubbing Level 2 - CV123 and CV125

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

SN214, SN215, SN216 to CV123 Transfer Chutes: Condition, loose/missing bolts, holes, spillage, impact rollers, hard skirts

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

CV123 Tail to Head: Tail pulley, scrapers, rollers, tracking frames, drop protection mesh build up, safety devices

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

CV123 Weightometer: Free of build up? If not clean immediately

-

CV123 GTU: Bend pulleys are free of build up, GTU pulley rope has tension and guarding is secure

-

CV123 Drive, Brake, Gearbox & Local Start: Excessive/unusual noise, smells, leaks, ID plaque clearly labelled

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

CV123 Head Chute: Check build up inside head chute, tilt probe is and door in good condition with no holes

-

CV125 Weightometer: Refer to weightometer

-

SN214, SN215, SN216 to CV125 Transfer Chutes: Refer to step 2

-

CV123 Tail to Head: Refer to step 4

-

Check the following on all 3 Trains

-

SN226, SN225, SN224:

-

Drive, Exciters & Drive Belts: No excessive noise, heat, smells

-

*Always check drive belts on start up. Local start clearly labelled

-

Screen Panels: Loose/missing panels/pegging rails

-

Spray Bars: Working, blocked, secure

-

CV125 GTU: Bend pulleys are free of build up, GTU pulley rope has tension and guarding is secure

-

CV123 Head Chute:

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Go downstairs to CV123/CV102 Transfer Chute

-

Additional Comments/Notes:

