Information

-

Inspection criteria set by customer for outgoing ZoMazz product. To be submitted to Production Manager after completion.

RECEIVING & SHIPPING

Quality Control

-

Verify Fabric/ Pattern Information

Receiving

-

Is this the correct product? Check the PO/ Invoice.

-

STOP! INFORM LOGISTICS AND THE PRODUCTION MANAGER IMMEDIATELY FOR FURTHER INSTRUCTIONS!

-

Fabric Number/ Name

-

Color/ Graphic

-

Invoice

PRODUCT INSPECTION- describe any defects found in/ on product (take pictures of product and any noticeable damage to the product).

-

Select the Fabric Cut Size appropriate to this order.

- KORA

- TITUS

-

As per Logitech Standard: The roll length tolerance is as follows:

KORA: 235mm +/- 2mm (max 237mm, min 233mm)

TITUS: 260mm +/- 2mm (max 262mm, min 258mm) -

Is Fabric is Free From Stains, Dirt, and Grease. If No, please take pictures.

-

Is Fabric is Free of Dust, Lint, and Fray. If No, take pictures.

-

Is the image printed correctly? (Verify no print false like spots, snags, imperfections)

-

STOP! REMOVE THIS ITEM FOR FURTHER INSPECTION. REPORT TO QC IMMEDIATELY.

-

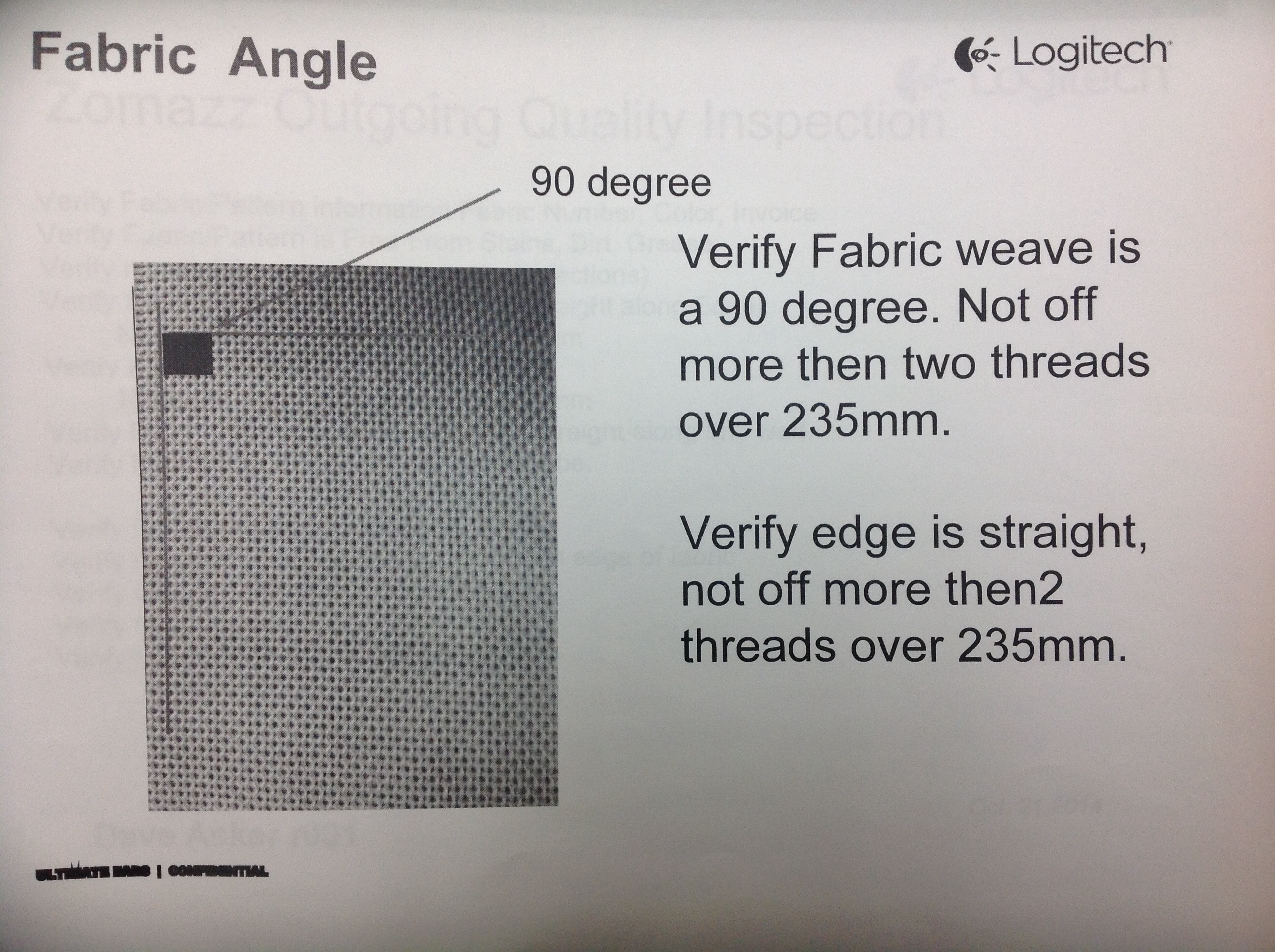

Use a right angle to verify that the Fabric is cut straight along Edge NO MORE THAN 2 THREADS OVER 235mm (9-1/4in).

-

Is Fabric cut straight along edge, no more than 2 threads over 9-1/4in? If No, take pictures.

-

Use right angle to verify Fabric weave angle is 90 degrees. NO MORE THAN 2 threads over 235mm (9-1/4in).

-

Is Fabric weave angle 90 degrees, no more than 2 threads over 9-1/4in? If No, take pictures.

-

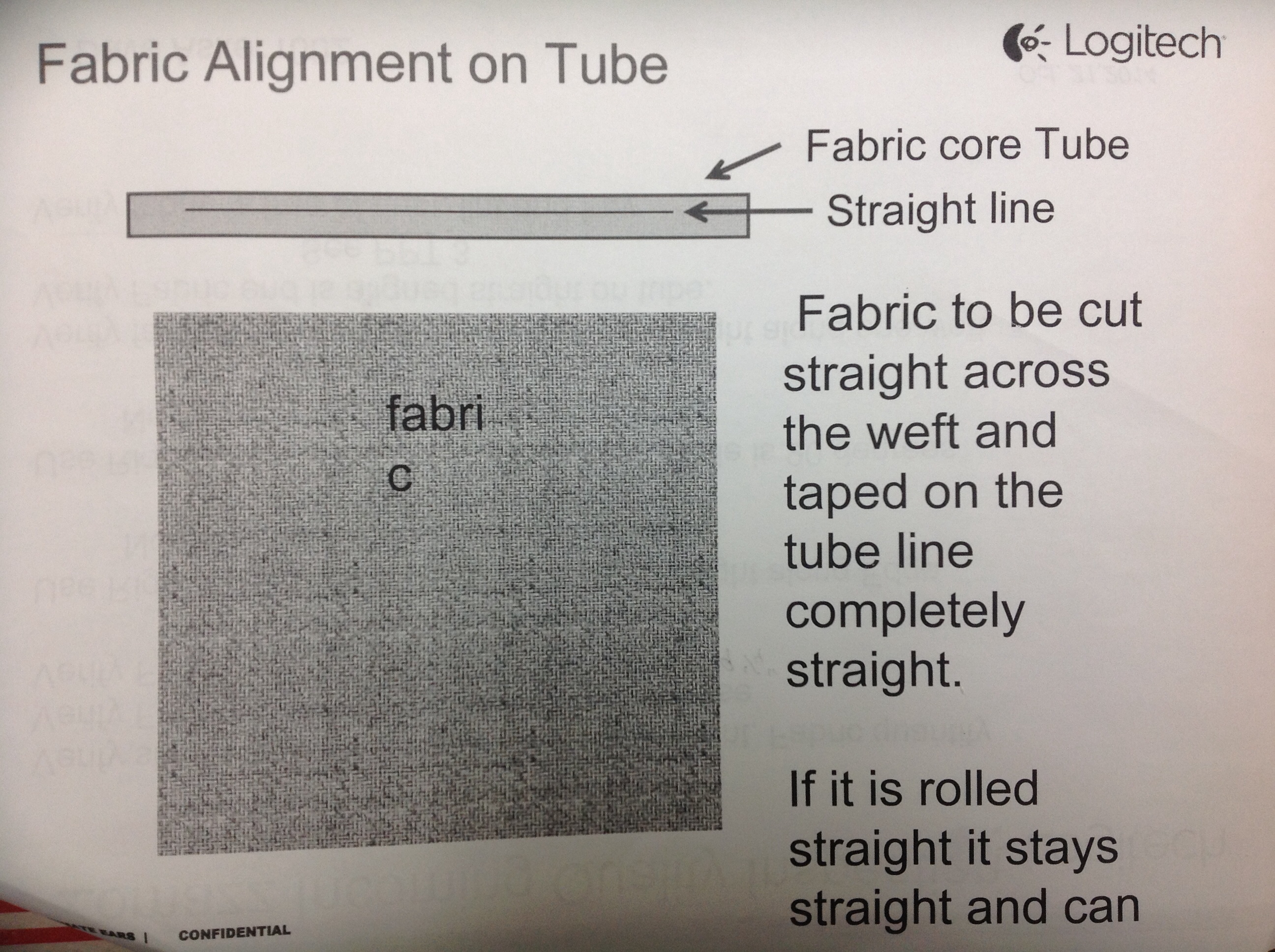

Examine beginning and end of roll. Verify that the ends are cut straight along ONE weft and that the Fabric is aligned straight on the tube.

-

Is the Fabric cut straight at the ends along one weft? If No, take pictures.

-

Is the Fabric aligned straight on the tube? If No, take pictures.

-

Is the ID Line at least 10mm?

-

STOP! REMOVE THIS ITEM FOR FUTHER INSPECTION. REPORT TO QC IMMEDIATELY.

-

Is graphic all the way to the bottom edge of Fabric?

-

STOP! REMOVE THIS ITEM FOR FUTHER INSPECTION. REPORT TO QC IMMEDIATELY.

-

Is graphic height 225mm +/- 5mm?

-

STOP! REMOVE THIS ITEM FOR FUTHER INSPECTION. REPORT TO QC IMMEDIATELY.

-

Is graphic length 200mm +/- 5mm?

-

STOP! REMOVE THIS ITEM FOR FUTHER INSPECTION. REPORT TO QC IMMEDIATELY.

-

Is graphic width 235mm +/- 5 mm?

-

STOP! REMOVE THIS ITEM FOR FUTHER INSPECTION. REPORT TO QC IMMEDIATELY.

-

The current Lab color value for this material is XXX,XXX,XXX. Below, record the measured color values of the newly arrived material.

-

L* Color Value

-

a* Color Value

-

b* Color Value

-

Using a Delta E Calculator, determine the Delta E of the new fabric compared to the "Gold Standard"

-

IF THE PRODUCT IS INCORRECT OR THE DAMAGE TO THE PRODUCT REQUIRES A RMA OR PRODUCT REJECTION, PLEASE FILL OUT THE FOLLOWING SECTIONS (Rejection Incident Report).

-

Inspector Name and Signature

REJECTION INCIDENT REPORT

-

IF THE ABOVE PRODUCT IS INCORRECT OR THE DAMAGE TO THE PRODUCT REQUIRES A RMA OR PRODUCT REJECTION, PLEASE FILL OUT THE FOLLOWING SECTIONS AND DELIVER TO THE APPROPRIATE SUPERVISOR.

Incident

-

List products rejected & invoice #

-

Reason for rejection

RECALLS

-

What is the purpose of this Rejection Incident Report?

- Product Rejection

- ZoMazz Product Recall

- Supplier Product Recall

Recalled Materials/ Supplies (Initiated by a Supplier)

-

Name of Supplier Issuing Recall

-

List Materials & Lot #'s or Identifiers

-

Reason for Supplier Recall

-

List Quantity(s) of Recalled Product Received

-

List Quantity(s) of Recalled Product On-Hand

Rejected Product (Initiated by ZoMazz)

-

List Materials & Lot #'s or Idetifier

-

Reason for Rejection

-

List Quantity(s) of Product Affected

-

List Quantity(s) of Rejected Product On-Hand

Recalled Product (Initiated by ZoMazz)

-

List Products & Lot #'s or Identifiers

-

Reason for Product Recall

-

List Quantity(s) of Product Affected

-

List Quantity(s) of Recalled Product On-Hand

Disposition

-

Affected Product Quarantined

-

Enter Disposition Plan (where will product be placed, for how long?)

-

IN THE EVENT OF A PRODUCT RECALL OR REJECTION:

Complete this form, in its entirety, to this point. Then, notify the Recall Team or Customer Service and they will complete the rest of this form. -

Name & Signature of Inspector releasing form to Customer Service

Communication of Recall or Rejection

-

Recall Team / Customer Service Notified

-

Affected Customers Notified

-

Press Release Issued

-

Person completing Rejection/ Recall Log Name & Signature

Signatures

-

Supervisor Name & Signature