Information

Information

-

Client:

-

Site:

-

Address:

-

Date:

-

Business Manager:

-

Person(s) Met:

-

Operations:

-

Prepared by

SUMMARY:

JUSTIFICATION SUMMARY:

-

The attached executive summary and information in the report highlights the key points identified from the audit, both good and bad practices and any major / critical issues noted.

-

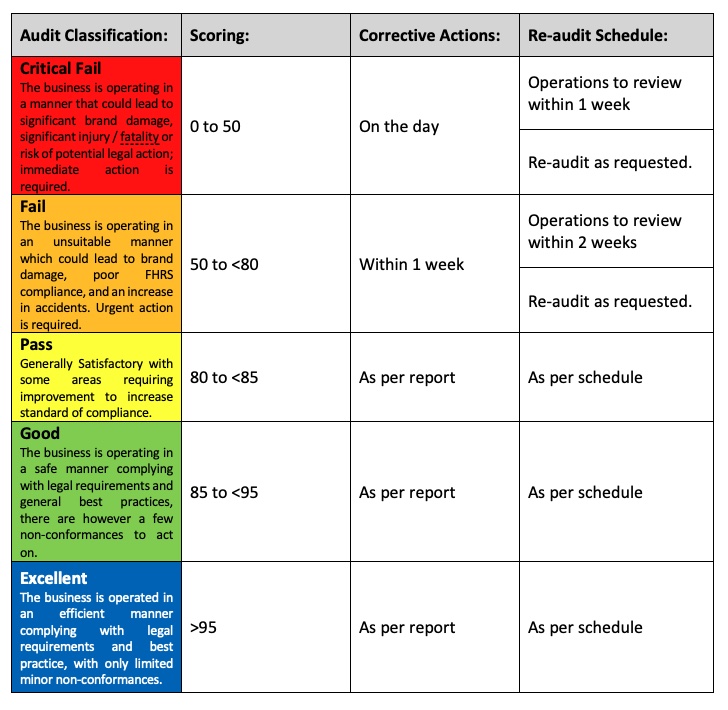

Audit Classication

-

-

Food Safety:

-

undefined

-

H&S and Fire Safety:

-

undefined

-

Training:

-

undefined

-

Audit reinspection period:

Safety Systems Management :

0.0 Head Office Function and Control

-

This section is to audit implementation of the Corporate Safety Management System and servicing by Head Office.

-

Comments:

-

0.1 Are there up-to date and signed copies of the relevant policy statements SOP's /. PRP's and is the Management System available?

-

0.2 Have all recommended actions been completed since the last Regulatory visit (EHO, HSE, FSA, DEFRA, EA or FB?

-

0.3 Is a copy of the previous audit available and has the action plan been completed so far as practicable?

-

0.4 Is the employers liability Insurance certificate on display?

-

0.5 Has there been an Annual Fire Risk Assessment carried out under The Regulatory Reform (Fire Safety) Order 2005 (The findings of the risk assessment are to be consistent with known or forseeable site hazards and the actions completed (SFARP)?

-

0.6 Are the required external fire safety servicing checks being completed?

-

0.7 If required is there a suitable fire suppression system in place (Ansul/Sprinklers) and it is to be suitably serviced and staff understand its operation?

-

0.8 Has there been a deep clean of the extraction within the prescribed timescale and is it evidenced?

-

0.9 All lifts and hoists used by staff or public are subject to specified thorough examination as required by LOLER (6 month / 12 month) by a competent person?

-

0.10 Are pressurised vessels used on site are subject to regular examination by a competent person as required by The Pressure Systems Safety Regulations 2000?

-

0.11 All gas appliances, supply pipes and fittings are regularly serviced by Gas Safe Certified engineer with no visual evidence of defects apparent at the time of audit, is the annual service certificate on file, The gas supply must be confirmed as interlocked with the ventilation system by senior chef or manager on site and are staff are aware of any alarm mechanisms installed?

