Titelseite

-

Client Company Logo

-

Document ID No.

-

Title

-

Client

-

Aircraft Make and Model

-

Aircraft Serial No.

-

Audit prepared by

QCM CONTACT & DISCLAIMER

-

Company Picture

-

Company Address and Contact

-

This report has been prepared on the basis of information as made available to NCG Aviation. It provides basic information and is neither intended to provide any rights or causes of action, nor does it imply an express or implied warranty in relation to the aircraft, its technical condition or aircraft documentation. NCG Aviation excludes any liability, under contract or law, for the contents hereof. All questions concerning this document should be addressed to NCG Aviation.

AIRCRAFT INSPECTION SUMMARY

OBJECTIVE

-

NCG Aviation was requested by 'the client' (as mentioned below) to accomplish an Annual Inspection on a 'Aircraft' with S/N, MFD and delivery date together with model engines (as listed below) collectively referred to as the `Aircraft`. The reason of this Inspection is to give 'the client' a clear and objective view of the Aircraft’s technical condition. This includes improvements or deteriorations since last inspection.

-

"Client" i.e. Name of Financial Institute

-

Aircraft Make (OEM) and Model

-

S/N

-

Engine(s) Make (OEM) and Model

AIRCRAFT INSPECTION SUMMARY cont.

CONCLUSION GENERAL

-

The aircraft and the aircraft records were presented according to date and location stipulated below. The aircraft is maintained according the manufacturer’s requirements, at the same time also meeting the requirements of the state of registry. The records were complete, if not otherwise stated below, and the technical coordinator or Nominated responsible Person Continuing airworthiness is keeping track of the documents.

-

Operator

-

Accountable Manager / PA

-

responsible Technical coordinator

-

responsible Person flight operations

-

Home Base

-

Main Maintenance Provider (Part-145 if applicable) & location

-

The Aircraft Physical inspection and location may differ from the ones for the documents inspection.

-

Aircraft Physical Inspection Location

-

Aircraft Physical Inspection Date

-

Documents inspection location

-

Documents Inspection Date

-

The aircraft is being operated according to the following legal standards.

- EU, EASA PART-CAT

- EU, EASA PART-NCC

- EU, EASA PART-SPO

- US, FAR PART 135

- US, FAR PART 91

- IOMAR

- Aruba-SMS

- SMAR

- OTAR-Cayman

- OTAR-Bermuda

- other

-

Tech and Journey Logbooks must be available in original for inspection.

-

Are the journey logs complete?

-

What is the quality of documentation of the journey logs since last inspection?

-

Is the maintaining of documentation standards assured for the future?

-

Are the tech logs complete?

AUDIT CONDITION

-

Aircraft Inspection Condition

- In Maintenance

- In Hangar - airworthy flyable condition

- In Storage

- On Tarmac - airworthy flyable condition

- On Tarmac - not airworthy

- In Hangar - not airworthy

-

Summary on nominated responsible persons, Audit conditions, accessibility, evidenced quality assurance... etc.

AIRCRAFT INSPECTION SUMMARY cont.

CONCLUSION AIRCRAFT

-

The aircraft accumulated hours and cycles since new (THSN / TCSN) as stated below. It was physically verified that the #1/#2/#3... engines & matching S/N, were installed at the time of the inspection (unless explicitly stated otherwise in the respective report section). The engines are installed since delivery of the aircraft (unless explicitly stated otherwise in the respective Engine Section).

It was also physically verified that the APU (as stated below) was installed at time of inspection. -

Aircraft: Hours & cycles (THSN / TCSN)

-

No.1 Engine: MSN, THSN, TCSN

-

No.1 Engine Installed and operational?

-

No.2 Engine: MSN, THSN, TCSN

-

No.2 Engine Installed and operational?

-

3 ENG a/c

-

No.3 Engine: MSN, THSN, TCSN

-

No.3 Engine Installed and operational?

-

4 ENG a/c

-

No.4 Engine: MSN, THSN, TCSN

-

No.4 Engine Installed and operational?

-

If major change or modification was done to the aircraft, find the information on the right. The aircraft is in its original configuration as delivered by OEM, unless stated by the auditor here.

-

APU: MSN, THSN, TCSN

-

APU Installed and operational?

AIRCRAFT INSPECTION SUMMARY / WARRANTY PROGRAMMES

Warranty Contract - TIP TO TAIL

-

Contract in place?

-

Name of Contract

-

Expiry Date

-

Payment evidenced?

Warranty Contract ENGINE(s)

-

Contract in place?

-

Name of Contract

-

Expiry Date

-

Payment evidenced?

Warranty Contract APU

-

Contract in place?

-

Name of Contract

-

Expiry Date

-

Payment evidenced?

Warranty Contract AIRFRAME

-

Contract in place?

-

Name of Contract

-

Expiry Date

-

Payment evidenced?

Warranty Contract AVIONICS

-

Contract in place?

-

Name of Contract

-

Expiry Date

-

Payment evidenced?

OVERALL IMPRESSION SUMMARY

SCORING SUMMARY

-

Scoring information

-

Physical and Technical Status Summary.<br>Summary of weighted items.

-

Aircraft Interior and furnishings Status Summary.<br>Summary of weighted items.

-

Document and Logbook Status Summary.<br>Summary of weighted items.

OVERALL REMARKS & COMMENTS

REMARKS & COMMENTS

-

The purpose of this section is to summarize the comments during the Inspection. It also includes recommendations to the operator, owner or beneficial owner.

-

#1

-

#2

-

#3

-

#4

-

#5

-

#6

-

#7

-

#8

-

#9

-

#10

-

more than 10 remarks?

-

Summarize minor remarks here

AIRCRAFT CONDITION COMPARISON TO PREVIOUS INSPECTION

-

Corrective action from previous inspection?

-

undefined

-

undefined

-

undefined

-

Has the interior condition improved?

-

undefined

-

undefined

-

Has the exterior condition improved?

-

undefined

-

undefined

FUTURE MAINTENANCE & REQUIREMENTS

Next scheduled Maintenance requirements (OEM)

-

Item Description, next due

-

Item Description, next due

-

Item Description, next due

-

Item Description, next due

Future Maintenance requirements (Regulatory)

-

Item requirements

-

Due Date

-

Scheduled installment?

-

Planned execution Date

-

Cost Estimate USD

GENERAL DESCRIPTION OF THE AIRCRAFT

AIRCRAFT

-

Make & Model No.

-

Serial No.

-

Registration

-

Date of Manufacture (MFD)

-

Entry into Service - Delivery Date (EIS)

-

Basic Empty Weight/Mass as per last weighing report

-

Date of Last weighing

DESCRIPTION OF ENGINE No. 1

ENGINE NO.1

-

Make

-

Model No.

-

Serial No.

-

MFD

-

Date of Installation

-

TSN at installation

-

CSN at installation

-

Next OVH

-

Next HSI

-

Lowest LLP

-

LLP Limit HRS

-

LLP Limit CYC

-

Remaining Hours & Cycles

DESCRIPTION OF ENGINE No. 2

ENGINE NO.2

-

Make

-

Model No.

-

Serial No.

-

MFD

-

Date of Installation

-

TSN at installation

-

CSN at installation

-

Next OVH

-

Next HSI

-

Lowest LLP

-

LLP Limit HRS

-

LLP Limit CYC

-

Remaining Hours & Cycles

DESCRIPTION OF ENGINE No. 3

-

Engine No. 3 installed?

ENGINE NO.3

-

Make

-

Model No.

-

Serial No.

-

MFD

-

Date of Installation

-

TSN at installation

-

CSN at installation

-

Next OVH

-

Next HSI

-

Lowest LLP

-

LLP Limit HRS

-

LLP Limit CYC

-

Remaining Hours & Cycles

DESCRIPTION OF ENGINE No. 4

-

Engine No. 4 installed?

ENGINE NO.4

-

Make

-

Model No.

-

Serial No.

-

MFD

-

Date of Installation

-

TSN at installation

-

CSN at installation

-

Next OVH

-

Next HSI

-

Lowest LLP

-

LLP Limit HRS

-

LLP Limit CYC

-

Remaining Hours & Cycles

DESCRIPTION OF APU

APU

-

Make

-

Model No.

-

Serial No.

-

MFD

-

Date of Installation

-

TSN at installation

-

CSN at installation

-

Next OVH

-

Next HSI

-

Lowest LLP

-

LLP Limit HRS

-

LLP Limit CYC

-

Remaining Hours & Cycles

DESCRIPTION OF NLG & MLG(s)

NOSE LANDING GEAR

-

Part No.

-

Serial No.

-

Installment Date

-

Lowest LLP

-

Remaining Cycles

-

The nose landing gear were installed by OEM at time of manufacture and were only removed, if stated aside.

RH MAIN LANDING GEAR

-

Part No.

-

Serial No.

-

Installment Date

-

Lowest LLP

-

Remaining Cycles

-

The RH main landing gear were installed by OEM at time of manufacture and were only removed, if stated aside.

LH MAIN LANDING GEAR

-

Part No.

-

Serial No.

-

Installment Date

-

Lowest LLP

-

Remaining Cycles

-

The LH main landing gear were installed by OEM at time of manufacture and were only removed, if stated aside.

DESCRIPTION OF REPORT GRADING SYSTEM

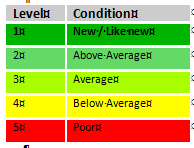

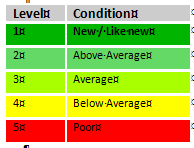

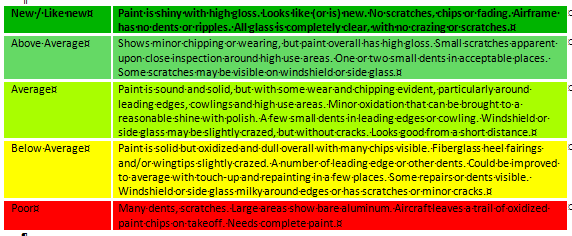

Scale of condition

-

Deterioration Scale

EXTERIOR / PAINT

INTERIOR

DATA PLATES

Data Plates

-

Data Plates (Bank, Registration, Engines, APU)

-

All installed an in proper condition?

EXTERNAL AIRCRAFT PHYSICAL INSPECTION - FUSELAGE EXTERNAL CONDITION

Fuselage Exterior

-

Overall Pictures

-

Fuselage exterior - Overall Impression

Technical Status - Fuselage Exterior

-

Condition of Rivets

-

Lower Lobe and Fuselage area

-

Cargo Compartments Doors and Hatches (Forward, Mid / Underfloor / Aft)

-

Door Exteriors, Latches and Mechanism

-

Access panels

-

Fairings and Sealants

-

Cabin Windows

-

Flight Compartment Windows

-

Antenna(s)

-

Lights and covers

WINGS CONDITION, FLAPS and FLIGHT CONTROLS

Wings, Flaps, Slats and Flight Controls

-

Overall Pictures

-

Wings, Flaps, Slats and Flight Controls external - Overall Impression

Damage, Dents, Repairs, Modification and Mapping

-

Condition of Rivets

-

Access Panels

-

Structure

-

Leading edges and high lift devices

-

Flight Controls, Speed Brakes

-

Flaps, Slats

-

Systems installation, i.e. obvious discrepancies, leaks etc.

-

Fuel Tanks, Vents and panels (Fuel leakage)

-

Winglets, Fairings and Sealants

-

Lights and covers

-

Static Wicks

TAIL-SECTION, EMPENNAGE

Tailsection / Stabilizer / Elevators

-

Overall Pictures

-

Tailsection external - Overall Impression

Technical Status - Tail & Stabilizer

-

Condition Tail Skid

-

Access Panels, Tail Doors & hatches

-

APU In & Outlet, Fairings

-

Leading Edges

-

Flight Control surfaces

-

Static Wicks

-

Systems installation, i.e. obvious discrepancies, leaks

-

Fairings and Sealants

-

Lights and covers

-

Antenna(s)

LANDING GEARS AND BAYS CONDITION

LANDING GEARS

-

Overall Pictures

-

Landing Gear - Overall Impression

Right Main gear Data

-

Data Plate installed?

Left Main gear Data

-

Data Plate installed?

Nose gear Data

-

Data Plate installed?

Landing Gears and Bays

Gear, Actuators & Doors

-

Painting Condition, struts, mechanism and wheel well

-

Damage, Dents and Scratches

-

Corrosion

-

Door seals, Fairings

-

Gear strut, Structure

-

Gear Door, Door actuator and Panels

-

Steering Mechanism

-

Gear & actuators, Systems installation, i.e. obvious discrepancies, Hydraulic leaks, etc.

-

Lights and covers

-

Wheels

-

Brakes assembly & hydraulic lines

-

Tyres

-

Markings and Placards

INTERNAL STRUCTURE, A/C SYSTEMS AND INSTALLATIONS

Fuselage & Tail section - Internal Structure, A/C Systems

-

Overall Picture

-

Fuselage, Tail section internal - Overall Impression

Structural condition, Damages, Dents, Repairs, Modifications

-

Structure

-

Lightning Strike indications

Access Panels

-

Access Panels, Doors to A/C systems, installations

Systems installation, i.e. obvious discrepancies, leaks etc.

-

Air-conditioning packs, ducts, vents and inlets

-

Systems installation, i.e. obvious discrepancies, leaks etc.

Wire Bundles, brackets

-

Flight Control cables or wirings

-

Wire Bundles, Brackets, Joints

ENGINE 1 CONDITION

Engine No.1

-

Overall Picture

-

Engine No.1 - Overall Impression

Technical Status - No.1 Engine

-

Surface Condition, Scratches on Cowling, Mechanism, Pylon & surrounding structure

-

Accessory Gearbox, FADEC, Systems installation and obvious discrepancies, leaks etc.

Fans, inlet area, blade damage

-

Nose Cowl, Inlet Cowl

-

Fans, inlet area, blade damage

Engine cowlings, Fairings & Seals, Panels, Lights, Markings

-

Fan cowl doors

-

Engine cowlings

-

Lights and covers

Exhaust, Thrust reverser sleeves and system

-

Thrust reverser

-

Turbine exhaust nozzle area

-

Pylon fairings

-

Access panels

ENGINE 2 CONDITION

Engine No.2

-

Overall Picture

-

Engine No.2 - Overall Impression

Technical Status - No.2 Engine

-

Surface Condition, Scratches on Cowling, Mechanism, Pylon & surrounding structure

-

Accessory Gearbox, FADEC, Systems installation and obvious discrepancies, leaks etc.

Fans, inlet area, blade damage

-

Nose Cowl, Inlet Cowl

-

Fans, inlet area, blade damage

Engine cowlings, Fairings & Seals, Panels, Lights, Markings

-

Fan cowl doors

-

Engine cowlings

-

Lights and covers

Exhaust, Thrust reverser sleeves and system

-

Thrust reverser

-

Turbine exhaust nozzle area

-

Pylon fairings

-

Access panels

ENGINE 3 CONDITION

-

Engine No. 3 installed?

Engine No.3

-

Overall Picture

-

Engine No.3 - Overall Impression

Technical Status - No.3 Engine

-

Surface Condition, Scratches on Cowling, Mechanism, Pylon & surrounding structure

-

Accessory Gearbox, FADEC, Systems installation and obvious discrepancies, leaks etc.

Fans, inlet area, blade damage

-

Nose Cowl, Inlet Cowl

-

Fans, inlet area, blade damage

Engine cowlings, Fairings & Seals, Panels, Lights, Markings

-

Fan cowl doors

-

Engine cowlings

-

Lights and covers

Exhaust, Thrust reverser sleeves and system

-

Thrust reverser

-

Turbine exhaust nozzle area

-

Pylon fairings

-

Access panels

ENGINE 4 CONDITION

-

Engine No.4 installed?

Engine No.4

-

Overall Picture

-

Engine No.2 - Overall Impression

Technical Status - No.4 Engine

-

Surface Condition, Scratches on Cowling, Mechanism, Pylon & surrounding structure

-

Accessory Gearbox, FADEC, Systems installation and obvious discrepancies, leaks etc.

Fans, inlet area, blade damage

-

Nose Cowl, Inlet Cowl

-

Fans, inlet area, blade damage

Engine cowlings, Fairings & Seals, Panels, Lights, Markings

-

Fan cowl doors

-

Engine cowlings

-

Lights and covers

Exhaust, Thrust reverser sleeves and system

-

Thrust reverser

-

Turbine exhaust nozzle area

-

Pylon fairings

-

Access panels

APU

APU

-

Overall Picture

-

APU - Overall Impression

APU Technical Status

-

Surrounding structure & cleanliness

-

Access panels

-

Inlet, Duct & Cowl

-

Exhaust

-

Duct & plumbing installation

-

General installation condition, leaks etc.

PAINT & SURFACE CONDITION

Condition of Paint

-

Estimate painting costs

-

Scale condition of external painting

-

Special remarks on Paint (Damage)

Condition of External Surface (Damage History)

-

Estimate repair cost

-

Scale condition of Surface

-

Special remarks on Fuselage Damages, Dents and Scratches

Last aircraft paint

-

Last paint date

-

Location - Facility

-

Price

-

Pictures:

For detailed big pictures of the exterior condition, please refer to the confidential submitted Weblink or Report Annex Chapter.

GENERAL EXTERIOR CONDITION

-

Corrosion

-

Damages, Dents and Scratches

-

Markings, Registrations and Placards

FLIGHT DECK

Flight Deck

Flight Deck Condition

-

Overall Picture & Data Plate

-

Flight Deck - Overall Impression

Documents, on board and valid?

-

NOTE: Company manuals and checklist may be allowed to be carried in digital format,(i.e. if the Operator or Owner is in possession of an EFB approval)

-

Does the Operator use an approved EFB?

-

State which manuals are carried on EFB and state last revision status

-

CofR ?

-

CofA ?

-

ARC (if applicable) ?

-

Radio Stations License ?

-

Aircraft Insurance ?

-

Journey Log and CRS ?

-

AFM ?

-

QRH ?

-

Company Manuals, FCOM etc.?

Instrument and Flight Guidance Panels, Warnings, Cautions, Aural alerts and Lights

-

Instument Panel Switches, Warnings, Cautions, Aural alerts and Lights

-

Overhead Panels, Switches, Warnings, Cautions, Aural alerts and Lights

-

Center Pedestal, Warnings, Cautions and Lights

-

FMGC, FMS, FMGC, Flight Guidance Panel - Status

-

C/B, Ceiling and sidewall panels

-

Other Instruments Functionality and Installation

Controls, Windows, Doors & Varia

-

Captains Seat and control mechanism

-

First Officer Seat and control mechanism

-

Observer Seats and control mechanism

-

Side Sticks, Control Column or Yokes

-

Flap, Slat, Gear, Speed Brake levers

-

Thrust Levers and reversers

-

Markings, Registrations and Placards, Compass card

-

Reinforced Cockpit Door, Camera, Access System

-

Windows

-

Shades

-

Ceiling, Window Sealings and Fairing Panels

-

Floor

-

Emergency Equipment & EEL

CABIN & GALLEYS

Cabin, Galleys and Lavatories

-

Overall Pictures, one per Class, Room or Lavatory & Aircraft Identification Plate

-

Cabin, Galleys and Lavatories - Overall Impression

Main Passenger Cabin(s), Suites, Rooms, Crew Lounge (Rest Area)

-

Passenger Seats, Beds and Sofas Physical and technical condition

-

Attendant Seats with Associated Emergency Equipment and Panels, Switches

-

Condition of complete interior

-

Passenger Service Units

-

Markings and Placards

-

Windows and Window Blinds, Shades or Darkening System

-

Sidewall panels and cabin dividers

-

Ceiling panels

-

Floor Panels

-

Door entrance area and escape slides, placards, cleanliness

-

Carpets

-

Floor Mats

-

Seat Tracks & Covers

-

Entry / Corridors and service areas

-

Lighting

-

Emergency doors, Emergency Exit lights, Labels & Markings

-

Systems installations, i.e. obvious discrepancies, leaks, etc.

-

Curtains

-

Veneer, lacquer and polish finish

-

Partitions, Room Doors / Sliders

-

Door Linings

-

Class Divider

-

Closets

-

IFES - In-Flight Entertainment & Installations (WLAN, Internet, SATCOM)

-

Fwd Lavatories, installations, Closets and applied finish

-

Aft Lavatories, Bathtub, Shower, installations, Closets and applied finish

-

Emergency equipment condition and stowage - Life vests, ELT, Medical Kits, First-Aid Kits

-

Life rafts, medical & survival kits, ELT, Over water equipment

-

Instument Panels, Warnings, Cautions, Aural alerts and Lights

GALLEYS & LAVATORY CONDITION

-

Cabinets, Kitchen

-

Counter

-

Ovens, Coffee makers, Kitchen (Systems, CB Panel & Installations)

-

Fridge

-

Drawer runners, hinges, screws

-

Galley, Lightning and Installation

AVIONINCS / EQUIPMENT / AIRCRAFT SYSTEM BAY(S)

Avionics and Equipment Bays & compartments

-

Overall Picture

-

Avionics and Equipment compartments - Overall Impression

Technical Status

-

Technical Status, Damage, Dents

-

Vent Inlets, Fans, Duct & Cowls

-

General installation condition, missing or U/S equipment

-

Wiring installation / condition (EWIS)

-

Access panels

-

Systems installation

-

Markings and Placards

CARGO & BAGGAGE COMPARTMENTS

Cargo & Baggage compartments

-

Overall Picture

-

Cargo & Baggage compartments - Overall Impression

Technical Status, Cleanliness and Scratches on Compartment & surrounding structure

-

Damage, Dents and Scratches

-

Cleanliness, Tidiness

Installations, Fire detection, Extinguishing & Suppression

-

Air conditioning, Pack(s), Ducts, Life support in Bay

-

Fire and Smoke detectors, Extinguishing system

-

Nets, Hooks and tie down equipment

-

Lights

-

Access panels

CONDITION OF INTERIOR

INTERIOR

-

Interior Refurbishment (value if known)

-

Condition of Interior

-

Special remarks on Interior (Damages / Wear)

INTERIOR REFRUBISHMENTS

-

Last Date of investment

-

Descpription & Valuation evidence (if available)

-

Accomplished by

-

Pictures:

For detailed big pictures of the exterior condition, please refer to the confidential submitted Weblink or Report Annex Chapter.

AIRCRAFT ADDITIONAL EQUIPMENT

-

Item 1: Description, Age & Price

-

Item 2: Description, Age & Price

STC, AD and SB

STC

-

List & Approval No. of Installed STC

AD - Open AD within the in the next inspection period or 12 months (whichever is greater)

-

All AD's complied with?

-

AD No. & Description

-

AD No. & Description

-

AD No. & Description

-

Next AD - Due at

-

Futher AD's and due dates

SB - Mandatory SB within the in the next inspection period or 12 months (whichever is grater)

-

All SB's complied with?

-

Mandatory SB No. & Description

-

Mandatory SB No. & Description

-

Mandatory SB No. & Description

-

Next SB - Due at

-

Futher mandatory SB's and due dates

AIRCRAFT RECORDS - SUMMARY

Aircraft Records Overall Status Information

Historical and Day-to-Day Records

-

Overall Status - Summarized

-

List Missing Documentation or Records

-

Influence on asset value

-

In the following sub-section below we state the Overall-status / Overview of the Records at Inspection Date.

For Date and Location information of Record Inspection refer to Header Page information. -

AFM applicable for the Aircraft configuration: state actual observed versus mandatory revision status

-

FCOM applicable for the Aircraft configuration: state actual observed versus mandatory revision status

-

QRH applicable for the Aircraft configuration: state actual observed versus mandatory revision status

-

Airframe logs

-

Engine, No.1 logs

-

Engine, No.2 logs

-

Engine, No.3 logs (if applicable)

-

Engine, No.4 logs (if applicable)

-

APU logs

-

Propeller or Rotor blade Logs (if applicable)

-

Tech logs, traceability demonstrated

-

Journey logs, full traceability shown

-

AD’s, airframe, engine, propeller, APU and appliances have been applied and are properly registered and tracked for at least the next 12 upcoming months

-

Alert SB's and SBs’ status is clearly defined, registered and tracked for at least the next 12 upcoming months

-

All modification and repairs applied to the Aircraft since last complete ARC or C-Check (whichever came last) duly recorded?

-

All service life limited components installed on the Aircraft are properly identified - registered and have NOT exceeded their approved service life limit

-

Structural repair file listing and / or<br>Structural repair mapping

MAINTENANCE AND CAMO

Maintenance & CAMO Suppliers

-

List Maintenance execution facilities (EASA Part 145, FAR Part 145 or equivalent regulated provider) currently and 3. most frequently used

-

Location of current Maintenance facility

-

Contracted or In-house CAMO (MX Planning) provider

-

Location of CAMO

-

CAMO Approval

-

AMP approval

-

Engine trend monitoring (ETM)

-

Report period of ETM?

-

attach ETM report

-

Margin Satisfactory or Value at risk?

Deferred Defects

-

Number of deferred defects in the current inspection period (at least 12 months)

-

Number of deferred defects in the previous period (12 months)

-

All rectifications duly released and signed by qualified MX staff or CRS evidenced?

-

Airworthiness currently affected?

-

Open HIL items (if HIL system used), or equivalent document listing

Accidents, MOR and Occurrences

-

Number of accidents, incidents, MOR or Occurrences in the current inspection period (at least 12 months)

-

Number of accidents, incidents, MOR or Occurrences in the previous inspection period (at least 12 months)

-

All rectifications, repairs duly released and signed by qualified MX staff or CRS evidenced?

-

Insert open item evidence (if applicable)

-

Airworthiness currently affected?

-

Current open accidents / occurrence investigation, MOR?

Recorded Damage History

-

Any NEW damages evidenced or recorded since last inspection?

SIGNATORY

STATEMENT

-

The information herein has been prepared from many sources and believed to be correct. NCG Aviation does not warrant the accuracy of the source material.

An inspection and inventory was conducted by a physical examination of the external surfaces of the aircraft, cockpit and passenger cabin. It includes an inventory and assessment of condition of avionics, instrumentation and aircraft systems. No inspection plates were removed for internal inspection. Further, the logbooks and other aircraft records were carefully examined for compliance with the current aviation regulations relating to Airworthiness Directives, damage and maintenance history, along with other required inspections.

The inspector hereby certifies that he has no personal interest in the aircraft identified in this annual inspection or any bias toward any of the parties who may be involved in the continuing airworthiness of the aircraft. All values expressed in this report are in U.S. Dollars unless otherwise stated.

The value expressed (if applicable) in this report is valid on the effective date of this report.

This annual inspection report may be used for the stated purpose exclusively and only in its entirety. Inspection procedures, research methodology, market selection, and the resulting value conclusions can vary with the various purposes and functions of the report assignments. Therefore, this report, the markets selected, and the value conclusions are intended solely for the stated purpose and function. They are invalid for any other purpose or function.

In the event of error or omission, the liability of NCG Aviation, if any, is limited and may not, in any event, exceed the amount paid for the annual report. Further, NCG Aviation accepts no responsibility for usage of this form unless signed by an officer of the company. -

Wil, Switzerland, on

-

Auditor Signature