Information

Non-Conforming Audit Process Audit Card

-

LINE: S550 STATION: F1-20 AUDIT TYPE: Key Process / Characteristic OPERATION DESCRIPTION: PS Track Load

-

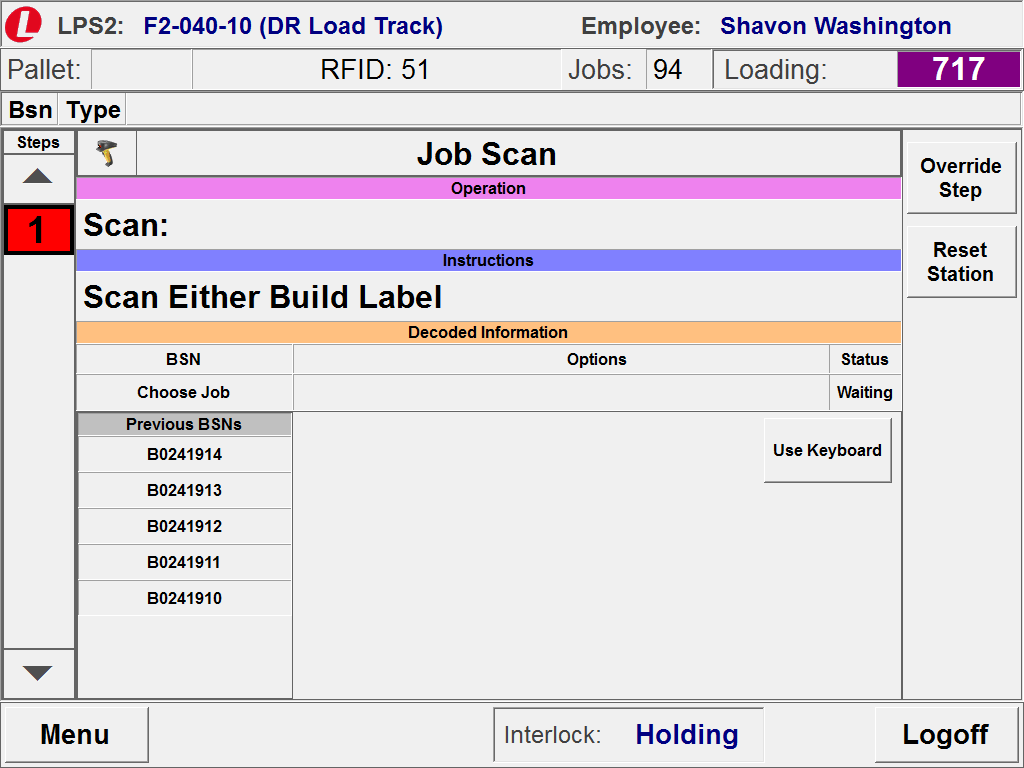

1.Obtain build label and place on DR build pallet.

-

2.Scan build label, then obtain chassis from the sequencing racks.

-

3.Place PS chassis on build pallets and lock them in. Scan PS chassis.

-

4. Get the inboard recliner cover and clip it to the PS chassis. Secure the cover with one screw.

S550: 1.7 Nm +/- 0.1 Nm

"Process / Operation Summary:

-

1.Obtain build label and place on DR build pallet. 2.Scan build label, then obtain chassis from the sequencing racks. 3.Place PS chassis on build pallets and lock them in. Scan PS chassis. 4. Get the inboard recliner cover and clip it to the PS chassis. Secure the cover with one screw. S550: 1.7 Nm +/- 0.1 Nm

Audit 1

Conforming Audit Process Audit Card

-

LINE: S550 STATION: F1-20-10 AUDIT TYPE: Key Process / Characteristic OPERATION DESCRIPTION: PS Track Load

Key Process Characteristics:

-

1.Build label Scan 2.PS Track Scan 3.Inboard Recliner cover Install

Audit Procedure

Question 1

-

Is the SWI present?

-

Date

-

Visible and Readable?

-

Current and Accurate?

-

Is the area clean and free of debris?

Question 2

-

Watch and scan the 5 jobs when the operator finishes the job. Please hit the check before continuing.

-

BSN 1

-

BSN 2

-

BSN 3

-

BSN 4

-

BSN 5

-

Are the components parts easily accessible?

-

Does the operator follow each line of the SWI?

Question 3

-

Is there any Quality Alert(s)

-

Present?

-

Being Followed?

-

Quality Alert Number

-

Expired?

-

Select date

Question 4

-

Is there any Visual Aids?

-

Are they controlled? (sign and Dated)

-

Please Sign here

-

Select date

Question 5

-

Was Poke Yoke Performed?

-

Select date

Question 6

-

Verify - is Nonconforming material

-

Stored in proper location?

-

Disposition tags filled out properly?

Question 7

-

Verify - is operator trained on this job?

-

Operator Name

-

Operator Competency Level?

Question 8

-

PMs complete (for previous week)?

Question 9

-

Are Stickers on torque equipment present and legible?

-

Torque ID

-

Calibration Date

-

Any additional torques?

-

Torque iD

-

Calibration Date

-

Torque ID

-

Calibration Date

Question 10

-

Is the Hot Spot sign present?

Question 11

-

Is the FMVSS sign present

Question 12

-

Does the Control Plan meet process control requirements for the station?

Question 13

-

Does the PFMEA meet process requirements for the station?

Question 14

-

Verify - Cardboard bins do not have other trash.

Result Page

After Completed The Aduit

-

Was this a Non Conforming Audit or a Conforming Audit

-

What are the Non-Conformance(s) found?

-

Immediate Response(s)

-

Any Errors in the Torques?

-

Enter the Torque Specs:

Once Finished

-

Add signature

-

Enter Today Date and Time Completed

-

What Shift?