-

0.12 The building installation is examined by a competent person every 5 years (fixed wiring test)?

-

0.13 Annual PAT testing completed?

-

0.14 Earth-bonding cables are fitted correctly where practicable?

-

0.15 Has a Legionella Risk Assessment been completed at site?

ISSUES NOTED AT SITE NOT UNDER BUSINESS DIRECT CONTROL

-

Items reported but pending and/or beyond the business control are-listed in this section to highlight the safety risk but are not scored against the main audit score.

Safety Issue No.

-

Risk:

-

Issue:

-

Identify issues that pose a risk at site.

Food safety:

-

Food Safety: comments or observations that affect food safety?

FOOD SAFETY

1.0 PRACTICE AND CONTROLS (DUE DILIGENCE)

-

1.1 Delivery Procedures - Food is accepted in a properly controlled manner with the correct monitoring procedures being followed. Ensure that the Control documentation is being completed correctly and consistently?

-

1.2 Storage - Refrigerated and frozen storage temperatures are correct and control documentation is being completed correctly and consistently (Fridge <8°C, Freezer >-18°C)?

-

1.3 Defrosting - Carried out in a controlled manner in a refrigerator or time controlled ambient?

-

1.4 Preparation - High risk ingredients are not left at ambient temperature for excessive periods during preparation (30 minutes). Separation controls are in place for preventing bacterial and allergenic contamination?

-

1.5 Cooking / Reheating food - correct cooking / reheating temperatures (>75°C or equivalent) are being achieved and control documentation is being completed?

-

1.6 Cooking and Cooling - Cooling is carried out by the use of a blast cool unit or in compliance with 90 minute procedure if ambient cooling is undertaken. Control documentation being completed correctly and consistently?

-

1.7 Ambient Storage - High risk foods are not left at ambient temperature for excessive periods. Separation controls are in place for food safety and allergen management.

-

1.8 If Vacuum Packing (VP) is in operation is a suitable control procedure in place. HACCP, cleaning and signage in place to minimise the risk of food-borne illness from cross contamination (multiple VP use)?

-

1.9 Are dispatch temperatures recorded if required to be temperature controlled at <8°C or >-18°C as required?

-

1.10 If sous-vide cooking is in operation are suitable control procedures in place to minimise the risk of food-borne illness from improper temperature control (HACCP/Due Dilligence)?

2.0 HACCP FOOD SAFETY MANAGEMENT

-

A spot check of all documented DD information and a visual check of procedures and practices.

-

2.1 All food safety control records maintained correctly and in a consistent manner. The records are stored in an orderly manner for monitoring purposes, to ensure that all CCP's adequately controlled to offer an effective due diligence defence?

-

Documents viewed:

-

2.2 Is there an up-to date and verified modular / product specific HACCP plan representative of the operation and products on offer?

-

Documents Viewed

-

2.3 All food businesses must have an Allergen Management System (AMS) that controls risk from allergen in the business especially 14 Major allergens. The AMS should included the Caterer HACCP, Allergen Risk Assessment• Practical Allergen Management• Allergen Communication.

-

Allergen Procedures:

-

2.4 Is there an approved supplier list on site with copies of accreditation documents available as required?

3.0 CLEANING AND DISINFECTION

-

3.1 All all parts of the structure of the food preparation area, tables, equipment, and ancillary areas maintained in a clean condition?

-

3.2 All food preparation equipment is stored and maintained in a clean hygienic condition and fit for purpose?

-

3.3 The Pot-wash area and dishwasher / area is clean with correct chemical dosage and wash and rinse water temperatures satisfactory at 82C; with clear segregation between clean and dirty equipment. If fitted is the grease trap / grease pack machine fitted and functioning effectively?

-

3.4 All cleaning equipment is stored and maintained in a clean hygienic condition and fit for purpose (mops clean and not in dirty water)?

-

3.5 Is there sufficient hot water to allow effective cleaning?

-

3.6 Adequate supply of sanitiser, to correct dosage and used appropriately; and do staff clean as they go?

4.0 PEST MANAGEMENT

-

Uncontrolled Pest infestation is a significant cause of food business closure, it is vital that pest issues are managed correctly

-

4.1 Are the premises free from infestation and from any visible signs of pests, have they been spotted and are pest issues suitably managed on site, have the recommendations on the pest control report been actioned?

-

4.2 EFK's - A sufficient number of EFK's is provided and sited correctly. The units are subject to a planned maintenance and cleaning?

-

4.3 External Openings - any windows or doors opening directly from an area in which open food is being prepared is fitted with adequate screening/brushes in order to prevent the ingress of pests. There are no cavities etc from disrepair which would allow access to pests. All doors are kept closed?

5.0 PERSONAL HYGIENE

-

Are team members changing gloves, washing hands, working in a safe manner to ensure that all food is produced to the safest and highest standard. WHB to be stocked with liquid antibacterial soap, Hot and cold water and drying facilities - suitable signage to be provided. Not consuming food or drink in preparation area..

http://www.food.gov.uk/sites/default/files/multimedia/pdfs/publication/fitnesstoworkguide09v3.pdf -

5.1 Are hand wash facilities sufficient, fully stocked with supplies and operating at an approximate temperature of between 40°C and 45°C? and are team members using the Wash hand-basin (WHB) effectively?

-

5.2 Are the personal habits of all team members suitable and sufficient at time of audit are they following the personal hygiene rules not picking at food or 'double dipping'. It is advised that disposable gloves are used for the direct handling of ‘ready to eat’ foods, If gloves are worn they must not be overused or misused in a manner to cause cross-contamination?

-

5.3 Are all personnel in suitable uniform and suitably coloured plasters?

6.0 WASTE AND REFUSE

-

6.1 Internal Storage: refuse is stored in a hygienic manner in the catering areas, storage bins are suitable and/or fitted with foot operated lids as required?

-

6.2 Housekeeping: The refuse is regularly removed from the catering areas so that no unacceptable build-up of refuse occurs?

-

6.3 External Storage: refuse is stored in bins fitted with a lid. The storage area is generally clean and tidy with no spillages or overflows of refuse likely to attract pests?

7.0 FOOD PREMISES DESIGN, CONSTRUCTION AND EQUIPMENT

-

The site shall be of suitable size, location, construction and design to enable the production of safe and legal products. It shall be suitably maintained and controlled to ensure that conditions hazardous to food safety (e.g. pest infestation) do not occur.

-

7.1 All structural surfaces are in good repair and comply with the requirements of food safety legislation. Ceilings, walls, doors and windows are sound and in good repair?

-

7.2 Adequate standards of lighting are provided to all work areas. All light fittings are correctly designed and in good repair. Are light diffuser covers fitted in food preparation areas?

-

7.3 Adequate ventilation is provided to the preparation / cooking areas to ensure a comfortable and safe working environment. The optimum temperature for comfort within a catering establishment should be 19°C to 23°C.

-

7.4 All preparation and work surfaces are smooth, impervious and in good general repair to allow effective sanitising to take place.

-

7.5 Are adequate changing facilities provided to staff and is cleanliness and housekeeping satisfactory?

-

7.6 All sinks and wash hand basins are in good repair and provided with the correct facilities?

8.0 STORAGE AND LABELLING

-

All food must be stored at the correct temperature and labelled with the correct 'use-by' or 'best-before' date to meet both legal and company requirements.

-

8.1 Are all items suitably stored under the right conditions, labelled and dated in the fridge?

-

8.2 Are all items suitably stored, labelled and dated the freezer?

-

8.3 Are all items suitably stored, labelled and dated in the dry stores. The area is orderly with sufficient storage space and no foodstuffs stored on the floor. Opened packages are correctly protected within suitable containers. Is all food is adequately covered and protected from contamination during storage?

-

8.4 Good stock rotation is evident with the F.I.F.O. system being operated and no out of date foods being identified (following 3-day rule unless authorised)?

9.0 CONTAMINATION CONTROLS

-

9.1 Is separation of RAW and RTE foods in the premises adequate to control microbial contamination risks?

-

9.2 Is food handled correctly to minimise the risk of contamination and no foods exposed to excessive risk of contamination (Ph, Ch, Mb or All)?

-

9.3 Are probe wipes available and do staff know how to use and disinfect probe?

-

9.4 Is the separation of known allergens (14 Major) adequate?

-

9.5 Is the site using correct colour coded chopping boards to minimise cross contamination and are they stored in the correct manner?

FOOD SAFETY ISSUES NOTED AT SITE

-

Food Safety Issue No.

-

undefined

-

Identify food safety issue:

Health and Safety:

-

Health and Safety: Comments or observations on safety performance that need to be noted at the restaurant?

HEALTH AND SAFETY

10.0 WORKPLACE AND PREMISES

-

10.1 Is the available space in the building suitable for the operation, are floors marked on the level and/or low ceilings highlighted. Are floors an walkaways suitable and kept clear of obstructions?

-

10.2 Have changing facilities and lockers, suitable toilet facilities and an area for employees to take rest breaks been provided and If available a ‘Drinking Water’ tap is to be clearly identified and labelled for dedicated water system??

-

10.3 Are the external areas of the business under their control suitable and safe, if signage or structures are present are they visually safe and is the lighting level present sufficient to allow safe access and egress?

-

10.4 Is the temperature in the workplace suitable to ensure thermal safety and comfort?

-

10.5 Are there any non demised areas in use that pose a potential hazard, roof access, clear access or riser cupboards?

11.0 WORK AT HEIGHT

-

11.1 Are all work at height activities conducted safely or are there any significant safety failures?

-

11.2 Are ladders, steps or ‘elephants feet’ in good order and safe to use. Is a ladder checklist present and in use?

12.0 MANUAL HANDLING OPERATIONS AND ERGONOMICS

-

12.1 Are Manual Handling operations conducted in a safe manner?

13.0 GENERAL EQUIPMENT SAFETY

-

13.1 All equipment used in food preparation is constructed of correct material and maintained in good condition. ‘Dangerous Machines’ are provided with correct guarding, suitably sited and are emergency shut-off buttons free from obstruction and labelled?

14.0 FIRST AID AND ACCIDENT REPORTING

-

14.1 Is the first aid kit available and adequately stocked including eye wash solution (2x 500ml bottles)? and is a First Aid Notice is prominently displayed giving details of First Aiders available and their contact details; is the list current?

-

14.2 Accident Reporting - Is the accident book on site and are all accidents recorded in the accident book and company records maintained by sending to nominated person, with suitable accident investigation - All accidents are investigated and corrective action taken where necessary?

15.0 CHEMICALS (COSHH) AND HAZARDOUS SUBSTANCES

-

15.1 Documented systems. Are the COSHH risk assessments and chemical register present and valid, correct Material Safety Data Sheets (MSDS) are available for all chemicals?

-

15.2 Are the chemicals stored in a safe manner following the traffic light system and are all chemical used on site appropriate for their purpose and no unauthorised chemicals are present?

-

15.3 Is the correct COSHH required PPE on site, used and stored correctly (e.g. goggles gloves, masks aprons if required)?

-

15.4 Is there a biological spill kit available?

-

15.5 Are the controls on site appropriate to manage the risk from Asbestos on site, is there Asbestos present if yes is there an asbestos plan?

-

15.6 Are the controls on site appropriate to manage the risk from Legionella on site, has monitoring been completed and or testing completed?

16.0 SAFE WORKING PRACTICES

-

16.1 Is any equipment unsafe with obvious Safety Critical faults or defects?

-

16.2 Is the area free from any uncontrolled spillages or trip hazards and are the wet floor signs used correctly?

-

16.3 Are the knives used and stored in a safe manner?

-

16.4 Is the correct "safety" PPE on site, used and stored correctly (e.g. knife gloves and shoes)?

17.0 HEALTH AND SAFETY RISK MANAGEMENT CONTROLS

-

An overview of the risk management process is undertaken. In the snapshot traceability exercise a range of risk assessments may be selected against a specific employee staff file to review your legal compliance, (WPRA, MHRA, WPRA training and toolbox talk trainings)

-

17.1 Are current site risk controls (specific WPRA available for inspection, valid and up to date) suitable?

-

WPRA / safety control documents inspected:

-

17.2 Have Consultation with Employees (CWE) meetings been completed with the team as required, minutes completed and kept for a minimum of 3-years?

18.0 SAFETY SIGNAGE

-

18.1 Is a current Health and Safety law poster in place?

-

18.2 Is the general health and safety and COSHH safety signage adequate?

-

18.3 Does the business have a no-smoking sign and CCTV sign if present?

19.0 ELECTRICAL AND GAS SAFETY

-

19.1 Electrical equipment is visually safe, no damaged cables noted or observed?

-

19.2 Emergency isolation switches are provided and clearly marked?

-

19.3 is gas safety equipment visually safe and interlocked to extraction system?

-

19.4 is the boiler-room visually safe, suitable and sufficient?

HEALTH AND SAFETY ISSUES NOTED AT SITE

-

Health and Safety issue No.

-

undefined

-

Identify Health and Safety issue:

Fire safety:

-

Fire safety : Comments or observations that affect Fire Safety at the restaurant?

20.0 ONSITE FIRE SAFETY

-

As a responsible employer we shall ensure our premises are compliant with the requirements of the RRO 2005 and an annual FRA Completed.

https://www.gov.uk/workplace-fire-safety-your-responsibilities -

20.1 Are the weekly and monthly fire safety checks being completed?<br>

-

20.2 Has their been a full evacuation drill in the last 6/12 months?

-

20.3 Correct storage of combustibles and/or flammables?

-

20.4 Are the emergency exit(s) and MOE clearly signed and its access unimpeded?

-

20.5 Are the fire doors closed or self closable and suitable to ensure fire compartmentalisation?

-

20.6 Are sufficient fire extinguishers / blankets provided and are they signed, tagged, easily accessible and unblocked?

FIRE SAFETY ISSUES NOTED AT SITE

-

Fire Safety issue No.

-

undefined

-

Identify Fire Safety issue:

Training:

21.0 COMPLIANCE TRAINING

-

Comments on training:

FOOD SAFETY TRAINING

-

21.1 As a minimum has the Manager achieved appropriate food safety training having achieved 'Level 3' within a reasonable period?

-

21.2 Have staff have received appropriate food safety training with high risk food handlers trained to 'Level 2', within the required 3-month period?

-

21.3 Have on the spot knowledge checking questions been answered satisfactorily (are staff aware of the allergen controls in place, asking customers do they have any allergens and location of allergen information)?

H&S TRAINING

-

21.5 As a minimum has the Manager achieved appropriate H&S training and achieved 'Level 3' Health and Safety?

-

21.6 Have staff have received appropriate H&S training with team members trained to 'Level 2', and accurate training records are maintained?

-

21.7 Have staff have received either COSHH training from their chemical supplier or suitable internal training within the last 12 months?

-

21.8 Are there sufficient trained First Aiders on site according to the first aid risk assessment?

-

21.9 Spot check of the WPRA (Risk Assessment) training records of selected members of the team?

FIRE SAFETY TRAINING

-

21.10 Have sufficient fire wardens been trained sufficient for expected risk on site?

-

21.11 Have team members been trained sufficiently for the expected fire risk on site (induction)?

Swab Testing:

-

ATP is an organic chemical and used as a hygiene indicator . A failed swab test result will affect the score for either cleaning (structure/equipment) or personal hygiene (hands).

PERSON OR EQUIPMENT TESTED

-

SWAB TEST RESULTS

SWABBING

-

Person or Equipment:

-

RLU result: