Title Page

-

Site conducted

-

Business unit

-

undefined

-

Conducted on

-

Prepared by

-

Incident ref or NC ref number

8D Driver:

-

What is the 8D Driver?

-

What is the accident category?

1D – Designate Team

-

Team Leader:

-

Team Members:

2D – Define Problem

-

(When) Date and Time of occurrence:

-

(Where) Location: (e.g. Branch, department, area, product)

-

(What) Equipment/ Product Involved: (e.g. details of consignment number, AWB reference, equipment reference)

-

Add photo of location and Equipment used if possible/ relevant

-

(Who) Personnel/ Customer/ Supplier Involved:

-

(How) Description of Incident (Major/Serious) or Non Conformance

-

include photos where possible. Witness Statements/ Communications should be saved separately

3D Interim Containment

-

Describe what has been put in place to stop the issue from escalating

-

Include screen shots of communication and additional information where possible

-

(e.g. product placed in quarantine, area cordoned off, additional communication to effected persons)

Root Cause Analysis

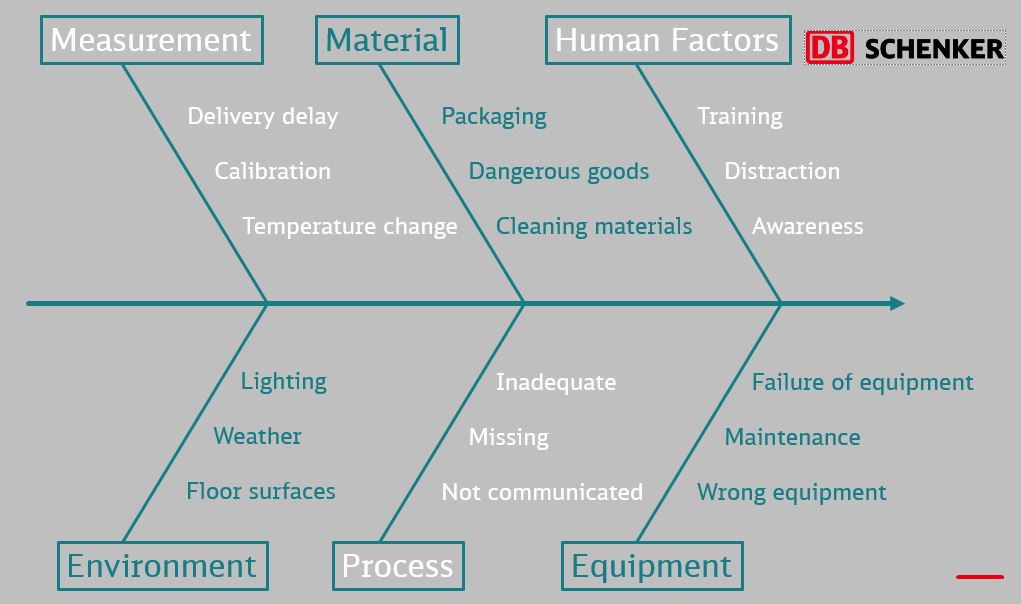

Determine the root cause

-

You can use the simple Ishikawa principle to determine a potential root cause as a brain storming tool with the colleagues or the 5 Why process

-

Which root cause analysis will you use?

- 5 Why

- Ishikawa

- Other

5 Why Analysis (click on the green + button to add analysis)

-

What is the problem you are going to root cause analyse

-

Why?

-

Why?

-

Why?

-

Why?

-

Why?

-

Include evidence of your Ishikawa

-

Which root cause analysis tool did you use? (provide evidence of methodology)

-

What was determined as the root cause of this non-conformance?

-

Include your actions to prevent the action from reoccurring

-

Has the customer/ supplier been contacted to relay the corrective actions?

-

Provide evidence that the customer/ supplier has been contacted

-

Include an action to contact the customer/ supplier

Verification of corrective actions

-

Can the issue be recreated by removing one or more of the results identified in section 5?

-

Can the problem be corrected again by reinstating the results identified above?

4D Verify and Determine the root cause

-

What was determined as the root cause of this non-conformance?

-

Include your actions to prevent the action from reoccurring

7D: Prevent Recurrence

-

The problem has reoccurred since implementation of all actions.

-

Has the procedure/ risk assessment/ process been updated?

-

Have the results and improvements been communicated to all affected persons?

-

Has the corrective action been witnessed?

Sign off

-

Has the customer/ supplier been contacted to inform them of the closure of the investigation?

-

Provide evidence that the customer/ supplier has been contacted

-

Include an action to contact the customer/ supplier

-

Team Leader sign off:

-

Completion Date

undefined

-

5 Why Analysis

-

What is the Immediate/Direct Causes (circumstances that immediately precede the contact)

- Acts/ Practices

- Conditions

-

Detail the act or practice that is the immediate root cause

-

Detail the condition that is the root cause

-

What is the Basic/Root Cause?

- Personal/ Human Factors

- Job/ System Factors

-

What was the Person/ Human Factor Root cause?

-

What is the job/ system factor of the root cause

5D: Define and implement Corrective Actions (e.g what actions can be taken to rectify the root casues identified in section 4)

-

Include a Actions and assign a SMART objective

6D: Verify Permanent Corrections (PCs) for Problem

-

Can the issue be recreated by removing one or more of the results identified in section 5?

-

Can the problem be corrected again by reinstating the results identified above?

7D: Prevent Recurrence

-

The problem has not reoccurred since implementation of all actions.

-

Has the procedure/ risk assessment/ process been updated?

-

Have the results and improvements been communicated to all affected persons?

-

Has the corrective action been witnessed?

-

If the answer is yes to all of the above then the 8D investigation is ready to be closed

8D: Congratulate Your Team

-

Team Leader sign off:

-

Completion Date