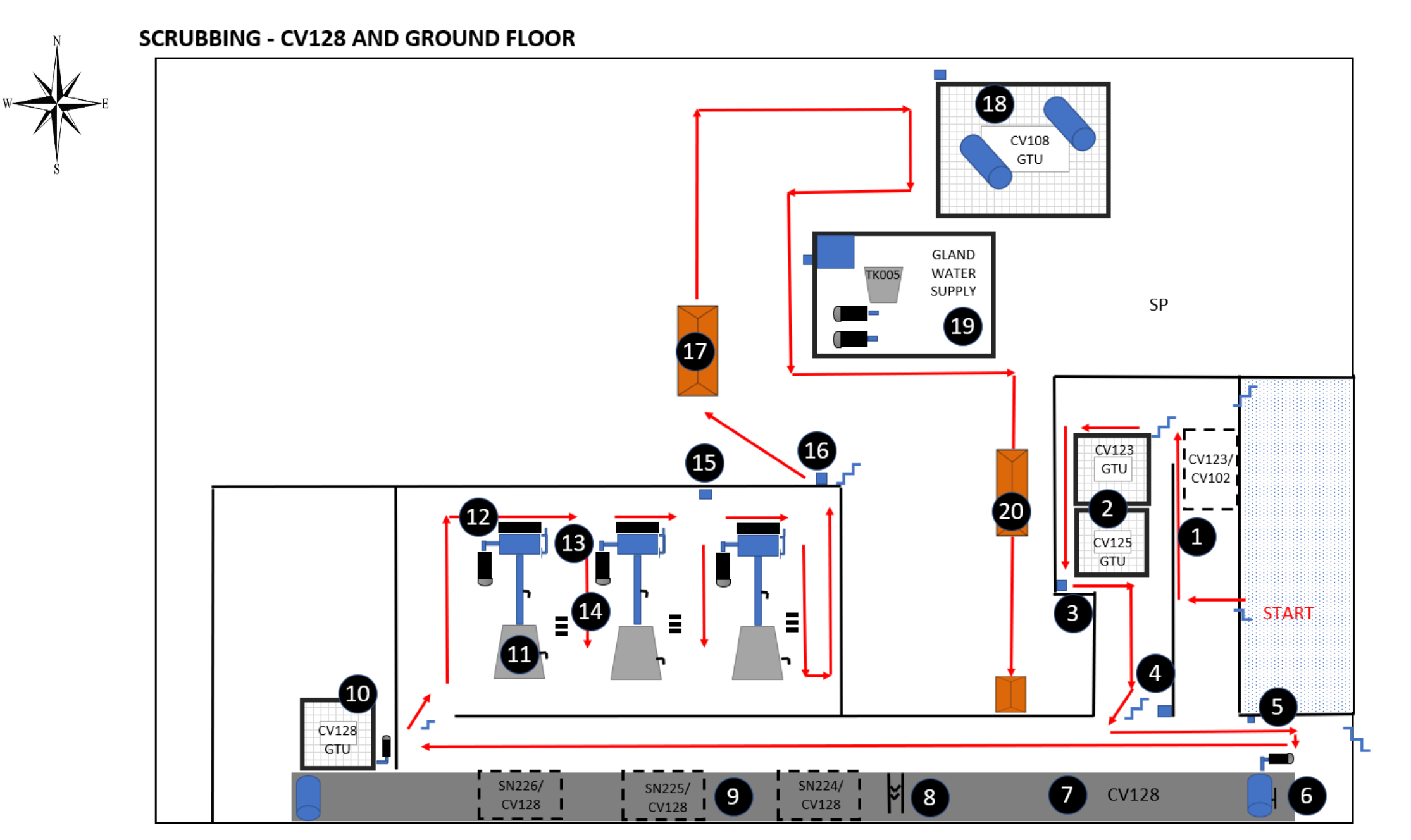

Scrubbing – CV128 and Ground Floor

-

Scrubbing – CV128 and Ground Floor

-

CV123/CV102 Transfer Chute: Structure, loose/missing bolts, holes

-

CV123 and CV125 GTU: Bend pulleys are free of build up, guarding is secure, spillage from above

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

CV128 Drive, Brake, Gearbox and Local Start: Excessive/unusual noise, smells, leaks, ID plaque clearly labelled

-

CV128 Head Chute: Structure, build up inside chute, tilt probe in place, head pulley and scraper not obstructed, door closed

-

CV128 Head to Tail: Belt, scrapers, rollers, tracking frames, drop protection mesh build up, safety devices, tail pulley

-

CV128 Weightometer: Free of build up? If not clean immediately

-

SN214, SN215, SN216 to CV123 Transfer Chutes: Condition, loose/missing bolts, holes, spillage, impact rollers, hard skirts

-

CV128 GTU: Guarding, build up

-

TK223, TK222, TK221 Underpan: Structure, holes, spillage

-

Drive, Drive Belts, Local Starts: Excessive/unusual noise, smells, leaks, loose/missing belts, ID plaque clearly labelled

-

Gland Water Pipework: Leaks, valves, gauges working, corrosion

-

Underpan Suction Lines and Drain: Leaks from pipework or knifegate valves, air supply line leaks

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

PPE Box: Stocked

-

Pedestrian Shedder: Corrosion, rust or build up on roof

-

CV108 GTU and Local Start: Guarding, build up on bend pulleys, ID plaques clearly labelled

-

Gland Water TK005: Structure and pipework leaks, valves, pumps, local starts ID plaques clearly labelled

-

Pedestrian Shedder x 2: Corrosion, rust or build up on roof

-

Check the following on all 3 Trains

-

Additional Comments/Notes

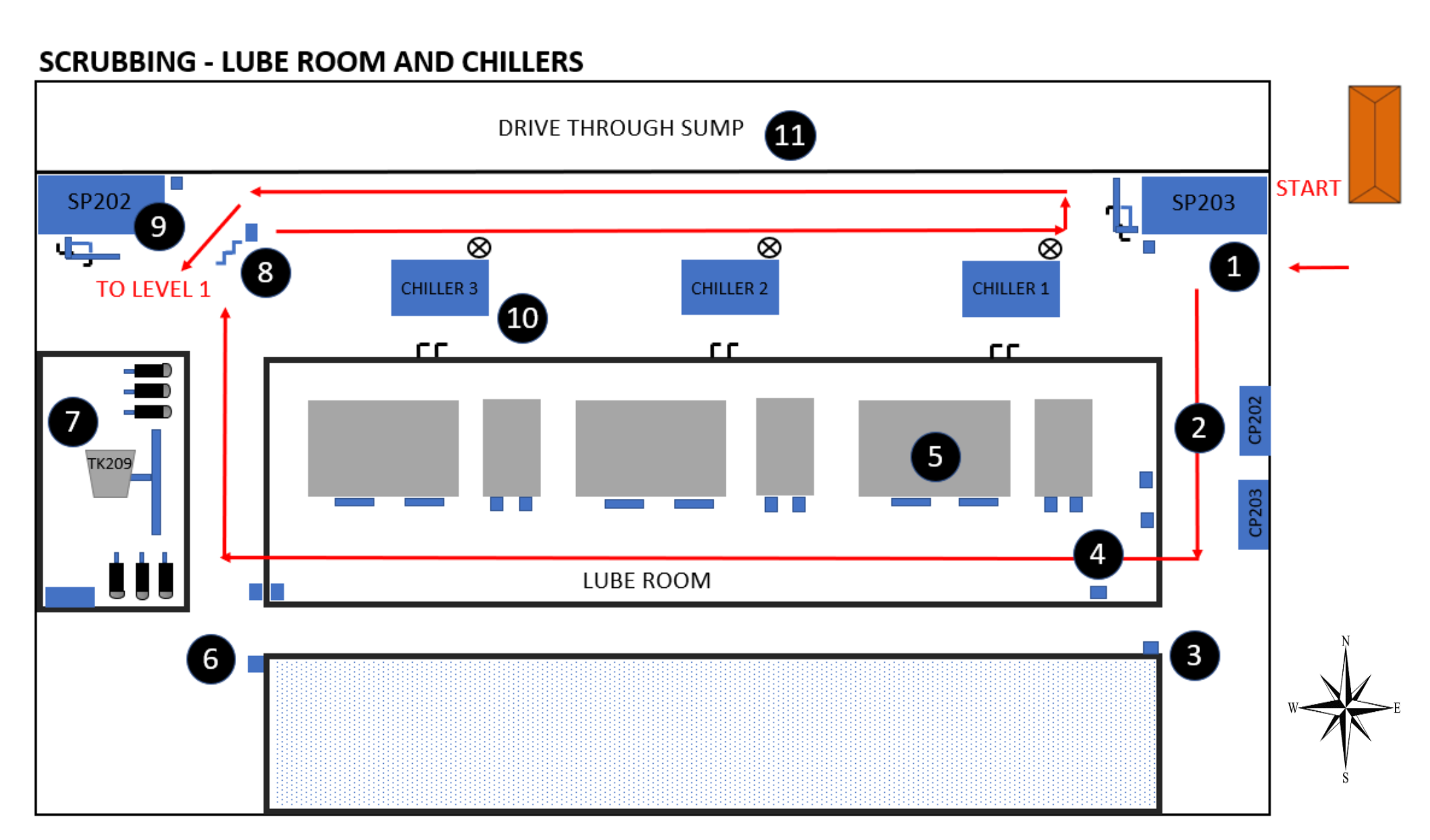

Scrubbing – Lube Room and Chillers

-

Scrubbing – Lube Room and Chillers

-

Check the following on all 3 Trains

-

SP203, Discharge Lines to Underpans and Local Start: Clearly discharge up to TK221/bypass to vault

-

Air Compressors CP202 and CP203: Working, no damage/ build up

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Eye wash/Shower: Report if not working/no water

-

Spill kit: Ensure bin is stocked with spill mats

-

Lube pack: No unusual/excessive leaks, smells, heat

-

Lube and Heat Exchanger Local Starts: ID plaques clearly labelled

-

Fire Extinguishers: Unobstructed & bagged? If not report to Chubb

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Chiller Water TK209: Structure, leaks

-

Pipework: Leaks, valves, gauges working, corrosion

-

Pumps: Unusual/excessive noise, smells, heat, leaks

-

Control Panel: ID plaque clearly labelled

-

PPE Box: Stocked

-

SP202, Discharge Lines to Underpans and Local Start: Clearly discharge up to TK222 and TK223/bypass to vault

-

Chiller Units and Valves: Fan blades intact, no leaks, clearly labelled

-

Drive Through Sump: Arrange to have loader dig out if full

-

Additional Comments/Notes

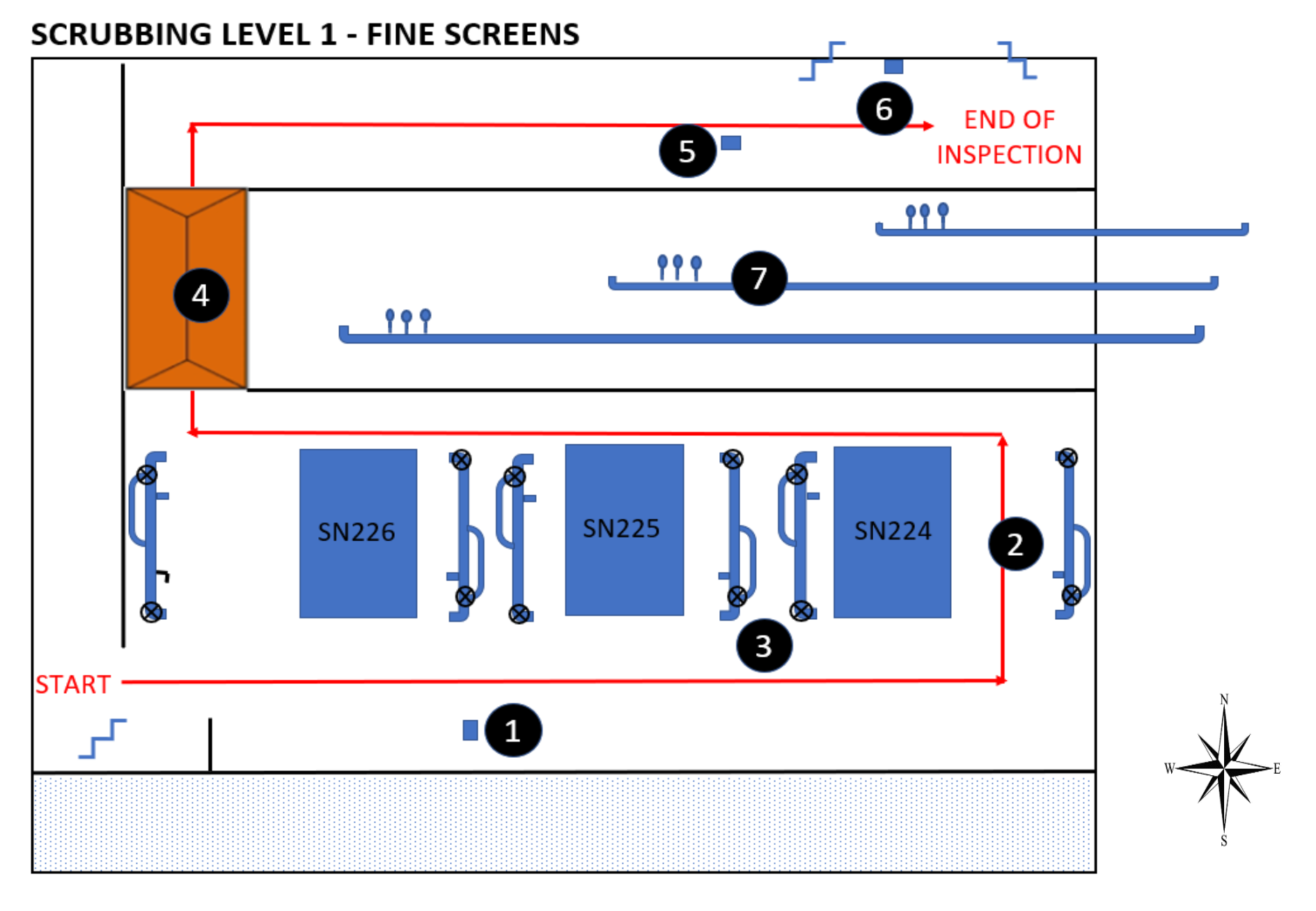

Scrubbing Level 1 – Fines Screens

-

Scrubbing Level 1 – Fines Screens

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Check the following on all 3 Trains

-

TK221, TK222, TK223 Process Water Lines: Valves, pipework, flow corrosion and all points are clearly labelled for isolation purposes

-

SN224, SN225, SN226 Spray Bar Water Lines: Valves, pipework, corrosion and all points are clearly labelled for isolation purposes

-

Pedestrian Shedder: Corrosion, rust or build up on roof

-

Fire Cabinet: Cabinet tied shut? If not report to Chubb

-

Fire Extinguisher: Unobstructed & bagged? If not report to Chubb

-

Feed Lines from PU224, PU225, PU226 to Desands TK261:

-

*Note: This is a non-accessible area during operations* Visual inspection from walkway of pipework – check for leaks, listen for airline leaks, check build up on gridmesh from belts above

-

Additional Comments/Notes

Housekeeping

-

Hoses: Rolled up or set along kick rails so not to cause a trip hazard

-

Rubbish: Cleaned up, bins are not full/overflowing

-

Equipment: New equipment is in appropriate lay down areas. Old equipment/materials should be removed and taken to waste site

-

Sump Pumps: Not full. If they are, All sump pumps should work in auto. If they don’t, raise a notification

-

Start sup pumps to clear.

-

Raise Notification (Enter Number)

-

Structural: Gridmesh, checker plate, handrails, stairs, gates, maintenance

-

Guarding/Barricading: Check all guarding is secure, and intact

-

Check scaffolding is necessary, and tags are in date. If scaffolding in place is unnecessary, call supervisor and arrange removal

-

Signage: Check all signage is present, appropriate, clean, intact and securely fixed

-

Lighting/Electrical Check all lights are clean and working.

-

Ensure all electrical cabinet doors are closed

-

Notify Electricians

Continuous Improvement

-

• Report any additional hazards

-

If you require additional photos or specific information added to this inspection check sheet, please provide the photos/information to your supervisor

Signature

-

Inspection Conducted By:

-

Date:

-

Supervisor

-

Date: