Title Page

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

-

Does the machine have safeguards?

-

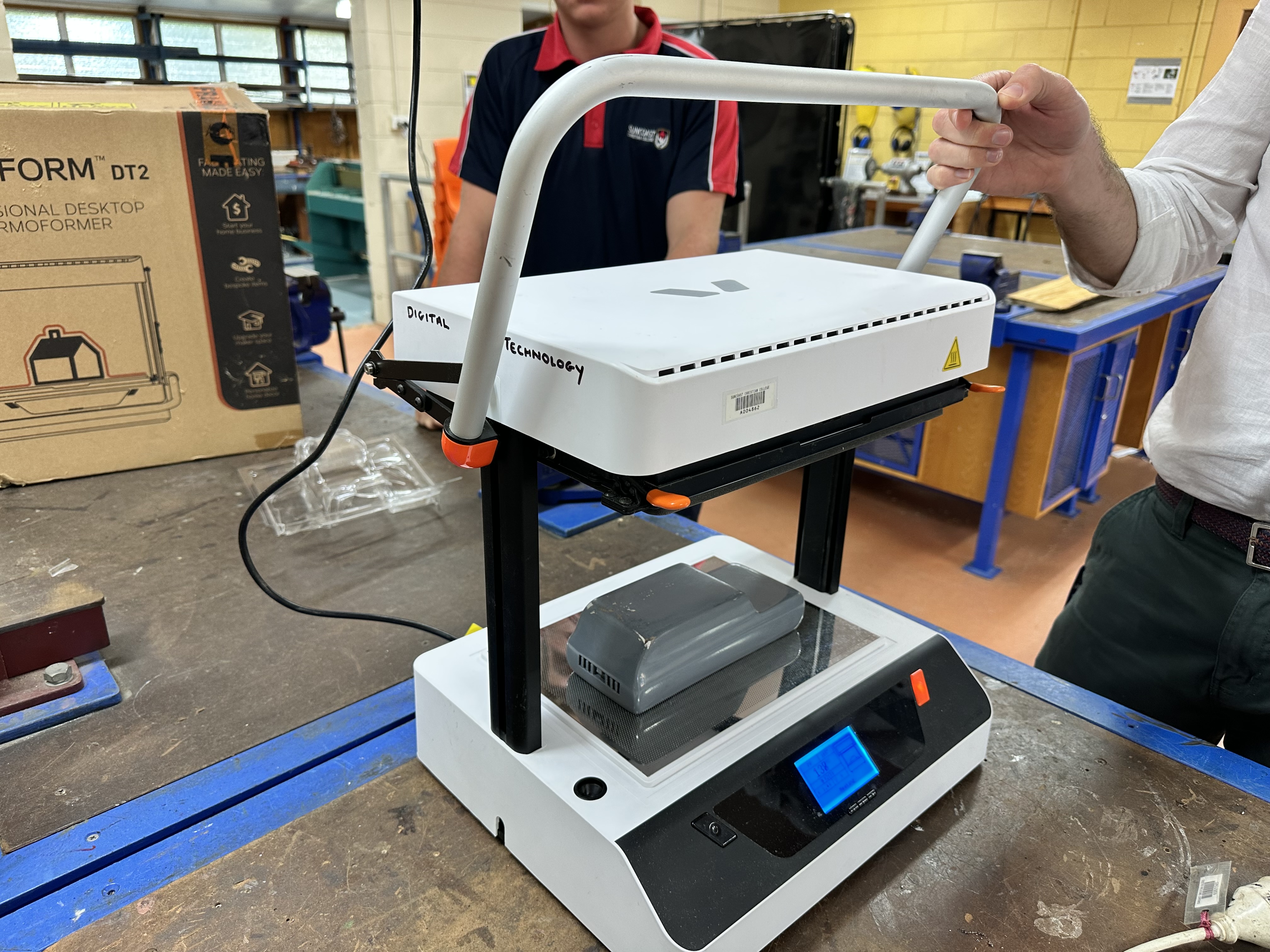

Add media

-

Are safeguards provided for all hazardous moving parts of the machine, including auxiliary parts?

-

What safeguards, if any, are being used to protect the operator?

-

Is there evidence that the safeguards have been tampered with or removed?

-

Add media

-

Do the safeguards provided meet the minimum OSHA requirements?

-

Add media

-

Are the safeguards firmly secured and not easily removable?

-

Do the safeguards insure that no object will fall into the moving parts?

-

Do the safeguards permit safe, comfortable, and relatively easy operation of the machine?

-

Is there a system for shutting down the machinery before safeguards are removed?

-

Can the existing safeguards be improved?

-

Is there a point of operation safeguard provided for the machine?

-

Do the point of operation safeguards keep the operators hands, fingers, body out of the danger area?

-

Are there any unguarded gears, sprockets, pulleys, or flywheels on the apparatus?

-

Add media

-

Are there any exposed belts or chain drives?

-

Add media

-

Are starting and stopping controls within easy reach of the operator?

-

Add media

-

Is the machine installed in accordance with National Fire Protection Association and National Electrical Code requirements?

-

Are there loose conduit fittings?

-

Add media

-

Is the machine properly grounded?

-

Add media

-

Is the power supply correctly fused and protected?

-

Add media

-

Have operators and maintenance workers been trained in how to use the safeguards and equipment?

-

Is the appropriate PPE available to reduce appropriate hazards for operators?

-

Is protective equipment in good condition?

-

Do maintenance persons use appropriate lockout tag out methods before servicing machines?